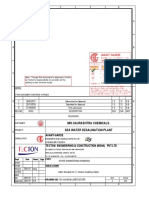

For Emergency Callback, Please Call : (62 21) 8086 6666, (62 21) 2278 0701

SERVICE REPORT SR No :

EQUIPMENT TYPE : 5 TRACTION ELEVATOR 5 HYDRAULIC ELEVATOR

PT CITAS OTIS ELEVATOR Technician :

CIBIS 9 3rd Floor, Jl. TB. Simatupang No. 2 Primary Job Type : 5 Routine Maintenance 5 Stand By

Signature :

Cilandak Timur, Jakarta Selatan 12560 - INDONESIA

Additional Measurement (as necessary) :

Phone : 62 - 21 - 8086 6666

DATE :

62 - 21 - 2278 0701 Date :

Fax : 62 - 21 - 2278 0773

BUILDING NAME : Supervisor :

START :

a.

CONTRACT NO. : Signature :

b.

FINISH :

CONTRACT TYPE : Date :

MAINTENANCE SERVICES VISITING SCHEDULE

LOC MAINTENANCE POINT STANDARD JAN FEB MAR APR MAY JUN JUL AUG SEPT OCT NOV DEC FREQ

a b a b a b a b a b a b a b a b a b a b a b a b

Machine Gear Oil Level Visual E

Brush MG / Motor Visual 2

Main Shave Condition Rope Deep Max 4mm 6

Brake Spring, Coil and Canvas Thickness & Clearance Function & Visual 2

MACHINE ROOM

Brake Switch Contact & Clearance Approx 0,8 - 1,3mm 2

Brake Coil Mechanism (For GETM5.5A Machine only) Spring distance 139~148mm; Gap plunger & lever 1 + 0.5mm 6

Lubrication of moving parts Function & Visual E

Control Panel Fuse, Contactor and Relay Continuity Test Less 5 Ohm E

Check & Test Governor OS and Governor Brake Trip Function & Manual Method 12

Tighten Screw & Nut Cable/ Mech. Support Visual & Manual Method 6

Controller & Drive, EMS, AES & Supervisory panel Function & Visual 6

ARD, Brake Release (Gen 2) and Battery Function & Visual 3

Power Source Voltage 3 phase : 380 Volt ± 5%, 1 phase : 220 Volt ± 5% E

Car Top & Emergency Exit Condition. Function & Visual 6

Door Interlock Clearance & Cleanliness Function & Visual 6

Limit Switches Condition Continuity Test Less 5 Ohm 4

HOISTWAY

Car & Counterweight Roller/Sliding Guide Condition Visual, Noise & Liner Thickness 3

Main Rope & Governor Rope Diameter & Tension Dia Max 10% Less Than Original, No broken 12

Main Rope, Insulating Steel Wire & Gov. Rope Solid Twist or No Crack 12

Tighten Rail, Junction & Support Nut. Function & Manual Method 12

Hall Call & Indicator Function Visual E

Travelling cable Function & Visual 12

Door Sill, Guide & Weighing Moving Function & Manual Method 4

COP Indicator, Button & Switch Function Function & Visual E

Car Fan & Lighting Fixture Function & Visual E

Door Motor Condition Visual & Manual Method 4

CAR STATION

Door Operator Function & Contact Device Function & Visual 4

Door Safety Device Function & Visual E

Door Mechanical Moving Parts Function & Visual 6

Intercom/ Interphone or Emergency Light. Function & Visual E

Tighten Screw & Nut of Cable/ Mech. Support Function & Manual Method 6

Proximity Switch Condition Function & Visual 6

Car Sheave Condition Function & Visual 12

Top Car Safety Device Function & Visual E

Pit Lamp & PES Function Function & Visual E

Spring/Oil Buffer Condition. Function & Visual 6

Compensating Rope Diameter and Tension Max 10% Less Than Original 12

PIT

Compensating Rope Insulating Steel Wire Solid Twist or No Crack 12

Compensating Rope Sheave Clearance Approx + 25 mm 6

Counterweight to CWT Buffer Clearance Approx + 300 mm 6

Governor Tension to Ground Clearance Approx + 300 mm 6

Customer Signature

HYD Hydraulic Pump and Distribution Piping. Function & Visual 4

ONLY Plunger and Stroke Condition Function & Visual 6

TECHNICIAN NOTE : CUSTOMER NOTE :

Name :

Date :

Checklist Remark V : Ok or Normal X : Fail O : Cleaned or Lubricated N : Not Applicable White : OTIS Office Yellow : OTIS Office Red : Customer Blue : Technician

FORM/COE/SFD/001 Rev. 03