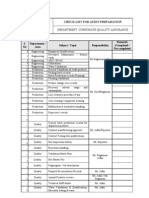

PROCESS FLOW CHART

(PRESSURE/ GRAVITY DIE CAST COMPONENT)

PAGE : 1 OF 09

PART NAME

: PIPE, AIR TRANSFER

PART / DRG. NUMBER : 5336251

DATE (Org.) : 12.05.2014

DATE (Rev. 1) :

Characteristics

Oper.

No.

Operation Description

Al. alloy5016 Receipt

& Storage

Work

Instruction

Reference

Number

> PE/ WI/ 3.18

Location

Raw Material Store

Fixture / Die

Reference

Number

Product

1) Identification (Colour code)

Process

Spl.

Char.

Class

> PE/WI/3.19

Control Method

> Supplier Invoice

> Supplier T.C

> Raw Materail

Verification (Batchwise)

> Indent

2) Supplier

3) Chemical Compositiuon

> Approved source list

> W.I. # 3.19.A

4) Storage

> Third Party Spectro

Report

> Stock Register

for Al. alloy.

CONTD. TO NEXT PAGE

> Different location

for different Al. alloy

FORMAT NO. PE-F-QS-PPAP/PFC-036

REV- 01

(SIGNATURE)

PROCESS

INSPECTION STORAGE TRANSPORT

�PROCESS FLOW CHART

PAGE : 2

PART NAME

: PIPE,

AIR TRANSFER

PART / DRG. NUMBER :

5336251

DATE (Org.)

12.05.2014

Characteristics

Oper.

No.

Operation Description

Shell Core

Making

Work

Instruction

Reference

Number

PE/WI/3.4

Location

Ganesh Shell Core

Fixture / Die

Reference

Number

Product

Shell Core Die

Process

Spl.

Char

Class

1) Die Temp

2) Zirkote coating

3) Curing Time

Control Method

> PCS (F-10)

> W.I. # 3.33.A (for Span Core

m/c)

> W.I. # 3.33 (for Span Core m/c)

> Operator awareness

> W.I. # 3.33.B (for Span Core m/c)

4) Resin Coated

Sand

CONTD. TO NEXT PAGE

FORMAT NO. PE-F-QS-PPAP/PFC-036

REV- 01

> Operator awareness

5) Parting line clean

Visual Sample displayed on the

Shop floor.

> Visual Sample displayed on the

Shop floor.

6) Parting line mismatch

> Visual Sample displayed on the

Shop floor.

7) Core Baking

> Visual Sample displayed on the

Shop floor.

8) Inside Core

> Visual Sample displayed on the

Shop floor.

9) Outside Surface of Core

> Visual Sample displayed on the

Shop floor.

10) Damage

> PCS (F-10)

>

(SIGNATURE)

PROCESS

INSPECTION

STORAGE TRANSPORT

�PROCESS FLOW CHART

PAGE : 3

PART NAME

Oper. No.

: PIPE,

AIR TRANSFER

Operation

Description

Work

Instruction

Reference

Number

Location

Fixture / Die

Reference

Number

Melting of

Al. alloy

PE/WI/3.2

Preparation of Al.

alloy

Melting Furnace

(Electric)

GDC area

> Temperatrure Controller

> Molten Metal

> W.I. # 3.41 (for Melting Furnace)

> Purification of metal with

Al. cover flux.

> W.I. # 3.41 (for Melting Furnace)

> To avoid Mix-up of

different Al. alloy

> Different Bins for different alloy.

(colour code)

> Holding Furnance Temp.

> Temperatrure Controller

> Molten Metal Temp.

> PCS (F-08)

> Degassing with Tablet

> W.I # 3.2.A (For Molten metal)

> Al. Cover Flux

> W.I # 3.2.A (For Molten metal)

> Al. Innoculent Tablet

> W.I # 3.2.A (For Molten metal)

> Tensile Stength

> Hardness Test

> Mechanical properties log book

PE/WI/3.23

Control Method

PE/WI/3.22

Process

Spl. Char

Class

: 12.05.2014

> Holding Furnance Temp.

PE/WI/3.2

DATE (Org.)

Product

PE/WI/3.1

5336251

PART / DRG. NUMBER :

> Mechanical properties

CONTD. TO NEXT PAGE

FORMAT NO. PE-F-QS-PPAP/PFC-036

REV- 01

(SIGNATURE)

PROCESS

INSPECTION STORAGE TRANSPORT

�PROCESS FLOW CHART

PAGE : 4

PART NAME

: PIPE,

AIR TRANSFER

5336251

PART / DRG. NUMBER :

DATE (Org.)

: 12.05.2014

Spl.

Char.

Class

Control Method

Characteristics

Oper.

No.

Operation Description

Work

Instruction

Reference

Number

Gravity

Die. Casting

Location

G.D.C Area

( Holding

Furnance)

Fixture / Die

Reference

Number

G.D.C Die.

Product

Process

> Molten metal temp.

> PCS (F-08)

> Preparation of Die coat

> PE/WI/3.3

> Die Coat Spray

> W.I. # 3.3 (For Die Coating)

> PE/WI/3.5

> Die Temp.

> W.I. # 3.5 (For G.D.C)

> PE/WI/3.7

>Pouring Time.

> Operator awareness

> Solidification Time

> Operator awareness

> W.I. # 3.3 (For Die Coating)

> Dimn Parameter

> F.P.A (F-15)

> Grain structure

> PCS (F-08)

> Crack / Blow Hole

> PCS (F-08)

> Surface finish

> Visual Sample displayed on the Shop

floor

> Product Identification

> Visual Sample displayed on the Shop

floor

CONTD. TO NEXT PAGE

FORMAT NO. PE-F-QS-PPAP/PFC-036

(SIGNATURE)

REV- 01

PROCESS

INSPECTION STORAGE TRANSPORT

PROCESS FLOW CHART

PAGE : 5

PART NAME

:PIPE,

AIR TRANSFER

PART / DRG. NUMBER : 5336251

DATE (Org.)

: 12.05.2014

Characteristics

Oper.

Operation Description

No.

Work

Instruction

Reference

Number

Location

Fixture / Die

Reference

Number

Product

Process

Spl.

Char.

Class

Control Method

Cutting of Runner/ Riser

6

PE/WI/3.8

> PE/ M / 49

Cutting fixture

> Cutting blade 10 TPI

> Vibration &

> Work Insruction for Bandsaw cutting

> Visual Sample Displayed

sharpness of cutting

blade

> Components free from

Runner / Riser

7

Fetting

PE/WI/3.9

Fetting Area

> Parting line

>W.I. # 3.9 (for fetting )

> Visual Sample

displayed on the Shop floor

> Sharp edge

>W.I. # 3.9 (for fetting )

> Visual Sample

displayed on the Shop floor

> Unwanted Projection

>W.I. # 3.9 (for fetting )

> Visual Sample

displayed on the Shop floor

> Inside surface

>W.I. # 3.9 (for fetting )

> Visual Sample

displayed on the Shop floor

> Porosity sealed of component. > Hot Water temp.

>

Vacuum Pressure at

Auto clave

> Cycle Time

> Daily Check List ( For V.I )

> W.I.# 3.13 for V.I

Vacuum Impregnation

> PE / WI / 3.13 V.I. Plant

> Record

for V.I

> L.P.T

CONTD. TO NEXT PAGE

FORMAT NO. PE-F-QS-PPAP/PFC-036

REV- 01

(SIGNATURE)

PROCESS

INSPECTION STORAGE TRANSPORT

PROCESS FLOW CHART

PAGE : 6

PART NAME

: PIPE,

AIR TRANSFER

PART / DRG. NUMBER : 5336251

DATE (Org.) : 12.05.2014

Characteristics

Oper.

Operation Description

No.

9

Work

Instruction

Reference

Number

Location

Product

Process

Spl.

Char.

Class

Control Method

Leak proof test

Leak Proof Test

area.

10

Fixture / Die

Reference

Number

> PE/FIX/LPT/32

Machining

(C.N.C)

> PE / WI / 3.11 > PE/M/82/60

> PE/FIX/LM-34

> Air Pressure

> Calibration of Gauge

> W.I. # 3.14 for L.P.T

> Leak Proof

> Dipping in water

> LPT Record

> 54.0 0.10 (Diameter)

> 56.0 0.25 (Diameter)

> Clamping of

component in fixture

> 65.85 0.15 (Diameter)

> Tool change

frequency

> PCS (F-11)

> PDS

> Cpk (major)

> RPM & FEED of m/c

> 3.22 0.10 (Width)

> 2.0 0.08 (Depth)

> 2.33 0.13 (Height)

> 3.65 0.05 (Width)

CONTD. TO NEXT PAGE

>

/ 0.10 (Flatness)

> 155.8 1.02 (C. H)

> 0.5 0.2 x 45 (Chamfer)

> 0.5 0.2 x 45 (Chamfer)

FORMAT NO. PE-F-QS-PPAP/PFC-036

REV- 01

(SIGNATURE)

PROCESS

INSPECTION

STORAGE TRANSPORT

��PROCESS FLOW CHART

PAGE : 7

PART NAME

: PIPE,

AIR TRANSFER

PART / DRG. NUMBER :

5336251

DATE (Org.)

: 12.05.2014

Characteristics

Oper.

Operation Description

No.

Work

Instruction

Reference

Number

Location

> PE/WI/3.11

> Drilling m/c

Fixture / Die

Reference

Number

Product

Process

Spl.

Char.

Class

Control Method

11

-

> Facing surface

> Component Cleaning

(free from burrs, dust oil

particles)

Deburring

12

High Pressure

Cleaning

PE/WI/3.12

High Pressure

Cleaning M/c

> Millipore Test

> Filtration

> Solvent Temp.

> Daily Check list (For H.P.C)

> Compressed air

pressure

> Daily Check list (For H.P.C)

CONTD. TO NEXT PAGE

FORMAT NO. PE-F-QS-PPAP/PFC-036

REV- 01

PROCESS

INSPECTION

STORAGE TRANSPORT

(SIGNATURE)

��PROCESS FLOW CHART

PAGE : 8

PART NAME

: PIPE,

AIR TRANSFER

PART / DRG. NUMBER :

5336251

DATE (Org.)

: 12.05.2014

Characteristics

Oper.

No.

13

Operation Description

Final Inspection/

Pre Dispatch Insp.

Work

Instruction

Reference

Number

> PE/ WI/3.17

Location

> Final Insp. area

Fixture / Die

Reference

Number

Product

Process

> Diameter 54.0 0.10

> Diameter 65.85 0.15

> Width 3.22 0.10

> Depth 2.0 0.08

>

/ 0.10 (Flatness)

Spl.

Char.

Class

Control Method

> PDI Report (F-6)

-

> Quality Plan (F-37)

> Log Book for Final Inspection

(PE-LB-QS-FI -004)

> Diameter 76.7 0.76

> Center Height 155.8 1.02

> Smooth

> Free from sand particles

(inner surface)

> Smooth

> Free from burrs / Sharp

edge & Casting defect.(outersurface)

CONTD. TO NEXT PAGE

FORMAT NO. PE-F-QS-PPAP/PFC-036

REV- 01

(SIGNATURE)

PROCESS

INSPECTION STORAGE TRANSPORT

��PROCESS FLOW CHART

PAGE : 9

PART NAME

: PIPE, AIR TRANSFER

PART / DRG. NUMBER : 5336251

DATE (Org.)

: 12.05.2014

Characteristics

Oper.

No.

14

Operation Description

Packaging

15

Work

Instruction

Reference

Number

> PE/ WI/ 3.18

> PE/ WI/ 3.18

Location

Fixture / Die

Reference

Number

Product

Dispatch

> PE/ WI/ 3.18

Control Method

Packaging area

> Labeling with bar code

sticker

Ware - House

> Tagging for Material

Identification

> Presence of 100% Tagging

Ware - House

Storage

16

Process

Spl.

Char.

Class.

> PDI Report

> Packing slip

> Dock Audit

FORMAT NO. PE-F-QS-PPAP / PFC-036

REV- 01

(SIGNATURE)

PROCESS

INSPECTION STORAGE TRANSPORT