0% found this document useful (0 votes)

34 views9 pagesFinal Synopsis

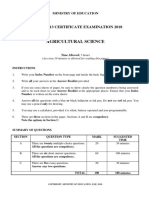

This document provides a synopsis for a dissertation proposal on designing and evaluating a semi-automatic electromechanical single plate clutch for an autonomous agricultural vehicle. It lists the students, guide, college and proposed title. It discusses the relevance of reducing labor costs for agriculture. The current practices of manual spraying are outlined. The document then reviews several existing theories and literature on transmission systems, automated manual transmissions, clutch actuation systems, and gear shifting control algorithms for hybrid vehicles.

Uploaded by

Uttkarsh ShelarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

34 views9 pagesFinal Synopsis

This document provides a synopsis for a dissertation proposal on designing and evaluating a semi-automatic electromechanical single plate clutch for an autonomous agricultural vehicle. It lists the students, guide, college and proposed title. It discusses the relevance of reducing labor costs for agriculture. The current practices of manual spraying are outlined. The document then reviews several existing theories and literature on transmission systems, automated manual transmissions, clutch actuation systems, and gear shifting control algorithms for hybrid vehicles.

Uploaded by

Uttkarsh ShelarCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 9