0% found this document useful (0 votes)

198 views4 pagesFace Mounted Bracket Design Guide

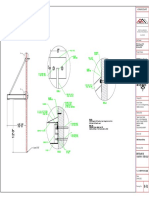

The document describes the design of a face mounted bracket. It includes calculations to check stresses in vertical and horizontal plates, as well as welds connecting the plates. The vertical plate is designed as two 150mm x 150mm x 8mm plates. Stress calculations show the design satisfies limits for bending, shear, tension and bearing stresses. An 8mm thick horizontal base plate is selected. Weld sizes are assumed and stress calculations verify the weld design is also adequate.

Uploaded by

vishal tomarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

198 views4 pagesFace Mounted Bracket Design Guide

The document describes the design of a face mounted bracket. It includes calculations to check stresses in vertical and horizontal plates, as well as welds connecting the plates. The vertical plate is designed as two 150mm x 150mm x 8mm plates. Stress calculations show the design satisfies limits for bending, shear, tension and bearing stresses. An 8mm thick horizontal base plate is selected. Weld sizes are assumed and stress calculations verify the weld design is also adequate.

Uploaded by

vishal tomarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 4