0% found this document useful (0 votes)

30 views16 pagesChecklist For Section Manager - Final

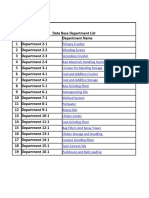

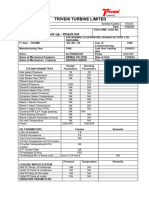

The document is a daily checklist for section managers covering various equipment and systems in the MRSS, Crusher, Stacker, Reclaiming & Grinding, and Pyro sections. It includes details on equipment names, locations, and various operational parameters such as cleaning condition, oil levels, temperatures, and motor vibrations. The checklist is structured for systematic monitoring and maintenance of the equipment to ensure optimal performance.

Uploaded by

mr.sbmishraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

30 views16 pagesChecklist For Section Manager - Final

The document is a daily checklist for section managers covering various equipment and systems in the MRSS, Crusher, Stacker, Reclaiming & Grinding, and Pyro sections. It includes details on equipment names, locations, and various operational parameters such as cleaning condition, oil levels, temperatures, and motor vibrations. The checklist is structured for systematic monitoring and maintenance of the equipment to ensure optimal performance.

Uploaded by

mr.sbmishraCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 16