Recirculation System

A] 60.77 MLD – 8 Twin bed sections of size (5.1 m x 6.75 m)

Quantity required for wash of one section for 8 min = 5.1 x 6.75 x 0.6 x 8 = 165.24 cum

If we consider 20 hrs working period every bed having 2 sections will come to wash every

2.5 hrs

B] Sludge from Clariflocculators :-

Usually max. sludge to be washed is 2%

Sludge volume = 0.02 x 2642.174 x 23 = 1215.40 cum/day

= 52.85 x cum/hr considering 23 hrs working

Considering 2 hrs of sludge storage of capacity 105.70 cum (say 110.00cum)

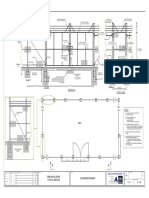

C] Back wash sump :-

Considering storage of 2 beds (4 sections) the capacity reqd.

2 x 165.24 x 2 = 660.96

Two hours flow of sludge from clariflocculator 2 x 52.85 = 105.70

_________

766.66

Say 800.00 cum

D] Thickner :-

Sludge from Clariflocculator = 1215.40 cum/day

Residual sludge 5% from filter back wash = 0.05 x 2643.85 = 132.20 cum/day

for all filter beds

Total sludge to thickner = 1215.40 + 132.20 = 1347.60 cum/day

= 58.59 cum/hr. 60 cum/hr.

Considering solid loading of 25 cum/day/m2 ;

Thickner dia = 8.28 say 8.30

SWD = 3.0 m

�Considering consistency of 3% i.e. 0.03 x 1346.60 = 40.398 say 41.0 cum in a day will go to

centrifuge

Centrifuge capacity (12 hrs working) = 41 / 12 = 3.41 cum/hr say 3.5 cum/hr.

Provide centrifuge of capacity 3.5 cum/ hr and sludge will be pumped from thickner to

centrifuge by screw of capacity 3.5 cum/hr.

E] Pumping to inlet chamber from back wash sump :-

Volume to be pumped in two hrs = 800 cum

Capacity to be pumped/ hr. = 400 cum/hr.

Provide (2 W + 1 S) pumps of capacity 200 cum/hr.

Non clog submersible pumps

F] Pumping to Thickner from back wash sump :-

Volume to be pumped = 60 cum/hr.

Provide (1 W + 1 S) non clog submersible pumps of capacity 60 cum/hr.