0% found this document useful (0 votes)

22 views6 pages2 Introduction

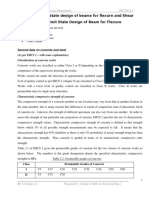

The document outlines the design codes for reinforced concrete in Kenya, primarily guided by British Standard BS 8110, which includes guidelines for design, materials properties, and loading considerations. It emphasizes the importance of limit states, characteristic strengths of materials, and partial safety factors in ensuring structural integrity and safety. Additionally, it addresses the need for durability and fire resistance in concrete structures.

Uploaded by

amoketonneyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

22 views6 pages2 Introduction

The document outlines the design codes for reinforced concrete in Kenya, primarily guided by British Standard BS 8110, which includes guidelines for design, materials properties, and loading considerations. It emphasizes the importance of limit states, characteristic strengths of materials, and partial safety factors in ensuring structural integrity and safety. Additionally, it addresses the need for durability and fire resistance in concrete structures.

Uploaded by

amoketonneyCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 6