0% found this document useful (0 votes)

561 views38 pagesSAP PM Module Equipment Checklist

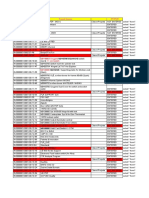

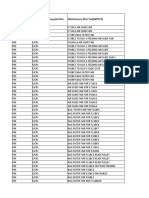

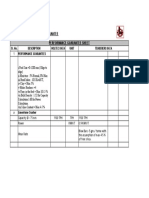

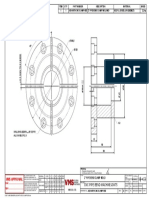

This document provides an equipment list and task list for the SAP PM module. The equipment list includes 4 sections of a plant with equipment descriptions and tag numbers. The task list includes sub-equipment, type of tasks, and tasks to be performed with frequency for items like a conveyor belt drive system. Tasks include checking bearings, dampers, gears and performing lubrication. Frequency of tasks ranges from daily to yearly.

Uploaded by

Durga PrasadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

561 views38 pagesSAP PM Module Equipment Checklist

This document provides an equipment list and task list for the SAP PM module. The equipment list includes 4 sections of a plant with equipment descriptions and tag numbers. The task list includes sub-equipment, type of tasks, and tasks to be performed with frequency for items like a conveyor belt drive system. Tasks include checking bearings, dampers, gears and performing lubrication. Frequency of tasks ranges from daily to yearly.

Uploaded by

Durga PrasadCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 38