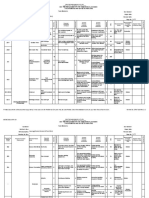

FMEA No

POTENTIAL FAILURE MODE AND EFFECT ANALYSIS

Revision.

(Process FMEA )

Customer : Revision D

Drawing No. Revision No. : 00 Core Team Supplier C

Part No. Part Name Process Responsibility Prepared

Assly No. Assly Name -- : Key Date : Page

Model Year (S) Vehicle.: FMEA Date

S C O D Reco Responsib

Current Process Control

Potential E L Potential cause (s) / C E R mme ility &

Process Function Potential Failure

Opn. Effects (S) of V A Mechanism (S) Of C T P nded Target

Requirements Mode

Failure E S Failure U Prevention Detection E N Actio Completio

R S R C n (S) n Date

Defective

material will

Magnaflux setting Opr. Training, Supp quality plan

Crack process, failure 8 2 8 80

improper Work instruction verification

of componant in

working

Proper fitment

Draw operation Opr. Training, Supp quality plan

Dimension variation. on collet not 7 1 8 56

parameters not ok Work instruction verification

possible

Incoming Chemical

10 Material not as per Wrong material Opr. Training, Supp quality plan

Inspection 8 composation not as 1 8 64

specification will process Work instruction verification

per specification

Improper setting First piece

Opr. Training, inspection &

Forging not ok 4 2 7 56

Work instruction Inprocess

inspection.

Dimn Not OK

Improper setting First piece

Opr. Training, inspection &

Forging not ok 7 2 7 98

Work instruction Inprocess

inspection.

Wear out tap used , First piece

Fittment

Tapping M12*1.75 Tap change freq inspection &

Problem 7 2 7 98

Go not ok not followed Inprocess

During assy

inspection.

� FMEA No

POTENTIAL FAILURE MODE AND EFFECT ANALYSIS

Revision.

(Process FMEA )

Customer : Revision D

Drawing No. Revision No. : 00 Core Team Supplier C

Part No. Part Name Process Responsibility Prepared

Assly No. Assly Name -- : Key Date : Page

Model Year (S) Vehicle.: FMEA Date

S C O D Reco Responsib

Current Process Control

Potential E L Potential cause (s) / C E R mme ility &

Process Function Potential Failure

Opn. Effects (S) of V A Mechanism (S) Of C T P nded Target

Requirements Mode

Failure E S Failure U Prevention Detection E N Actio Completio

R S R C n (S) n Date

Wear out tap used ,

Loose fitment at

First piece

final stage it

Tapping M12*1.75 Tap change freq inspection &

occure engine 7 2 7 98

NOGO Answer not followed Inprocess

not lifting by

inspection.

eye bolt

Part mix up

Opr. Training, First piece

Fittment

Work instruction inspection &

Tapping Missing Problem 7 2 7 98

Tagging and Inprocess

During assy

binning inspection.

Broken tap used First piece

Fittment

Tap change freq inspection &

Thread Damage Problem 7 2 7 98

not followed Inprocess

During assy

inspection.

Wrong setting

First piece

Tap depth 23.0±0.2 Customer inspection &

VMC Operation 7 2 Wrong tap used 7 98

20 O/S dissatisfied Inprocess

inspection.

Wrong program setting First piece

Fittment

Tap depth 23.0±0.2 Wrong program inspection &

Problem 7 2 7 98

U/S followed Inprocess

During assy

inspection.

� FMEA No

POTENTIAL FAILURE MODE AND EFFECT ANALYSIS

Revision.

(Process FMEA )

Customer : Revision D

Drawing No. Revision No. : 00 Core Team Supplier C

Part No. Part Name Process Responsibility Prepared

Assly No. Assly Name -- : Key Date : Page

VMC Operation

20 Year (S) Vehicle.:

Model FMEA Date

S C O D Reco Responsib

Current Process Control

Potential E L Potential cause (s) / C E R mme ility &

Process Function Potential Failure

Opn. Effects (S) of V A Mechanism (S) Of C T P nded Target

Requirements Mode

Failure E S Failure U Prevention Detection E N Actio Completio

R S R C n (S) n Date

Wrong setting Opr. Training, First piece

Customer not Frequency of tool inspection &

Drill depth 28.0 O/S 7 2 7 98

satisfied sharpening is Inprocess

defined inspection.

Wrong setting , First piece

Tapping depth Tool broken Opr. Training, inspection &

Drill depth 28.0 U/S not achive as 7 2 7 98

Work instruction Inprocess

per spec

inspection.

Drill resharpening freq Opr. Training,

First piece

Fittment not followed Work

inspection &

Drill Dia 12+0.3 O/S Problem 4 properly,Wrong drill 2 instruction,Drilll 7 56

Inprocess

During assy used change freq

inspection.

followed

Drill resharpening freq Opr. Training,

First piece

Fittment not followed Work

inspection &

Drill Dia 12+0.3 U/S Problem 7 properly,Wrong drill 2 instruction,Drilll 7 98

Inprocess

During assy used change freq

inspection.

followed

Improper setting

Assembly

Phosphetting cycl Opr. Training,

fitment not 7 2 Inward insp 7 98

time O/S Work instruction

possible

30 Phosphetting

Improper setting

Phosphetting cycl Loose Opr. Training,

7 2 Inward insp 7 98

time U/S Assembly Work instruction

� FMEA No

POTENTIAL FAILURE MODE AND EFFECT ANALYSIS

Revision.

(Process FMEA )

Customer : Revision D

Drawing No. Revision No. : 00 Core Team Supplier C

Part No. Part Name Process Responsibility Prepared

Assly No. Assly Name -- : Key Date : Page

Model Year (S) Vehicle.: FMEA Date

S C O D Reco Responsib

Current Process Control

Potential E L Potential cause (s) / C E R mme ility &

Process Function Potential Failure

Opn. Effects (S) of V A Mechanism (S) Of C T P nded Target

Requirements Mode

Failure E S Failure U Prevention Detection E N Actio Completio

R S R C n (S) n Date

packing material not

Damage in proper.

Packing not as per handeling. Packing material not Opr. Training, First packinmg

40 Packing 6 2 8 96

specification Rusty due to used properly. Work instruction inspection

environment.

FPA - First Piece Approval IPIR - Inprocess Inspection Report

Prepared By: `

###

�FMEA No.

Revision. No.

Revision Date

Supplier Code

Prepared by

Page

Action Results

S O D R

Action Taken E C E P

V C T N

�FMEA No.

Revision. No.

Revision Date

Supplier Code

Prepared by

Page

Action Results

S O D R

Action Taken E C E P

V C T N

�FMEA No.

Revision. No.

Revision Date

Supplier Code

Prepared by

Page

Action Results

S O D R

Action Taken E C E P

V C T N

�FMEA No.

Revision. No.

Revision Date

Supplier Code

Prepared by

Page

Action Results

S O D R

Action Taken E C E P

V C T N