0% found this document useful (0 votes)

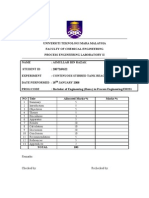

210 views11 pagesEx-1 - Isothermal Batch Reactor-Mir Ahmed

The document describes an experiment to study a saponification reaction in an isothermal batch reactor. It details the objectives, theory, equipment used, procedures, observations made and calculations done to determine the reaction rate constant and activation energy of the reaction at different temperatures.

Uploaded by

atiq ahmedCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

210 views11 pagesEx-1 - Isothermal Batch Reactor-Mir Ahmed

The document describes an experiment to study a saponification reaction in an isothermal batch reactor. It details the objectives, theory, equipment used, procedures, observations made and calculations done to determine the reaction rate constant and activation energy of the reaction at different temperatures.

Uploaded by

atiq ahmedCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 11