0% found this document useful (0 votes)

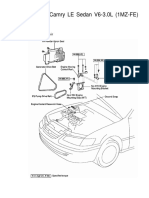

40 views45 pagesEngine Mechanical System - Timing System

The document provides detailed instructions for the removal and installation of various engine components, including timing chain covers, variable force solenoids, and oil pumps. It emphasizes safety precautions, proper torque specifications, and the importance of using new parts during reassembly. Additionally, it includes steps for marking and aligning components to ensure correct installation.

Uploaded by

shaneyoneal1Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

40 views45 pagesEngine Mechanical System - Timing System

The document provides detailed instructions for the removal and installation of various engine components, including timing chain covers, variable force solenoids, and oil pumps. It emphasizes safety precautions, proper torque specifications, and the importance of using new parts during reassembly. Additionally, it includes steps for marking and aligning components to ensure correct installation.

Uploaded by

shaneyoneal1Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 45