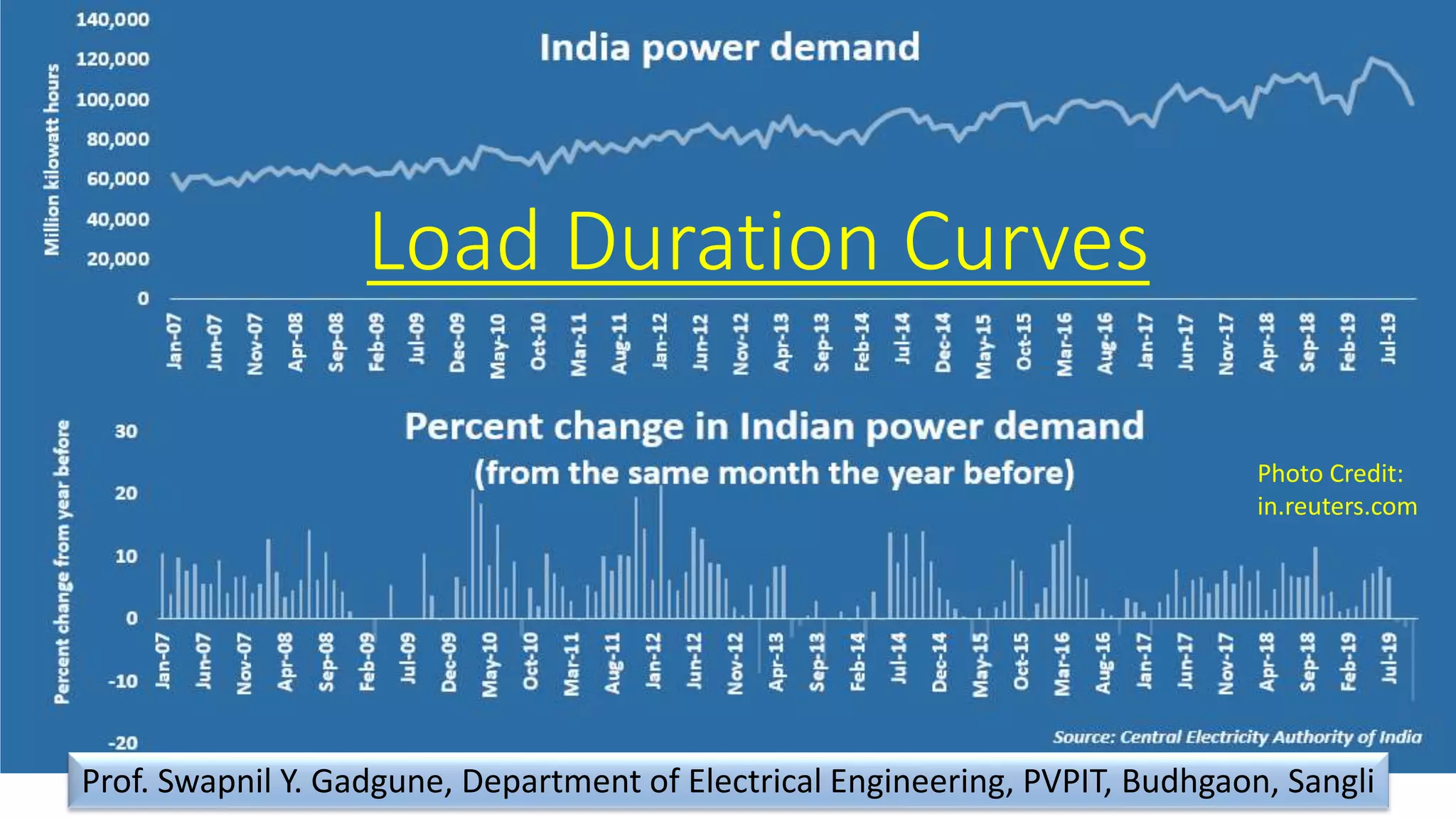

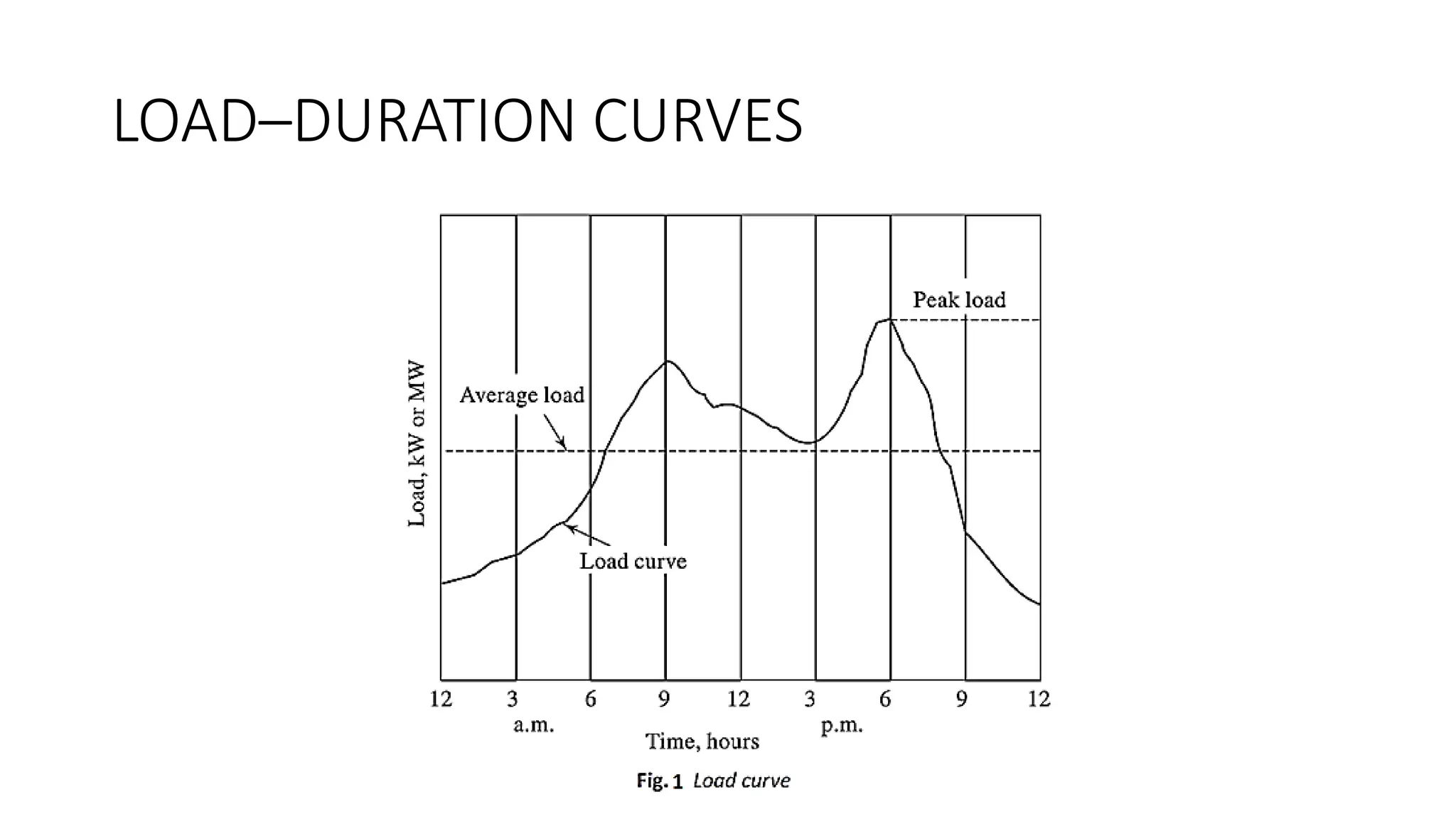

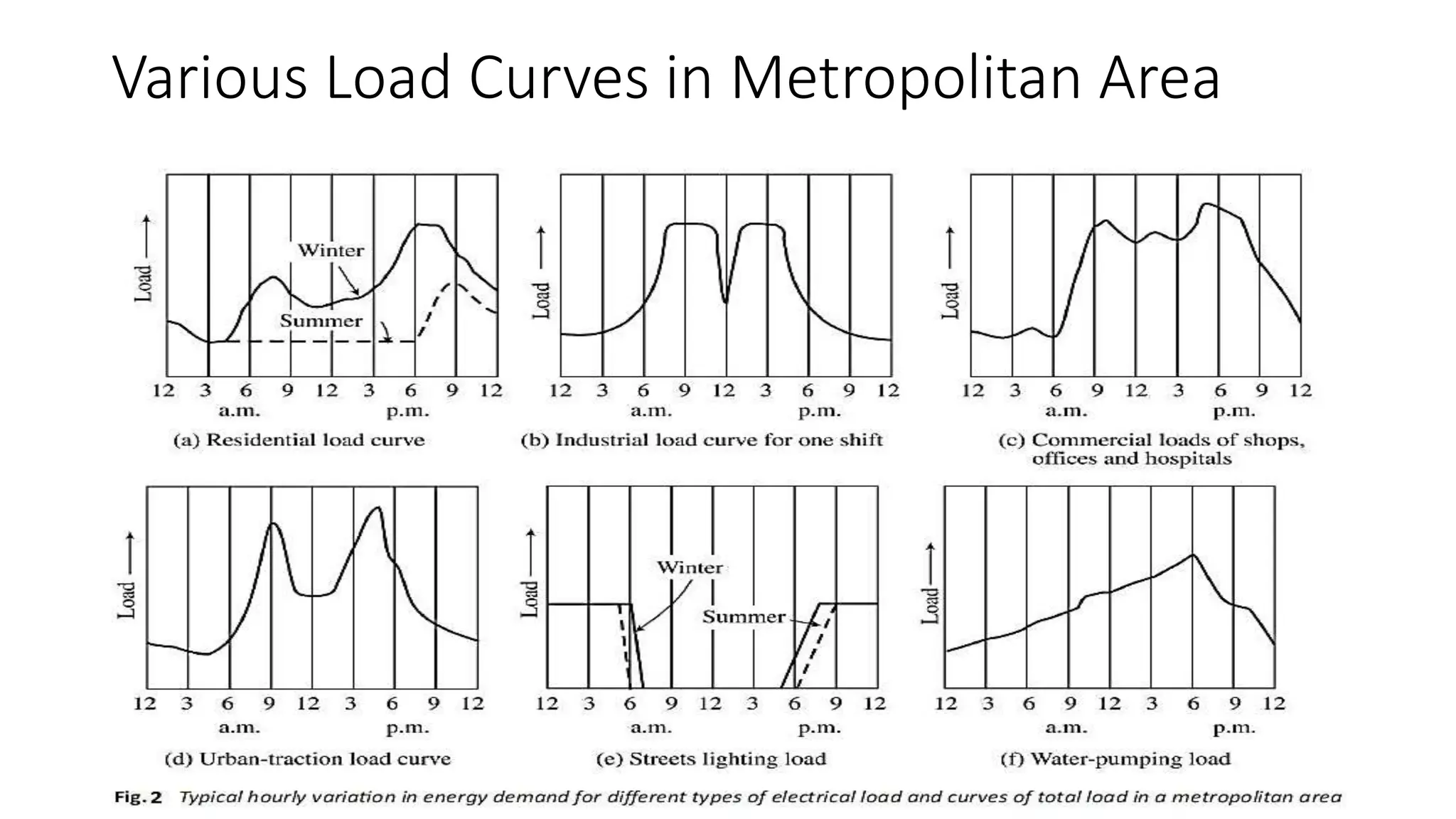

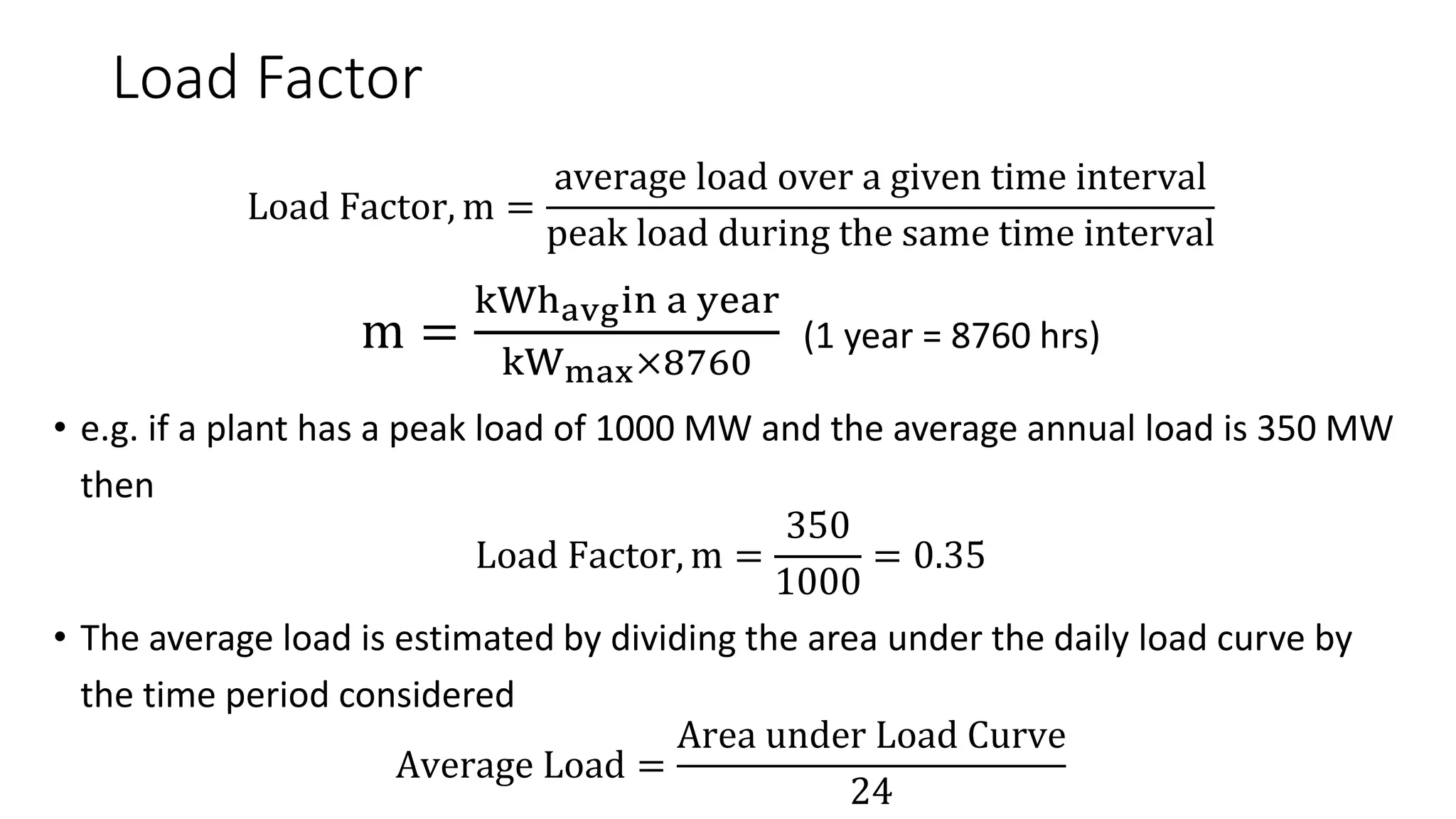

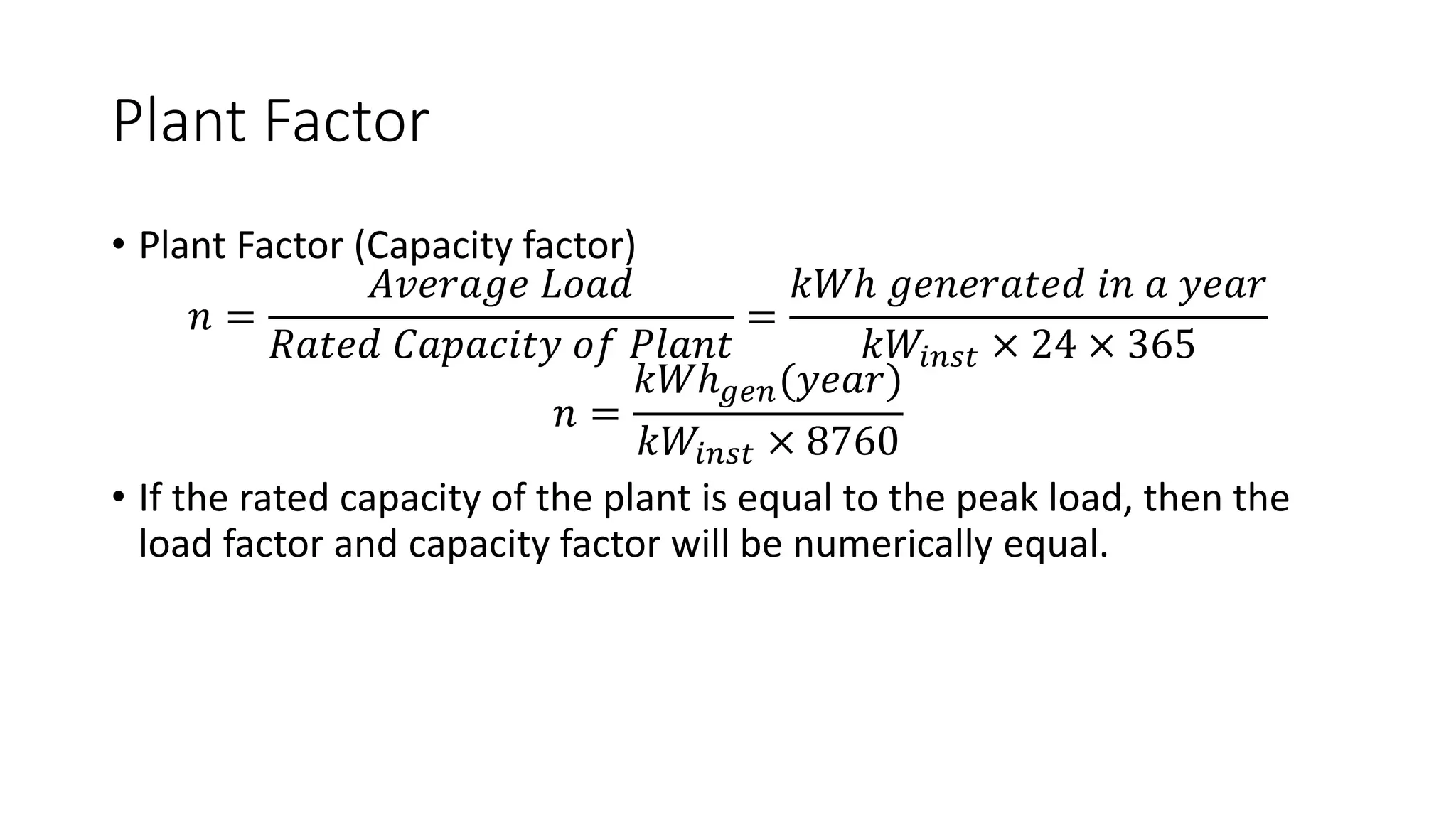

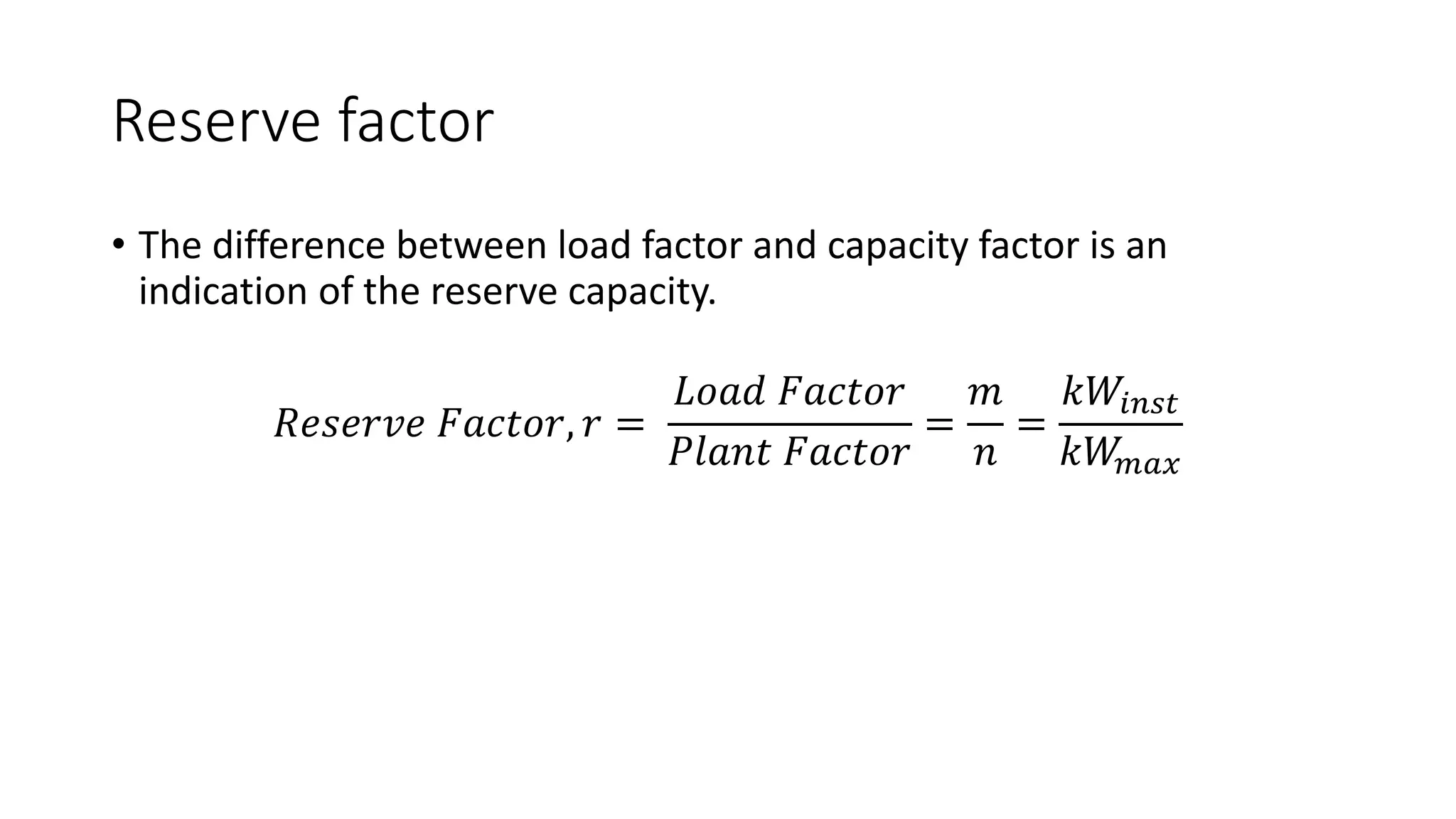

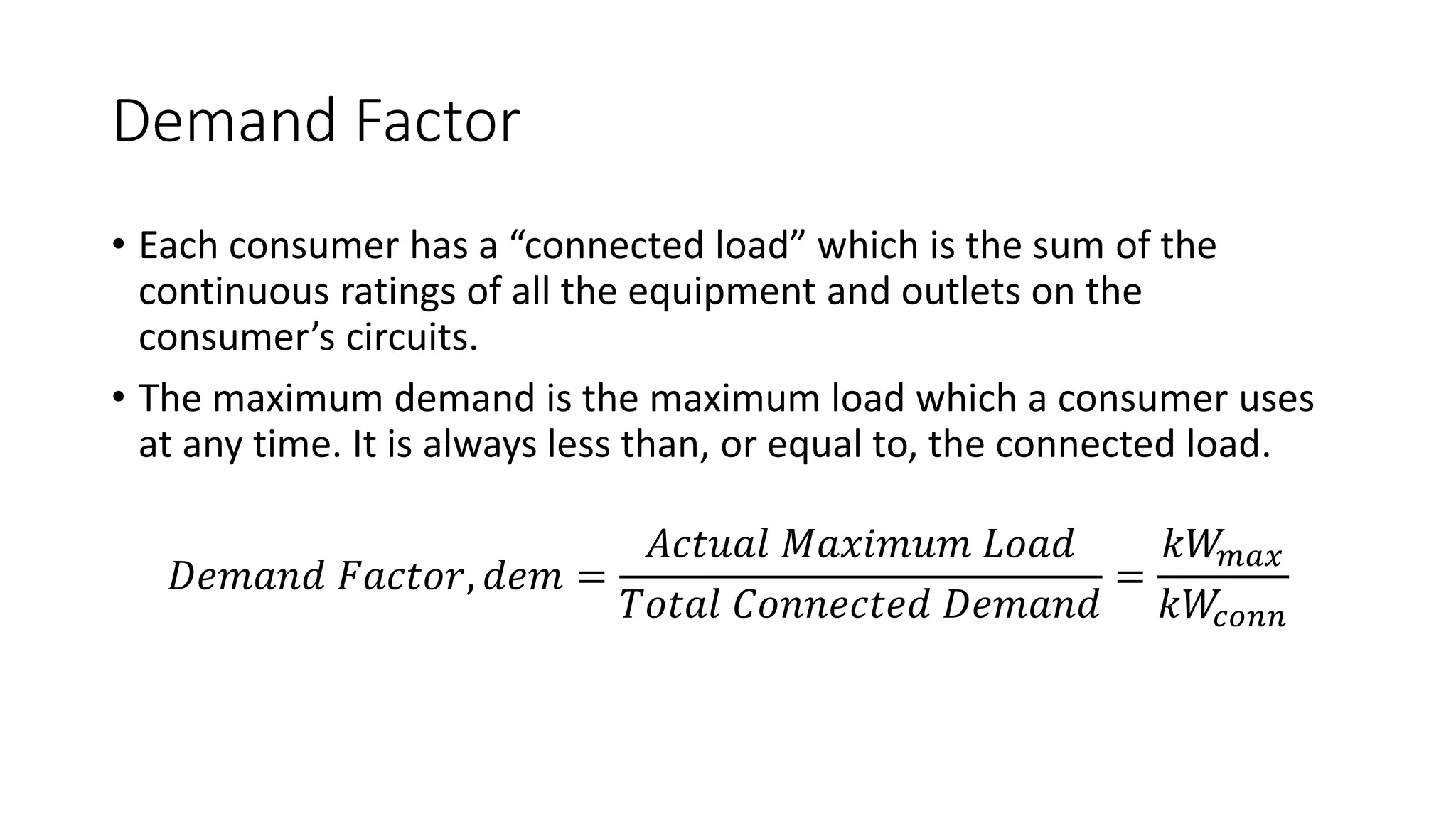

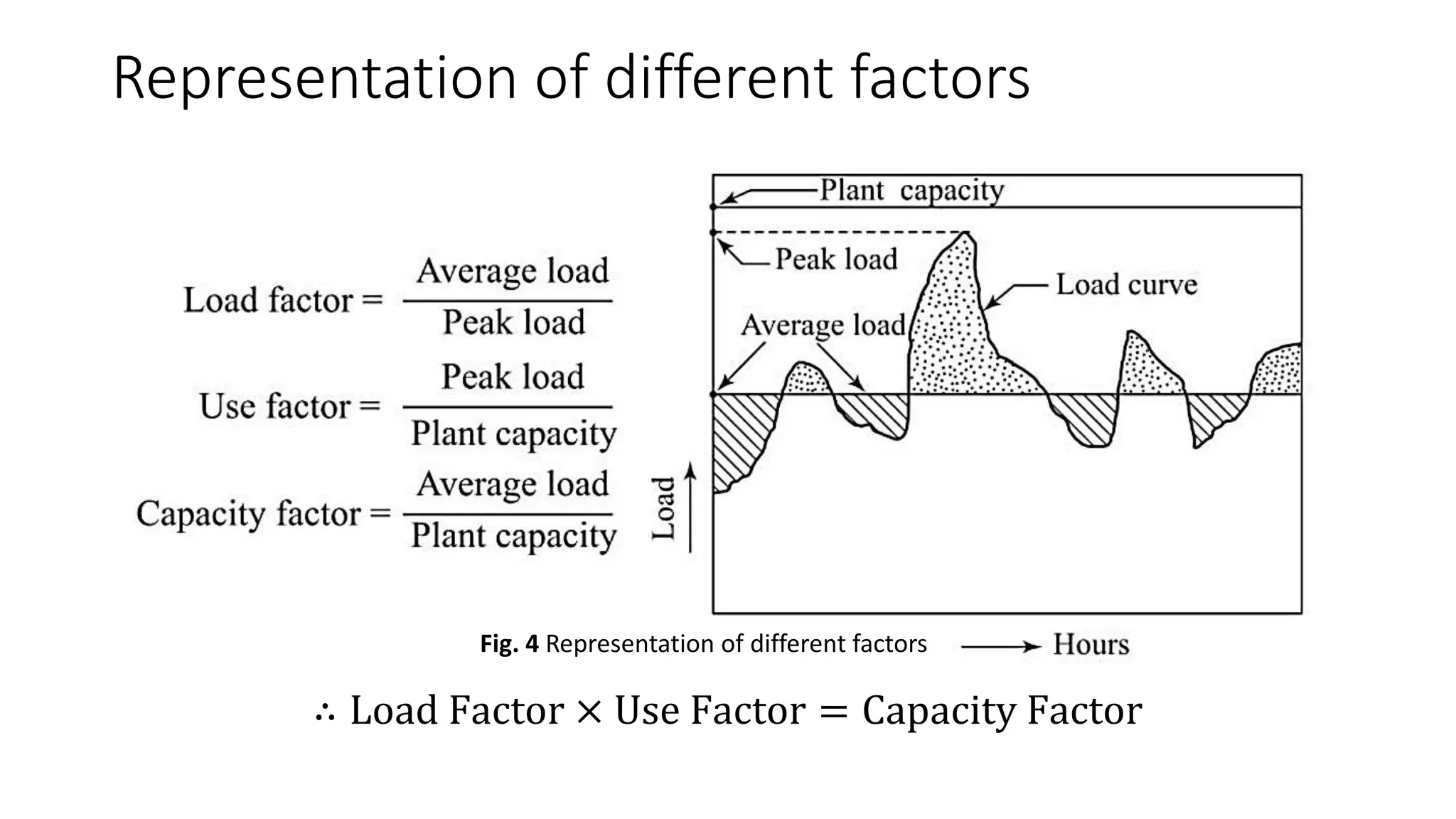

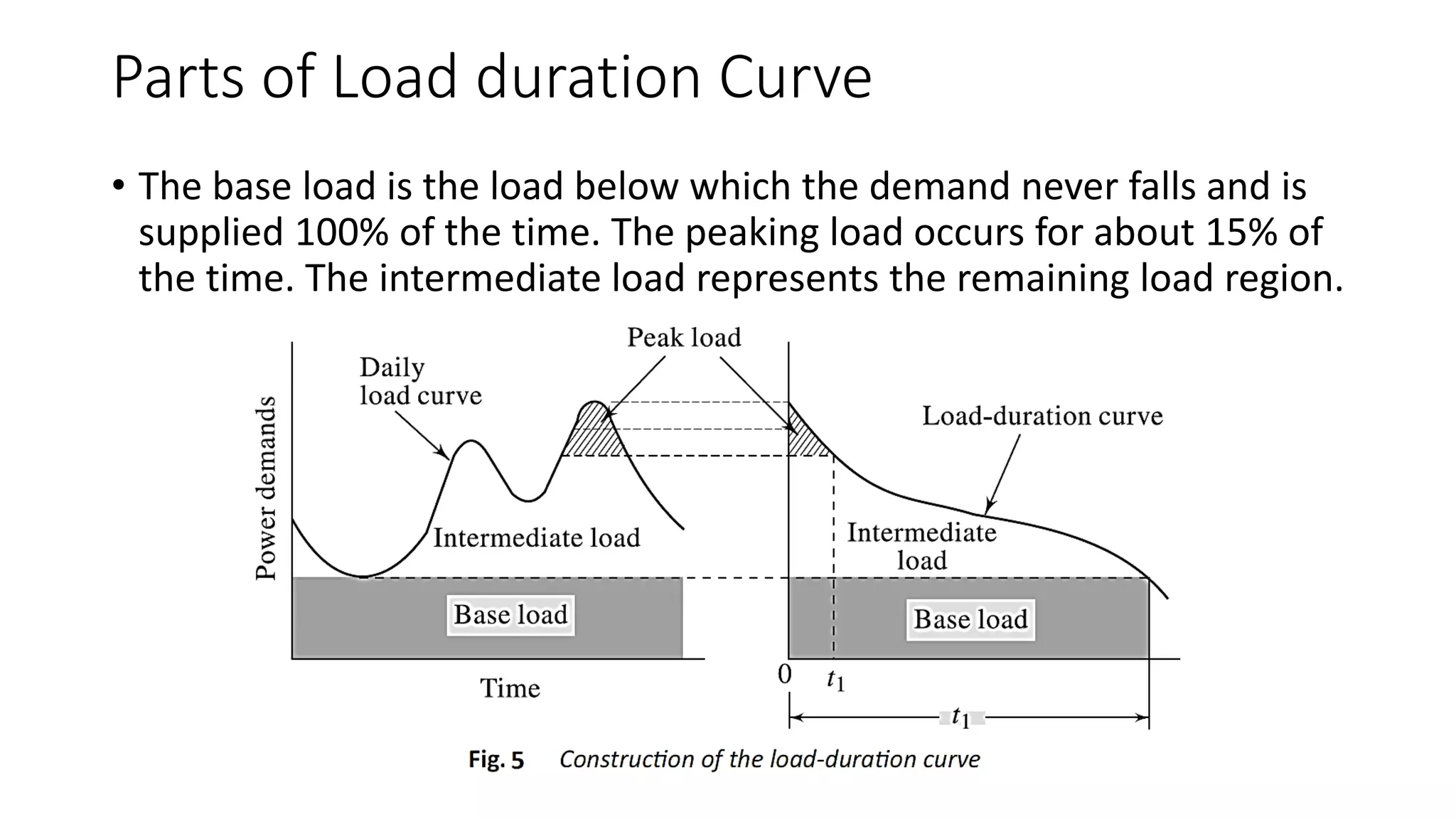

Load duration curves show how load demand for electricity varies over time, such as daily or monthly. They are useful for predicting future energy needs and determining the appropriate capacity and size of generating units for a power plant. When planning a power plant, its total installed capacity and size of generating units must be decided based on the expected maximum load and factors like load factor, capacity factor, reserve factor, demand factor, and diversity factor, which all influence the economic operation of the plant. The load duration curve is divided into base, intermediate, and peaking loads, and different types of generating plants are suited for meeting each type of load demand.