0% found this document useful (0 votes)

19 views39 pagesModule 2

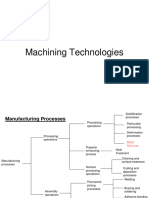

The document provides an overview of machine tool operations, focusing on lathes, drilling machines, and milling machines, detailing their working principles and various operations such as turning, facing, and knurling. It also introduces advanced manufacturing systems, particularly Numerical Control (NC) and Computer Numerical Control (CNC), explaining their components and advantages, including improved accuracy and production volume. The document emphasizes the importance of CNC systems in modern manufacturing for complex shapes and high-volume production.

Uploaded by

sandeepkumar.agmme2022Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

19 views39 pagesModule 2

The document provides an overview of machine tool operations, focusing on lathes, drilling machines, and milling machines, detailing their working principles and various operations such as turning, facing, and knurling. It also introduces advanced manufacturing systems, particularly Numerical Control (NC) and Computer Numerical Control (CNC), explaining their components and advantages, including improved accuracy and production volume. The document emphasizes the importance of CNC systems in modern manufacturing for complex shapes and high-volume production.

Uploaded by

sandeepkumar.agmme2022Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 39