100% found this document useful (1 vote)

92 views34 pagesLecture2 Formworks

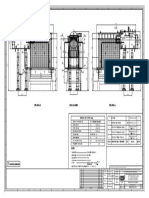

The document discusses different types of formwork used for constructing concrete structures. It describes various materials used for formwork including wood, steel, aluminum and others. It also discusses factors to consider for economical, fast and quality formwork as well as safety aspects. Classification and uses of different formwork systems are explained.

Uploaded by

samrawit aysheshimCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

92 views34 pagesLecture2 Formworks

The document discusses different types of formwork used for constructing concrete structures. It describes various materials used for formwork including wood, steel, aluminum and others. It also discusses factors to consider for economical, fast and quality formwork as well as safety aspects. Classification and uses of different formwork systems are explained.

Uploaded by

samrawit aysheshimCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 34