100% found this document useful (1 vote)

200 views4 pagesEngineering Formulas

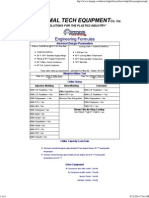

This document provides nominal design parameters and formulas for engineering systems including chillers, cooling towers, and piping. It lists typical flow rates for chillers as 2.4 GPM per ton at a 10 degree temperature differential. Cooling towers are rated at 15,000 BTU/hour per ton. Formulas are provided to calculate chiller and cooling tower capacity in tons based on flow rates and temperature differentials. Metric conversions and abbreviations used in engineering are also defined.

Uploaded by

Saleem BashaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

200 views4 pagesEngineering Formulas

This document provides nominal design parameters and formulas for engineering systems including chillers, cooling towers, and piping. It lists typical flow rates for chillers as 2.4 GPM per ton at a 10 degree temperature differential. Cooling towers are rated at 15,000 BTU/hour per ton. Formulas are provided to calculate chiller and cooling tower capacity in tons based on flow rates and temperature differentials. Metric conversions and abbreviations used in engineering are also defined.

Uploaded by

Saleem BashaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

/ 4