0% found this document useful (0 votes)

55 views16 pagesSession1-3 Process View

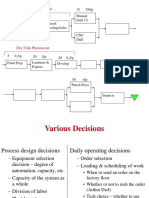

The document discusses processes in manufacturing and healthcare contexts. It provides examples of process flows for an automobile plant and an interventional radiology unit. Key process performance measures discussed include flow time, flow rate, throughput rate, inventory, and Little's Law. The document also discusses different types of processes based on volume and variety, and outlines steps for analyzing processes including defining boundaries, estimating resource capacities, and calculating flow rates and utilizations.

Uploaded by

Ayushi MehtaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

55 views16 pagesSession1-3 Process View

The document discusses processes in manufacturing and healthcare contexts. It provides examples of process flows for an automobile plant and an interventional radiology unit. Key process performance measures discussed include flow time, flow rate, throughput rate, inventory, and Little's Law. The document also discusses different types of processes based on volume and variety, and outlines steps for analyzing processes including defining boundaries, estimating resource capacities, and calculating flow rates and utilizations.

Uploaded by

Ayushi MehtaCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

/ 16