0% found this document useful (0 votes)

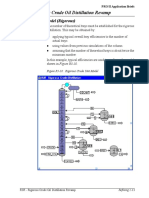

79 views18 pagesFigure R4-1: Vacuum Column Flowsheet

The document describes simulating an existing vacuum column to match test run data. Key aspects include:

1) The vacuum column has two packed sections with total draws and pumparounds returning cooled liquid. Laboratory data on the feed assay and product balances are provided for the simulation.

2) The simulation models the column with 7 theoretical trays representing the real trays and packed sections. Specifications include draw rates, return temperatures, and the top tray temperature.

3) A separate flash calculation is used to determine the feed temperature to the column, accounting for any cracking in the furnace by adding light gases to the feed stream.

Uploaded by

nico123456789Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

79 views18 pagesFigure R4-1: Vacuum Column Flowsheet

The document describes simulating an existing vacuum column to match test run data. Key aspects include:

1) The vacuum column has two packed sections with total draws and pumparounds returning cooled liquid. Laboratory data on the feed assay and product balances are provided for the simulation.

2) The simulation models the column with 7 theoretical trays representing the real trays and packed sections. Specifications include draw rates, return temperatures, and the top tray temperature.

3) A separate flash calculation is used to determine the feed temperature to the column, accounting for any cracking in the furnace by adding light gases to the feed stream.

Uploaded by

nico123456789Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 18