Basic Input: Introduction To Aspen Plus

Uploaded by

nico123456789Basic Input: Introduction To Aspen Plus

Uploaded by

nico123456789Introduction to Aspen Plus Basic Input

Basic Input

Introduction to Aspen Plus

©2003 AspenTech. All Rights Reserved.

Lesson Objectives

• Introduce the basic input required to run an Aspen Plus

simulation.

Aspen Plus References:

User Guide, Chapter 3, Using Aspen Plus Help

User Guide, Chapter 5, Global Information for Calculations

User Guide, Chapter 6, Specifying Components

User Guide, Chapter 7, Physical Property Methods

User Guide, Chapter 9, Specifying Streams

User Guide, Chapter 10, Unit Operation Models

User Guide, Chapter 11, Running Your Simulation

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–1 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

The User Interface (1)

• Menus

– Used to specify program options and commands

• Toolbar

– Allows direct access to certain popular functions

– Can be moved

– Can be hidden or revealed using the Toolbars dialog box from

the View menu

• Data Browser

– Can be moved, resized, minimized, maximized or closed

– Used to navigate the folders, forms, and sheets

©2003 AspenTech. All Rights Reserved.

The User Interface (2)

• Folders

– Refers to the root items in the Data Browser

– Contain forms

• Forms

– Used to enter data and view results for the simulation

– Can be comprised of a number of sheets

– Are located in folders

• Sheets

– Make up forms

– Are selected using tabs at the top of each sheet

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–2 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

The User Interface (3)

• Object Manager

– Allows manipulation of discrete objects of information

– Can be created, edited, renamed, deleted, hidden, and

revealed

• Next Button

– Checks if the current form is complete and skips to the next

form which requires input

©2003 AspenTech. All Rights Reserved.

The Data Browser Go Back Previous

Sheet Comments

Parent Go

Next

Button Units Forward Status

Sheet

Next

Menu

Tree

Description

Area

Status

Area

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–3 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Help

• Help Topics

– Contents: Used to browse through the documentation,

including User Guides and Reference Manuals.

• All information in the User Guides is found under the “Using Aspen

Plus” book.

– Index: Used to search for help on a specific topic using the

index entries.

– Find: Used to search for a help on a topic that includes any

word or words.

• “What’s This?” Help

– Select “What’s This?” from the Help menu and then click on

any area to get help for that item.

©2003 AspenTech. All Rights Reserved.

Functionality of Forms

• When you select a field on a form (click left mouse

button in the field), the prompt area at the bottom of the

window gives you information about that field.

• Click the drop-down arrow in a field to bring up a list of

possible input values for that field.

– Typing a letter will bring up the next selection on the list that

begins with that letter.

• The Tab key will take you to the next field on a form.

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–4 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Basic Input

• The minimum required inputs (in addition to the graphical

flowsheet) to run a simulation are:

– Setup

– Components

– Properties

– Streams

– Blocks

• Data can be entered on input forms in the above order by clicking

the Next button.

• These inputs are all found in folders within the Data Browser.

• These input folders can be located quickly using the Data menu

or the Data Browser buttons on the toolbar.

©2003 AspenTech. All Rights Reserved.

Status Indicators

• Colors and shapes are used to describe the current

status of input and results:

Symbol Status

Input for the form is incomplete.

Input for the form is complete.

No input for the form has been entered. It is optional.

Results for the form exist.

Results for the form exist, but there were calculation

errors.

Results for the form exist, but there were calculation

warnings.

Results for the form exist, but input has changed since

the results were generated.

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–5 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

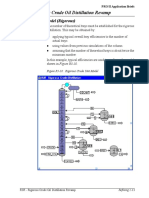

Cumene Production Conditions

RECYCLE

REACTOR

COOL

FEED

SEP

REAC -OUT COOL-OUT P = 1 atm

T = 220°F Q = 0 Btu/hr

P = 36 psia Q = 0 Btu/hr T = 130°F

Benzene: 40 lbmol/hr Pdrop = 0 psi Pdrop = 0.1 psi

Propylene: 40 lbmol/hr PRODUCT

C6H6 + C3H6 à C9H12

Benzene Propylene Cumene (Isopropylbenzene)

90% Conversion of Propylene

Use the RK-SOAVE Property Method Filename: CUMENE.BKP

©2003 AspenTech. All Rights Reserved.

Setup

• Most of the commonly used Setup information is entered

on the Setup Specifications Global sheet

– Flowsheet title to be used on reports

– Run type

– Input and output units

– Valid phases (e.g. vapor-liquid or vapor-liquid-liquid)

– Ambient pressure

• Stream report options are located on the Setup Report

Options Stream sheet

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–6 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Setup Specifications Form

©2003 AspenTech. All Rights Reserved.

Stream Report Options

• Property Sets are located on the Stream sheet

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–7 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Setup Run Types

Run Type

Flowsheet Standard Aspen Plus flowsheet run including sensitivity studies and optimization.

Flowsheet runs can contain property estimation, assay data analysis, and/or property analysis

calculations.

Assay Data A standalone Assay Data Analysis and pseudocomponent generation run.

Analysis Use Assay Data Analysis to analyze assay data when you do not want to perform a flowsheet

simulation in the same run.

Data A standalone Data Regression run. Use Data Regression to fit physical property model parameters

Regression required by ASPEN PLUS to measured pure component, VLE, LLE, and other mixture data. Data

Regression can contain property estimation and property analysis calculations. ASPEN PLUS cannot

perform data regression in a Flowsheet run.

PROPERTIES PROPERTIES PLUS setup run. Use PROPERTIES PLUS to prepare a property package for use

PLUS with Aspen Custom Modeler (formerly SPEEDUP) or Aspen Pinch (for merly ADVENT), with third-

party commercial engineering programs, or with your company's in-house programs. You must be

licensed to use PROPERTIES PLUS.

Property A standalone Property Analysis run. Use Property Analysis to generate property tables, PT-

Analysis envelopes, residue curve maps, and other property reports when you do not want to perform a

flowsheet simulation in the same run. Property Analysis can contain property estimation and assay

data analysis calculations.

Property Standalone Property Constant Estimation run. Use Property Estimation to estimate property

Estimation parameters when you do not want to perform a flowsheet simulation in the same run.

©2003 AspenTech. All Rights Reserved.

Setup Units

• Units in Aspen Plus can be defined at three different

levels:

1. Global Level (“Input Data” and “Output Results” fields on the

Setup Specifications Global sheet)

2. Object level (“Units” field in the top of any input form of an

object such as a block or stream

3. Field Level

• Users can create their own units sets using the Setup

Units Sets Object Manager. Units can be copied from an

existing set and then modified

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–8 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Components

• Use the Components Specifications form to specify all

the components required for the simulation

• If available, physical property parameters for each

component are retrieved from databanks

• Pure component databanks contain parameters such as

molecular weight, critical properties, etc. The databank

search order is specified on the Databanks sheet

• The Find button can be used to search for components

• The Electrolyte Wizard can be used to set up an

electrolyte simulation

©2003 AspenTech. All Rights Reserved.

Components Specifications Form

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3–9 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Entering Components

• The Component ID is used to identify the component in

simulation inputs and results

• Each Component ID can be associated with a databank

component as either:

– Formula: Chemical formula of component (e.g., C6H6)

• A suffix is added to formulas when there are isomers,

e.g., C2H6O-2

– Component Name: Full name of component (e.g., BENZENE)

• Databank components can be searched for using the

Find button

©2003 AspenTech. All Rights Reserved.

Find

• Search using component name, formula, component

class, molecular weight, boiling point, or CAS number

– All components containing specified items will be listed

• Find performs an AND search when more than one

criterion is specified

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3 – 10 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Pure Component Databanks (1)

• Parameters missing from the first selected databank will

be searched for in subsequent selected databanks

Databank Contents Uses

PURE11 Data from the Design Institute for Physical Primary component

Property Data (DIPPR) and AspenTech databank in Aspen Plus

AQUEOUS Pure component parameters for ionic and Simulations containing

molecular species in aqueous solution electrolytes

SOLIDS Pure component parameters for strong Simulations containing

electrolytes, salts, and other solids electrolytes and solids

INORGANIC Thermochemical properties for inorganic Solids, electrolytes, and

components in vapor, liquid, and solid states metallurgy applications

PURE10 Data from DIPPR & AspenTech delivered For upward compatibility

with Aspen Plus 10.1-2

PURE93 Data from DIPPR & AspenTech delivered For upward compatibility

with Aspen Plus 9.3

PURE856 Data from DIPPR & AspenTech delivered For upward compatibility

with Aspen Plus 8.5-6

©2003 AspenTech. All Rights Reserved.

Pure Component Databanks (2)

Databank Contents Uses

ETHYLENE Pure component and binary interaction Ethylene process

parameters for components typically found simulation

in ethylene processes for use with the SRK

property method

AQU92 Aqueous databank compatible with Aspen For upward compatibility

Plus 9.2

ASPENPCD Databank delivered with Aspen Plus 8.5-6 For upward compatibility

COMBUST Pure component parameters for components Simulations containing

typically found in combustion products, combustion products

including free radicals

POLYMER Chains of repeating monomer units Polymers processes

SEGMENT Individual monomer groups or segments Polymers processes

FACTPCD FACT species (components referenced in a Pyrometallurgical

specific pure or solution phase for use only processes

with the Aspen/FACT/Chemapp interface in

Aspen Plus)

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3 – 11 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Properties

• Use the Properties Specifications form to specify the

physical property methods to be used in the simulation

• Property methods are a collection of models and

methods used to describe pure component and mixture

behavior

• Choosing the right physical properties is critical for

obtaining reliable simulation results

• Selecting a Process Type will narrow the number of

methods available

©2003 AspenTech. All Rights Reserved.

Properties Specifications Form

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3 – 12 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Streams

• Use Stream Input forms to specify the feed stream

conditions and composition

• To specify stream conditions enter two of the following:

– Temperature

– Pressure

– Vapor Fraction

• To specify stream composition enter either:

– Total stream flow and component fractions

– Individual component flows

• Specifications for streams that are not feeds to the

flowsheet are used as estimates

©2003 AspenTech. All Rights Reserved.

Streams Input Form

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3 – 13 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Blocks

• Each Block Input or Block Setup form specifies operating

conditions and equipment specifications for the unit

operation model

• Some unit operation models require additional

specification forms

• All unit operation models have optional information forms

(e.g., Block Options form)

©2003 AspenTech. All Rights Reserved.

Block Form

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3 – 14 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Starting the Run

• Select Control Panel from the View menu or press the

Next button to be prompted

– Execute the simulation when all required forms are complete.

– The Next button will take you to any incomplete forms

©2003 AspenTech. All Rights Reserved.

Control Panel

• The Control Panel consists of a:

– Message window showing the progress of the simulation by

displaying the most recent messages from the calculations

– Status area showing the hierarchy and order of simulation

blocks and convergence loops executed

– Toolbar that you can use to control the simulation

Run Start or continue calculations

Step Step through the flowsheet one block at a time

Stop Pause simulation calculations

Reinitialize Purge simulation results

Results Check simulation results

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3 – 15 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Reviewing Results

• History file or Control Panel Messages

– Contains any generated errors or warnings

– Select History or Control Panel on the View menu to display

the History file or the Control Panel

• Stream Results

– Contains stream conditions and compositions

• For all streams (/Data/Results Summary/Streams)

• For individual streams (bring up the stream folder in the Data

Browser and select the Results form)

• Block Results

– Contains calculated block operating conditions (bring up the

block folder in the Data Browser and select the Results form)

©2003 AspenTech. All Rights Reserved.

Benzene Flowsheet Conditions Workshop (1)

• Objective: Add the process and feed stream conditions

to a flowsheet

– Starting with the flowsheet created in the Benzene Flowsheet

Definition Workshop (saved as BENZENE.BKP), add the

process and feed stream conditions as shown on the next page

• Questions:

1. What is the heat duty of the COOL block? _________

2. What is the temperature in the FL2 block? _________

Note : Answers for all of the workshops are located in the back of

the course notes in Appendix C

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3 – 16 Aspen Technology, Inc.

Introduction to Aspen Plus Basic Input

Benzene Flowsheet Conditions Workshop (2)

VAP1

COOL

FL1 T = 100°F

FEED COOL VAP2

P = 500 psia

Feed T = 200°F

FL2 P = 1 atm

T = 1000°F Pdrop = 0 LIQ1

Q=0

P = 550 psia

Hydrogen: 405 lbmol/hr

LIQ2

Methane: 95 lbmol/hr

Benzene: 95 lbmol/hr

Toluene: 5 lbmol/hr

Use the PENG-ROB Property Method When finished, save as

filename: BENZENE.BKP

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 3 – 17 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

RadFrac

Introduction to Aspen Plus

©2003 AspenTech. All Rights Reserved.

Lesson Objectives

• Enter the minimum input required for the RadFrac

fractionation model

• Implement design specifications and stage efficiencies

• Introduce Tray Sizing function

Aspen Plus References:

Unit Operation Models Reference Manual, Chapter 4, Columns

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–1 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

RadFrac: Rigorous Multistage Separation

• Vapor-Liquid or Vapor-Liquid-Liquid phase simulation of:

– Ordinary distillation

– Absorption, reboiled absorption

– Stripping, reboiled stripping

– Azeotropic distillation

– Reactive distillation

• Configuration options

– Any number of feeds

– Any number of side draws

– Total liquid draw off and pumparounds

– Any number of heaters

– Any number of decanters

©2003 AspenTech. All Rights Reserved.

RadFrac Flowsheet Connectivity

Vapor Distillate

Top-Stage or 1

Condenser Heat Duty Heat (optional)

Liquid Distillate

Water Distillate (optional)

Feeds

Reflux Pseudo Streams (optional)

Heat (optional) Side Products (optional)

Pumparound

Decanters

Heat (optional)

Heat (optional)

Boil-up Product

Return

Bottom Stage or Nstage

Heat (optional)

Reboiler Heat Duty

Bottoms

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–2 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

Some RadFrac Options

• To set up an absorber with no condenser or reboiler, set

condenser and reboiler to none on the RadFrac Setup

Configuration sheet.

• Either Vaporization or Murphree efficiencies on either a

stage or component basis can be specified on the

RadFrac Efficiencies form.

• Tray and packed column design and rating is possible.

• A Second liquid phase may be modeled if the user

selects Vapor-liquid-liquid as Valid phases.

• Reboiler and condenser heat curves can be generated.

©2003 AspenTech. All Rights Reserved.

Methanol-Water RadFrac Demonstration

RadFrac specifications

OVHD Total Condenser

Kettle Reboiler

FEED COLUMN 9 Stages

Reflux Ratio = 1

T = 65°C Distillate to feed ratio = 0.5

P = 1 bar Column pressure = 1 bar

Feed stage = 6

BTMS

Water: 100 kmol/hr

Methanol: 100 kmol/hr

Use the NRTL-RK Property Method Filename: RAD -EX.BKP

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–3 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

RadFrac Setup Configuration Sheet

• Specify:

– Number of stages

– Condenser and

reboiler configuration

– Two column operating

specifications

– Valid phases

– Convergence

©2003 AspenTech. All Rights Reserved.

RadFrac Setup Streams Sheet

• Specify:

– Feed stage location

– Feed stream convention:

• ABOVE-STAGE:

- Vapor from feed goes

to stage above feed

stage

- Liquid goes to feed

stage

• ON-STAGE

- Both Vapor and Liquid

from feed go to

specified feed stage

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–4 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

Feed Convention

Above-Stage On-Stage

(default)

n-1 n-1

Vapor

Feed

Liquid

n Feed

n

©2003 AspenTech. All Rights Reserved.

RadFrac Setup Pressure Sheet

• Specify one of:

– Column pressure

profile

– Top/Bottom pressure

– Section pressure drop

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–5 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

Plot Wizard (1)

• Use Plot Wizard (on the Plot menu) to quickly

generate plot results of a simulation. You can use Plot

Wizard for displaying results for the following

operations:

– Assay data analysis

– Physical property analysis

– Data regression analysis

– Profiles for all separation models including RadFrac, MultiFrac,

PetroFrac and RateFrac

• Click the object of interest in the Data Browser to

generate plots for that particular object.

©2003 AspenTech. All Rights Reserved.

Plot Wizard (2)

• The Plot Wizard guides you in the basic operations for

generating a plot.

• In Step 2, click on the

plot type you wish to

generate, then click

Next> to continue.

• Click on the Finish

button to generate a

plot with default

settings.

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–6 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

Plot Wizard Demonstration

• Use the Plot Wizard on the column to create a plot of the

vapor phase compositions throughout the column.

©2003 AspenTech. All Rights Reserved.

RadFrac DesignSpecs and Vary

• Design specifications can be specified inside the

RadFrac block using DesignSpecs and Vary forms.

• One or more RadFrac inputs can be manipulated to

achieve specifications on one or more RadFrac

performance parameters.

• The number of specs should, in general, be equal to the

number of varies.

• The DesignSpecs and Varys in a RadFrac are solved in

a “Middle loop.” If you get an error message saying that

the middle loop was not converged, check the

DesignSpecs and Varys you have entered.

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–7 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

RadFrac Convergence Problems (1)

• If a RadFrac column fails to converge, doing one or

more of the following could help:

1. Check that physical property issues (choice of

Property Method, parameter availability, etc.) are

properly addressed.

2. Ensure that column operating conditions are feasible.

3. If the column err/tol is decreasing fairly consistently,

increase the maximum iterations on the RadFrac

Convergence Basic sheet.

©2003 AspenTech. All Rights Reserved.

RadFrac Convergence Problems (2)

4. Provide temperature estimates for some stages in the

column using the RadFrac Estimates Temperature

sheet (useful for absorbers).

5. Provide composition estimates for some stages in

the column using the RadFrac Estimates Liquid

Composition and Vapor Composition sheet (useful

for highly non-ideal systems).

6. Experiment with different convergence methods on

the RadFrac Setup Configuration sheet.

Note: When a column does not converge, it is usually

beneficial to Reinitialize after making changes.

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–8 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

RadFrac Workshop (1)

Part A

• Set up the Methanol tower and note the column duties:

Condenser Duty: _________ Reboiler Duty: _________

63.2 wt% Water

36.8 wt% Methanol

Flow = 120000 lb/hr

DIST

Pressure 18 psia

Saturated liquid 38 trays (40 stages)

Feed tray = 23 (stage 24)

FEED COLUMN Total condenser

Top stage pressure = 16.1 psia

Pressure drop per stage = 0.1 psi

Distillate flowrate = 1245 lbmol/hr

Use the NRTL-RK Molar reflux ratio = 1.3

Property Method BTMS

• Make plots of temperature, flows, and composition.

Filename: RADFRAC.BKP

©2003 AspenTech. All Rights Reserved.

RadFrac Workshop (2)

Part B

• Set up design specifications within the column so the

following two objectives are met:

– 99.95 wt% methanol in the distillate

– 99.90 wt% water in the bottoms

• Vary the distillate rate (800-1700 lbmol/hr) and the reflux

ratio (0.8 -2).

• Make sure stream compositions are reported as mass

fractions before running the problem. Note the

condenser and reboiler duties:

Condenser Duty:_________ Reboiler Duty:_________

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5–9 Aspen Technology, Inc.

Introduction to Aspen Plus RadFrac

RadFrac Workshop (3)

Part C

• Perform the same design calculation after specifying a

65% Murphree efficiency for each tray. Assume the

condenser and reboiler have stage efficiencies of 90%.

• How do these efficiencies affect the condenser and

reboiler duties of the column?

Part D

• Perform a tray sizing calculation for the entire column,

given that Bubble Cap trays are used.

©2003 AspenTech. All Rights Reserved.

© 2003 AspenTech. All Rights Reserved. 5 – 10 Aspen Technology, Inc.

You might also like

- Basic Input: Introduction To Aspen PlusNo ratings yetBasic Input: Introduction To Aspen Plus17 pages

- Aspen Plus® Tips: Tips and Frequently Asked QuestionsNo ratings yetAspen Plus® Tips: Tips and Frequently Asked Questions16 pages

- Aspen Plus & Dynamic Workshop (Step by Step)100% (14)Aspen Plus & Dynamic Workshop (Step by Step)137 pages

- AspenPlus2004 (1) 1GettingStartedCustomizingNo ratings yetAspenPlus2004 (1) 1GettingStartedCustomizing101 pages

- Aspen-Getting Started Building and Running Process Model100% (1)Aspen-Getting Started Building and Running Process Model101 pages

- Aspen Plus Workshop For Reaction Engineering100% (1)Aspen Plus Workshop For Reaction Engineering44 pages

- Modeling Separation Systems With Aspen PlusNo ratings yetModeling Separation Systems With Aspen Plus23 pages

- Aspen Plus, Reaction Engineering and Design100% (1)Aspen Plus, Reaction Engineering and Design45 pages

- Reactor Models: Introduction To Aspen PlusNo ratings yetReactor Models: Introduction To Aspen Plus8 pages

- Cyclohexane Production Workshop: Introduction To Aspen PlusNo ratings yetCyclohexane Production Workshop: Introduction To Aspen Plus2 pages

- Process Advancement in Chemistry and Chemical Engineering Research (2015) PDFNo ratings yetProcess Advancement in Chemistry and Chemical Engineering Research (2015) PDF378 pages

- DSTWU - A Shortcut Distillation Model in Aspen Plus® V8.0: 1. Lesson ObjectivesNo ratings yetDSTWU - A Shortcut Distillation Model in Aspen Plus® V8.0: 1. Lesson Objectives39 pages

- Get Software Process Improvement and Capability Determination 18th International Conference SPICE 2018 Thessaloniki Greece October 9 10 2018 Proceedings Ioannis Stamelos Free All Chapters100% (4)Get Software Process Improvement and Capability Determination 18th International Conference SPICE 2018 Thessaloniki Greece October 9 10 2018 Proceedings Ioannis Stamelos Free All Chapters65 pages

- Analytics Made Easy For Beginners Long CleanedNo ratings yetAnalytics Made Easy For Beginners Long Cleaned6 pages

- How To Write and Publish An Original Research Article: EducationNo ratings yetHow To Write and Publish An Original Research Article: Education6 pages

- Analysis of Marketing Strategy of Eastern Bank Limited100% (7)Analysis of Marketing Strategy of Eastern Bank Limited55 pages

- Rafa Souza Academy Software ZBrush 2024No ratings yetRafa Souza Academy Software ZBrush 202426 pages

- Providing Remote Users With Protected Access To A Corporate Network and Internet Using SSL VPNNo ratings yetProviding Remote Users With Protected Access To A Corporate Network and Internet Using SSL VPN8 pages

- Why Buildings Are Sentient and Evil (Extended Phenotype & Living Systems Theory) Agora Road's Macintosh CafeNo ratings yetWhy Buildings Are Sentient and Evil (Extended Phenotype & Living Systems Theory) Agora Road's Macintosh Cafe19 pages

- Submarine Air Purification and Monitoring NATO100% (1)Submarine Air Purification and Monitoring NATO11 pages

- Governor Brian P. Kemp Commissioner Spencer R. Moore100% (1)Governor Brian P. Kemp Commissioner Spencer R. Moore1 page

- Customer Satisfaction: A Comparative Study of Public and Private Sector Banks in BangladeshNo ratings yetCustomer Satisfaction: A Comparative Study of Public and Private Sector Banks in Bangladesh8 pages

- Finite Element Analysis of Thermopiezoelectric StructuresNo ratings yetFinite Element Analysis of Thermopiezoelectric Structures12 pages

- Legal Case Analysis: Arbitration DisputeNo ratings yetLegal Case Analysis: Arbitration Dispute6 pages