0% found this document useful (0 votes)

30 views6 pagesCOMPDROP Compressible Flow Press - Drop

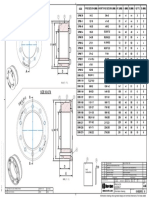

The document contains calculations for compressible flow pressure drops in a pipeline system, detailing conditions such as inlet and outlet pressures, temperatures, and flow rates. It includes results for volumetric and mass flow rates, as well as pipe dimensions and friction factors. The calculations are based on references from chemical engineering literature and provide insights into the behavior of gas flow in pipelines.

Uploaded by

Ahmed Yehia Youssef El SayedCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

30 views6 pagesCOMPDROP Compressible Flow Press - Drop

The document contains calculations for compressible flow pressure drops in a pipeline system, detailing conditions such as inlet and outlet pressures, temperatures, and flow rates. It includes results for volumetric and mass flow rates, as well as pipe dimensions and friction factors. The calculations are based on references from chemical engineering literature and provide insights into the behavior of gas flow in pipelines.

Uploaded by

Ahmed Yehia Youssef El SayedCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

/ 6