0% found this document useful (0 votes)

1K views61 pagesCNC Part Programming

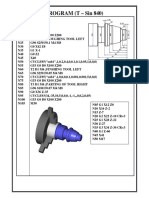

The document describes developing part programs for CNC turning, milling, and verifying on simulation software. It involves:

- Co-developing part programs that control machine tool movement and auxiliary functions to produce a part.

- Using codes for functions like linear interpolation, spindle speed, coolant, and tool changes.

- Inputting the program into the machine control unit which reads, decodes, and implements the coded instructions to generate axis motion and control auxiliary functions.

Uploaded by

rajaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views61 pagesCNC Part Programming

The document describes developing part programs for CNC turning, milling, and verifying on simulation software. It involves:

- Co-developing part programs that control machine tool movement and auxiliary functions to produce a part.

- Using codes for functions like linear interpolation, spindle speed, coolant, and tool changes.

- Inputting the program into the machine control unit which reads, decodes, and implements the coded instructions to generate axis motion and control auxiliary functions.

Uploaded by

rajaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

/ 61