0% found this document useful (0 votes)

49 views11 pagesFeasibility Study Process

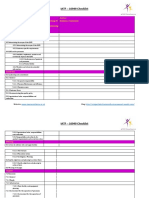

The document outlines the feasibility study process for new projects aligned with IATF 16949 standards, focusing on evaluating customer requirements and identifying risks early in the APQP Phase 1. It details the flow of the feasibility study, including the formation of a cross-functional team and assessments in technical, manufacturing, quality, supply chain, cost, and compliance areas. The process emphasizes the importance of documented approvals and compliance with customer-designated feasibility requirements.

Uploaded by

rerisefiqmieCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

49 views11 pagesFeasibility Study Process

The document outlines the feasibility study process for new projects aligned with IATF 16949 standards, focusing on evaluating customer requirements and identifying risks early in the APQP Phase 1. It details the flow of the feasibility study, including the formation of a cross-functional team and assessments in technical, manufacturing, quality, supply chain, cost, and compliance areas. The process emphasizes the importance of documented approvals and compliance with customer-designated feasibility requirements.

Uploaded by

rerisefiqmieCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

/ 11