0% found this document useful (0 votes)

297 views7 pagesKnock Module Manual & Calibration Guide

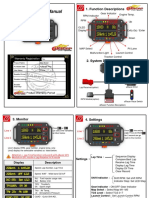

1. The document provides instructions for installing and configuring an aRacer knock module and sensor. It includes diagrams of wiring configurations and sensor mounting locations.

2. The knock module detects engine knocking and sends a digital signal to the aRacer Sport D display or RC Super2 ECU. The ECU can then retard ignition timing to protect the engine when knocking is detected.

3. The document provides details on setting calibration parameters like cylinder bore size, knock gain level, detection threshold, and ignition retard amount and timing. Examples are given of successful knock detection and situations where detection is difficult.

Uploaded by

Zaita FregaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

297 views7 pagesKnock Module Manual & Calibration Guide

1. The document provides instructions for installing and configuring an aRacer knock module and sensor. It includes diagrams of wiring configurations and sensor mounting locations.

2. The knock module detects engine knocking and sends a digital signal to the aRacer Sport D display or RC Super2 ECU. The ECU can then retard ignition timing to protect the engine when knocking is detected.

3. The document provides details on setting calibration parameters like cylinder bore size, knock gain level, detection threshold, and ignition retard amount and timing. Examples are given of successful knock detection and situations where detection is difficult.

Uploaded by

Zaita FregaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 7