0% found this document useful (0 votes)

601 views13 pagesSample Foundation Design

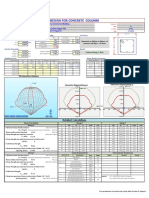

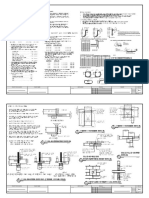

This document provides design details for the footing of a column. It includes:

1. Material properties and design parameters for the concrete footing including minimum cover thickness and reinforcement size.

2. Calculations of loads on the footing from self-weight of concrete and soil, and bearing capacity of the soil.

3. Determination of the footing size and depth to satisfy requirements for bending moment, shear, and punching shear.

4. Reinforcement calculations to resist bending moments at the face of the column in both x and y directions based on design code requirements.

Uploaded by

Dino AbdelaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

601 views13 pagesSample Foundation Design

This document provides design details for the footing of a column. It includes:

1. Material properties and design parameters for the concrete footing including minimum cover thickness and reinforcement size.

2. Calculations of loads on the footing from self-weight of concrete and soil, and bearing capacity of the soil.

3. Determination of the footing size and depth to satisfy requirements for bending moment, shear, and punching shear.

4. Reinforcement calculations to resist bending moments at the face of the column in both x and y directions based on design code requirements.

Uploaded by

Dino AbdelaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 13