0% found this document useful (0 votes)

330 views3 pagesR51 Product Data Sheet

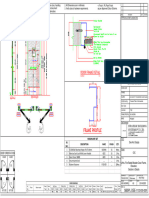

The document provides information about an SMD floor deck profile called R51+ including its dimensions, properties, and design guidelines. It includes tables with concrete volume and weight calculations for various slab depths. Graphs show the profile's construction stage spans for different gauges and a composite slab design graph for selecting slab depth based on fire rating and load/span requirements.

Uploaded by

mdavies20Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

330 views3 pagesR51 Product Data Sheet

The document provides information about an SMD floor deck profile called R51+ including its dimensions, properties, and design guidelines. It includes tables with concrete volume and weight calculations for various slab depths. Graphs show the profile's construction stage spans for different gauges and a composite slab design graph for selecting slab depth based on fire rating and load/span requirements.

Uploaded by

mdavies20Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 3