100% found this document useful (1 vote)

2K views4 pagesPFD - Example..

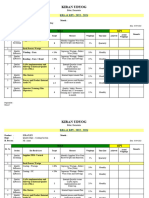

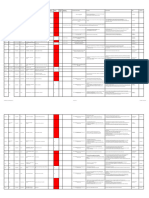

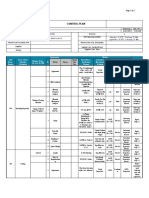

This document provides a process flow diagram for manufacturing an electronic product. It outlines 8 key steps:

1) Receipt of raw materials and bought out parts

2) Incoming inspection of components

3) Raw material inspection

4) Storage of raw materials

5) Tumble shot blasting and shot blasting of back plates

6) Glue preparation

7) Glue application to back plates

8) The process flow diagram includes operation descriptions, pictures, and characteristics for tracking materials and quality.

Uploaded by

lalit GuptaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

2K views4 pagesPFD - Example..

This document provides a process flow diagram for manufacturing an electronic product. It outlines 8 key steps:

1) Receipt of raw materials and bought out parts

2) Incoming inspection of components

3) Raw material inspection

4) Storage of raw materials

5) Tumble shot blasting and shot blasting of back plates

6) Glue preparation

7) Glue application to back plates

8) The process flow diagram includes operation descriptions, pictures, and characteristics for tracking materials and quality.

Uploaded by

lalit GuptaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 4