0% found this document useful (0 votes)

10 views2 pagesSan Ace EPWMControlFunction

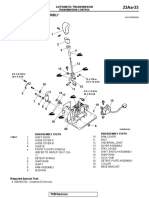

The document provides an overview of the Pulse Width Modulation (PWM) control function for fans, detailing how it allows for external speed control by varying PWM input signals. It highlights the advantages of precise control, the ability to manage multiple fans, and customization options for fan speed responses. Additionally, it includes technical specifications, wiring diagrams, and application examples demonstrating the functionality and benefits of PWM-controlled fans.

Uploaded by

احمد الناصريCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

10 views2 pagesSan Ace EPWMControlFunction

The document provides an overview of the Pulse Width Modulation (PWM) control function for fans, detailing how it allows for external speed control by varying PWM input signals. It highlights the advantages of precise control, the ability to manage multiple fans, and customization options for fan speed responses. Additionally, it includes technical specifications, wiring diagrams, and application examples demonstrating the functionality and benefits of PWM-controlled fans.

Uploaded by

احمد الناصريCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 2