0% found this document useful (0 votes)

179 views16 pagesElectronics DIY Guide

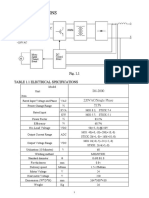

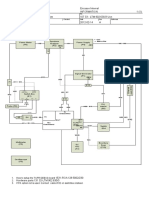

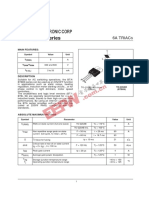

This document provides instructions for constructing electronic circuits by soldering components to a printed circuit board (PCB). It describes how to solder common electronic components like resistors, capacitors, diodes, transistors, regulators, and switches. The introduction explains that building circuits requires knowing what components to use and where to place them on the PCB. Readers are advised to check which chapters are relevant for their specific circuit kit before soldering. Proper soldering equipment is also listed.

Uploaded by

EbrahemAlatfeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

179 views16 pagesElectronics DIY Guide

This document provides instructions for constructing electronic circuits by soldering components to a printed circuit board (PCB). It describes how to solder common electronic components like resistors, capacitors, diodes, transistors, regulators, and switches. The introduction explains that building circuits requires knowing what components to use and where to place them on the PCB. Readers are advised to check which chapters are relevant for their specific circuit kit before soldering. Proper soldering equipment is also listed.

Uploaded by

EbrahemAlatfeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 16