Fire Alarm Specs

Uploaded by

Eng Abdurrahman MohammedFire Alarm Specs

Uploaded by

Eng Abdurrahman MohammedNEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

SECTION 283111 - ADDRESSABLE FIRE ALARM SYSTEM

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Particular

Conditions, and Division 01 Specification Sections, apply to this Section.

1.2 SUMMARY

A. Section includes a microprocessor based, non-coded, addressable fire alarm system with

manual and automatic alarm initiation; automatic sensitivity control of certain smoke

detectors and multiplexed signal transmission dedicated to fire alarm service only including

but not limited to:

1. Fire-alarm control panels.

2. Manual fire-alarm stations.

3. System smoke detectors.

4. Heat detectors.

5. Multi Criteria sensors.

6. Notification appliances.

7. Device guards.

8. Remote annunciators.

9. Graphic annunciator.

10. Addressable interface devices.

11. Digital alarm communicator transmitter.

12. Network communications.

13. System printers.

B. Section includes Fire Alarm System interface with Access Control System, HVAC, smoke

management system, elevators, escalators, CCTV, public address, fire suppression systems,

clean agent fire suppression systems, Emergency Lighting System, lighting control system

etc.. These interfaces shall be hardwired where required by code. Monitoring information

shall be output to the BMS / SCADA

C. Related Sections:

1. Section 078800 - Fire Curtains.

2. Section 087111 - Door Hardware .

3. Section 114000 - Food Service Equipment

4. Section 141000 – Dumbwaiters.

5. Section 142100 - Electric Traction Elevators.

6. Section 142400 - Hydraulic Elevators.

7. Section 212200 - Clean-Agent Fire-Extinguishing Systems.

8. Section 233413 - Axial HVAC Fans

9. Section 233416 - Centrifugal HVAC Fans

10. Section 233423 - HVAC Power Ventilators.

11. Section 233723 - HVAC Gravity Ventilators.

12. Section 260500 – Basic Electrical Materials and Methods.

13. Section 260519 – Low - Voltage Electrical Power Conductors and Cables.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 1 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

14. Section 260526 - Grounding and Bonding for Electrical Systems.

15. Section 260533 - Raceways and Boxes for Electrical Systems.

16. Section 260543 - Underground Ducts and Raceways for Electrical Systems.

17. Section 260548 - Vibration and Seismic Controls for Electrical Systems.

18. Section 263353 - Static Uninterruptible Power Supply.

19. Section 264313 – Surge Protection for Low-Voltage Electrical Power Circuits.

20. Section 271005 – Common Clauses for Structured Cabling.

21. Section 271055 - Identification for Communications Systems.

22. Section 271305 - Communications Backbone Cabling.

23. Section 271505 - Communications Horizontal Cabling.

24. Section 281300 – Access Control.

25. Section 282300 - Video Surveillance.

1.3 REFERENCE STANDARDS

A. The latest published edition of a reference shall be applicable to this Project unless

identified by a specific edition date.

B. The publications listed below form a part of this specification. The publications are referred

to in the text by basic designation only.

C. Specific reference in specifications to codes, rules, regulations, standards, manufacturer’s

instructions, or requirements of regulatory agencies shall mean reference to the latest printed

edition of each.

D. Conflicts

1. Should an instance occur in this Specification or on the Drawings in which material

or construction methods called for is less than minimum requirement of the reference

standards, immediately inform the Engineer in writing. Consequent to Engineer's

approval, supply the materials and perform the work as though called for to minimum

code standards.

E. Codes and Standards: System design, operation, installation and workmanship shall comply

with the applicable requirements and standards addressed within the following references:

1. Local regulations and codes.

a. Egyptian Code for the foundations of design and implementation requirements

for the protection of facilities from fire.

2. FM standards

3. NFPA 70, National Electrical Code.

4. NFPA 72, National Fire Alarm and Signaling Code.

5. NFPA 101, Life Safety Code.

6. NFPA 5000, Building Construction and Safety Code.

F. Codes and Standards: System components shall comply with the applicable requirements

and standards addressed within the following references or an equivalent requirements and

standard for the following references:

1. UL 38: Manual Signaling Boxes for Fire Alarm Systems

2. UL 217: Single and Multiple Station Smoke Alarms

3. UL 228: Door Holders for Fire Protective Signaling systems.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 2 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

4. UL 268: Smoke Detectors for Fire Alarm System

5. UL 268A: Smoke Detectors for Duct Application

6. UL 464: Audible Signal Appliances

7. UL 521: Heat Detectors for Fire Protective Signaling Systems

8. UL 632: Electrically-Actuated Transmitters

9. UL 864: Control Units and Accessories for Fire Alarm Systems

10. UL 1480: Speakers for Fire Alarm, Emergency, and Commercial and Professional

Use

11. UL 1711: Amplifiers for Fire Protective Signaling Systems

12. UL 1887: Safety Fire Test of Plastic Sprinkler Pipe for Visible Flame and Smoke

Characteristics

13. UL 1971: Signaling Devices for the Hearing Impaired

14. NFPA 1221: Standard for the Installation, Maintenance, and Use of Emergency

Services Communications Systems

G. The contractor can propose a complete fire alarm system which is either UL listed or EN54

certified, subject to the Engineer/Client approval. The above listing are for guidance and

equivalent listing are accepted.

H. System components, design, operation, installation and workmanship shall comply with the

applicable local regulations and code requirements of Authorities Having Jurisdiction

including Egyptian Civil Defense Authority. These shall have precedence over other codes

and standards indicated, unless otherwise approved by the Employer, in writing.

1.4 DEFINITIONS AND ABBREVIATIONS

A. Definitions

1. Alarm Verification Feature: A feature of automatic fire detection and alarm systems

to reduce unwanted alarms wherein smoke detectors report alarm conditions for a

minimum period of time, or confirm alarm conditions within a given time period after

being reset, in order to be accepted as a valid alarm initiation signal.

2. A “ / “ used throughout the text between two consecutive words is equivalent to and

shall be used interchangeably with “ and “.

3. Alarm: A warning of fire danger.

4. Signal: A status indication communicated by electrical or other means.

a. Alarm Signal: A signal indicating an emergency that requires immediate

action, such as a signal indicative of fire.

b. Evacuation Signal: A distinctive signal intended to be recognized by the

occupants as requiring evacuation of the building.

c. Fire Alarm Signal: A signal initiated by a fire alarm-initiating device such as a

manual fire alarm box, automatic fire detector, water-flow switch, or other

device in which activation is indicative of the presence of a fire.

d. Supervisory Signal: A signal indicating the need for action in connection with

the supervision of the fire suppression systems or equipment, or the

maintenance features of related systems.

e. Trouble Signal: A signal initiated by the fire alarm system or device indicative

of a fault in a monitored circuit or component.

5. Conveying systems: this includes horizontal and vertical transportation systems

(HVTS) such as elevators, moving walks, escalators and dumbwaiters.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 3 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

6. Positive Alarm Sequence. An automatic sequence that results in an alarm signal, even

when manually delayed for investigation, unless the system is reset. It provides a

timed delay of a general alarm signal in a building and at a supervising station. This

gives a trained responder up to 3 minutes to investigate the cause of an alarm signal.

The time limits to acknowledge the alarm signal and reset the system are designed to

assure all alarm system functions are actuated in the event personnel are not available

to acknowledge, investigate and reset the alarm. A positive alarm sequence feature

can only be used with the specific approval of the Authority Having Jurisdiction.

B. Abbreviations

1. EMT: Electrical Metallic Tubing.

2. FACP: Fire Alarm Control Panel.

3. FAS: Fire Alarm System.

4. FCC: Fire command center.

5. GUI: Graphical User Interface

6. HLI: High Level Interface.

7. LED: Light-emitting diode.

8. MFACP: Main Fire Alarm Control Panel.

9. PA / PAS Public Address System.

10. PC: Personal computer.

11. UL: Underwriters Laboratories Inc.

12. VES: Voice evacuation Sub-system.

1.5 SCOPE OF WORK

A. Provide the following:

1. FACP, manual stations, automatic fire detectors, notification appliances, wiring,

wire-ways and all accessories to form a complete system.

2. Remote annunciator(s).

3. Graphic annunciator (s).

4. Networking of MFACP and FACP.

5. Digital alarm communicator transmitter.

6. Voice evacuation sub-system.

7. System printers.

8. Interface with CCTV, Access Control and other low current systems as shown on

drawings and schematic diagram.

9. Interface with HVAC, firefighting, BMS/ SCADA and other building services

systems

B. New Fire alarm control panel will be provided to serve new Mars Wrigley factory expansion

and will be connected with the existing Main Fire Alarm Control Panel (MFACP).

C. New Fire alarm workstation will be responsible to monitor the existing and new factory.

D. Contractor shall ensure seamless integration with the existing system

1.6 COORDINATION

A. The Contractor shall coordinate with the Employer and other Contractors for interfaces with

the relevant systems. The Contractor shall provide in the shop drawings the final solution

for those interfaces for Engineer’s review and approval.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 4 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

B. Fire alarm zoning shall be coordinated with Architectural Fire Zoning, HVAC, smoke

management, and fire-fighting systems.

C. The Contractor shall coordinate with the BMS/ SCADA Contractor and other Security and

Building Services Contractors as specified.

1. All controls in case of fire shall remain with the fire alarm system in accordance with

the applicable NFPA codes.

1.7 ACTION SUBMITTALS

A. Product Data: For each type of product, including furnished options and accessories.

1. Include construction details, material descriptions, dimensions, profiles, and finishes.

2. Include rated capacities, operating characteristics, and electrical characteristics.

3. Name and address of the manufacturer and country of origin of the product.

4. Name and address of the authorized local representative and/or dealer.

5. Compliance statement to specification, with necessary supporting documents.

6. Complete catalog pages of proposed equipment.

7. Detectors characteristic curves of coverage area against ceiling height and air

movement speed.

B. Shop Drawings: For fire alarm system.

1. Comply with recommendations and requirements in the "Documentation" section of

the "Fundamentals" chapter in NFPA 72.

2. Include plans, elevations, sections, details, and attachments to other work.

3. Include details of equipment assemblies. Indicate dimensions, weights, loads,

required clearances, method of field assembly, components, and locations. Indicate

conductor sizes, indicate termination locations and requirements, and distinguish

between factory and field wiring.

4. Basic system architecture indicating tie-in points with interfaced services.

5. Detail assembly and support requirements.

6. Include voltage drop and cable sizing calculations for notification-appliance circuits.

7. Include battery-size calculations.

8. Include input/output (Cause/Effect) matrix. Show in a matrix format, the effect of

every initiating device on the MFACP/MFS/FACP, notification devices, system

peripherals, and auxiliary systems interfaced with it.

9. Details of data communication with the BMS/ SCADA.

10. Include statement from manufacturer that all equipment and components have been

tested as a system and meet all requirements in this Specification and in NFPA 72.

11. Include performance parameters and installation details for each detector.

12. Verify that each duct detector is listed for the complete range of air velocity,

temperature, and humidity possible when air-handling system is operating.

13. Provide program report showing that air-sampling detector pipe layout balances

pneumatically within the airflow range of the air-sampling detector.

14. Include plans, sections, and elevations of heating, ventilating, and air-conditioning

ducts, drawn to scale; coordinate location of duct smoke detectors and access to them.

a. Show field wiring and equipment required for HVAC unit shutdown on alarm

and override by firefighters' control system.

b. Locate detectors according to manufacturer's written recommendations.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 5 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

15. Include voice/alarm signaling-service equipment rack or console layout, grounding

schematic, amplifier power calculation, and single-line connection diagram

16. Include floor plans to indicate final outlet locations showing address of each

addressable device. Show size and route of cable and conduits and point-to-point

wiring diagrams.

17. Include coordination drawings with other systems that interface with the fire alarm

system as listed under Article “Scope Of Work” of this Specification.

18. Coordination drawings on reflected ceiling plans drawn to scale shall include, but not

limited to fire alarm detectors and notification appliances, light fixtures, PAS

speakers, sprinkler heads, AC grills, access panels etc.

C. Sound Levels: Measure and submit audible sound levels. Verify that 15 decibels (dB)

above ambient noise levels or 5 dB above the maximum sound level that occurs at the

location for 60 seconds or more, but not greater than 120 dB, are achieved.

D. System Graphics: Provide system schematics in AutoCAD DWG format indicating the

location of monitoring and control points. Coordinate with the BMS/ SCADA Contractor.

E. Submit suitably framed Fire Zone drawings of proper size to be located in the Fire

Command Center/ Control room.

F. General Submittal Requirements:

1. Submittals shall be approved by Authorities Having Jurisdiction prior to submitting

them to Engineer.

a. In addition to distribution requirements for Submittals specified in Division 01

Section "Submittal Procedures", prepare an identical submission to authorities

having jurisdiction. Include copies of annotated Contract Drawings as needed

to depict component locations to facilitate review. Resubmit if required to

make clarifications or revisions to obtain approval. On receipt of comments

from Authorities Having Jurisdiction, submit them to the Engineer for review.

2. Shop Drawings shall be prepared by persons with either of the following

qualifications:

a. Trained and certified by manufacturer in fire alarm system design.

b. Licensed or certified by Authorities Having Jurisdiction

G. For notification appliances and smoke and heat detectors, in addition to submittals listed

above, indicate compliance with performance requirements and design criteria, including

analysis data.

1. Drawings showing the location of each notification appliance and smoke and heat

detector, ratings of each, and installation details as needed to comply with listing

conditions of the device.

2. Design Calculations: Calculate requirements for selecting the spacing and sensitivity

of detection, complying with NFPA 72. Calculate spacing and intensities for strobe

signals and sound-pressure levels for audible appliances.

3. Indicate audible appliances required to produce square wave signal per NFPA 72.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 6 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

H. Coordination Drawings:

1. Plans, sections, and elevations drawn to scale and coordinating installation of smoke

detectors in ducts and access to them. Show the following near each duct smoke

detector installation:

a. Size and location of supply and return ducts, including lining.

b. Size and location of piping.

c. Size and arrangement of structural elements.

d. Size and location of duct smoke detector, including air-sampling elements.

2. Location of detectors and notification devices in ceilings and reflected ceilings.

I. Contractor shall submit Manufacturer’s technical validation and endorsement of the design

documentation and implementation.

1.8 INFORMATIONAL SUBMITTALS

A. Qualification Data: For Manufacturer and Installer/Contractor as outlined in “QUALITY

ASSURANCE” article.

B. Seismic Qualification Certificates

1. For fire alarm control Panel, accessories, and components, from manufacturer.

a. Basis for Certification: Indicate whether withstand certification is based on

actual test of assembled components or on calculation.

b. Dimensioned Outline Drawings of Equipment Unit: Identify center of gravity

and locate and describe mounting and anchorage provisions.

c. Detailed description of equipment anchorage devices on which the certification

is based and their installation requirements.

C. Field quality-control reports.

D. Signed warranty: As specified.

1.9 CLOSEOUT SUBMITTALS

A. Operation and Maintenance Data: For fire alarm systems and components to include in

emergency, operation, and maintenance manuals.

1. In addition to items specified in Division 01, Section "Operation and Maintenance

Data", include the following and deliver copies to Authorities Having Jurisdiction:

a. Comply with the "Records" section of the "Inspection, Testing and

Maintenance" chapter in NFPA 72.

b. Provide "Fire Alarm and Emergency Communications System Record of

Completion Documents" according to the "Completion Documents" Article in

the "Documentation" section of the "Fundamentals" chapter in NFPA 72.

c. Complete wiring diagrams showing connections between all devices and

equipment. Each conductor shall be numbered at every junction point with

indication of origination and termination points.

d. Riser diagram.

e. Device addresses. Coordinate with final system programming and labeling.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 7 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

f. System Operation Description: Detailed description for this Project, including

method of operation and supervision of each type of circuit and sequence of

operations for manually and automatically initiated system inputs and outputs.

Manufacturer's standard descriptions for generic systems are not acceptable.

g. Record copy of site-specific software.

h. Provide "Inspection and Testing Form" according to the "Inspection, Testing

and Maintenance" chapter in NFPA 72, and include the following:

1) Equipment tested.

2) Frequency of testing of installed components.

3) Frequency of inspection of installed components.

4) Requirements and recommendations related to results of maintenance.

5) Manufacturer's user training manuals.

i. Manufacturer's required maintenance related to system warranty requirements.

j. Abbreviated operating instructions for mounting at fire alarm control panel and

each annunciator panel.

B. Software and Firmware Operational Documentation:

1. Software operating and upgrade manuals.

2. Program Software Backup: On magnetic media or compact disk, complete with data

files.

3. Device address list.

4. Printout of software application and graphic screens.

1.10 QUALITY ASSURANCE

A. Materials and equipment shall comply with applicable local regulations and code

requirements of Authorities Having Jurisdiction. These shall have precedence over other

codes and standards indicated, unless otherwise approved by the Employer, in writing.

B. Installer Qualifications: An experienced Installer who is an authorized and certified

representative of the fire alarm system manufacturer for both installation and maintenance

of units required for this Project.

1. Experience: Minimum 5 years.

2. Demonstrate that Installer has satisfactorily completed at least 2 system installations

similar in design and extent to that indicated for this Project, and with a record of

successful in-service performance.

C. Manufacturer Qualifications: A firm experienced in manufacturing systems similar to those

indicated for this Project and with a record of successful in-service performance.

D. Source Limitations: Obtain fire alarm system components through a single source from a

single manufacturer.

E. Certification

1. All components of the fire alarm system including system hardware and software

shall be UL listed or EN54 certified.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 8 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

2. The entire fire alarm system including integration arrangement with the BMS/

SCADA, the Access Control and other Building Services Systems shall be UL listed

or EN54 certified and suitable for life safety and fire alarm applications.

F. Equipment Country of Origin

1. Equipment Country of Origin (manufacturing country) shall be indicated in the

proposal at time of bid submission.

1.11 DELIVERY, STORAGE AND HANDLING

A. Comply with Division 01, Section “Product Requirements”.

1.12 PROJECT/SITE CONDITIONS

A. Environmental Conditions: Equipment shall be capable of withstanding the project

environmental conditions specified under Division 26 Section “Basic Electrical Materials

and Methods” encountered at the installed location without mechanical or electrical damage

or degradation of operating capability.

B. Use of Devices during Construction: Protect devices during construction unless devices are

placed in service to protect the facility during construction.

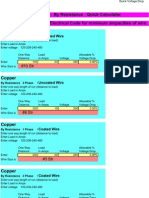

C. Power Supply

1. Power supply for all products shall be supplied or derived from the voltage system

described below, as shown on the Drawings, or as otherwise specified.

2. Nominal characteristics of power supply and distribution system (AC voltage / No. of

Phases / Frequency / Earthing system) shall be as per local country standard. For

details, refer to Division 26 Section “Basic Electrical Materials and Methods”.

1.13 WARRANTY

A. Provide complete system warranty in which Manufacturer, Installer, and Contractor are

jointly and severally liable and agree to repair or replace all defective components of the

warranted item. Warranty shall include both, materials and workmanship.

B. Provide system warranty in which Manufacturer, Installer, and Contractor are jointly and

severally liable and agree to repair or replace defective components of the warranted item.

C. Warranty shall include:

1. Defective materials and installation.

2. Failure to comply with requirements stated in technical specifications.

3. Structural failures including, but not limited to, excessive deflection.

4. Faulty operation of movable parts such as hardware.

5. Deterioration of metals, metal finishes, and other materials beyond normal

weathering and use.

6. Delamination of exterior or interior facing materials.

7. Making good and installation and finishing all items that are disturbed and that may

be required due to repair or replacement of defective items. Coordinate with

Employer, manufacturer, and installer of adjacent disturbed items to ensure that their

warranty is not cancelled due to the repair work.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 9 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

D. Special Warranty

1. The Fire Alarm System (comprising any associated hardware and software) shall be

warranted by the Manufacturer to be free from defects in equipment, software and

workmanship for a period defined below in paragraph “Warranty Period”.

2. Manufacturer’s Warranty: Provide written warranty, signed by the Manufacturer and

the Installer agreeing to replace system devices and equipment that fail in materials or

workmanship and to provide software patch support and updates within specified

warranty period.

3. To maintain the manufacturer’s warranties, equipment shall be installed,

commissioned and serviced by those installers authorized by said manufacturer to

perform those duties. If the Contractor is not authorized, by the said manufacturer, it

is his sole responsibility to make the appropriate arrangements and bear all cost and

consequences thereof.

4. All manufacturers’ equipment warranties shall be activated in the Employer’s name

and shall commence on the date indicated in paragraph “Warranty Period” below.

E. Experimental Period

1. There shall be an Experimental Period during which the Contractor shall undertake

supervision and responsibility for operation of the Fire Alarm System under actual

site conditions. If any malfunction or degradation in the performance is noted on the

system during this period, it shall be attended to immediately.

2. During this period, the Contractor shall fully demonstrate the system performance

under actual operation conditions. This demonstration is to confirm, to the

satisfaction of the Employer / Engineer that the Fire Alarm System is free of remarks

and is ready for taking over.

3. The Experimental Period shall extend over one month and shall start following the

certification by the Engineer of the successful testing and commissioning of the

system. The Experimental Period shall, each time a malfunction is detected, be

extended by one month starting from the certification by the Engineer of the

successful testing of the system following the rectification of the malfunction.

F. Taking Over of the System

1. The system shall be considered ready for taking over by the Employer following:

a. The expiry, with no malfunctions being detected during the last one month, of

the Experimental Period (as may be extended), and

b. The submission by the Contractor, and approval by the Engineer, of the

documents and information required from the Contractor for the use,

occupation and maintenance of the system in accordance with the Contract.

(updated as necessary to reflect any rectification(s) introduced during the

Experimental Period).

G. Warranty Period

1. The Contractor shall include a statement of warranty on the entire system and on the

individual pieces of equipment for two years from the date of the taking over of the

system.

2. During the Warranty Period, the Contractor shall undertake Maintenance actions as

defined in the “MAINTENANCE AND SUPPORT DURING WARRANTY

PERIOD” Article below.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 10 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

3. During the Warranty Period, the Contractor shall provide all equipment, material,

software and labor needed to replace or repair defective products without any

additional cost to the Contract.

4. Warranty period shall be revised in accordance with Division 01, Section “Product

Requirements” depending on Equipment Country of Origin.

1.14 MAINTENANCE AND SUPPORT DURING WARRANTY PERIOD

A. Initial Maintenance Service: Beginning at system Taking Over, maintenance service shall

include full maintenance by skilled employees of manufacturer's designated service

organization.

B. Include preventive maintenance, repair or replacement of worn or defective components,

lubrication, cleaning, and adjusting as required for proper operation. Parts and supplies shall

be manufacturer's authorized replacement parts and supplies.

1. Include visual inspections according to the "Visual Inspection Frequencies" table in

the "Testing" paragraph of the "Inspection, Testing and Maintenance" chapter in

NFPA 72.

2. Perform tests in the "Test Methods" table in the "Testing" paragraph of the

"Inspection, Testing and Maintenance" chapter in NFPA 72.

3. Perform tests per the "Testing Frequencies" table in the "Testing" paragraph of the

"Inspection, Testing and Maintenance" chapter in NFPA 72.

C. During the Warranty Period, Manufacturer or factory-authorized agency shall maintain a

service center capable of providing spare parts and emergency maintenance and repairs for

the overall system, 7 days a week and 24 hours a day,. Competent personnel shall be

dispatched to rectify system failures at any time when being called on by the Employer.

D. The Contractor shall submit a Service-Call Report to the Employer immediately following

every call out, indicating the time of call out visit, cause, remedial action taken and the time

that the service was restored.

E. A Maintenance Manpower Plan shall demonstrate the Contractor’s committed resource level

available for all types of activities to be carried out within the Warranty Period. Such a plan

shall be submitted for Approval six months before commencement of the Warranty Period.

F. The Contractor’s response time, during the Warranty Period, shall not exceed 1 hour. The

response time is defined as the time that elapses between the reporting of a fault and the

maintenance personnel arriving at where the faulty equipment is located.

G. During the Warranty Period, the MTTR shall not exceed 30 minutes. The MTTR shall

include the diagnostic time, active repair/replacement time and the adjustment/testing time

on site, but shall exclude the response time.

H. During the Warranty Period, the monthly average of the Repair Time shall be lower than or

equal to 6 minutes for each device. This performance will be monitored.

I. The Contractor shall provide at least four inspection visits at six-month interval during the

Warranty Period. The Contractor shall submit a Service-Call Report to be sent to the

Employer immediately following every inspection visit, indicating the time of call out visit,

cause, remedial action taken – if any - and the time that the service was restored.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 11 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

J. The Contractor shall be responsible to clear away from the Site all surplus materials,

rubbish, temporary works of every kind and leave the whole of the Site and installation

clean and in a workmanlike condition to the satisfaction of the Employer, upon completion

of each item of the repair, and maintenance works.

K. Software Service Agreement

1. Technical Support: Beginning at Taking Over, service agreement shall include

software support for two years.

2. Upgrade Service: At Taking Over, update software to latest version. Install and

program software upgrades that become available within two years from date of

Taking Over. Upgrading software shall include operating system and new or revised

licenses for using software.

a. Upgrade Notice: At least 30 days to allow Employer to schedule access to

system and to upgrade computer equipment if necessary.

1.15 SPARE PARTS AND EXTRA MATERIAL

A. Contractor shall handover manufacturer’s recommended spare parts for all major

components in the system for two years fault-free operation.

B. However furnish the following extra materials, as a minimum, that match products installed

and that are packaged with protective covering for storage and identified with labels

describing contents, irrespective of Manufacturer’s recommendation:

1. Lamps for Remote Indicating Lamp Units: Quantity equal to 2 percent of amount

installed, but no fewer than one unit.

2. Lamps for Strobe Units: Quantity equal to 2 percent of amount installed, but no fewer

than one unit.

3. Fire Detectors: Quantity equal to 2 percent of amount of each type installed, but no

fewer than one unit of each type.

4. Detector Bases: Quantity equal to 1 percent of amount of each type installed, but no

fewer than one unit of each type.

5. Keys and Tools: One extra set for access to locked or tamper-proofed components.

6. Audible and Visual Notification Appliances: One of each type installed.

7. Fuses: Two of each type installed in the system. Provide in a box or cabinet with

compartments marked with fuse types and sizes.

8. Linear heat detectors: Quantity equal to 2 of amount installed but no fewer than

100m.

9. Manual stations: Quantity equal to 2 percent of amount of each type installed, but no

fewer than one unit of each type.

10. Loudspeakers: Quantity equal to 2 percent of amount of each type installed, but no

fewer than one unit of each type.

11. Printer paper: 10 packets.

12. FACP LCD display screen/module: 5 percent with a minimum of one piece.

13. Loop cards: 2 percent with a minimum of one piece.

14. FACP power supply: 5 percent with a minimum of two.

C. The manufacturer shall guarantee the flow and availability of the spare parts without a major

design change for at least ten years’ period from date of System Acceptance by the

Employer.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 12 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

D. Handover manufacturer’s test equipment and tools required for normal routine inspection

and maintenance and testing of system components as appropriate for equipment supplied.

PART 2 - PRODUCTS

2.1 MANUFACTURERS

A. Available Manufacturers of Fire Alarm System: Subject to compliance with requirements

2.2 SEISMIC PERFORMANCE REQUIREMENTS

A. Seismic Performance: Fire alarm control panel and raceways shall withstand the effects of

earthquake motions determined according to [ASCE/SEI 7] / IBC.

1. The term "withstand" means "the panel will remain in place without separation of any

parts from the device when subjected to the seismic forces specified and the panel

will be fully operational after the seismic event."

2.3 SYSTEM DESCRIPTION

A. Control of System: By the FACP/ existing MFACP.

B. System Supervision: Automatically detect and report open circuit, short circuit, and ground

fault of wiring for initiating device, signaling line, and notification-appliance circuits.

System shall detect ground fault by panel, loop circuit, and group of devices.

C. Priority of Signals: Automatic alarm response functions resulting from an alarm signal from

one zone or device are not altered by subsequent alarm, supervisory, or trouble signals. An

alarm signal has the highest priority. Supervisory and trouble signals have second- and

third-level priority. Higher-priority signals take precedence over signals of lower priority,

even when the lower-priority condition occurs first. Annunciate and display all alarm,

supervisory, and trouble signals regardless of priority or order received.

D. Noninterference: A signal on one zone shall not prevent the receipt of signals from other

zones.

E. System Reset: All zones are manually re-settable from the MFACP/FACP after initiating

devices are restored to normal.

F. System shall continually monitor any changes in the sensitivity of individual smoke or heat

sensors due to environmental effects.

G. All operations shall be according to the approved Cause & Effect Matrix.

H. System Alarm Capability during Circuit Fault Conditions: System wiring, including peer-

to-peer loop, and circuit arrangement prevent alarm capability reduction when an open

circuit, ground or wire-to-wire short occurs, or an open circuit and a ground occur at the

same time in Initiating-Device, Notification-Appliance, and Signaling-Line Circuits.

1. Pathway Class Designations: NFPA 72, Class A for initiating-devices and

notification-appliance circuits; NFPA 72, Class X for signaling-line circuits.

2. Pathway Survivability: as per NFPA 72 requirement

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 13 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

3. Install no more than 200 addressable devices on each signaling-line circuit or as per

manufacturer recommendations of the approved fire alarm system to maintain 25%

spare capacity for initiating devices on each loop..

4. Serial Interfaces: type and quantity as recommended by manufacturer to suit Project

requirements for interface with:

a. Fire Alarm Repeater Panel.

b. Remote annunciators, Ethernet module, or multi-interface module (printer

port).

c. PC configuration.

d. Voice evacuation interface.

5. Provide addressable fault isolator circuit modules not less than one isolator for a

group of 20 devices. The module shall be capable of isolating and removing a fault

from a Class A data circuit while allowing the remaining data loop to continue

operating.

I. Loss of primary power at the FACP initiates a trouble signal at the MFACP/FACP. The

MFACP/FACP indicates when the fire alarm system is operating on the secondary power

supply.

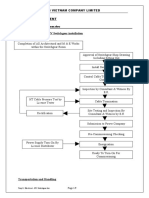

J. The Fire Command Center (FCC)/ Control room

1. The existing control room shall function as the center point for all operational and

administration functions required for the systems provided within the specification. It

shall contain a console that will display and house any equipment necessary for

system operation. Console space shall be provided for other equipment provided

under other sections of the specifications.

2. A Graphical User Interface (GUI) workstation shall be provided that will enable

primary control of the systems provided by this Specification. An Operator shall not

have to operate multiple workstations to receive, view, process and record system

events for each system provided.

3. The FCC equipment shall include the following:

a. Voice fire alarm system panels and controls.

b. Main Fire detection and fire alarm system annunciation panel (MFACP)

c. Sprinkler valve and water flow standard LED annunciator panel.

d. Emergency generators status indicators.

e. Controls for any automatic stairway door unlocking system.

f. Fire pumps status indicators (LED’s).

g. A telephone for fire department use with controlled access to the public

telephone system.

h. System printers.

4. The FCC console furniture shall form part of the Contractor’s scope.

a. A sit/stand ergonomic console with the capability to support multiple monitors

and is suitable for 24/7 operations by FCC staff with independently adjustable

sit-to-stand keyboard surfaces and sit-to stand monitor lift. Refer to Section

271800 - common clauses for it & security systems.

5. The FCC shall be provided with a workstation for central monitoring system of

Vertical Transportation Systems VTS (elevators,..). This Workstation shall be

provided by the VTS Contractor.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 14 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

K. Source Limitations for Fire alarm System and Components: Components shall be

compatible with, and operate as an extension of, existing system. Provide system

manufacturer's certification that all components provided have been tested as, and will

operate as, a system.

L. Fire alarm signal initiation shall be by one or more of the following devices:

1. Manual stations.

2. Smoke detectors.

3. Projected beam detectors.

4. Multi-criteria detectors.

5. Heat detectors.

6. Duct smoke detectors.

7. Automatic sprinkler system water flow.

8. Fire-extinguishing system operation.

9. Fire standpipe system.

10. Fire pump running.

11. Clean Agent system operation.

M. Fire alarm signal shall initiate the following actions:

1. Continuously operate alarm notification appliances including voice evacuation

notices.

2. Identify alarm and specific initiating device at MFACP/ FACP, remote annunciators

and fire alarm workstation.

3. Flashing of the device location-indicating-light for the device that has operated

(water-flow switch, elevator’s shaft detector, etc..).

4. Transmit an alarm signal to the remote alarm receiving station.

5. Unlock electric door locks in designated egress paths.

6. Release fire and smoke doors held open by magnetic door holders.

7. Activate voice/alarm communication system.

a. Broadcast Evacuation signal in zone of incidence; alert signal in adjacent

zones.

8. Switch heating, ventilating, and air-conditioning equipment controls to fire alarm

mode in accordance with Mechanical Specifications.

9. Activate smoke-control system (smoke management):

a. Activate stairwell and elevator-shaft pressurization systems.

b. Activate smoke dampers in air ducts of designated air-conditioning duct

systems.

c. Operate smoke curtains where applicable.

10. Activate pre-action sprinkler system.

11. Recall elevators to primary or alternate recall floors.

12. Activate emergency lighting control.

13. Activate emergency shutoffs for gas and fuel supplies.

14. The CCTV camera(s) corresponding to the alarm zone shall start recording the event

and shall be automatically prompted to pop up in the CCTV monitors located at the

Control room. This shall be achieved via CCTV system interface with the Access

Control.

15. Mute public address (PA) and music equipment and broadcast fire alarm evacuation/

alert signals through voice/alarm communication system.

16. Control the operation of the escalators.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 15 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

17. Record events in the system memory.

18. Record events by the system printer.

19. Indicate device in alarm on the graphic annunciator.

20. Transmit system status to BMS/ SCADA.

N. Supervisory signal initiation shall be by one or more of the following devices and actions:

1. Valve supervisory switch (sprinkler valve-tamper switch).

2. High- or low-air-pressure switch of a dry-pipe or pre-action sprinkler system.

3. Elevator shunt-trip supervision.

4. Fire pump running.

5. Fire-pump loss of power.

6. Fire-pump power phase reversal.

7. Independent fire-detection and -suppression systems.

8. User disabling of zones or individual devices.

9. Loss of communication with any panel on the network.

O. System Trouble signal initiation shall be by one or more of the following devices and

actions:

1. Open circuits, shorts, and grounds in designated circuits.

2. Opening, tampering with, or removing alarm-initiating and supervisory signal-

initiating devices.

3. Loss of communication with any addressable sensor, input module, relay, control

module, remote annunciator, printer interface, or Ethernet module.

4. Loss of primary power at fire alarm control panel.

5. Ground or a single break in internal circuits of fire alarm control panel.

6. Abnormal AC voltage at fire alarm control panel.

7. Break in standby battery circuitry.

8. Failure of battery charging.

9. Abnormal position of any switch at fire alarm control panel or annunciator.

10. Voice signal amplifier failure.

P. System Trouble and Supervisory Signal Actions:

1. Initiate notification appliances.

2. Flashing of the device location-indicating-light for the device that has operated.

3. Identify specific device initiating the event at MFACP/FACP, and remote

annunciators.

4. Record the event in system memory.

5. Record the event on system printer.

6. After a time delay of 200 seconds, transmit a trouble or supervisory signal to the

remote alarm receiving station.

7. Transmit system status to BMS/SCADA.

8. Display system status on graphic annunciator.

Q. Alarm Silencing, System Reset and Indication: Controlled by switches in the MFACP/

FACP.

1. Silencing-switch operation halts alarm operation of notification appliances and

activate an "alarm silence" light. Display of identity of the alarm zone or device is

retained.

2. Subsequent alarm signals, from other devices or zones, shall reactivate notification

appliances, until silencing switch is operated again.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 16 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

3. When alarm-initiating do not return to normal and system reset switch is operated,

notification appliances operate again until alarm silence switch is reset.

4. When fire alarm system is reset, all auxiliary systems shall be released from fire

mode.

R. Stairwell and Elevator Shaft Pressurization: Provide an output signal using an addressable

relay to start the stairwell and elevator shaft pressurization system. Signal shall remain on

until alarm conditions are cleared and fire-alarm system is reset. Signal shall not stop in

response to alarm acknowledge or signal silence commands.

1. Pressurization starts when any alarm is received at fire-alarm control unit.

2. Alarm signals from smoke detectors at pressurization air supplies have a higher

priority than other alarm signals that start the system.

S. Smoke-Alarm Verification:

1. Initiate audible and visible indication of an "alarm-verification" signal at fire alarm

control panel.

2. Activate an approved "alarm-verification" sequence at fire alarm control panel and

detector.

3. Record events by the system printer.

4. Sound general alarm if the alarm is verified.

5. Cancel fire alarm control panel indication and system reset if the alarm is not verified.

T. Notification-Appliance Circuit:

1. Audible appliances shall sound in a three-pulse temporal pattern, as defined in

NFPA 72.

2. Visual alarm appliances shall flash in synchronization where multiple appliances are

in the same field of view, as defined in NFPA 72.

U. Elevator Recall:

1. Elevator recall shall be initiated only by one of the following alarm-initiating devices:

a. Elevator lobby detectors except the lobby detector on the designated recall

floor.

b. Smoke detector in elevator machine room.

c. Smoke detectors in elevator hoist way.

2. Elevator controller shall be programmed to move the cars to the alternate recall floor

if lobby detectors located on the designated recall floors are activated.

3. Water-flow alarm connected to sprinkler in an elevator shaft and elevator machine

room shall shut down elevators associated with the location without time delay.

a. Water-flow switch associated with the sprinkler in the elevator pit may have a

delay to allow elevators to move to the designated floor.

V. Remote Smoke-Detector Sensitivity Adjustment: Controls shall select specific addressable

smoke detectors for adjustment, display their current status and sensitivity settings, and

change those settings. Allow controls to be used to program repetitive, time-scheduled, and

automated changes in sensitivity of specific detector groups. Record sensitivity adjustments

and sensitivity-adjustment schedule changes in system memory, and print out the final

adjusted values on system printer.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 17 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

W. Transmission to Remote Alarm Receiving Station: Automatically transmit alarm,

supervisory, and trouble signals to a remote alarm station.

X. Voice/Alarm Signaling Service: “Central emergency communication system with redundant

microphones, preamplifiers, amplifiers, and tone generators. provided in a separate cabinet

located in the fire command center/Control Room.

1. Indicate number of alarm channels for automatic, simultaneous transmission of

different announcements to different zones or for manual transmission of

announcements by use of the central-control microphone.

a. Allow the application of, and evacuation signal to, indicated number of zones

and, at the same time, allow voice paging to the other zones selectively or in

any combination.

b. Programmable tone and message sequence selection.

c. Standard digitally recorded messages for "Evacuation" and "All Clear."

d. Generate tones to be sequenced with audio messages of type recommended by

NFPA 72 and that are compatible with tone patterns of notification-appliance

circuits of fire alarm control panel.

e. Amplifiers shall comply with UL 1711 or equivalent.

2. Status Annunciator: Indicate the status of various voice/alarm speaker zones and the

status of firefighters' two-way telephone communication zones (where applicable).

3. Preamplifiers, amplifiers, and tone generators shall automatically transfer to backup

units, on primary equipment failure.

Y. Printout of Events: On receipt of signal, print alarm, supervisory, and trouble events.

Identify zone, device, and function. Include type of signal (alarm, supervisory, or trouble)

and date and time of occurrence. Differentiate alarm signals from all other printed

indications. Also print system reset event, including same information for device, location,

date, and time. Commands initiate the printing of a list of existing alarm, supervisory, and

trouble conditions in the system and a historical log of events.

Z. Power Supply: Refer to Article “System Power Supply” of this Specification Section.

AA. Instructions: Computer printout or typewritten instruction card mounted behind a plastic or

glass cover in a stainless-steel or aluminum frame. Include interpretation and describe

appropriate response for displays and signals. Briefly describe the functional operation of

the system under normal, alarm, and trouble conditions.

BB. System shall support English language as coordinated with the Authority Having

Jurisdiction.

CC. Communication of Events: On receipt of the signal, communicate alarm, supervisory, and

trouble events to the BMS/ SCADA. Identify zone, and function. Include type of signal

(alarm, supervisory, or trouble), and date and time of occurrence. Differentiate alarm signals

from all other indications. Also communicate system-reset event, including the same

information for device, location, date, and time.

DD. The Fire Alarm System shall control directly the controlled doors, HVAC units and VTS

systems in accordance with the approved Cause and Effect Matrix via hardwired interlocks.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 18 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

EE. The Fire Alarm System shall carry out handshaking with the smoke management exhaust

fans by receiving a feedback on the fire alarm system to confirm that the requested action

has taken place, otherwise a trouble signal shall be indicated and reported on the

corresponding firefighter’s smoke control station (FSCS).

FF. FACP Alphanumeric Display: Plain English language descriptions of alarm, supervisory,

and trouble events; and addresses and locations of alarm-initiating or supervisory devices

originating the report. Display monitoring actions, system and component status, system

commands, programming information, and data from the system's historical memory.

GG. System shall be able to report a map of all initiating devices connected to the system for

confirmation of As-Built drawings, and it shall show physical wiring of T-type by device

type and number. Other proposed alternatives shall be considered.

HH. Expansion Capability: Increase number of devices in the future by 25 percent above those

indicated without adding any internal or external components or cable conductors.

2.4 FIRE ALARM CONTROL PANELS (FACP)

A. Description: FACPs shall be identical to and compatible with the existing MFACP in all

respect, capable of operating the system on a stand-alone basis. Each panel maintains the

status and control of its own dedicated circuit points.

1. Extent of control and monitoring of each of MFACP and FACP is defined under

Paragraph “Hierarchical control and monitoring functions of MFACPs, FACPs, and

GUIs” of Article “FIRE ALARM NETWORK”.

2. Comply with UL 864 or equivalent.

B. The FACP shall be an independent, local fire alarm control unit as well as being listed as a

critical component in a multiplex fire alarm system. FACPs shall be located where shown

on the Drawings.

C. The FACP shall serve as the interface between initiating fire devices, controlled signaling

devices, and each fire alarm node. The supervised multiplex communication port shall be

an integral part of the FACP.

D. Each FACP shall be powered from a local power supply, and shall provide all power

necessary for its own operation and related components, including standby power.

Contractor shall verify by calculations that the voltage drop limits on the lines feeding the

different components do not exceed the limits recommended by manufacturer, and shall

rectify wherever needed.

E. FACPs shall be used to house amplifiers, batteries, and power supplies to allow true

distributed processing and amplification.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 19 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

2.5 MANUAL FIRE ALARM STATIONS

A. General Requirements for Manual Fire Alarm Stations (Boxes): finished in red with molded,

raised-letter operating instructions in contrasting color; shall show visible indication of

operation; and shall be mounted on recessed outlet box. If indicated as surface mounted,

provide manufacturer's surface back box.

1. Double-action mechanism requiring two actions to initiate an alarm, breaking-glass,

pull-lever type or equivalent; with integral addressable module arranged to

communicate manual-station status (normal, alarm, or trouble) to fire alarm control

panel.

2. Station Reset: Key- or wrench-operated switch.

3. For manual stations installed in areas indicated to require weather proof installations

use a weatherproof Protective Shield: Factory-fabricated, clear plastic enclosure

hinged at the top to permit lifting for access to initiate an alarm.

4. Comply with UL 38 or equivalent.

5. For manual stations installed in hazardous/ Explosion areas indicated; manual pull

station shall be UL Listed, NEMA 4X and ATEX compliant or equivalent for use in

the intended environment.

2.6 SYSTEM SMOKE DETECTORS

A. General Requirements for System Smoke Detectors:

1. Operating at 24-V dc, nominal.

2. Base Mounting: Detector and associated electronic components shall be mounted in a

twist-lock module that connects to a fixed base. Provide terminals in the fixed base

for connection to building wiring.

3. Self-Restoring: Detectors do not require resetting or readjustment after actuation to

restore them to normal operation.

4. Integral Visual-Indicating Light: LED type, indicating detector in normal

operational/alarm condition.

5. Comply with UL 268 or equivalent.

6. Detector shall be addressed through soft-addressing mechanism

7. Remote Control: Unless otherwise indicated, detectors shall be digital-addressable

type, individually monitored at fire alarm control panel for calibration, sensitivity,

and alarm condition .

a. Multi-sensor: Rate-of-rise temperature characteristic of combination smoke-

and heat-detection units shall be selectable at fire alarm control panel for 8 or

11 deg C (15 or 20 deg. F) per minute.

b. Multi-sensor: Fixed-temperature sensing characteristic of combination smoke-

and heat-detection units shall be independent of rate-of-rise sensing and shall

be settable at fire alarm control panel to operate at 57 or 68 deg C (135 or 155

deg F).

c. Multiple levels of detection sensitivity for each sensor.

d. Sensitivity levels based on time of day.

B. Photoelectric Smoke Detectors:

1. Detector address shall be accessible from fire alarm control panel and shall be able to

identify the detector's location within the system and its sensitivity setting.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 20 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

2. An operator at fire alarm control panel, having the designated access level, shall be

able to manually access the following for each detector:

a. Primary status.

b. Device type.

c. Present average value.

d. Present sensitivity selected.

e. Sensor range (normal, dirty, etc.).

C. Duct Smoke Detectors: Photoelectric type.

1. Detector address shall be accessible from fire alarm control panel and shall be able to

identify the detector's location within the system and its sensitivity setting.

2. An operator at fire alarm control panel, having the designated access level, shall be

able to manually access the following for each detector:

a. Primary status.

b. Device type.

c. Present average value.

d. Present sensitivity selected.

e. Sensor range (normal, dirty, etc.).

3. Weatherproof Duct Housing Enclosure: IP 66; listed for use with the supplied

detector for smoke detection in HVAC system ducts.

4. Each sensor shall have multiple levels of detection sensitivity.

5. Sampling Tubes: Design and dimensions as recommended by manufacturer for

specific duct size, air velocity, and installation conditions where applied.

6. Comply with UL 268A or equivalent.

D. Explosion Proof Smoke Detectors:

1. Explosionproof Smoke Detectors feature a rugged design built to withstand

environmental extremes.

2. Detectors shall be provided with Alarm, Auxiliary, Fault relays and required interfac-

es with fire panel/loop.

3. Comply with FM and IEC/IECx requirements.

4. Ingress Protection: IP44.

5. Detectors shall perform effectively with slow-burning smoldering fires, as well as

quickly rising flames.

6. The sensor module is hot-swappable and intrinsically safe while powered.

E. Explosion Proof Heat Detectors:

1. Explosionproof Heat Detectors feature a rugged design built to withstand shock and

vibration.

2. Detectors shall be provided with Alarm, Auxiliary, Fault relays and required interfac-

es with fire panel/loop.

3. Detectors shall allow for various temperature settings.

4. Comply with FM and IECEx requirements.

5. Ingress Protection: IP66/67.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 21 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

PROJECTED BEAM SMOKE DETECTORS

F. The Projected Beam Light Source and Receiver shall be designed to accommodate small

angular movements and continue to operate and not cause nuisance alarms.

G. Detector Address: Accessible from fire alarm control panel and able to identify the

detector's location within the system and its sensitivity setting.

H. An operator at fire alarm control panel, having the designated access level, shall be able to

manually access the following for each detector:

1. Primary status.

2. Device type.

3. Present average value.

4. Present sensitivity selected.

5. Sensor range (normal, dirty, etc.).

I. Features

1. Adjustable Sensitivity: More than a 6-level range, minimum.

2. Linear Range of Coverage: 100 m minimum.

3. Tamper Switch: Initiates trouble signal at the MFACP/FACP when either transmitter

or receiver is disturbed.

4. Separate Color-Coded LEDs: Indicate normal, alarm, and trouble status. Any

detector trouble, including power loss, is reported to the MFACP/FACP as a

composite "trouble" signal.

5. Transmitter incorporates an LED array to indicate signal strength and assist in the

alignment of the beam.

2.7 MULTICRITERIA DETECTORS

A. Mounting: Twist-lock base interchangeable with smoke-detector bases.

B. Integral Addressable Module: Arranged to communicate detector status (normal, alarm, or

trouble) to fire alarm control panel.

C. Automatically adjusts its sensitivity by means of drift compensation and smoothing

algorithms. The detector shall send trouble alarm if it is incapable of compensating for

existing conditions.

D. Test button tests all sensors in the detector.

E. An operator at fire alarm control panel, having the designated access level, shall be able to

manually access the following for each detector:

1. Primary status.

2. Device type.

3. Present sensitivity selected.

4. Sensor range (normal, dirty, etc.).

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 22 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

F. Sensors: The detector shall be comprised of sensing elements including a smoke sensor, an

infrared sensor and heat sensor.

1. Smoke sensor shall be photoelectric type as described in "System Smoke Detectors"

Article.

2. Heat sensor shall be as described in "Heat Detectors" Article.

3. Each sensor shall be separately listed according to requirements for its detector type.

2.8 HEAT DETECTORS

A. General Requirements for Heat Detectors:

1. Temperature sensors shall test for and communicate the sensitivity range of the

device.

2. Comply with UL 521 or equivalent.

3. Detector shall be addressed through soft-addressing mechanism.

B. Heat Detector, Combination Type: Actuated by either a fixed temperature of 57 deg. C (135

deg. F) or a rate of rise that exceeds 8 deg. C (15 deg F) per minute unless otherwise

indicated.

1. Mounting: Twist-lock base interchangeable with smoke-detector bases.

2. Integral Addressable Module: Arranged to communicate detector status (normal,

alarm, or trouble) to fire alarm control panel.

C. Heat Detector, Fixed-Temperature Type: Actuated by temperature that exceeds a fixed

temperature of 88 deg. C (190 deg. F).

1. Mounting Twist-lock base interchangeable with smoke-detector bases.

2. Integral Addressable Module: Arranged to communicate detector status (normal,

alarm, or trouble) to fire alarm control panel.

D. Continuous Linear Heat-Detector System: consisting of detector cable and control unit

1. Detector Cable: Shall be flexible in installation and recoverable after operation. It

shall have high sensitivity to small temperature variations and shall monitor the

precise point of risk. The analog sensor shall consist of a 4-core cable. Two of the

four color-coded conductors shall be insulated with a negative temperature coefficient

material. The other two conductors shall have normal PVC insulation. The cores shall

be twisted together and protected by an outer sheath of high temperature, flame-

retardant PVC insulation. The analogue sensor senses temperature variations by

continuously monitoring the resistance such that a change in temperature produces a

relative change in resistance between the two loops within the sensor cable.

2. Control Panel: Microprocessor controlled that can automatically detect the length and

the ambient temperature of the attached sensor cable. The control unit shall

continuously monitor the sensor cable and shall have the following minimum

features:

a. Several programmable levels

b. Short circuit monitoring of analog type sensor cable.

c. Open circuit monitoring of analog and digital type sensor cable.

d. History and event log storage that can be downloaded using a PC.

e. Relay outputs for alarms and faults.

f. Detecting hot spots.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 23 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

g. Providing advanced notification of temperature increase.

3. Signals to the MFACP/FACP: Any type of local system trouble is reported to the

MFACP/FACP as a composite "trouble" signal.

4. Provide Addressable Monitoring modules for monitoring the Linear Heat Detection

system Zone and provide two-way communication with MFACP/FACP. One module

shall be used for each zone to report Alarm information to MFACP/FACP.

2.9 FLAME DETECTOR

A. Detectors shall be able to detect hydrocarbon and non-hydrocarbon fuel fires in all

environmental conditions

B. Detectors shall have high Sensitivity and provided with UV/Dual IR/VIS sensing technolo-

gy.

C. The enclosure materials shall be 316 Stainless Steel or equivalent, complying with 4X, IP66

and NEMA 4 requirements.

2.10 GAS DETECTOR

A. Gas detector is used for the protection of personnel and plant from flammable and toxic gas

hazards.

B. Gas detection set to alarm at 15% LEL and 30% LEL in all normally unmanned building

areas housing gas fittings or equipment (e.g. boiler room). LEL to be confirmed and ap-

proved by Mars.

C. The enclosure materials shall be 316 Stainless Steel or equivalent supporting IP66

requirements.

D. Detectors shall be located, mounted, and wired according to manufacturer's installation

manual.

E. Gas detectors shall be provided with required addressable interface modules .

F. Compliant with IECEx and UL standards or equivalent.

2.11 NOTIFICATION APPLIANCES

A. General Requirements for Notification Appliances: Individually addressed, connected to a

signaling-line circuit, equipped for mounting as indicated, and with screw terminals for

system connections.

B. General Requirements for Notification Appliances: Connected to notification-appliance

signal circuits, zoned as indicated, equipped for mounting as indicated, and with screw

terminals for system connections.

1. Combination Devices: Factory-integrated audible and visible devices in a single-

mounting assembly, equipped for mounting as indicated, and with screw terminals for

system connections.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 24 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

C. Horns: Electric-vibrating-polarized type, 24-V dc; with provision for housing the operating

mechanism behind a grille. Horns shall produce a sound-pressure level of 90 dBA,

measured 3 m (10 feet) from the horn, using the coded signal prescribed in UL 464 test

protocol or equivalent.

D. Visible Notification Appliances: Xenon strobe lights, with clear or nominal white

polycarbonate lens mounted on an aluminum faceplate. The word "FIRE" is engraved in

minimum 25-mm- (1-inch-) high letters on the lens.

1. Rated Light Output:

a. 15/30/60/75/110 cd, selectable in the field.

2. Provide a label inside the strobe lens to indicate the listed candela rating of the

specific strobe.

3. Mounting: Wall mounted unless otherwise indicated.

4. For units with guards to prevent physical damage, light output ratings shall be

determined with guards in place.

5. Flashing shall be in a temporal pattern, synchronized with other units.

6. Strobe Leads: Factory connected to screw terminals.

7. Mounting Faceplate: Factory finished, red/white.

8. Comply with UL 1971 or equivalent.

E. Voice/Tone Notification Appliances:

1. Speakers for Voice Notification: Locate speakers for voice notification to provide the

intelligibility requirements of the "Notification Appliances" and "Emergency

Communications Systems" chapters in NFPA 72.

2. Low-Range Units: to include round baffles, steel with white finishes. The rear of the

speaker shall be completely sealed protecting the cone during and after installation.

Speaker shall be provided for use with 70 volt systems. Speakers shall provide power

taps at ½ W, 1W and 2 Watts. Speakers shall provide UL confirmed 87 dBA output at

2 watts. Speaker sound dispersion angle shall be minimum 120º

3. High-Range Units: shall be similar to ceiling type with rectangular shape and surface

mount rated 2 to 15 Watts for noisy environments. Speakers shall provide UL

confirmed 98 dBA output at 15 watts. Speaker sound dispersion angle shall be

minimum 150º

4. Mounting: surface mounted and bidirectional.

5. Matching Transformers: Tap range matched to the acoustical environment of the

speaker location.

6. Dedicated Audio risers to be considered within the staircases. Special attention to be

considered for the containment in the stairwells during the buildings works

construction.

7. Comply with UL 1480.

F. Weatherproof Speaker (At Hazardous location)

1. Intended for use in potentially explosive gas and dust atmospheres.

2. SPL: 109dBA at 25watts, 10 ft

3. Freq range : 400Hz to 8KHz

4. Power rating: 8, 15, 25 watt

5. Ingress Protection: IP67

6. Compliant with UL standards, ATEX or equivalent.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 25 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

G. Appliances intended for use in special environments, such as outdoors versus indoors, high

or low temperatures, high humidity, dusty conditions, and hazardous locations, or where

subject to tampering, shall be listed for the intended application.

2.12 REMOTE INDICATING LAMP

A. Description: LED indicating light near each smoke detector that may not be readily visible,

and each sprinkler water-flow switch and valve-tamper switch. Light shall be wired in such

a way as to flash when the associated device is in an alarm or trouble mode. Lamp is flush

mounted in a single gang wall plate. A red, laminated, phenolic-resin identification plate at

the indicating light identifies, in engraved white letters, device initiating the signal and room

where the smoke detector or valve is located. For water-flow switches, the identification

plate also designates protected spaces downstream from the water-flow switch.

2.13 GRAPHIC ANNUNCIATOR

A. Graphic Annunciator Workstation: PC-based, with fire alarm annunciator software with

historical logging, report generation, and a graphic interface showing all alarm points in the

system. PC with operating system software, minimum 500 Gigabit hard drive, support

multiple display configuration for minimum two 24" digital display monitors, with wireless

keyboard and mouse.

2.14 REMOTE ANNUNCIATOR

A. Description: Annunciator functions shall match those of fire alarm control panel for alarm,

supervisory, and trouble indications. Manual switching functions shall match those of fire

alarm control panel, including acknowledging, silencing, resetting, and testing.

1. Mounting: Flush cabinet, IP 20.

B. Display Type and Functional Performance: Alphanumeric display and LED indicating lights

shall match those of fire alarm control panel. Provide controls to acknowledge, silence,

reset, and test functions for alarm, supervisory, and trouble signals.

2.15 FIRE ALARM NETWORK

A. Basic Network Operation: Each MFACP/FACP panel shall have a stand-alone control with

direct communications into network, and shall be defined as a node. Although performing

different functions, each MFACP/FACP serves as a "peer-to-peer" (equal) partner in

controlling network communications. Network information is sequentially transmitted from

one node to another. At each node, the network message is captured and either retransmitted

as received, or modified before retransmission to provide the network with a status update.

The ability of the message to circulate through the network defines the network status and

allows the nodes to respond accordingly. If a node goes "off-line", or if the wires between

nodes experience either a short circuit, an open circuit, or have any other form of

communication problems, the nodes will isolate that section of wiring. Nodes that cannot

retransmit onto the next node of the network will transmit back to the previous node to

maintain communications and to notify the network of the node status. In the event of

multiple wiring problems, the remaining nodes will effectively "regroup" and establish new,

smaller "sub-networks" that will maintain communications among the active nodes.

ADDRESSABLE FIRE ALARM SYSTEM 283111 - Page 26 of 35

ECO22190-0100D-FD-SPC-15A-EL-02 REV 0

NEW MARS WRIGLEY FACTORY EXPANSION IN EGYPT MEP PACKAGE

B. The network reporting terminal (GUI) shall form part of the fire alarm network, with all

information from the MFACP/FACP relayed to this workstation. Provide one GUI in the

FCC/ control room for monitoring and control of fire alarm system.

C. In addition, the fire alarm system Contractor shall provide the appropriate zoning and

drawings to the BMS/ SCADA Contractor in AutoCAD DWG format for display at the

BMS/ SCADA GUI. The graphics shall indicate the zones to which all monitored points

belong.

1. Alarm messages sent to the BMS/ SCADA shall carry, at minimum, the following

information:

a. Time and date.

b. Type and origin.

c. Description of affected alarm location/zone.

d. Counter-action to be taken.

D. Hierarchical control and monitoring functions of MFACPs, FACPs, and GUIs:

1. MFACP controls and monitors all fire alarm system of the Project.

2. FACP controls and monitors fire alarm system and devices directly connected to it,

and monitors the remainder of Project fire alarm system.

3. FCCs’ GUIs shall have local control and monitoring of all fire alarm system and

points inside the respective building.

4. Control of “Trouble” function shall be possible from the FACP as well.

5. It shall be possible to modify and program any configuration required for the

hierarchical control and monitoring functions of MFACPs, FACPs, and GUIs.

Modifications shall be easily configurable.

E. Network Media: The network shall communicate via wire or fiber optic medium. The

network shall also support the use of both copper wire and fiber optic in the same network

(hybrid network). Contractor to properly select and install either type of cable depending on