0% found this document useful (0 votes)

385 views1 pageIntroduction Spark Test

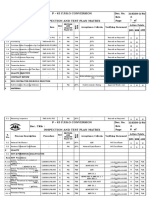

This document discusses the basic crystal structures of metals and how to identify different metals using spark testing. It explains that metals can be classified as ferrous, containing iron, or nonferrous. Spark testing involves creating friction between a metal sample and an abrasive wheel, which causes small glowing particles to break off along a "carrier line," allowing identification by the sparks' color, length, and number. Common metals each produce distinctive spark patterns that can be used to determine the metal's type.

Uploaded by

Karl CastroCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

385 views1 pageIntroduction Spark Test

This document discusses the basic crystal structures of metals and how to identify different metals using spark testing. It explains that metals can be classified as ferrous, containing iron, or nonferrous. Spark testing involves creating friction between a metal sample and an abrasive wheel, which causes small glowing particles to break off along a "carrier line," allowing identification by the sparks' color, length, and number. Common metals each produce distinctive spark patterns that can be used to determine the metal's type.

Uploaded by

Karl CastroCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 1