0% found this document useful (0 votes)

19 views16 pagesTutorial

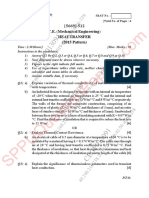

The document contains a series of tutorials on heat transfer processes and equipment, covering conduction, convection, radiation, and heat exchanger design. Each tutorial includes problems with specific parameters and solutions related to heat transfer calculations. Key topics include heat loss through materials, rates of heat transfer in various scenarios, and the design of heat exchangers.

Uploaded by

han.huynh.14.05.2004Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

19 views16 pagesTutorial

The document contains a series of tutorials on heat transfer processes and equipment, covering conduction, convection, radiation, and heat exchanger design. Each tutorial includes problems with specific parameters and solutions related to heat transfer calculations. Key topics include heat loss through materials, rates of heat transfer in various scenarios, and the design of heat exchangers.

Uploaded by

han.huynh.14.05.2004Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 16