0% found this document useful (0 votes)

2K views1 pageTeam Feasibility Commitment

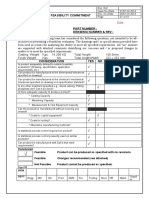

The team feasibility commitment document considers whether a new product is feasible to manufacture based on 10 criteria such as whether specifications are defined, engineering requirements can be met, manufacturing tolerances can be achieved, and statistical process control is possible. The team answers yes, no, or not applicable for each criteria. They then conclude whether the product is feasible as-is, feasible with changes, or requires a design revision to meet requirements.

Uploaded by

murali4095Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

2K views1 pageTeam Feasibility Commitment

The team feasibility commitment document considers whether a new product is feasible to manufacture based on 10 criteria such as whether specifications are defined, engineering requirements can be met, manufacturing tolerances can be achieved, and statistical process control is possible. The team answers yes, no, or not applicable for each criteria. They then conclude whether the product is feasible as-is, feasible with changes, or requires a design revision to meet requirements.

Uploaded by

murali4095Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 1