0% found this document useful (0 votes)

7 views29 pagesCHMT 5000A - Solvent Extraction

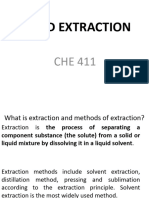

The document provides an overview of solvent extraction, a method for separating two immiscible liquids based on their solubilities, commonly used in various industries for metal recovery and purification processes. It discusses the basic principles, ideal solvents, extraction methods, and important parameters for effective operation. Additionally, it highlights the applications of solvent extraction in fields such as metallurgy, pharmaceuticals, and effluent treatment.

Uploaded by

princenton.samboCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

7 views29 pagesCHMT 5000A - Solvent Extraction

The document provides an overview of solvent extraction, a method for separating two immiscible liquids based on their solubilities, commonly used in various industries for metal recovery and purification processes. It discusses the basic principles, ideal solvents, extraction methods, and important parameters for effective operation. Additionally, it highlights the applications of solvent extraction in fields such as metallurgy, pharmaceuticals, and effluent treatment.

Uploaded by

princenton.samboCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 29