0% found this document useful (0 votes)

118 views3 pagesGas Line Size Result

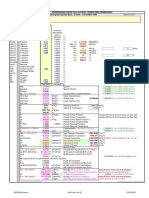

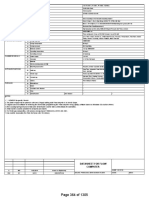

This document provides input data and calculations for sizing a gas pipeline for a project in Nigeria. It includes flow rates, temperatures, pressures, pipe sizes and schedules, and friction factor calculations to determine the optimal pipe size based on pressure drop and velocity criteria. The analysis shows a 4 inch, 2 inch, 4 inch, 2 inch and 6 inch pipe sizing is needed for different sections of the pipeline based on the flow parameters.

Uploaded by

jenish parekhCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

118 views3 pagesGas Line Size Result

This document provides input data and calculations for sizing a gas pipeline for a project in Nigeria. It includes flow rates, temperatures, pressures, pipe sizes and schedules, and friction factor calculations to determine the optimal pipe size based on pressure drop and velocity criteria. The analysis shows a 4 inch, 2 inch, 4 inch, 2 inch and 6 inch pipe sizing is needed for different sections of the pipeline based on the flow parameters.

Uploaded by

jenish parekhCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 3