• FLOW STRAIGHTENER •

FOR VORTEX FLOW METERS

DESCRIPTION

The optional flow straightener accessory for ONICON

F-2000 Series Vortex Flow Meters is a wafer-style flow

conditioner that is designed to be installed between

two ANSI class 150 or class 300 flanges (provided by

installer) that are located a specified distance upstream

of the flow meter.

Use of a flow straightener significantly reduces the

upstream straight pipe length requirement for ONICON

Vortex Flow Meters.

The size of the straightener should always match the

meter size (as opposed to the original pipe size).

The flow straightener is made of 304/A 351 CF8

Stainless Steel.

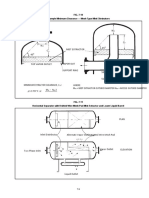

TABLE 1 - ALL DIMENSIONS SHOWN IN INCHES

NUMBER OF

SIZE DIM A DIM B DIM C DIM D

HOLES

2” 3.93 1.0625 .28 2.14 35

3” 5.31 1.0625 .43 3.24 35

4” 6.26 1.0625 .55 4.22 35

6” 8.50 1.0625 .78 6.07 35

8” 10.62 1.0625 1.02 7.98 35

10” 13.23 1.0625 1.30 10.02 35

12” 15.00 1.0625 1.53 12.00 35

0.125

GASKET THICKNESS, NOMINAL SERRATIONS SHOWN LOCATED UNDER GASKET, IF PROVIDED

NOTE: DIMENSION D INDICATES I.D. FOR SERRATIONS

DIM C

DIM D DIM A

DIM B

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699

0497-7 www.onicon.com • sales@onicon.com 03-18

� ECCENTRIC REDUCER

UPSTREAM OPTIONAL ANSI FLANGES ECCENTRIC EXPANSION

PIPE RUN DOWNSTREAM PIPE RUN

FLOW STRAIGHTENER

FLOW DIRECTION

2 DIAMETERS UPSTREAM STRAIGHT PIPE RUN MINIMUM DOWNSTREAM

TO FLOW STRAIGHTENER STRAIGHT PIPE RUN

≥ 5 DIAMETERS

* MINIMUM UPSTREAM STRAIGHT PIPE

RUN TO FIRST OBSTRUCTION

*Minimum Upstream Straight Pipe Run Requirements

Obstruction Straight pipe run without Straight pipe run to flow

flow straightener straightener

Single bend preceded by ≥ 9 diameters of straight pipe 10 Dia N/A

Outflowing tee 10 Dia N/A

Pipe size reduction before meter 10 Dia N/A

Single bend preceded by ≤ 9 diameters of straight pipe 15 Dia 8 Dia

Expansion before meter 20 Dia 8 Dia

Multiple bends out of plane 30 Dia 13 Dia

Partially open valve 30 Dia 13 Dia

PRESSURE LOSS CHART FOR

Control valve / P.R.V. 50 Dia 23 Dia

FLOW STRAIGHTENER

NOTES

1. Consult ONICON for meter size and applicable meter pipe run for each application. Install according to

manufacturer’s recommendations. PRESSURE LOSS CHART FOR

2. Provide eccentric reducer and expander when required.

3. Provide flow straightener when required to meet 0.023232 FLOW STRAIGHTENER

recommended minimum upstream pipe run requirements.

4. Flanges provided by contractor. CenterP:

straightener

Pressurebetween

loss in flanges

psi during installation.

: Density(lb/ft³)

c : Pressure loss coefficient

Pressure Loss for Flow Straightener

Nominal size (inch)

1½

12

10

10

1

6

2

8

4

1000

5 500

0.023232

Pressure loss coeff. of gas

2 200

P: Pressure loss in psi

: Density(lb/ft³)

1

Pressure loss coeff.

100

c : Pressure loss coefficient

0.5 50

and steam (C)

of liquid (C)

0.2 20

0.1 Nominal size (inch) 10

1½

12

10

10

3

1

6

2

8

4

1000

0.05 5

5 500

0.02 2

0.01

e loss coeff. of gas

1

Gas and steam

6 12 30 60 2

120 300 600 1,200 3,000 6,000 12,000

200

(ft³/min)

4.4 8.8 22 44 88 220 440 880 2200 4400 8800 Liquid (GPM)

1

re loss coeff.

100

Flow rate

0.5 50

11451 Belcher Road South, Largo, FL 33773 • USA • Tel +1 (727) 447-6140 • Fax +1 (727) 442-5699

m (C)

d (C)

0497-7 0.2 www.onicon.com • sales@onicon.com 20 03-18