AAPL Pipe Support/Span Calculation Sheet

Client: Description: Prepared By: Approval: Date: Rev.:

0

Customer No.: Item No.: 1

2

Owner No.: Dwg. No.: 3

Service: SG = 1.00 Measurement Units: Imperial

Design Temperature: F C 100 Deg. F Corrosion, erosion, mech. allow: C= 0.0000 inch

Factor of Safety: FS = 4.0 Ice Thickness (external): Tice = 0 inch

Pipe or Tubing Material: Pipe or Tube Dimensions:

ASTM A 53-B Type S Carbon Steel Pipe Nom. Size: NPS 8 (DN 200)

Hot modulus of elasticity 2.93E+07 psi E = 2.934E+07 psi Nom. Thk.: Sch 40 per ASME B36.10M

Hot allowable stress 20,000 psi Sh = 20,000 psi Actual OD: 8.625 inch Do = 8.625 inch

Design stress, Sh / FS 5,000 psi Sa = 5,000 psi Nominal thickness: 0.322 inch Tnom = 0.322 inch

Material density Pden = 2.833E-01 lb/in^3 Thickness tolerance: Mill = 12.5% and, h = 0.000 inch

Relative weight factor (vs. carbon steel) Mat = 1.000

Insulation: Semi-rigid Fiberglass Liner on ID: none

Density, Ins = 7.0 lb/ft^3 Iden = 4.051E-03 lb/in^3 Density: 0.000 lb/in^3 Lden = 0.000E+00 lb/in^3

Thk, Ti = 2 inch Thickness: 0.000 inch Tr = 0.000 inch

Comments: x Weight of concentrated load assumed at center of

x span (valves + flanges + animal, etc.):

x 0.0 lbs Wc = 0 lbs

Minimum pipe thickness, t = Tnom - (Tnom * Mill % / 100 ) - c - h t = 0.3216 inch

Outside radius of pipe, R = Do / 2 R= 4.313 inch

4 4 I = 7.241E+01 in^4

Pipe moment of inertia (based on t ), I = π / 64 [ Do - (Do - 2 t ) ] 7.241E+01 in^4

Pipe inside diameter, d = Do - 2 Tnom d= 7.981 inch

4 4

Pipe section modulus, Z = π / 32 (Do - d ) / Do 1.681E+01 in^3 Z = 1.681E+01 in^3

2 2

Metal area of pipe cross-section, Am = ( Do - d ) * π / 4 Am = 8.40 in^2

Conversion factor, water density, dw = 62.4 lb / cu ft dw = 62.40 lb/ft^3

Conversion factor: n = 1 ft / 12 in n = 8.3333E-02 ft / in

Pipe weight per unit length, Wp = Pden * Am / n Wp = 28.55 lb / ft

Pipe or liner or refractory inside diameter, dL = d - 2 Tr dL = 7.981 inch

2 2

Liner area cross-section, Ar = ( d - dL ) * π / 4 Ar = 0.00 in^2

Liner weight per unit length, Wr = Lden * Ar / n Wr = 0.00 lb / ft

2

Flow area, Af = d * L * π / 4 Af = 5.003E+01 in^2

2

Fluid weight per unit length, Wf = SG * Af * n * dw Wf = 21.68 lb / ft

Insulation outside diameter, Dio = Do + 2 Ti Dio = 12.63 inch

2 2

Insulation area cross-section, Ai = ( Dio - Do ) * π / 4 Ai = 66.76 in^2

2

Insulation weight per unit length (w/ factor 1.12 for lagging), Wi = 1.12 * Ai * n * Ins Wi = 3.63 lb / ft

2 2

Ice area cross-section, Aice = [ (Dio + ( 2 * Tice )) - Dio ] * π / 4 Aice = 0.00 in^2

2

Ice weight (external w/ S.G. = 0.9) per unit length, Wice = 0.9 * Aice * n * dw Wice = 0.00 lb / ft

Total weight per unit length, W = Wp + Wr + Wf + Wi + Wice (excluding Wc) 53.87 lb / ft W= 53.87 lb / ft

� Pipe or Tubing Support Span Calculations 2 of 2

8/4/2010, Sup.xls

Method ( A ) -- Reference book Design Of Piping Systems, pp. 239 - 240 & 356 - 358, by M. W. Kellogg, Second Edition, 1956

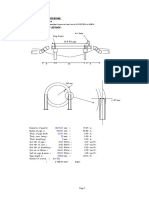

Single span, free ends

Type of support span

Length of support span 32.00 feet L= 32.00 feet

Factor for modifying stress value obtained by the basic formula for S fs = 1.250

2

Maximum calculated bending stress due to loads, S = fs ( 1.2 W L / Z ) ( 2 Wc / W L ) 4922.3 psi S= 4,922.3 psi

The calculated bending stress is within limits.

Factor for modifying deflection value obtained by the basic formula for y fy = 1.316

4

Deflection, y = fy (17.1 ( W L / E * I ) ) 0.598 inch y= 0.598 inch

0.5

Natural frequency estimate, fn = 3.13 / y fn = 4.046 Hz

OK. Natural frequency above 4 Hz is recommended for most spans. Consider 8 Hz or more for pulsating line.

2 2 2

Slope of pipe between supports for drainage, h = (12 * L) * y / ( 0.25 (12 * L) - y ) 2.393 inch h= 2.393 inch

Method ( B ) -- Reference Book: Piping Handbook, pg 22-47, by Crocker and King, Fifth Edition, 1967, McGraw-Hill

Wc

L1 L1 =

Length of support span (Single Span w/ Free Ends) 32.00 feet 32.00 feet

2

Maximum bending stress, Sw1 = ( 0.75 W * (L1) + 1.5 Wc * L1 ) * Do / I Sw1 = 4,927.8 psi

4 3

Deflection, y1 = (22.5 W * (L1) + 36 Wc * (L1) ) / ( E * I ) 0.60 inch y1 = 0.598 inch

The calculated bending stress is within limits. Deflection is within recommended limits.

0.5

Natural frequency estimate, fn1 = 3.13 / ( y1) fn1 = 4.047 Hz

OK. Natural frequency above 4 Hz is recommended for most spans. Consider 8 Hz or more for pulsating line.

2 2 2

Slope between supports for drainage, h1 = (12 * L1 ) * y1 / ( 0.25 (12 * L1 ) - (y1) ) 2.393 inch h1 = 2.393 inch

Wc

L2

Length of support span (Continuous Straight Run) 39.00 feet L2 = 39.00 feet

2

Maximum bending stress, Sw2 = ( 0.5 W * L2 + 0.75 Wc * L2) * Do / I Sw2 = 4,879.7 psi

4 3

Deflection, y2 = ( 4.5 W * (L2) + 9 Wc * (L2) ) / ( E * I ) 0.26 inch y2 = 0.264 inch

The calculated bending stress is within limits. Deflection is within recommended limits.

0.5

Natural frequency estimate, fn2 = 3.13 / (y2) fn2 = 6.092 Hz

OK. Natural frequency above 4 Hz is recommended for most spans. Consider 8 Hz or more for pulsating line.

2 2 2

Slope between supports for drainage, h2 = (12 * L2 ) * y2 / ( 0.25 (12 * L2 ) - (y2) ) 1.056 inch h2 = 1.056 inch