DynoLog Manual

Uploaded by

Jordy CinqvalDynoLog Manual

Uploaded by

Jordy CinqvalMainline

Index

Section 1 – DynoLog Main Screen – page 3

Section 2 – Setting Up the Dyno for New and

Existing Customers – page 15

Section 3 – Performing and Saving Ramp

Tests – page 25

Section 4 – Analysing Data, the Analyse

Screen – page 35

Section 5 – Printing Reports – page 49

Section 6 – Channel Properties – page 55

© Mainline DynoLog Dynamometers 2

Section 1

DynoLog Main Screen (Front Screen)

The DynoLog Main Screen or Front Screen (as some users are

accustomed to calling it), is used to “Statically” hold vehicles at the user

defined Hold Point in KPH anywhere between 0 and 200KPH. (240KPH on

some models).

The primary function for the Main or Front Screen would be for Tuning

Programmable Engine Management Systems at various load points. By

using the Hold Point for an RPM reference point, the operator simply

uses whatever throttle application they need to create the required load.

The Hold Point is varied Up or Down using any of the following 3 methods:

Method 1.

Page Up – moves set point higher at a very slow rate

Page Down – moves set point lower at a very slow rate

Using just Page Up or Page Down provides precise speed control, much more

accurate than using a rotary knob.

Method 2.

Shift + Page Up – moves set point higher at a moderate rate

Shift + Page Down - moves set point lower at a moderate rate

Using Shift + Page Up or Down could be used when moving from one Load

Point to the next when tuning Aftermarket Engine Management Systems

(Motec, Autronic etc.)

© Mainline DynoLog Dynamometers 3

Method 3.

Ctrl + Shift + Page Up – moves set point higher at the fastest system rate

(5kph per increment)

Ctrl + Shift + Page Down – moves set point lower at the fastest system

rate (5kph per increment)

This method is used to rapidly move from one set point to another.

The above 3 methods where derived with the intent for the operator to

have the mini keyboard controller resting on their lap, thus providing

ergonomic use for all keyboard controls.

© Mainline DynoLog Dynamometers 4

DynoLog Main Screen

ALL Dyno Controls can be controlled with the Keyboard; there is no

secondary hand controller. The advantage to the user because of this is the

ability to not have to leave the vehicle after any vehicle testing has been

performed.

Customising Speed,Torque and Power Dials

The operator has the option to customise the Speed, Torque and Power dials

such as the Speed Scale, the Torque Scale and Power Scale. All 3 Dials have

2 modes of operation:

• Fixed user defined Scaling, or

• Auto scale feature

© Mainline DynoLog Dynamometers 5

To customise any of these 3 Dials, Right Click on any Dial and the following

Pop-Up Screen will appear:

To change between the 3 different dials, simply click either the Speed

Meter, Torque Meter or Power Meter check buttons at the top of the

window, and the relevant options for that dial will appear. In the above

example, you can see the option of defining the speed scale to have a

maximum of 100, 120, 140, 160, 180 or 200KPH. Other options that are

available are Coloured Odometers, Bold Numbers, Show Max Odometers

and Auto scale Speed. If Auto scale Speed is selected, the speed scale will

drop to the lowest scale (0-20 kph), once the Dyno speed goes past 20kph

the scale will Automatically jump to the next scale, 0-40kph, and so on if the

Dyno speed keeps increasing. When the vehicle has come to a stop, the dial

will automatically revert back to 0-20kph.

The same principle applies for the Torque and Power Dials, but instead of

Speed, obviously the units will be Torque and Power. The only main

© Mainline DynoLog Dynamometers 6

difference on these Dials between a 2WD and AWD system is the option on

an AWD system to display either Total Torque or Front/Rear/Total Torque.

If the latter is chosen, 3 Torque needles will appear on the Torque Dial, one

thin Aqua coloured needle representing Front Torque, one thin Dark Green

needle representing Rear Torque, and one normal light green needle

representing Total Torque. There will also be a live Torque Split Percentage

(relationship between Front/Rear Torque) shown at the top of the Torque

Dial. The following screen shows this option selected:

There is also the option of changing the colours of Background, Needles etc.

If you have changed any of the colours of the Dial setup, there is a Default

Colours button so you can put the screen colours back to how they should be!

You will also notice the Channel Properties button on this window, it is

sometimes necessary to use the Channel Properties function to change such

things as Power unit from kW to HP or Torque unit from Nm to Ft/Lbs.

A complete explanation of the Channel Properties function will be covered

later in this text.

© Mainline DynoLog Dynamometers 7

Main Screen Dyno Controls

Vehicle Fan and Dyno Fans

To Manually activate either the Vehicle Cooling Fan or the Dyno Bed Cooling

fan, simply press “V” for Vehicle Fan or “D” for Dyno Fan. These 2 fans can

also be activated Automatically by the Dyno Software, to set these options,

Right Click on either the Vehicle Fan or Dyno Fan buttons on the screen and

the following option screen appears:

Automatic Fan Control Setup Screen

By choosing as in the example Fan On at: 20KPH and OFF Delay: 30 sec, the

following will happen:

When the Dyno Road Speed reaches 20KPH the Vehicle Fan will turn ON,

when the road speed declines to under 20KPH the Fan will continue to

operate for 30 seconds. If the same On Speed is selected for both Vehicle

Fan and Dyno Fan, the software will “Stage” the fans to prevent a sudden

electrical surge that may happen if they were to activate together.

© Mainline DynoLog Dynamometers 8

Automatic Fan Control is a Standard Feature of the Dynolog Software, if

for some reason you come across it not enabled on your system, please

contact Mainline to guide you through the enabling sequence.

Reset Max

By pressing “R” on the Keyboard resets the red Maximum Telltales that

appear on the Speed, Power and Torque Dials. The Tellatales are useful for

the following example:

A vehicle is held at Full Throttle at 100kph in whatever gear, a change is

made by the tuner to the Ignition Timing expecting an increase in Power and

Torque, the vehicle is then again held at 100kph, if the Power and Torque has

increased the maximum telltales will have moved higher.

A Digital indication is also displayed that corresponds to the telltales in the

bottom left hand corner of both the Power and Torque Dials, the Road

Speed at which point the Maximum was produced is shown in the bottom

right hand corner of the Power and Torque Dials. These Digital indications

are referred to as the Odometers.

Digital Meters

At the Top Right of the Main Screen are the Digital Meters. The Digital

Meters are there for the operator to personalize their system to enable

them to quickly view any of the Dyno Channels that their system has.

To change between different Digital Meter groups, the operator simply

presses any number on the keyboard from 1 to 0, ten more groups are

available by pressing Shift + 1 to 0, but in practice, numbers 1 to 9 are

normally all that is need to view any Dyno Channel. The numbers 1 to 9 would

give the operator the ability to view 45 Dyno Channels. By default, page 8 is

always the Weather Station inputs Ambient Temperature, Relative Humidity

and Barometric Pressure, it also has the Calculated Correction % on this

page.

© Mainline DynoLog Dynamometers 9

To Setup any of the Digital Meter groups, Right Click on any of the current

5 Data Channels Boxes that are displayed in the Digital Meters area and the

following Pop-Up window will appear:

Firstly, select which numbered Digital Group page you wish to modify, do

this by scrolling up or down through the available pages at the top of the

window. Once a particular page has been selected, you then have the option

of Naming that page such Atmos for the Weather Station Channels, or

EGT’s for a Group of Exhaust Gas Temperature probes. New dyno systems

come setup up with some pages already defined, but these can be modified

by the user.

To do this, simply Left Click, Hold and Drag a Dyno Channel from the list and

Drop it into any of the 5 available Digital Meter boxes for the page you wish

to setup. Again, you will notice that the Channel Properties function button is

available, should you wish to alter any Channel Property.

© Mainline DynoLog Dynamometers 10

Changing Dyno Control Mode (AWD Models only)

The Mainline DynoLog AWD Dyno has different modes of control

depending on what type of vehicle is being tested. The 3 different variations

of control are RWD (rear rollers only), FWD (front rollers only) or AWD

(Free/ Limited/ Locked Differential).

To set or change the dyno control mode, from the main screen, Right Click on

the Button at the lower centre of the screen that has whatever the current

dyno control mode indicated, this will make Dyno Control Setup window to

popup as follows:

© Mainline DynoLog Dynamometers 11

The Dyno Control Mode can also be set by using the shortcut CTRL +D from

the Main Screen, or alternatively by using the menu string

Setup – Vehicle/Dyno – Dyno Setup as indicated as follows:

If for example a

Front Wheel Drive

vehicle is operated

on the dyno whilst

the Dyno Setup is

set to RWD, a large

visible on screen

warning is displayed

to alert the

operator that there

is something not

right, this is

indicated as follows:

© Mainline DynoLog Dynamometers 12

When the Dyno Control Mode pop-up window is visible, notice there is a Tab

on this pop-up with the tag 4WD Errors. When this Tab is selected, the

operator has the choice of setting certain warnings relating to differences

in front to back dyno bed wheel speed errors. On some AWD vehicles, it can

be quite normal for either the Front or Rear wheel speed to be different

until the wheel speed gets up to the Dyno Set Point, once the wheel speed

has reached whatever the current dyno set point is, the dyno will accurately

keep both front and rear wheel speeds the same ensuring safe operation of

the test vehicle.

The operator has several choices of how sensitive the wheel speed error

settings can be, these are shown as follows:

On this Tab the operator

chooses from No Warnings, or

any setting from +/- 1% to

20%.

The on screen warning

when one dyno bed speed

has reached an error

threshold is as follows:

© Mainline DynoLog Dynamometers 13

Dyno Correction Factor

The Mainline DynoLog Dynamometer always displays the current

Atmospheric Correction Percentage AND chosen Correction Factor. This is a

fully automatic function and is continuously being updated as the

Environmental Conditions change during the day. The Atmospheric

Correction is calculated from Ambient Temperature, Relative Humidity and

Barometric Pressure, the Intake Air Temperature is not used as an Input

for calculating Atmospheric Correction like some other Dyno Manufacturers,

as we prefer the operator to not be able to influence power readings. If the

Intake Air Temp is used for calculating Atmos Correction, unrealistic

compensation would be applied, factors in the range of 15-20% are not

uncommon on another brand. The Mainline DynoLog has an inbuilt Atmos

Correction Limit of 10%, and in normal real world conditions this limit would

never be reached.

The Atmospheric Correction Standard is set at our factory after

consultation with the customer, as different correction standards are used

in different areas of the world, ie. Europe, Asia or USA etc.

As stated earlier in this manual, the Live Weather Station readings are

available by pressing the number 8 on the keyboard to show these readings

in Digital Meter page 8.

The Atmospheric

Correction is

indicated as

follows:

© Mainline DynoLog Dynamometers 14

Section 2

Setting Up the Dyno for New and Existing Vehicles

One of the first questions a new dyno owner asks is how to setup the dyno

for a new vehicle. The following procedure outlines this process so the

operator can successfully setup the dyno for a previously untested vehicle.

In practice, as the operator becomes more comfortable with the software,

the second option that will be outlined later will be the more often used.

Entering a new vehicle, previously untested.

To setup a new vehicle, from the Main Dyno screen, use the keyboard

shortcut CTRL+E (Edit New Test Header) and the following prompt will

appear for the operator: (or alternatively use the menu string: Setup – Edit

New Test Header)

Choose Yes

at this prompt

© Mainline DynoLog Dynamometers 15

At this point the operator should choose YES, and the following pop-up

window will appear that is called the Test Header:

Firstly, change the Test ID from Baseline Test to something that is

applicable to the tests that you will be performing.

Secondly, and more importantly, click on the Set Path for Data Files

tab and set the data path applicable for the vehicle being tested, as in the

following example a Holden Rodeo V6 would be saved in the data path

C:\dynolog\holden\v6\rodeo.

© Mainline DynoLog Dynamometers 16

This window shows an example

of setting the correct data

path for the vehicle being

tested

Additional Data Folders can be created by the operator to further refine

their data management, ie. An additional folder could be added to the above

example for particular year models, so the complete data path could be:

C:\dynolog\holden\v6\rodeo\2001

The other recommended action on the Test Tab would be to make sure the

checkbox that states “Copy New Test Comments to Default Header” is

unchecked.

Once finished with setting Data Path and Test Id, then click on the Vehicle

Tab to enter some vehicle details, the Vehicle tab looks as in the following

example on the next page:

© Mainline DynoLog Dynamometers 17

There are 2 required fields on the Vehicle Tab, these are the Description

Field and the Reg No: Field. These are required as they are search fields

that are available when using the Find Run function that will be outlined later

in this manual.

All of the other fields are optional and are up to the operator to fill in or

not, but the more information entered the more professional the Customer

Report will be when one is printed out as most of the Information on the

Vehicle Tab is printed out on Customer Reports.

© Mainline DynoLog Dynamometers 18

The number of cylinders can easily be changed by clicking the adjoining

Up/Down arrows. The options available for Number of Cylinders range from 1

to 8 Cyl, and then 1 to 4 Rotors.

To set the firing order, click on the Firing Order button and some preset

Firing Orders are available to choose from, if a firing order is not listed,

click, drag and drop the cylinder numbers into the correct firing order on

the pop-up window. The Firing Order pop-up window is as follows:

© Mainline DynoLog Dynamometers 19

The last tab on the Test Header is the Customer Tab. All fields on the

Customer Tab are optional, but, it is recommended to at least insert a

Customer Name, the advantage of this is that it also can be used as a search

field in the Find Run function that will be outlined later in this manual.

The Customer Tab is as follows:

© Mainline DynoLog Dynamometers 20

Select Test Header

The second option for setting up the dyno with Customer/Vehicle

information is to use the Select Test Header function. Once the dyno

operator has gathered a small base of previous runs from differing vehicles,

this option becomes much more beneficial, because it speeds up the process

of inputting information.

To use the Select Test Header function, from the Main Dyno Screen, use

the keyboard shortcut CTRL + T, or use the menu string Setup – Select

Test Header.

Once the CTRL + T shortcut is used, the following Pop-Up screen will appear:

To select a previous run to use as a base for testing the same vehicle, or, a

similar vehicle, work your way thru the folders in the Dynolog folder

(directory) until the folder with the run that you would like to use as a base

is current. Then select that run, (make sure the option Clear Runs and load

© Mainline DynoLog Dynamometers 21

as Reference checkbox is checked), next click on the Select Button first

and then click on the Save Button second.

Also on the Select Test Header window is the Find Run Button at the

bottom right, clicking on this button opens up the following window:

Use the Find Run function to find any previous saved run, there are 6

choices to use as Search fields - Test ID, Customer, Rego, Engine,

Comments and Run #.

In the above example, the Customer name was used as a search criteria, in

the folder c:\dynolog\holden, the top test was selected and the Use Folder

button was selected. This sequence sets up the Select Test Header window

to be at the desired Folder where the desired run will be to choose from

once the OK button is pressed.

Using a previous Test Header has numerous advantages, it obviously has

Customer and Vehicle details saved, this saves the operator from having to

re-enter these details, but what it also does which is setup the Ramp Test

© Mainline DynoLog Dynamometers 22

screen with all test parameters exactly as they were when the vehicle was

previously tested. Items such as the Ramp Pre-Start Speed, Ramp Start

Speed, Ramp Finish Speed, Ramp End Speed are all saved and will be

automatically reset to the previous Test.

Other parameters such as Ramp Rate is also set, as well as the Power Scale

and AFR Scale. The advantages of using the Select Test Header function

can now be seen.

Another way to use the Select Test Header function is to use it when a

similar vehicle is to be tested to one that has been previously tested, in this

case the Test Header is selected as it has all the test conditions set for the

similar vehicle. The recommended next step is to proceed to the Ramp Test

Screen (F2 from Main Screen, or menu string Test – Ramp/Step Test) and

click on the Header Button as shown below:

When the Header button is pressed the Test Header that has been selected

will pop-up with all of the details of the previously chosen vehicle. At this

point, Edit any details that need to be changed such as Test ID, Data Path,

© Mainline DynoLog Dynamometers 23

Vehicle Details and Customer Details and these new details will then be

saved with the first run that is performed on the new vehicle, saving the

operator a lot of time that would normally done in setup.

At this point,

edit any of

the

necessary

details that

need tobe

changed for

the new

vehicle

© Mainline DynoLog Dynamometers 24

Section 3

Performing and Saving Ramp Tests

One of the most common tasks performed on any dyno are Ramp Tests (or

Pulls in some countries). A Ramp Test is predominately a Test performed at

Wide Open Throttle, starting from a pre-defined Start point (Road Speed

Related) and continuing until the operator chooses to finish the Test. The 2

most common parameters analysed are Power and AFR, this enables the

operator to see how rich or lean the vehicle is under full power and if some

change needs to be performed.

Although in the Ramp Test Screen only Power and AFR are shown, every

Dyno Channel that is installed on the system are logged, so any parameter

can be Analysed after the Test by selecting the Analyse button once a Ramp

Test has been performed and saved.

Performing a Ramp Test

Follow this procedure to quickly Setup and perform Ramp Tests:

1. From Main Screen, press F2, or use the menu string Test –

Ramp/Step Test to enter the Ramp Test Screen. The Ramp Test

screen looks as follows:

© Mainline DynoLog Dynamometers 25

2. Click on the Header button and confirm all of the information in the

Test ID, Vehicle and Customer is correct, and if necessary make any

relevant changes, one of the main things to remember is make sure

the Data Path is correct, this determines that the Ramp Tests that

are performed will be saved in the correct directory, making them

easy to retrieve at a later date for Analysing etc.

3. Click on the Setup button, and the following Screen will Pop Up:

© Mainline DynoLog Dynamometers 26

The Ramp Setup screen can look quite daunting to the new operator, but

all it is really asking is, define a Pre-Start Speed, a Start Speed, an End

Speed and the Ramp Rate at which the operator wishes to perform the test.

The Pre-Start speed is the point at which the vehicle will be held at before

the Ramp Test is started (normally at this point the vehicle would be at

WOT).

The Start Speed is where the Data will start to be plotted on the screen.

The End Speed is where the Dyno software will end the test, please note

that the operator can end the test at any time before this point by merely

tapping the Space Bar on the Keyboard, or an option exists where the Ramp

Test can be ended by a pre-defined RPM limit. In any one of the 3 available

test end methods, the dyno will de-accelerate the vehicle down to the Finish

Speed, even if the operator still has the vehicle at WOT, this is done as a

safety feature to ensure at no time is the Dyno Load just released.

The Ramp Rate is the Acceleration Rate that the vehicle will be allowed to

Ramp (accelerate) at. The Software has Ramp Rates available from 1kph/sec

to 30kph/sec, basically, the more Powerful the vehicle is, the faster Ramp

Rate can be used, typically for vehicles that are seen by the average

workshop, ramp rates of between 5kph/sec and 10kph/sec are used. As a

guide, if a too fast a ramp rate is used, the Power figure obtained during a

Ramp test will be lower than what it would be at a slower rate, by the same

token, if a too slow ramp rate is used, the operator may experience traction

problems on very high powered vehicles.

The Ramp Down rate should be left at what the dyno was delivered with

(normally 10kph/sec).

Once the above Parameters are set, a Total Time is displayed to alert the

operator of how long the Ramp Test will take, and the Ramp Test is now

ready to be performed. Click on the OK button to exit the Ramp Setup

screen to return to the Ramp Test screen.

4. Setup the Power Scale. Whilst on the Ramp Setup window, click on the

Display Scales button and set a Power scale for the vehicle under test. If

the vehicle is an unknown quantity as far as power is concerned, choose a

scale that is at least 50-100KW/HP more than you would be expecting. You

© Mainline DynoLog Dynamometers 27

will notice an option on the Display Scales window that says “Autoscale after

each test run”, if this check box is selected, the dyno software will

automatically adjust the scales to suit the data displayed after a Ramp Test

has been performed.

5. To Start a Ramp test, click on the green BEGIN Button, or press the

Space Bar on the Keyboard, and the following pop-up screen will appear:

In the above example, the Pre-Start Speed is 40kph, the operator drives

the vehicle up to 40kph and then applies Full Throttle (this can feel quite

strange to new dyno operators), once Full Throttle is attained, click on the

OK button, or just tap the Space Bar on the Keyboard again and the vehicle

will start to ramp up to the End Speed, remembering that the data will not

be seen until the Start Speed has been reached, which in the above example

is 45kph. The above example has an End Speed of 145kph, if the vehicle can

safely reach 145kph in the gear chosen, then allow the test to go all the way

up to 145kph, if however the vehicle cannot reach the defined End Speed

© Mainline DynoLog Dynamometers 28

without over revving the engine, just tap the Keyboard Space Bar once the

Power trace on the screen has levelled out or has just “fallen over”.

Some Mainline DynoLog models have a maximum of road speed 200kph,

whilst newer versions have a maximum 240kph.

The 2 following screens show what happens during a Ramp Test and also what

happens at the finish of the test

This screen

shows the live

Power trace and

also a live Air

Fuel Ratio trace,

notice the blue

Indicator Bar

showing “Ramping

UP to 145KPH”.

© Mainline DynoLog Dynamometers 29

This screen

shows the

completed Power

and Air Fuel

Ratio traces, it

also shows the

Maximum KW/HP

and indicates at

what road speed

the maximum

power was

attained, if a

Tacho lead was

connected to the

test vehicle, the

maximum power will be shown at what RPM that it was reached, rather than

Road Speed.

© Mainline DynoLog Dynamometers 30

Saving a Ramp Test

Once a Ramp Test has been performed, the operator has 2 choices, either

save the Run or do not save the Run. In some cases, operators will want to do

numerous back to back Ramp tests in order just to get the Air Fuel Ratio to

where they want it, and have no need to save any of the Runs.

At other times, an operator may also want to do numerous back to back Ramp

tests, each time documenting exactly what changes are made on each

consecutive test, such as differing levels of Ignition Timing etc.

To save a Ramp test, click on the Save Run button after a Ramp test has

been completed, and the Test Header will pop-up as follows:

If necessary, edit any details on either the Test ID, Vehicle or Customer

tabs, a Test Comments box is also available where a more detailed

description relating to the test can be entered. Once again, double check

that the correct Data Path is set for the vehicle under test.

© Mainline DynoLog Dynamometers 31

Customising the Ramp Test Screen

The Ramp Test Screen has numerous options available for the operator to

customise it’s appearance to suit their specific needs. Traditionally most

operators show Power only in the Lower main window, and Air Fuel Ratio in

the Top secondary window. The following 2 screens show 2 different ways of

essentially showing the same data:

This screen shows

the Air Fuel Ratio on

a scale of 10-16,

with some limit lines

set at 12 and 13,

these can be used as

a guide when

performing a ramp

test, rather than

having to monitor an

exact number, the

operator can just

watch the Red Air

Fuel Ratio trace, and

if it goes above 13:1 for example, the operator can abort the test.

This screen

shows the same

data, except the

Air Fuel Ratio

has been shown

in Lambda, on a

scale of .75 to

1.25, with limit

lines set to .86

and .96. Some

tuners prefer to

work with

Lambda rather

than AFR.

© Mainline DynoLog Dynamometers 32

To customise the Ramp Test screen, Right Click on either the Top or Bottom

window and the following pop-up window will appear:

As can be seen in the above picture, any of the available Dyno Channels can

be Dragged and Dropped into any of the 8 Test Monitor Channels, this way

the operator can select various live information that may be relevant to the

test that is being performed.

Also notice the option of what Dyno Channel can be displayed as a 2nd

Channel Graph, in most cases the AFR or Lambda is displayed, but advanced

uses may opt to display parameters such as OBD2 Ignition Timing for

example. The Graph Scale for the Secondary Graph is also set here, there

is a Minimum and Maximum option, plus the option of defining some Limit

Lines that can be used as a guide for an overall indication of what is

happening in the Secondary Channel Graph.

© Mainline DynoLog Dynamometers 33

Another option that is available in the Ramp Test screen is the ability to

show Power only, Torque only, or Both. The following 2 screens show firstly

Power only, and then Power and Torque:

In this example,

the Torque is

still logged, it

has just been

chosen not to be

shown in the live

Test screen. The

advantage of

showing Power

only is that

better Data

Resolution can

be seen on the

live trace.

Power Only

If Power and

Torque are

selected, the

Red trace is

the Torque and

the Green trace

is the Power.

Power and Torque

© Mainline DynoLog Dynamometers 34

Section 4 - Analysing Data – the Analyse Screen

What sets the Mainline DynoLog Dynamometer apart from all others is it’s

ability to give the user unparalleled Data Analysis of any Saved Ramp Test,

and most users spend the majority of their time on the dyno in the Analyse

Screen, analysing data in numerous different ways. Also, by being able to

view data in many different fashions, the ability then arises where the user

can print out Reports of data in many different formats.

To enter the Analyse Screen:

From the Ramp Test Screen, just press F2, or click on the Analyse button

after you have saved a Ramp Test.

From the Main Screen, just Press “CTRL” + F2, or use the menu string

“Analyse – Ramp/Step Test”.

A typical Analyse Screen looks like the following:

© Mainline DynoLog Dynamometers 35

Before any “Analysing” can take place, the user must firstly “Select” what

Dyno runs or tests they actually want to Analyse. By default, normally the 6

most recent Ramp Tests that were performed will automatically be

transferred into each of the six available run buffers for viewing in the

Analyse Screen. At various times, it may be necessary to view runs which are

not one of the last 6 runs, instances when this may occur is when a vehicle is

retested days, months or years later, and they need to be compared to data

collected on the present day.

To select which runs are to be Analysed, use the menu string File-Select

Ramp/Step Runs as follows:

© Mainline DynoLog Dynamometers 36

When File-Select Ramp/Step Runs is selected, the following Pop-Up screen

will appear:

To use the Select Ramp Test Data function, just navigate to the applicable

folder within the C:\dynolog folder where the required runs are located. All

runs within the chosen folder will be displayed in the centre window with the

most recent runs at the top of the list whilst the oldest will be at the

bottom. Simply drag and drop or double click on the necessary runs to load

them into the Runs Selected buffer on the right hand side of the window,

which can hold six runs.

If there are already runs loaded into the 6 run buffer, the user can

individually Un-Select each run or Un-Select all runs so there is sufficient

space in the 6 run buffer for the runs that are needed to be Analysed.

In the above example, we have navigated to the c:\dynolog\toyota\corolla

folder and selected runs numbered 87 and 88. The dyno software

automatically takes care of the run file numbers, and there is really no limit

on the amount of Ramp Tests that can be saved.

© Mainline DynoLog Dynamometers 37

The Analyse Screen has many different options as far as what windows are

open, and how the data in that window is displayed. A “window” is just a

section on the screen, in the example on the previous page, you will see 5

windows open. In order to see what windows are already open and what other

windows are available to be opened, click on the word “Window” at the top of

the Analyse screen. A sub-menu will appear like the following:

By clicking on the word “window”, we see that 4 additional windows are open

(the main top window is always open, this window displays Power, Torque or

Motive Force, or any combination of the 3), in this example, the 4 additional

windows that are open are:

1. Statistics at Cursor

2. All Data at Cursor

3. Channel Graph 1

4. Channel Graph 2

These can be identified as being open as there is a tick next to these

options. If you would like to see some additional Channel Graphs open, just

click on the option of Channel Graph 3 or 4 or both, but be aware that with

the main top window open plus 4 Channel Graphs, the screen can get very

condensed.

Alongside each window option you will notice a Shortcut Key, such as F5, F6,

F7, F8 etc. These shortcuts are the quick and easy way of turn on or off

various windows within the Analyse without having to click on the window

menu and selecting windows. These shortcuts are only active when the top

window is focussed, ie, the Title Bar across the top of the window is dark

blue, as in the previous example of the Analyse Screen.

© Mainline DynoLog Dynamometers 38

What does each window mean?

Starting with the top option, which is Statistics at Cursor (F5), this is the

window at the top right of the Analyse Screen. The Statistics at Cursor

shows just that, the Power and Torque at whatever point the Cursor is at,

the cursor is just the white line that the user can move across the top

window with either the mouse pointer or the left/right arrows on the

keyboard.

Statistics at Cursor

In this example, the cursor is presently at 128kph, so in the Statistics at

Cursor window we can see the Power and Torque that is present at this point

for whatever runs we are viewing, in this case 3 runs. Next to the present

Power an Torque readings there is also shown the Average Power and

Average Torque, the dyno software automatically calculates the average

once the Average Range is set, this is normally setup before a dyno is

installed.

The Average Power and Torque sometimes is vastly more important than

the peak Power and Torque, as the vehicle with the higher Average Power

and Torque will typically be the faster/quicker vehicle due to it’s broader

spread of Power and Torque.

© Mainline DynoLog Dynamometers 39

The next option in the list is the All Data at Cursor (F6) option, the All

Data at Cursor window is under the Statistics at Cursor window, or if the

Statistics at Cursor window is not open, it will be at the top right, as in

these 2 examples:

Statistics at Cursor showing No Statistics at Cursor Showing

The All Data at Cursor window shows the data for all of the available Dyno

Channels at the particular cursor position (road speed). The advantage of

using the All Data at Cursor window is that even if there are just 3 windows

open showing Power, Air Fuel Ratio and Manifold Pressure, the data from any

dyno channel can be seen at whatever road speed the cursor is at.

The amount of Dyno Channels available will vary from one dyno to another

depending on what options a particular dyno has. An AWD dyno will obviously

have dyno channels such as Front Power, Rear Power and Total Power etc etc.

The white column on the left of the All Data at Cursor Window shows the

abbreviations for the dyno channels, such as Pwr, Trq, AFR1, RPM, MAP1 etc.

The different coloured columns refer to the same colour traces that will be

in the top window as well as any lower channel graph that may be open.

These means any red numbers is the relevant data for a red dyno trace.

© Mainline DynoLog Dynamometers 40

The All Data at Cursor window can be used in various different methods,

most commonly, as the cursor is moved on the screen, the relevant data for

that road speed is shown.

However, by Right clicking on the All Data at Cursor window, the following

pop up menu will appear:

The pop up menu shows

7 options for how to

display the Channel

Data at Cursor. The

default option is Data.

If Maximum is chosen,

only the Maximum

reading for any channel

will be shown, the same

for Minimum. You can

also view the Channel

Data Difference, or %

Difference from the

Reference Run. The

Average can also be

shown, as well as the

Integral, which is the

all of the data for each

channel added

together, which is

effectively the “Area

under Curve”

By being able to view the Data in various fashions, it opens up a whole new

world of how to look at data, as too often people are just focussed on the

maximum number.

© Mainline DynoLog Dynamometers 41

The next series of options just open up additional Channel Graphs, 2 of

these additional Channel Graphs can be opened up by using the Keyboard

Shortcuts F7 and F8. Within these Channel Graphs, any of the available dyno

channels can be displayed, and up to 10 dyno channels can be pre-selected in

each Channel Graph so that by merely tapping the space bar once a Channel

Graph is focussed, each one of the pre-selected channels can be viewed with

each tap of the space bar.

To view or change what channels are pre-selected in each Channel Graph,

right click on the chosen Channel Graph and the following pop up menu will

appear:

In this example, we can se that AFR 1, Manifold Pressure 1, Intake Air Temp,

Injector Duty Cycle, Engine Speed and Injector Frequency have been pre-

selected in this Channel graph, and the current Channel is AFR 1. As stated

earlier, by tapping the space bar with Channel Graph 1 focussed, each of

these 6 dyno channels can be viewed in turn.

© Mainline DynoLog Dynamometers 42

To change what channels are selected, click on the Select Channels option

and the following pop up menu will appear that enables the user to remove or

add channels to the selected list:

By double clicking on a particular Dynolog Channel, it will be added to the

list of Selected Channels in the right window. To remove a channel from the

Selected Channels list, click on the channel, then click the Left arrow and it

will be removed from the Selected Channels list.

Remember, a maximum of 10 Dyno Channels can be placed in the Selected

Channels list.

Once we have chosen what windows we want open, and what Dyno Channels

we want to analyse, we can actually start to analyse some data.

© Mainline DynoLog Dynamometers 43

As was the case with the All Data at Cursor window, there are also

different ways in which to view the same data within any of the Channel

Graphs numbered 1-4. For example, the following screen shows 3 AFR (Air

Fuel Ratio) traces as just that, Air Fuel Ratio on a scale of 10-15:

Normal AFR Trace from 3 dyno runs.

The next screen is the same data, only this time we have chosen to view the

data as a Percentage Difference relative to the Red run, which we have

chosen as a Reference run:

Analysing the Air Fuel Ratio in this fashion can be very helpful when tuning

aftermarket engine management systems where a percentage addition or

subtraction in fuel needs to be made. The way in which we interpret the

above graph is such, the Blue trace was leaner than the Red trace at it’s

worst point by approx 6%, likewise, the Yellow trace was richer than the Red

trace at it’s worst point by approx 3.5%.

Any Dyno channel can viewed in this fashion.

© Mainline DynoLog Dynamometers 44

To view the data in such a fashion, right click on the Channel Graph you

choose, and the following pop-up menu will appear:

There are 3 options at the bottom of the pop-up menu which determine how

the data can be displayed, Show Data, Show Difference and Show Percent

Difference. The previous 2 examples demonstrated 2 of these 3 options.

There is also an option on this pop-up window called Y-axis Scales, by clicking

on this option, we can choose to manually set the Scaling for the particular

channel being analysed, or we can let the dyno software Autoscale to it’s

desired scale. The pop-up window for setting this option is as follows:

To manually set the AFR scale, for

example, to have a scale of 10-15, type

the relevant numbers into Max Graph

Scale and Min Graph Scale boxes, and

make sure the Fixed Graph Scales check

box is checked. It is sometimes handy to

set a manual scale when analysing

Manifold Pressure on a N/A vehicle, a

scale of 1 to –5 would be a typical scale in

this instance.

© Mainline DynoLog Dynamometers 45

The main top window in the Analyse screen also has many options relating

how to view the data, and what data to display. To view these options, right

click on the top window and the following pop-up menu will appear:

We can see here that there are numerous options, most commonly the top 2

options are used to toggle either Power or Torque on or off to analyse.

There are also some options here that say Show Average Torque, Show

Average Power and Show Average Motive Force, by selecting anyone of

these 3 choices, the software will place a line across the screen showing the

Average point for each run.

The option second from the bottom says Show Flybox, this is the box that

follows the cursor across the screen and shows the data for wherever the

cursor is touching, this can be toggled on or off by clicking on this option.

There is an option on this pop-up menu that says Use Derived Torque, when

this option is selected, the software will show a “Derived Torque” value that

will show the Power and Torque intersect at 5252RPM providing the data is

shown in HP and Ft/Lbs. This function is primarily for use in overseas

markets where this is the standard way HP and Torque are plotted.

© Mainline DynoLog Dynamometers 46

The following graph shows the option of where Power and Torque have been

chosen to be viewed together:

In the pop-up menu you can see that both Power and Torque have been

selected by the presence of a tick next to each option.

When Power and Torque have been selected, they are placed on the same

Graph axis, so when analysing Power in KW, and Torque in Nm, they will

generally look as above, with the Power at the lower end of the Graph while

the Torque is will be near the top of the Graph.

Whereas Power will always be lower when calculated at the dyno rollers due

to Driveline losses, the Torque at the dyno rollers will always be a higher

amount than what is at the Engine due to Gear Multiplication thru the

Driveline.

A quick example is as follows:

Test engine has 400nm at the Engine, if the vehicle is tested in a gear of 1:1,

the Torque is still 400nm exiting the Gearbox. The Torque is then multiplied

by whatever the Differential Ratio is, for example 4:1, so we now have

1600nm at the axles. The Tyre to Dyno roller is normally a Torque reduction

due to the Tyre being larger than the Roller, typical values of tyre to roller

ratio’s are around 1:3 on 217mm Dyno rollers, so our 1600nm is divided by 3

which nets us 533nm at the roller. This example does not take into account

Driveline loss, so the Torque at the Dyno roller would be less than the

533nm in the example.

© Mainline DynoLog Dynamometers 47

At the top of the Analyse Screen, you will notice an option there that just

says Show. The Show menu has various options that have already been

discussed in the Right Click pop-up menu for the top window in the Analyse

screen.

Some of the options in the Show menu are not present in the Right Click

pop-up menu, the main option that is used from the Show menu is the option

of showing either Tacho RPM, Derived RPM or ODBII RPM across the

bottom axis of the top analyse screen. Normally, the data is displayed over

Road Speed, by selecting to show one of the available RPM Channels also

across the bottom axis, the user can see what RPM the Engine is at a

particular Road Speed, and at the same time see what Power/Torque is being

produced at what RPM point.

The Show menu has the following options:

Note here that the option of showing Tacho RPM is ticked, this means that

relevant Tacho RPM that has been taken during the Ramp test is plotted at

the various Road Speed increments. If this option is not ticked, there will

only be Road Speed data across the bottom axis.

The option of showing Tacho data across the bottom axis must be ticked if

any printed reports require Tacho Data to be shown across the bottom axis.

© Mainline DynoLog Dynamometers 48

Section 5 – Printing Reports

At the end of day, the thing that eventually pays for the Dyno, is the piece

of paper that is given to the customer showing how much power they have.

The scope of this manual cannot cover every conceivable different type of

Report that can be printed, as there is upward of several dozen different

styles of reports that can be printed. What this manual will do is describe

how to printout the 2 most common styles, which normally cover 99% of the

selected reports that are printed by most uses. More advanced users may

choose to print out many of the not so common reports, and coverage of how

to print these less common reports are normally covered in one on one

training in the various customers premises.

Printing the traditional Graph with AFR in the Lower Graph Channel.

The most common Graph (report) that is printed out, is a Graph showing

Power with the AFR in the lower Channel Graph. To printout an example of

this style of graph, do the following:

From within the Analyse Screen, choose the menu string File – Print

Ramp/Step Report as in the example:

and choose the run that you wish to print a report for from the possible 6

that could be listed. When you have selected which run you would like to

print a report for, the Report Setup window will appear, this looks as

follows:

© Mainline DynoLog Dynamometers 49

This example of the Report Setup page shows how to print a Graph that will

show Power (and Torque if chosen), and also a smaller Graph at the bottom

of the page that will show the AFR trace. Notice that in the top right corner

of the Report Setup page it says “1 page in report”, meaning that we have

correctly selected just 1 report to printout. Also notice that we have not

selected any other checkbox relating to different reports, as we just want

to printout a standard graph at this point.

© Mainline DynoLog Dynamometers 50

The Graph which has been chosen, can be previewed before printing by

clicking on the Preview to Screen button. It is recommended to always

preview the graph before printing so any changes that have to be made to

the Test Header can be made so the report looks as professional as possible.

If the Preview to Screen button is pressed, the next screen will appear:

This screen has 2 options, either OK which returns to the previous Report

Setup page, or Save BMP, which allows the user to save a Bitmap file of the

report. The Save BMP option can be used if a customer wants an electronic

copy of their report.

If the preview looks correct, click the OK button, which will return us to the

Report Setup page where we now would just click on the “Print to Printer”

button, which would then printout a copy of the Report. Please make sure

that the Printer is turned on at this point so a Report can be printed.

© Mainline DynoLog Dynamometers 51

The second most common Report would be a printout of an overlay of 2 or

more runs. To print a Report with an overlay of 2 or more runs, once again

select File – Print Ramp/Step Report, then choose one of the runs that you

would like to overlay against another. Once again the Report Setup page will

appear, this time, select the check boxes as in the following example to

select a printout of 2 runs overlayed:

Only select 2

Runs here, and

do not select

Large Graph.

© Mainline DynoLog Dynamometers 52

By selecting what was advised in the example, the following preview would

appear when Preview to Screen is selected:

This graph shows the 2 selected runs, it also shows any entered information

in the Test Header, as well as the Maximum Power/Torque and Motive Force

and at what road speed the maximums were made in the Max Statistics area

at the bottom of the page.

Each run is a different colour, and there is a corresponding key on each Test

Header so each run can be identified correctly.

If more than 2 runs are needed to be printed out, check the option on the

Print Report page that says “Large Graph”, and then select up to 6 runs that

can be overlayed. An example of a Large Graph (also known as a Landscape

Print) is shown on the next page.

© Mainline DynoLog Dynamometers 53

As mentioned, up to six runs can be overlayed on this style of Graph. When

this style of Graph is chosen, any Dyno Channel be overlayed, this is done by

clicking on the “Overlay Channel” button on the Report Setup page and

choosing the Channel you wish to printout, as follows:

If more than 2 runs are selected, but the Large Graph check box is not

checked, an error message will appear that warns “Cannot overlay more than

2 runs on small graph page”.

© Mainline DynoLog Dynamometers 54

Section 6 – Channel Properties.

You may of noticed in many of the Dyno Screen shots an option that said

Channel Properties or just Properties.

Channel Properties is a part of the Dyno Program were we change Properties

of the various Dyno Channels, most commonly we would use the Channel

Properties function to change over from Kilowatts to Horsepower and vice

versa. To open the Channel Properties window, from the Main Screen use the

menu string Setup – Channel Properties as follows:

There are several other ways of opening the Channel Properties window,

some of these are as follows:

1. From the Analyse Screen, right click on any window and an option will

be there for Channel Properties.

2. From the Ramp Test Screen, right click on the Graph area and there

is a Properties button on the pop-up window.

3. From the Main Screen, just use the Keyboard Shortcut CTRL+P.

4. From the Setup Digital Channels window, there is also a Properties

Button.

5. The Report Setup page also has a Channel Properties button.

© Mainline DynoLog Dynamometers 55

When any of the above mentioned procedures are used to open Channel

Properties, the following window will appear:

The above example is showing Power Rear as being highlighted, and the

available options for that channel are visible, such as Power Units. On any

Dyno channel the number of Decimal Points can be set from 0 to 4, this is

set, by selecting it from the Data Format option.

Other times when Channel Properties need to changed are normally if

changing from AFR to Lambda, also the Manifold Pressure channel has

many different units, plus the ability to view the data in either Gauge or

Absolute pressure. A selection of different Channels and their properties

are shown on the next page. It is recommended for the user to

experiment and click on each Dyno Channel and see what options there

are for each Channel.

© Mainline DynoLog Dynamometers 56

© Mainline DynoLog Dynamometers 57

Thankyou for taking the time to read this manual, we

hope it helps you to continue to use the all of the wide

variety of functions and tests available on the

Mainline Dynolog Dynamometer.

© Mainline DynoLog Dynamometers 58

You might also like

- Powersports Dynamometer Pricelist: Dynamometer and Diagnostic Test EquipmentNo ratings yetPowersports Dynamometer Pricelist: Dynamometer and Diagnostic Test Equipment5 pages

- KODAK PRINTOMATIC Instant Print Camera ManualNo ratings yetKODAK PRINTOMATIC Instant Print Camera Manual16 pages

- Flora Series: Professional 6-Part Nutrient SystemNo ratings yetFlora Series: Professional 6-Part Nutrient System2 pages

- FloraNova Professional 4 Part Nutrient System FeedNo ratings yetFloraNova Professional 4 Part Nutrient System Feed2 pages

- Dyna Run V3' Software User Manual: Advanced Dyno Control SoftwareNo ratings yetDyna Run V3' Software User Manual: Advanced Dyno Control Software76 pages

- Air Charge Estimation in Turbocharged Spark Ignition EnginesNo ratings yetAir Charge Estimation in Turbocharged Spark Ignition Engines245 pages

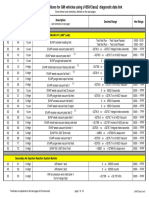

- How To Tune Your Mustang Using HP Tuners - Modular FordsNo ratings yetHow To Tune Your Mustang Using HP Tuners - Modular Fords12 pages

- Professional Obdii/Chip Tuning System For The Recalibration of Stock Ecu Engine Working ParametersNo ratings yetProfessional Obdii/Chip Tuning System For The Recalibration of Stock Ecu Engine Working Parameters20 pages

- FloraPro™ Feedcharts - General HydroponicsNo ratings yetFloraPro™ Feedcharts - General Hydroponics1 page

- FEN1021v002 DynPro 4.0 Advanced Printing User GuideNo ratings yetFEN1021v002 DynPro 4.0 Advanced Printing User Guide40 pages

- AP - Chrysler NGC Management Part 3 Introduction OBD II SystemNo ratings yetAP - Chrysler NGC Management Part 3 Introduction OBD II System210 pages

- Diagnostic and Fault Code Reader For The LucasNo ratings yetDiagnostic and Fault Code Reader For The Lucas52 pages

- Livnitup's FORScan - 2021-24 F150 - CommonNo ratings yetLivnitup's FORScan - 2021-24 F150 - Common3 pages

- Zeeltronic PDCI-12 Manual/Specs 02.02.2016No ratings yetZeeltronic PDCI-12 Manual/Specs 02.02.20168 pages

- OM - VI 450 - Ltec - Power - Source - 15-099No ratings yetOM - VI 450 - Ltec - Power - Source - 15-09928 pages

- The Demand For Audit and Other Assurance Services: Review Questions 1-1No ratings yetThe Demand For Audit and Other Assurance Services: Review Questions 1-112 pages

- One Month of Mindfulness: Mindful Walk in Your Cleaning Your Teeth orNo ratings yetOne Month of Mindfulness: Mindful Walk in Your Cleaning Your Teeth or1 page

- Making Hard Decisions With DecisionTools 3rd Edition Clemen Solutions Manual - Complete Set of Chapters Available For One-Click Download100% (14)Making Hard Decisions With DecisionTools 3rd Edition Clemen Solutions Manual - Complete Set of Chapters Available For One-Click Download44 pages

- MCA - FY08 - Anheuser-Busch InBev India PVT LTDNo ratings yetMCA - FY08 - Anheuser-Busch InBev India PVT LTD51 pages

- Generalized Periodontitis Treated With Periodontal, Orthodontic, and Prosthodontic Therapy: A Case ReportNo ratings yetGeneralized Periodontitis Treated With Periodontal, Orthodontic, and Prosthodontic Therapy: A Case Report16 pages

- The Rise of Thatcherism and The Effects of Her PoliciesNo ratings yetThe Rise of Thatcherism and The Effects of Her Policies10 pages

- Edupadi Com Classroom Lessons ss1 Ict Application Area of Ict Page 2...No ratings yetEdupadi Com Classroom Lessons ss1 Ict Application Area of Ict Page 2...5 pages