Automatic Power Factor Correction Using Mircrocontroller

Uploaded by

makibenAutomatic Power Factor Correction Using Mircrocontroller

Uploaded by

makibenTechnical Project

Automatic Power Factor Correction using Microcontroller

Student Name: Ahmed Mohamed Nagib Ashour

E-Mail: ahmednagib295@gmail.com

Automatic Power Factor Correction using Microcontroller

1. Introduction

To get the best economic advantage from electric power, both the utility system and the users

should operate their facilities at high efficiency and reliability. A key to do this is to have a high

power factor (near 1.0) throughout the system.

Currently, alternating current (AC) machines are seen to draw more power than they actually

convert into useful work. This is seen as extra current that the system must carry to supply the

load. All connecting cables and transformers must carry this extra current, which results in

inefficiencies and higher cost of electricity. Most utilities offer rates to industrial consumers that

encourage a higher a higher power factor by reducing the rates for improved power factor. This is

commonly expressed in terms of a penalty for poor power factor that provides sufficient economics

incentives for consumers to improve their power factor.

Any installation or facility contain the following various types of machinery or equipment is seen

to have a low power factor. If a penalty rate is in force, end users may achieve savings on the

monthly power bill by adding power factor correction capacitors:

• Induction motors of all types (the greatest industrial loads in utility systems)

• Power electronic power converters

• Power transformers and voltage regulators

• Welding machines

• Electric and induction furnaces

• Fluorescent and various types of arc lightning

Many utilities begin to assess a power factor penalty when the power factor drops below 0.95

(lagging). The amount of penalty is then proportional to the difference between actual power factor

and the value of 0.95 (lagging). The cost of improving power factor using capacitors could be

recovered quickly simply by eliminating the penalty.

Once an end user decides that capacitors are an economical option, the main issues become the

size, type and location of capacitors. The power factor metered by the utility can be corrected

simply by placing all the capacitors at service entrance. However, this does nothing for losses and

freeing up the capacity farther down into the plant. By dispersing the capacitors throughout the

plant, end users can take optimal advantage of the benefits of power factor correction. Not only is

the power factor penalty eliminated, but energy demand is reduced by reducing the losses and

capacity is releases so that the system may be expanded (new loads added) without increasing the

size of existing cabling.

The expression of power is known as the rate of energy produced or consumed at a time, which is

usually measured in horsepower (HP) in mechanical systems and in electrical systems in watts

(W), the meaning of active power is when you give electrical power to any electric machine, it

gives back useful and notable power i.e. moving power or thermal power. In this case the electric

power is converted directly into any other phase of power.

The definition of power in electric science is the multiply of voltage (V) applied on a load by the

current (I) passing through this load (P = VI), and this also could be expressed as the square of

current passing through a load multiplied by the resistance (R) of the load P = I 2R this is applied

Ahmed Mohamed Nagib Ashour -1-

Automatic Power Factor Correction using Microcontroller

in both direct current systems (DC) or alternating current systems (AC). But, in AC systems when

the voltage is shaped as a sinusoidal waveform, the current passes through the load takes the same

form with different magnitude or level, and the current keeps in phase due to the linear nature of

resistance explained by Ohm’s law (R=V/I), so, we will find that when the voltage is zero, the

current is also at zero value and if the voltage is at maximum value, the current is at zero value.

This means that the phase difference between V and I is equal to zero (Figure 2).

But in AC systems the loads are not always resistance only, two other types of loads are seen to

have effects on the current, these loads are inductive loads and capacitive loads.

Figure 1: Circuit with capacitor and the corresponding

sinusoidal waveforms of voltage and current through the

capacitor.

Figure 2: Circuit with voltage source and resistor, and Figure 3: Circuit with voltage source and inductor, and the

the corresponding sinusoidal waveforms of voltage corresponding sinusoidal waveforms of voltage and current

and current through the resistor. through the inductor.

Ahmed Mohamed Nagib Ashour -2-

Automatic Power Factor Correction using Microcontroller

At typically RL or RC loads, the apparent power has

a certain angle or phase shift and is defined as the

angle between the voltage applied on the load and the

current passing through this load. Typical triangle in

the figure 4 below describe the triangular relation

between the active power (Watt), reactive power

(VAr) and apparent power (VA).

The cosine of the angle between the apparent power

and active power (power angle) or cos (ϕ) is named

as power factor and it has another definition that it is

the ratio of the active power to the total apparent

power and the number is always between 0 and 1. As Figure 4: Power triangle.

figure indicates, the more the power angle is small,

the more the active power consumed become small

and the whole power consumed are converted to

useful and active power.

To completely describe this angle, we use the

expressions, lagging power factor and leading power

factor. Lagging power factor means that current lags

voltage, meaning an inductive load. Leading power

factor means that current leads voltage, meaning a

capacitive load. Both the power factor and the reactive

factor are convenient quantities to use in describing

electrical loads [1].

The importance of improving power factor becomes

clearer if we made an assumption, let us have an end

user which has the total power factor of its

consumption is for example 0.7 lagging pf, this means

that only 70% of the total apparent input power to the

utility is converted to useful power. If we assumed

that we have a motor that have 0.7 lagging power

factor and the mechanical power required from that Figure 5: Improving Power Factor results.

motor is equivalent to about 100 kW, that means, to

supply this motor with the sufficient power we need to supply it with a source that have total

apparent power as 142 kVA and will be seen to consume as much reactive power as 100 kVAr,

but if we improved the power factor to about 0.95 lagging pf, that means the required apparent

power will be decreased to 105kVA and the consumed reactive power from the grid will be about

33 kVAr with the amount of required active power is kept constant as 100 kW, figure 4 shows this

operation in using phasor diagram. Improving power factor helps us to find an alternative source

for the reactive power rather than taking it from the grid. There are different methods to improve

the power factor like synchronous motor, static VAr compensator and the best method, capacitor

banks.

Ahmed Mohamed Nagib Ashour -3-

Automatic Power Factor Correction using Microcontroller

2. How to Improve the Power Factor using Capacitor Banks

Installing capacitor banks in parallel on the low power factor load is considered the best

economical and effective way to overcome the low power factor and improving it, the effect of the

capacitors could be noticed from the following phasor diagram

Figure 6: The effect of connecting capacitors on parallel with the load.

The total I2 drawn from the supply will be equal to the vectoral sum of I1 and Ic that is I2 = I1 + Ic,

phasor diagram shows that the power angle ϕ is reduced using capacitance in parallel but how to

calculate the required capacitance for a desired power factor value?

From the figure 4, the power triangle we can calculate the required reactive power Qc which must

be added to improve the angle from ϕ1 to ϕ2 using the following equation.

𝑄𝑐 = 𝑃 (tan ∅1 − tan ∅2 ) (1)

And using the quantity of required reactive power calculated by equation (1), we can calculate the

required capacitance we need using the equation

𝑄𝑐 (2)

𝐶=

𝜔 × 𝑉2

Note that all these calculations are held per phase.

Another way to determine the value of capacitance required for improving the power factor to

desired value is using power factor correction tables. The use of these tables is about having a

current or initial power factor value and a desired or initial power factor value, you just meet the

value from final cos ϕ column with the value from initial cos ϕ row and you will get a value called

factor K (kVAr/kW), this value represent kVAr per kW, so, all you need to do is to multiply this

value by the kW so that you get the kVAr value and using equation (2), you can get the required

desired capacitance value.

Ahmed Mohamed Nagib Ashour -4-

Automatic Power Factor Correction using Microcontroller

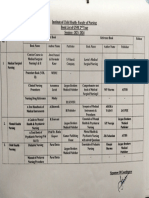

Figure 7 shows the table of power factor improvement

Figure 7: Table of improving power factor.

For example if we have the desired power factor as 0.90 and the actual power factor we have

currently is 0.75, the value of K factor is 0.398, this value is multiplied by the active power

consumed by the electric device to obtain the value of required reactive power that must be

supplied to the load and to determine the capacitance value we will use eq. (2).

In real life, the loads are not always kept fixed and it is changed frequently, so the power factor is

also changed according the loads. So, using a fixed capacitor banks is not always the best way to

overcome the low power factor as this sometime may lead to have a rise in voltage of the source,

an Automatic Power Factor Correction (APFC) gives a solution for this problem where we get

some separated groups of capacitors and they are connected and disconnected according to the

load nature using a classic control circuit that controls this connection and disconnection operation

of the capacitors.

Ahmed Mohamed Nagib Ashour -5-

Automatic Power Factor Correction using Microcontroller

3. The Function of the APFC

As the name suggests, the Automatic Power Factor Correction is designed to detect the bad power

factor and correct it automatically but connecting the suitable capacitor bank, and when there are

over number of capacitor banks connected, the APFC disconnect the suitable number so that it

keeps the power factor corrected properly but how our device works?

4. How the APFC works using Microcontroller

4.1. The Sensing Circuit

In order to correct the power factor, we need first to measure the power factor, this measurement

is quite hard using the microcontroller directly as we need to obtain the waveform of the voltage

and the waveform of current, then compare both of them to determine the time shift between them,

this time shift will be later converted to some value, this value is the power factor.

We instead use external sensing circuit that enable us to determine the exact value of the sensing

circuit consists of two comparator IC’s and one XOR gate to get the time shift of the two digitalized

waveforms. To get this shift between the two sinusoidal waves, we use two zero-crossing detectors

to digitalize the two sinusoidal waves, then send their outputs as inputs for an XOR gate, the

function of the XOR gate is to detect the time shift by detecting the time when there is only voltage

digital wave and the time when there is only current digital wave (as the zero-crossing detector

already converted the sine wave positive half cycle into +5V DC signal and the negative half cycle

into 0V signal). Note that we used a series resistance to obtain a sinusoidal wave directly

proportional and in phase with the current sinusoidal wave, because the comparator deals only

with voltage signals.

Figure 8: Sensing Circuit to measure the time shift width in order to obtain the power

factor value.

Ahmed Mohamed Nagib Ashour -6-

Automatic Power Factor Correction using Microcontroller

With the sinusoidal waves converted to digital waves, we can now

determine the amount of time shift between the two waves using

the XOR gate. As we know the XOR gate truth table is given as

shown in the table.

From the truth table, we conclude that the XOR gate gives 1 when

the inputs are in different conditions and gives 0 when the two

inputs are in typical conditions, that’s exactly what we need.

Finally, figure 9 represents the final waveforms we obtain from the

sensing circuit.

Figure 9: The waveforms at the different stages of the sensing circuit.

Ahmed Mohamed Nagib Ashour -7-

Automatic Power Factor Correction using Microcontroller

4.2. To the Microcontroller

Now what we have is a train of square pulses with a certain time width, this time width represents

the angle value and the time shift between the two sinusoidal waves. We can now measure its

width directly using the Arduino microcontroller using pulseIn() command.

It Reads a pulse (either HIGH or LOW) on a pin. For example, if value is HIGH, pulseIn() waits

for the pin to go from LOW to HIGH, starts timing, then waits for the pin to go LOW and stops

timing. Returns the length of the pulse in microseconds or gives up and returns 0 if no complete

pulse was received within the timeout. The timing of this function has been determined empirically

and will probably show errors in longer pulses. Works on pulses from 10 microseconds to 3

minutes in length.

The microcontroller acquires the time shift amount in microseconds, then we need to calculate the

angle value then calculate the cosine of this angle (the power factor) this is done by the following

equations (note that the microcontroller calculate returns the cosine value in rads only not in

degrees, hence we need to convert it into degrees):

𝐴𝑛𝑔𝑙𝑒 = 𝑡𝑖𝑚𝑒 𝑠ℎ𝑖𝑓𝑡 × 10−6 × 2 × 180 × 𝑓 (3)

𝑃𝐹 = cos(𝐴𝑛𝑔𝑙𝑒 ⁄57.295) (4)

Where:

time shift is the value obtained by the command pulseIn() (if the angle is 45, the value of pulseIn()

will be 2500) and we convert this time value into degrees by multiplying by (2 × 180 × f). The

57.295 represents the conversion from degrees to rads (180/π) as the cos function in Arduino use

the angle in rads unit not degrees.

Hence, we conclude the final block diagram of the project as shown:

Figure 10: The block diagram of microcontroller-based automatic power factor correction.

Ahmed Mohamed Nagib Ashour -8-

Automatic Power Factor Correction using Microcontroller

4.3. The strategy of connecting the capacitors

Here comes the idea of this project, there are a lot of ways of thinking about according-to-what of

connecting the capacitors, you now have a well-measured and accurate power factor value (if the

circuit is carried out properly), and remember that the size required of the capacitor bank is not a

function of power factor only but also a function of active power, then you can program your

microcontroller and determine the size of capacitors to suit some certain loads (loads that you

already know the nature of them and they would not be changed) and that is what we carried out

this project according to. Or you can think about keep adding capacitors as long as power factor is

low and when the power factor reaches a very high value (0.99 or 0.98) the microcontroller starts

to disconnect some stage of capacitor bank until it reaches a moderate value of about 0.93 or 0.92.

The tests of this project were done on certain and known loads, an incandescent lamp as a resistive

load (PF = 0.98) and single phase induction motor of a table fan as a lag power factor load, i.e. R-

L load (PF = 0.75), we then calculated the required capacitor size to make this lag bad power factor

reaches some good value as 0.88 or 0.9 using equations (1) and (2). Known that the active power

of that motor was approximately 63 watts and the capacitor bank size is 1.5 μF, The flowchart of

the project however could be represented as

Figure 11: Flowchart of the APFC

Ahmed Mohamed Nagib Ashour -9-

Automatic Power Factor Correction using Microcontroller

5. Economic Point of View

Power supply authorities apply a tariff system which imposes penalties on the drawing of energy

with a monthly average power factor lower than 0.9.

The contracts applied are different from country to country and can vary also according to the

typology of costumer: as a consequence, the following remarks are to be considered as a mere

didactic and indicative information aimed at showing the economic saving which can be obtained

thanks to the power factor correction.

Generally speaking, the power supply contractual clauses require the payment of the absor bed

reactive energy when the power factor is included in the range from 0.7 and 0.9, whereas nothing

is due if it is higher than 0.9. For cosϕ < 0.7 power supply authorities can oblige consumers to

carry out power factor correction.

It is to be noted that having a monthly average power factor higher than or equal to 0.9 means

requesting from the network a reactive energy lower than or equal to 50% of the active energy:

𝑄 (5)

tan 𝜑 = ≤ 0.5 𝑓𝑜𝑟 cos 𝜑 ≥ 0.89

𝑃

Therefore, no penalties are applied if the requirements for reactive energy do not exceed 50% of

the active one.

The cost that the consumer bears on a yearly base when drawing a reactive energy exceeding that

corresponding to a power factor equal to 0.9 can be expressed by the following relation:

𝐶𝐸𝑄 = (𝐸𝑄 − 0.5 × 𝐸𝑝 ) × 𝑐 (6)

where:

• CEQ is the cost of the reactive energy per year in $;

• EQ is the reactive energy consumed per year in kvarh;

• EP is the active energy consumed per year in kWh;

• (EQ – 0.5 × Ep) is the amount of reactive energy to be paid;

• c is the unit cost of the reactive energy in $/kvarh.

If the power factor is corrected at 0.9 not to pay the consumption of reactive energy, the cost of

the capacitor bank and of the relevant installation will be:

𝐶𝑄𝑐 = 𝐶𝑄 . 𝐶𝑐 (7)

Ahmed Mohamed Nagib Ashour - 10 -

Automatic Power Factor Correction using Microcontroller

where:

• CQc is the yearly cost in $ to get a power factor equal to 0.9;

• Qc is the power of the capacitor bank necessary to have a cosϕ of 0.9, in kvar;

• cc is the yearly installation cost of the capacitor bank in $/kvar.

The saving for the consumer shall be:

𝐶𝐸𝑄 − 𝐶𝑄𝑐 = (𝐸𝑄 − 0.5 × 𝐸𝑝 ) × 𝑐 − 𝑄𝑐 × 𝑐𝑐 (8)

It is necessary to note that the capacitor bank represents an “installation cost” to be divided suitably

for the years of life of the installation itself applying one or more economic coefficients; in the

practice, the savings obtained by correcting the power factor allow the payback of the installation

cost of the capacitor bank within the first years of use.

As a matter of fact, an accurate analysis of an investment implies the use of some economic

parameters that go beyond the purposes of this Technical Application Paper.

Example:

Let a company absorbs active and reactive energy according to the following table:

Month Active Energy (kWh) Reactive Energy (kVArh) Monthly average PF

January 7221 6119 0.76

February 8664 5802 0.83

March 5306 3858 0.81

April 8312 6375 0.79

May 5000 3948 0.78

June 9896 8966 0.74

July 10800 10001 0.73

August 9170 8910 0.72

September 5339 4558 0.76

October 7560 6119 0.78

November 9700 8870 0.74

December 6778 5879 0.76

Total 93746 79405 -

Known that 0.484 is tangent corresponding to a cosΦ equal to 0.9

Therefore,

Ahmed Mohamed Nagib Ashour - 11 -

Automatic Power Factor Correction using Microcontroller

Active Energy Monthly Operating Active Power

Month Qc = P (tanΦ – 0.484)

(kWh) Average PF Hours P (kW)

Jan 7221 0.76 160 45.1 16.4

Feb 8664 0.83 160 54.2 10.0

Mar 5306 0.81 160 33.2 8.1

Apr 8312 0.79 160 52.0 14.7

May 5000 0.78 160 31.3 9.5

June 9896 0.74 160 61.9 26.1

July 10800 0.73 160 67.5 29.8

Aug 9170 0.72 160 57.3 27.9

Sep 5339 0.76 160 33.4 12.3

Oct 7560 0.78 160 47.3 15.4

Nov 9700 0.74 160 60.6 26.1

Dec 6778 0.76 160 42.4 16.2

Let an automatically-controlled capacitor bank for power factor correction with Qc=30 kVAr,

against a total installation cost per year cc of 25 $/kvar, a total cost of 750$ is obtained. The saving

for the consumer, without keeping into account the payback and the financial charges, shall be:

CEQ – CQc = 1370 – 750 = 620$

Note: some of information were obtained from ABB – Power factor correction and harmonic

filtering in electrical plants.