0% found this document useful (0 votes)

14 views37 pagesBMT654C Module 2

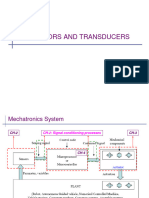

The document provides an overview of sensors and transducers, defining sensors as devices that produce output signals for sensing physical phenomena, while transducers convert signals from one physical form to another. It classifies sensors based on signal characteristics, power supply, mode of operation, and measurement subjects, and discusses various types of sensors including analog, digital, active, and passive. Additionally, it details the performance metrics of transducers, such as range, accuracy, sensitivity, and introduces specific types of light sensors and the linear variable differential transformer (LVDT).

Uploaded by

rajatmahaseth44Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

14 views37 pagesBMT654C Module 2

The document provides an overview of sensors and transducers, defining sensors as devices that produce output signals for sensing physical phenomena, while transducers convert signals from one physical form to another. It classifies sensors based on signal characteristics, power supply, mode of operation, and measurement subjects, and discusses various types of sensors including analog, digital, active, and passive. Additionally, it details the performance metrics of transducers, such as range, accuracy, sensitivity, and introduces specific types of light sensors and the linear variable differential transformer (LVDT).

Uploaded by

rajatmahaseth44Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 37