IPC-1602

Standard for Printed Board

Handling and Storage

Developed by the Printed Board Storage and Handling Subcommittee

(D-35) of the Rigid Printed Board Committee (D-30) of IPC

Supersedes: Users of this publication are encouraged to participate in the

IPC-1601A - June 2016 development of future revisions.

IPC-1601 - August 2010

Contact:

IPC

�April 2020 IPC-1602

Table of Contents

1 INTRODUCTION ....................................................... 1 3.2.3 Moisture Concerns for Etched Cores and

1.1 Background ........................................................... 1 Sub-Lams (Subcomposites) .................................. 5

3.3 Manufacture of the Laminated Panels/Printed

1.2 Scope ..................................................................... 1

Boards .................................................................... 6

1.3 Application ............................................................ 1

3.3.1 Processing Validation and Control ....................... 6

1.4 Terms and Definitions ........................................... 1 3.3.2 Handling and Transport of Product ...................... 6

1.4.1 Assembler .............................................................. 1 3.3.3 Environment .......................................................... 6

1.4.2 Dry Packaging ....................................................... 1 3.3.4 Test ........................................................................ 6

1.4.3 Humidity Indicator Card (HIC) ............................ 1 3.3.5 Inspection .............................................................. 6

1.4.4 Manufacturer (Printed Board Fabricator or 3.3.6 Moisture Levels Prior to Packaging ..................... 6

Assembler) ............................................................ 1

3.4 Baking for Moisture Removal .............................. 7

1.4.5 Moisture Barrier Bag (MBB) ............................... 1

3.4.1 Problems Caused by Baking ................................ 7

1.4.6 Shall ....................................................................... 1

3.4.2 Baking Environment ............................................. 8

1.4.7 Should .................................................................... 1

3.4.3 Baking Considerations .......................................... 8

1.4.8 Sub-Lam (Subcomposite) ..................................... 1 3.4.4 Establishing Baking Profiles ................................. 8

1.4.9 Sulfur Free ............................................................ 2

4 PACKAGING, STORAGE, AND SHIPMENT ............ 9

1.4.10 Supplier ................................................................. 2

4.1 Packaging Evaluation ............................................ 9

1.4.11 User ....................................................................... 2

4.1.1 Moisture Absorption ............................................. 9

1.4.12 Water Vapor Transmission Rate (WVTR) ........... 2

4.1.2 Physical Attributes ................................................ 9

1.5 Superseded Documents ......................................... 2

4.1.3 Effects on Final Finish Solderability .................... 9

1.6 Order of Precedence ............................................. 2

4.1.4 Storage and Packaging Environment ................. 10

1.6.1 Conflict .................................................................. 2

4.1.5 ESD Concerns ..................................................... 10

1.6.2 Clause References ................................................. 2

4.2 Dry Packaging Requirements ............................. 11

1.6.3 Appendices ............................................................ 2

4.2.1 MBB Water Vapor Transmission Rate

1.7 Requirements Flowdown ...................................... 2 (WVTR) ............................................................... 11

2 APPLICABLE DOCUMENTS .................................... 2

4.2.2 Available Packaging Material Types .................. 11

2.1 4.2.3 Desiccant Material .............................................. 11

IPC ......................................................................... 2

4.2.4 Humidity Indicator Card (HIC) .......................... 12

2.2 Joint Industry Standards ....................................... 3

4.2.5 Laminate Witness Coupons ................................ 12

2.3 Electrostatic Discharge Association (ESD) .......... 3

4.2.6 Immersion Silver Printed Boards ....................... 12

2.4 Europa ................................................................... 3

4.2.7 Moisture Barrier Bag Sealing ............................. 12

2.5 SAE International .................................................. 3

4.2.8 Desiccant Placement ........................................... 12

2.6 International Organization for Standardization .... 3

4.2.9 Bulk Packaging ................................................... 12

2.7 ASTM .................................................................... 3

4.3 External Packaging ............................................. 13

2.8 Military Specifications .......................................... 3

4.3.1 Sulfur/Chlorine Content in Packaging

3 PRINTED BOARD FABRICATION AND Material ............................................................... 13

PACKAGING (HANDLING) ....................................... 4 4.3.2 Packaging Concerns for Transportation ............. 13

3.1 Printed Board Materials ........................................ 4 4.3.3 Support Material ................................................. 13

3.1.1 Bonding Materials, Prepreg and Resin Coated 4.3.4 Packaging Container Gross Weight .................... 13

Foils ....................................................................... 4 4.4 Marking ............................................................... 13

3.1.2 Copper Clad Laminates ........................................ 4 4.4.1 Pb-Free/RoHS Compliance ................................. 13

3.2 Inner Layer Production ......................................... 4 4.4.2 ESD ..................................................................... 13

3.2.1 Phototooling .......................................................... 4 4.4.3 Moisture .............................................................. 14

3.2.2 Process Equipment ................................................ 5 4.4.4 Other Markings ................................................... 14

v

�IPC-1602 April 2020

5 PRINTED BOARD RECEIVING, STORAGE AND Figures

ASSEMBLY ............................................................. 14

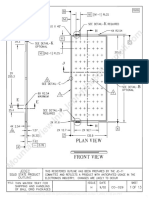

Figure 3-1 Examples of Clips used for Resealing

5.1 Before Opening ................................................... 14 Opened Bags ...................................................... 4

5.2 Storage Location (Stock Room) ......................... 14 Figure 4-1 Humidity Indicator Card (HIC) Example ........... 12

5.3 Upon Opening A Moisture Barrier Bag ............. 14 Figure 4-2 ANSI/ESD S8.1 Protective Symbol ................... 13

5.4 Production Environment (Temperature, Figure 4-3 Moisture Sensitivity Caution Symbol ................ 14

Humidity, and Atmosphere) ................................ 14 Figure A-1 Usage of Heat Sealed Polyethylene Bag in

Conjunction with MBB ....................................... 18

5.5 Storage Containers (Shop Floor) ........................ 15

Figure C-1 Moisture sorption isotherms for four FR-4

5.6 Soldering Operations .......................................... 15 printed board materials. .................................... 20

5.7 Maximum Acceptable Moisture Content Figure C-2 Moisture desorption experiments on four

(MAMC) .............................................................. 15 different FR-4 materials during a bakeout at

105 °C. Hollow shapes represent the FR-4

5.8 Evaluating Moisture Content .............................. 15 materials exposed to 85 °C/85% RH conditions,

the solid shapes represent the FR-4 materials

APPENDIX A Example Flowdown Of Packaging/ that were stored under room conditions ........... 21

Handling Requirements to A Printed

Board Manufacturer ........................... 17

APPENDIX B Desiccant Required as a Function Tables

of Moisture Barrier Bag (MBB)

Table 3-1 Recommendations for Printed Board Baking

Size ...................................................... 19

Profiles ................................................................ 8

APPENDIX C Moisture Diffusion and ‘‘Bound’’

Table B-1 Desiccant Bag Quantities Based on

Moisture .............................................. 20 MBB Size .......................................................... 19

vi

�April 2020 IPC-1602

Standard for Printed Board Handling and Storage

1 INTRODUCTION

1.1 Background Historically, the printed board industry has relied on military specifications and guidelines to define

packaging methods to preserve the quality and reliability of printed boards during shipment and storage. However, many of

these documents are obsolete, incomplete, do not address Pb-free assembly processes, or do not cover newer laminates or

final finishes.

1.2 Scope This standard provides requirements and recommendations for proper handling, packaging materials and meth-

ods, environmental conditions, and storage for printed boards. The requirements and recommendations are intended to pro-

tect printed boards from contamination, physical damage, solderability degradation, electrostatic discharge (ESD) (when

necessary), and moisture uptake. Moisture absorbed in printed board laminates expands at soldering temperatures, and in

some cases, the resulting vapor pressure can cause internal delamination or excessive strain on plated-hole walls and other

structures. This is especially challenging with the higher temperatures used for Pb-free soldering.

Note: This standard includes requirements for the handling, packaging and storage of printed boards and directly supersedes

IPC-1601 Revision A from 2016.

This document covers all phases from the manufacture of the bare printed board, through delivery, receiving, stocking,

assembly, and soldering.

1.3 Application The target audience includes those involved in all phases of printed board design, manufacture, assembly,

shipping, storage, and possible warranty activities. Information herein has been supplied for all of these functions.

1.4 Terms and Definitions Other than those terms listed below, the definitions of terms used in this Standard are in accor-

dance with IPC-T-50.

1.4.1 Assembler The entity that receives a completed printed board and performs subsequent assembly, wiring, or solder-

ing operations.

1.4.2 Dry Packaging Packaging that consists of desiccant material and a Humidity Indicator Card (HIC) sealed with the

printed boards inside a Moisture Barrier Bag (MBB) (see 4.2).

1.4.3 Humidity Indicator Card (HIC) An indicator of relative humidity in the form of a card with printed deposits of

moisture-sensitive chemicals, usually as round dots arranged in sequence, each changing color at a higher relative humid-

ity. Color will change (depending on the chemicals, either from blue to pink or from brown to azure) when humidity exceeds

the value printed on the dot. When humidity decreases, color will change back (to blue or brown).

1.4.4 Manufacturer (Printed Board Fabricator or Assembler) The individual, organization, or company responsible for

the applicable printed board fabrication or assembly process, and verification operations necessary to ensure full compliance

of printed boards or assemblies to this Standard.

1.4.5 Moisture Barrier Bag (MBB) A bag designed to restrict the transmission of water vapor and used to pack moisture

sensitive devices. An MBB is made of material with a low Water Vapor Transmission Rate (WVTR) (see 4.2.1). An MBB

includes a metallized layer (aluminum), making the bag appear shiny and opaque.

1.4.6 Shall The words ‘‘shall’’ and ‘‘shall not’’ are used in this document to establish a requirement, which is a provision

that is mandatory. To assist the reader, the words ‘‘shall’’ and ‘‘shall not’’ are presented in bold characters.

1.4.7 Should The words ‘‘should’’ and ‘‘should not’’ indicate suggestions, recommendations, best practices, or generally

accepted industry methods or procedures, and are intended for guidance only.

1.4.8 Sub-Lam (Subcomposite) In sequential lamination, a printed board subassembly composed of more than two layers

that have been laminated together, and which will subsequently be laminated with other layers into a complete printed board.