This document provides tutorials for using the ANSYS CFX software to simulate fluid flow and heat transfer. The tutorials cover a range of scenarios including flow through static mixers, injection mixing pipes, and a circular vent. They demonstrate defining simulations, obtaining solutions, and viewing results in ANSYS CFX-Pre, ANSYS CFX-Solver Manager, and ANSYS CFX-Post. The tutorials also illustrate using both standalone and integrated Workbench modes.

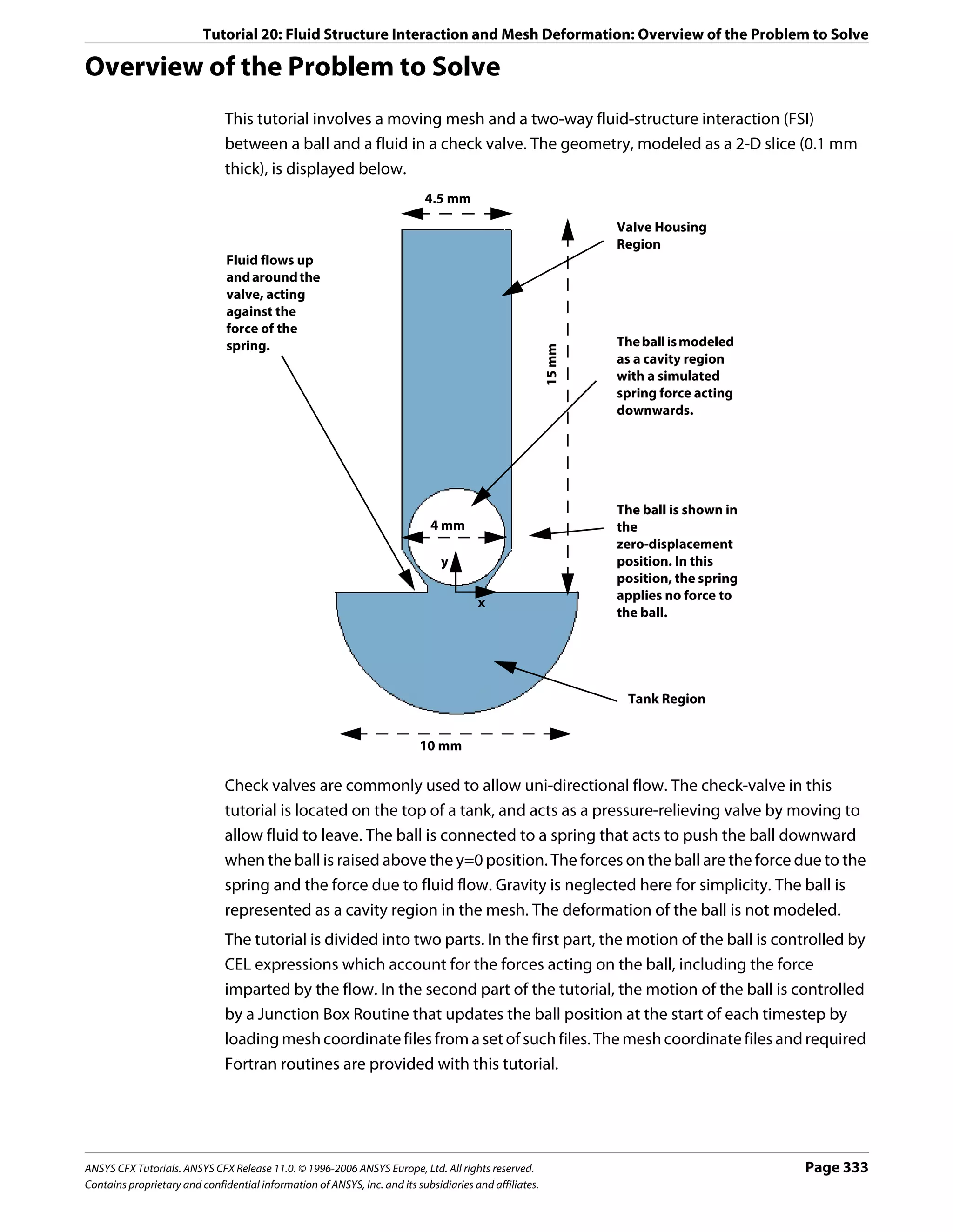

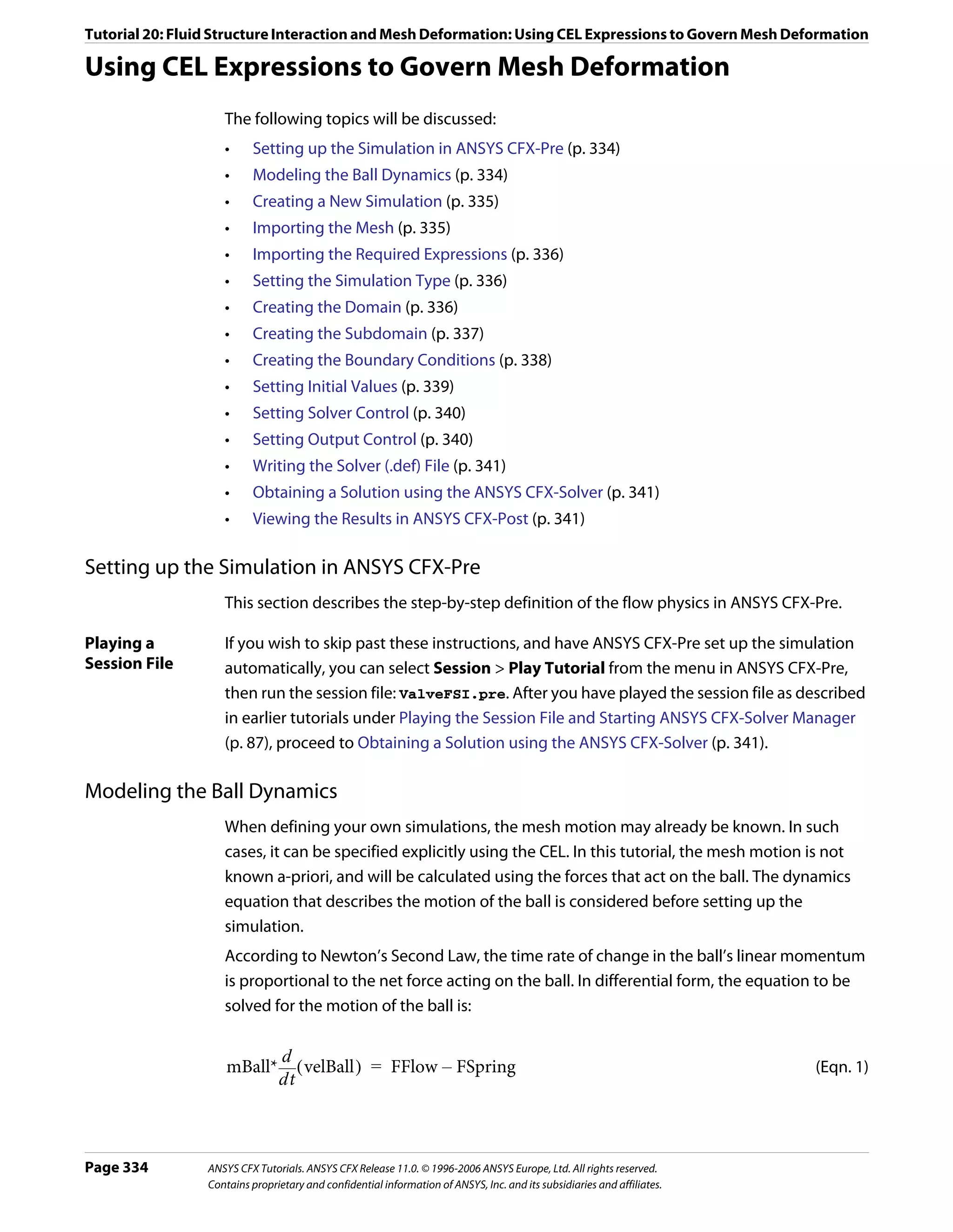

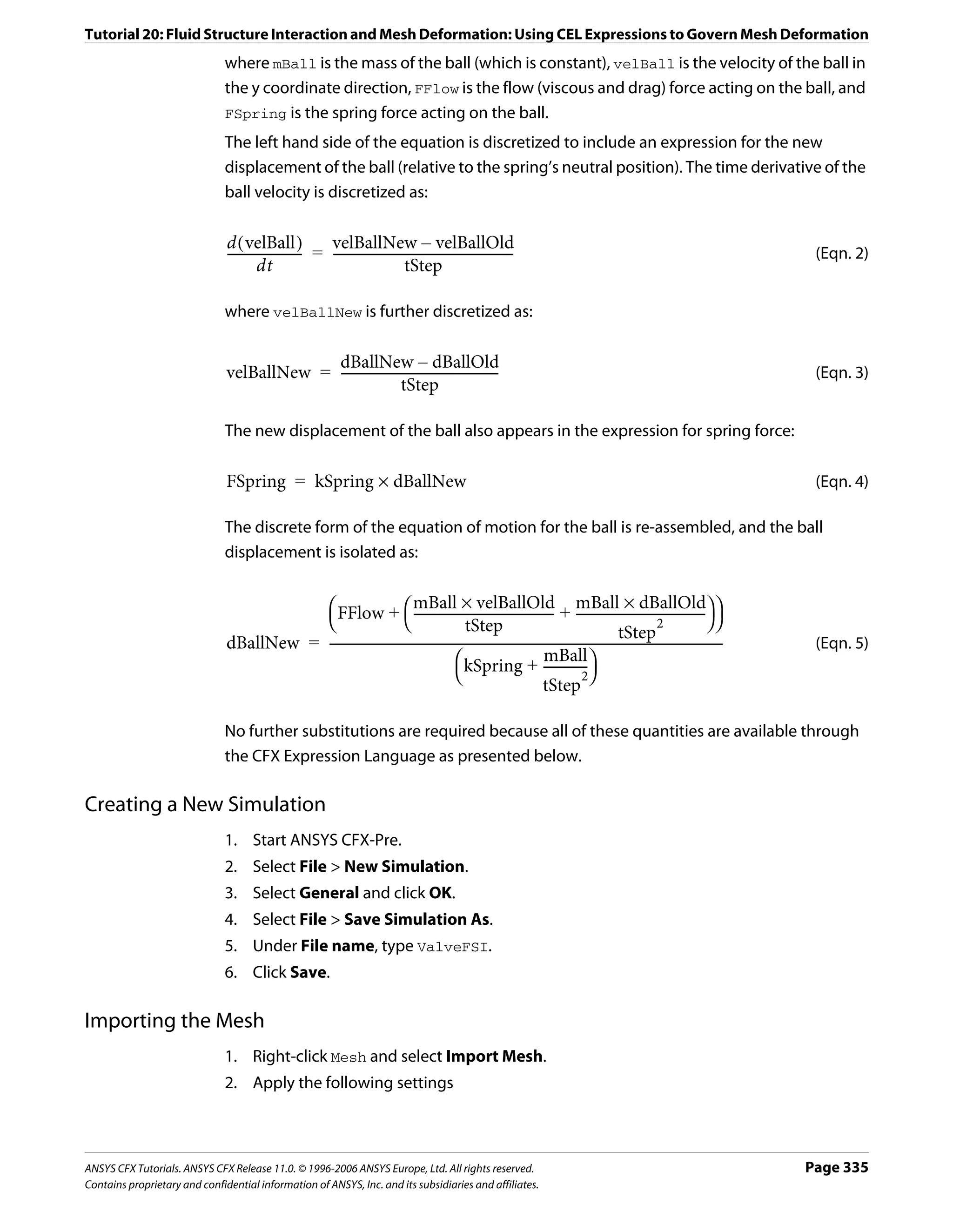

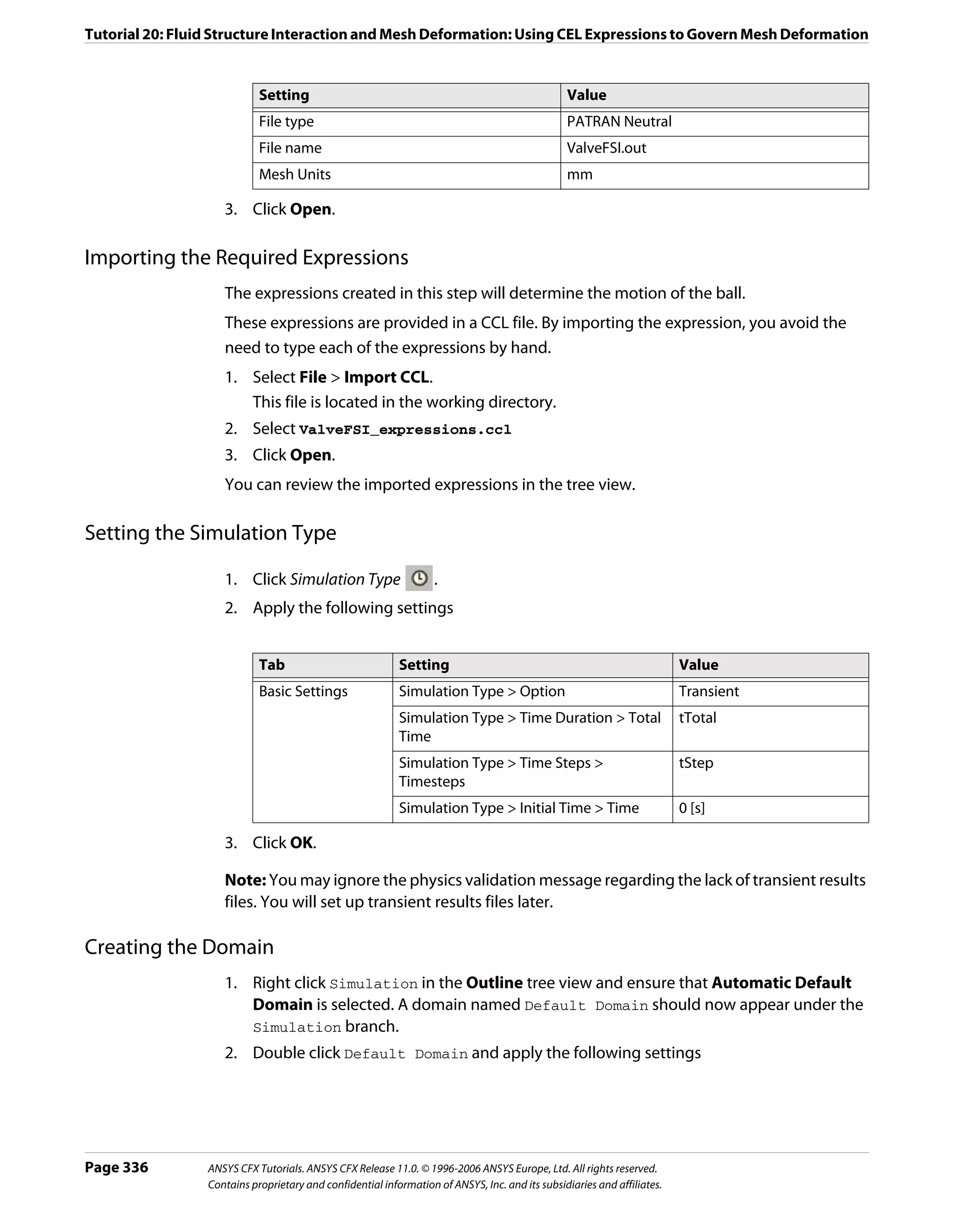

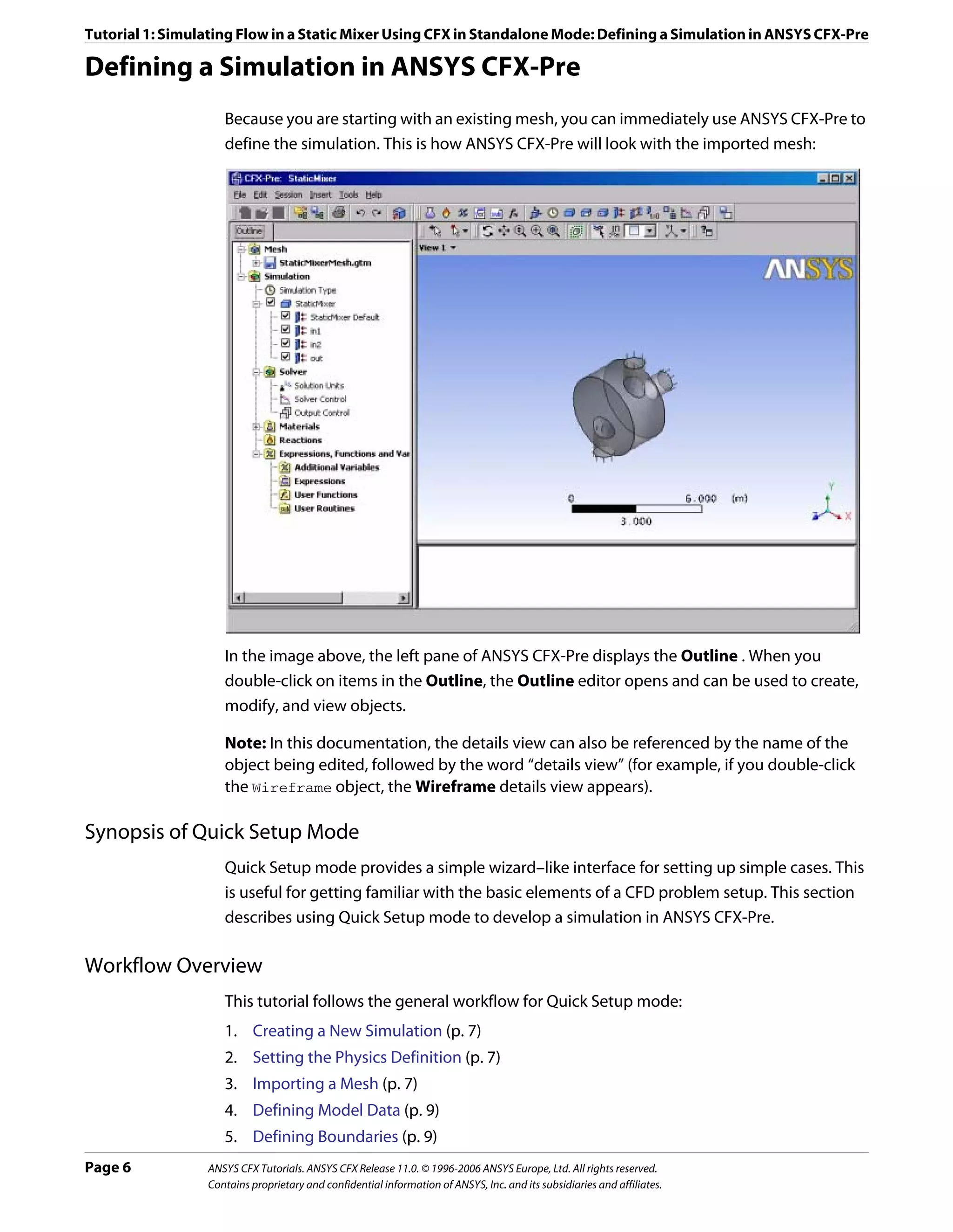

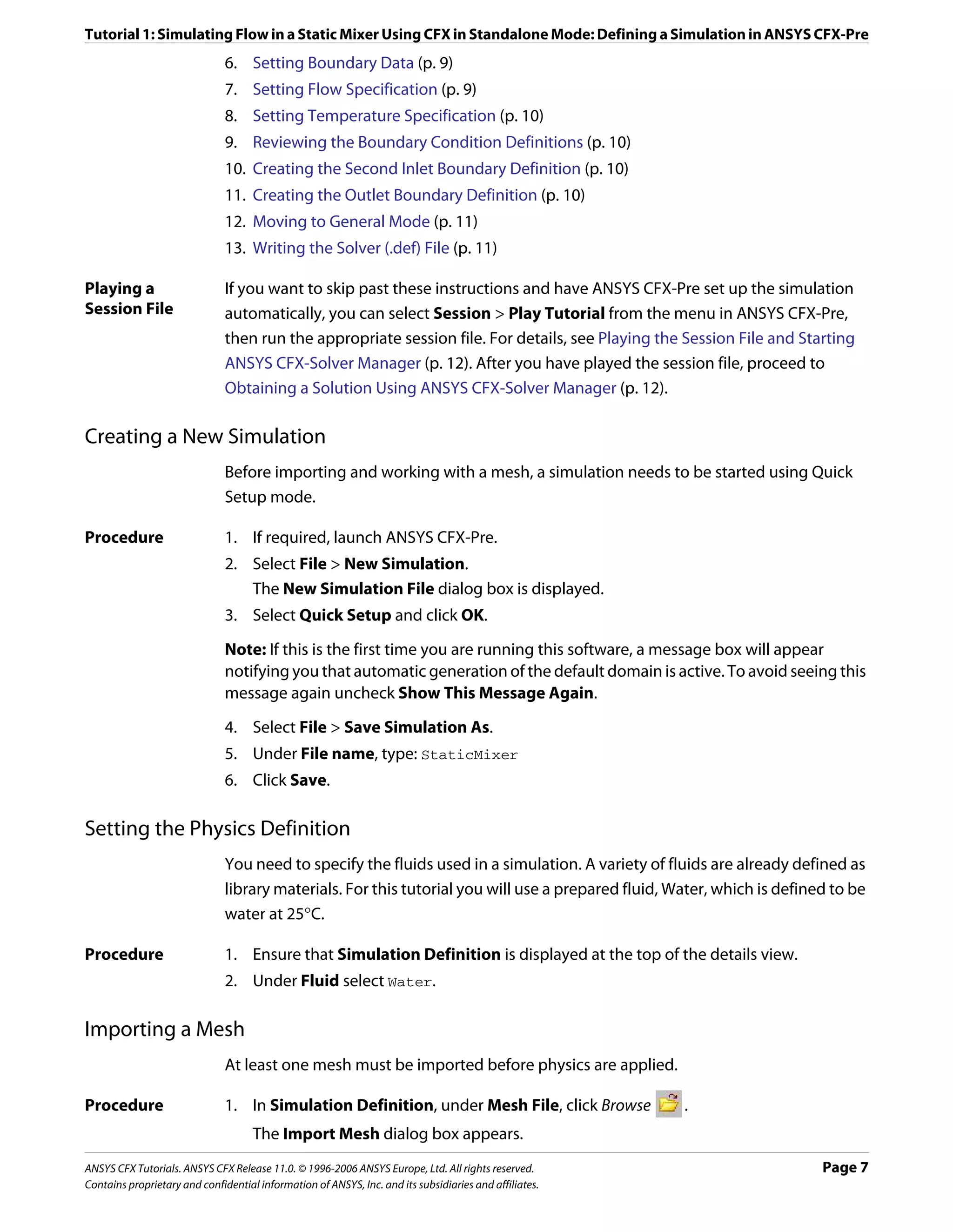

![Tutorial 1: Simulating Flow in a Static Mixer Using CFX in Standalone Mode: Defining a Simulation in ANSYS CFX-Pre

Defining Model Data

You need to define the type of flow and the physical models to use in the fluid domain.

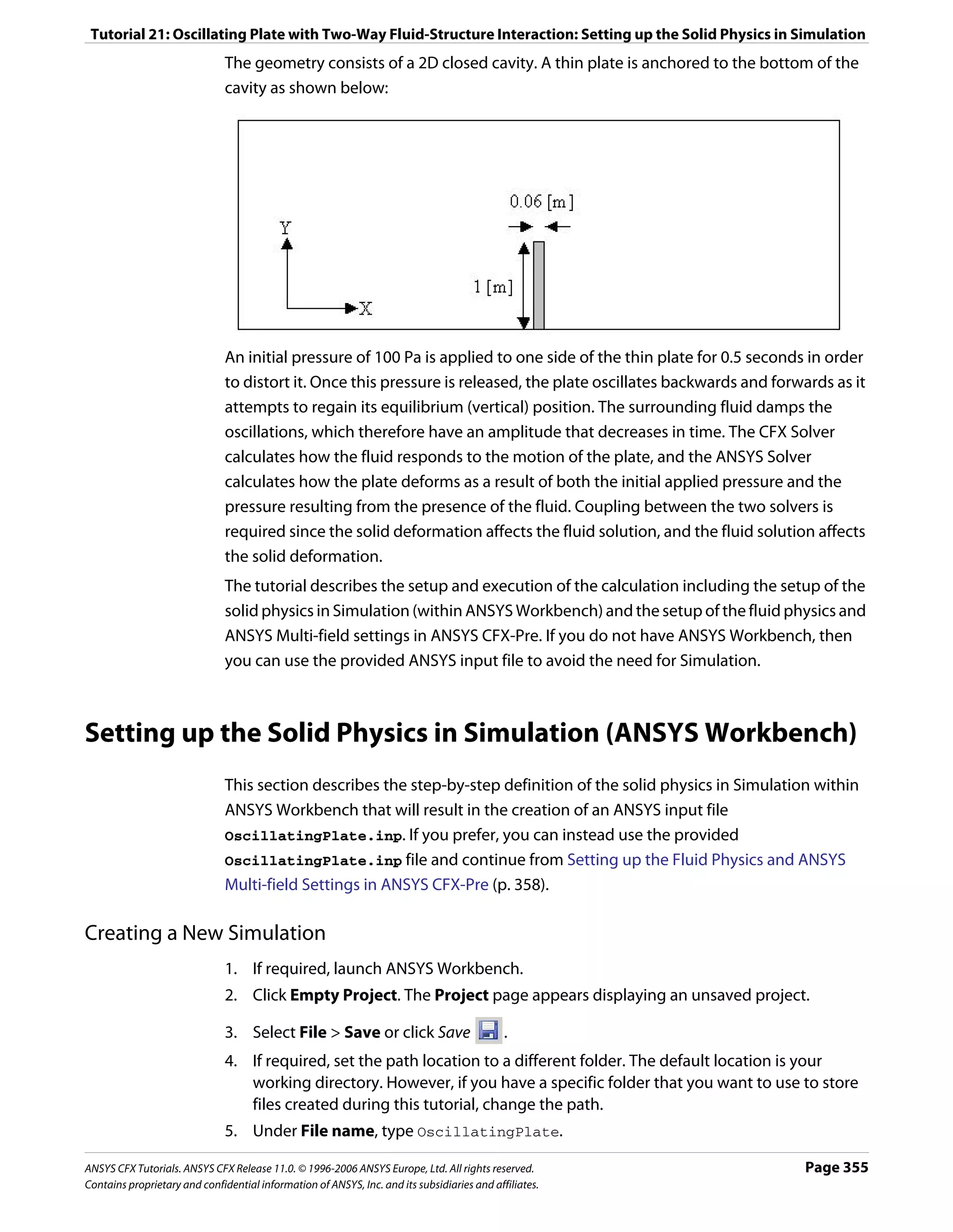

You will specify the flow as steady state with turbulence and heat transfer. Turbulence is

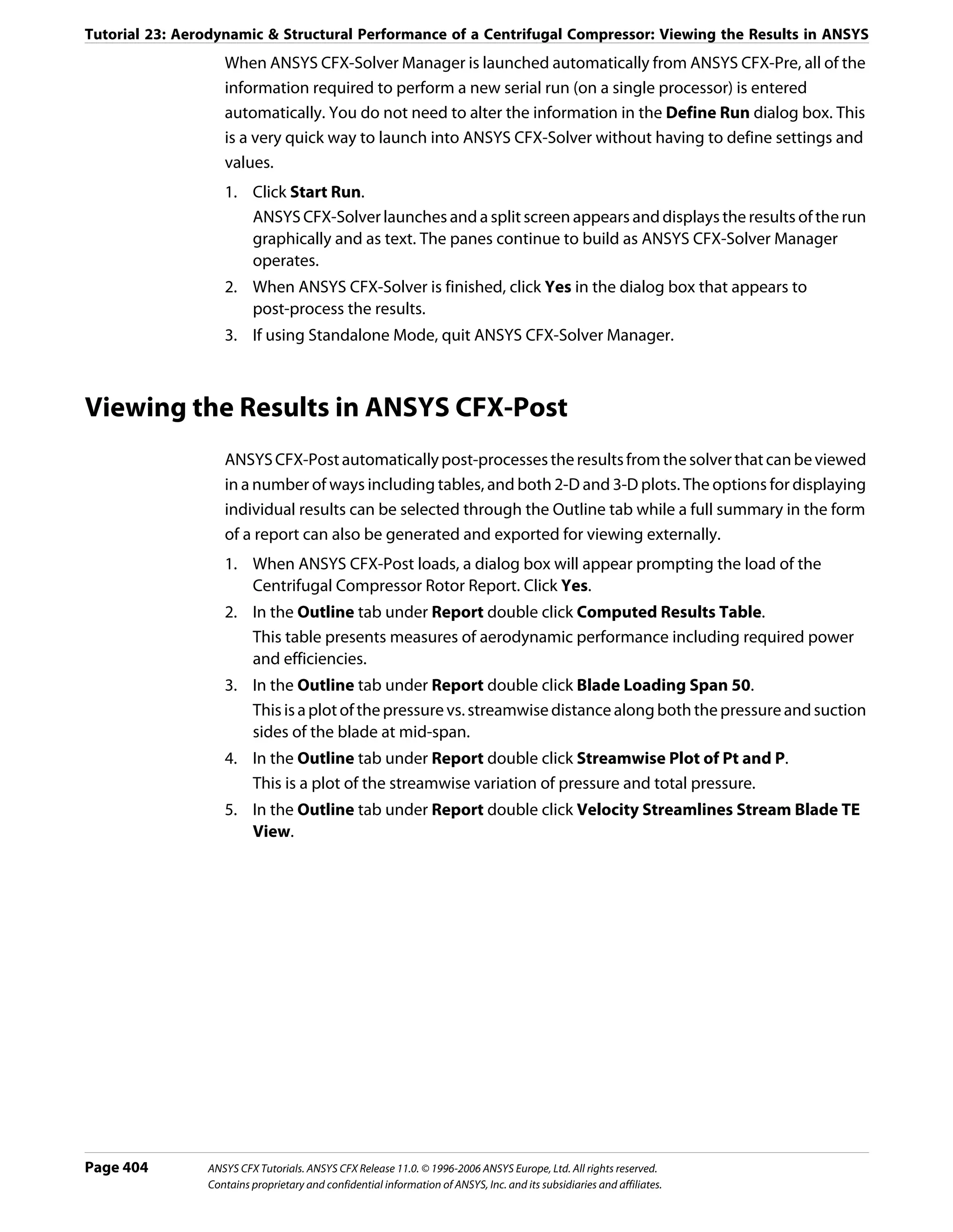

modeled using the k - ε turbulence model and heat transfer using the thermal energy

model. The k - ε turbulence model is a commonly used model and is suitable for a wide

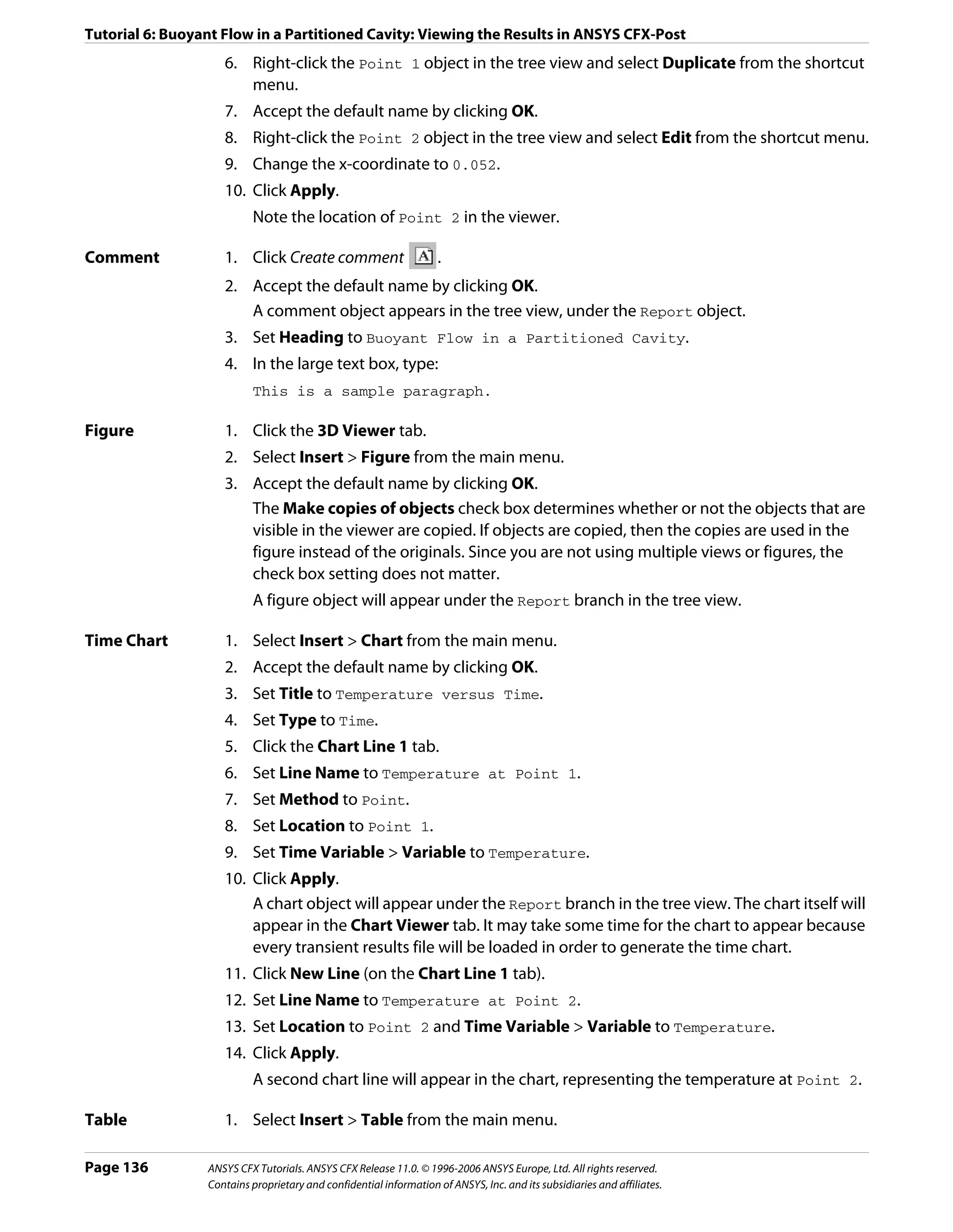

range of applications. The thermal energy model neglects high speed energy effects and is

therefore suitable for low speed flow applications.

Procedure 1. Ensure that Physics Definition is displayed.

2. Under Model Data, set Reference Pressure to 1 [atm].

All other pressure settings are relative to this reference pressure.

3. Set Heat Transfer to Thermal Energy.

4. Set Turbulence to k-Epsilon.

5. Click Next.

Defining Boundaries

The CFD model requires the definition of conditions on the boundaries of the domain.

Procedure 1. Ensure that Boundary Definition is displayed.

2. Delete Inlet and Outlet from the list by right-clicking each and selecting Delete.

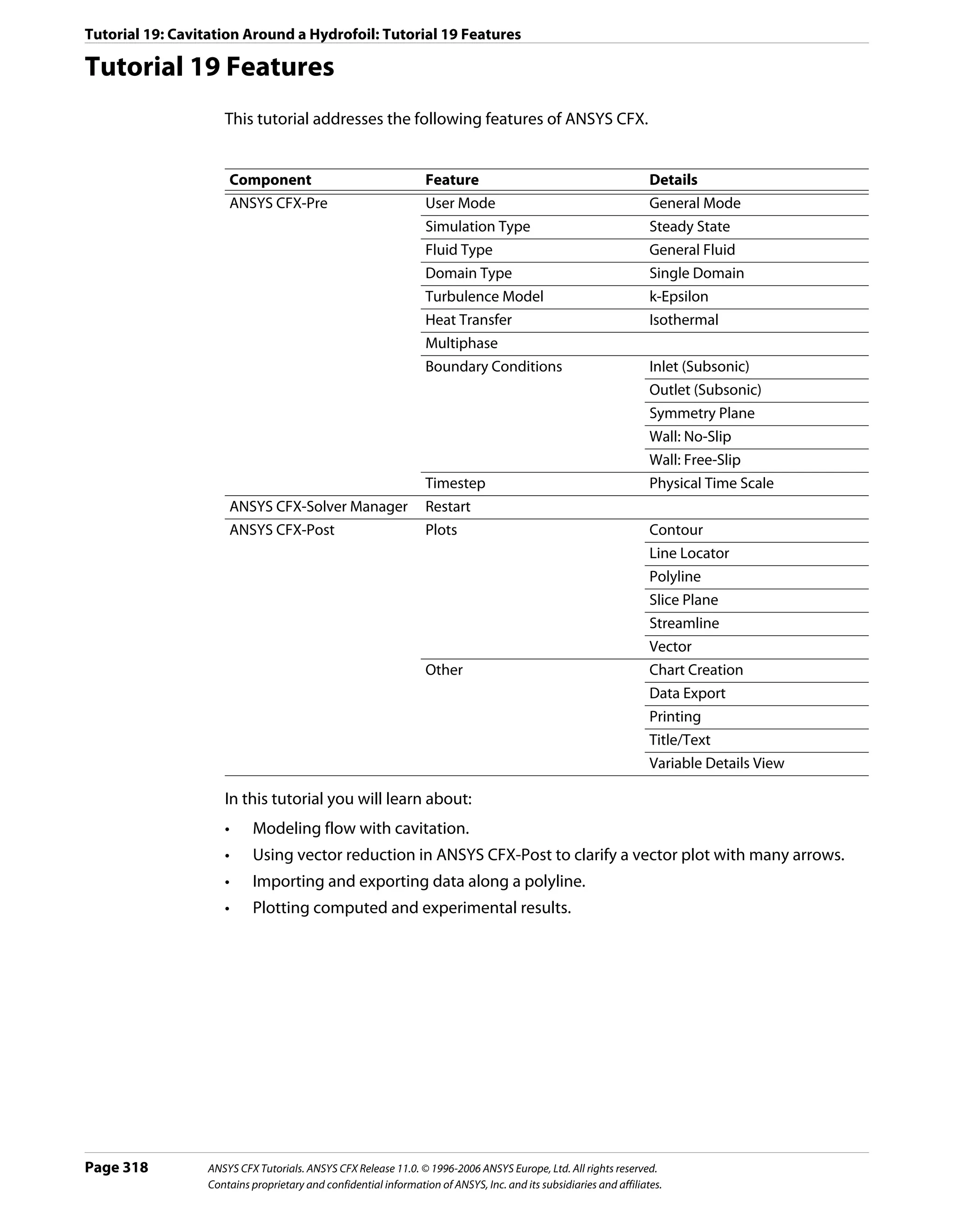

3. Right-click in the blank area where Inlet and Outlet were listed, then select New.

4. Set Name to in1.

5. Click OK.

The boundary is created and, when selected, properties related to the boundary are

displayed.

Setting Boundary Data

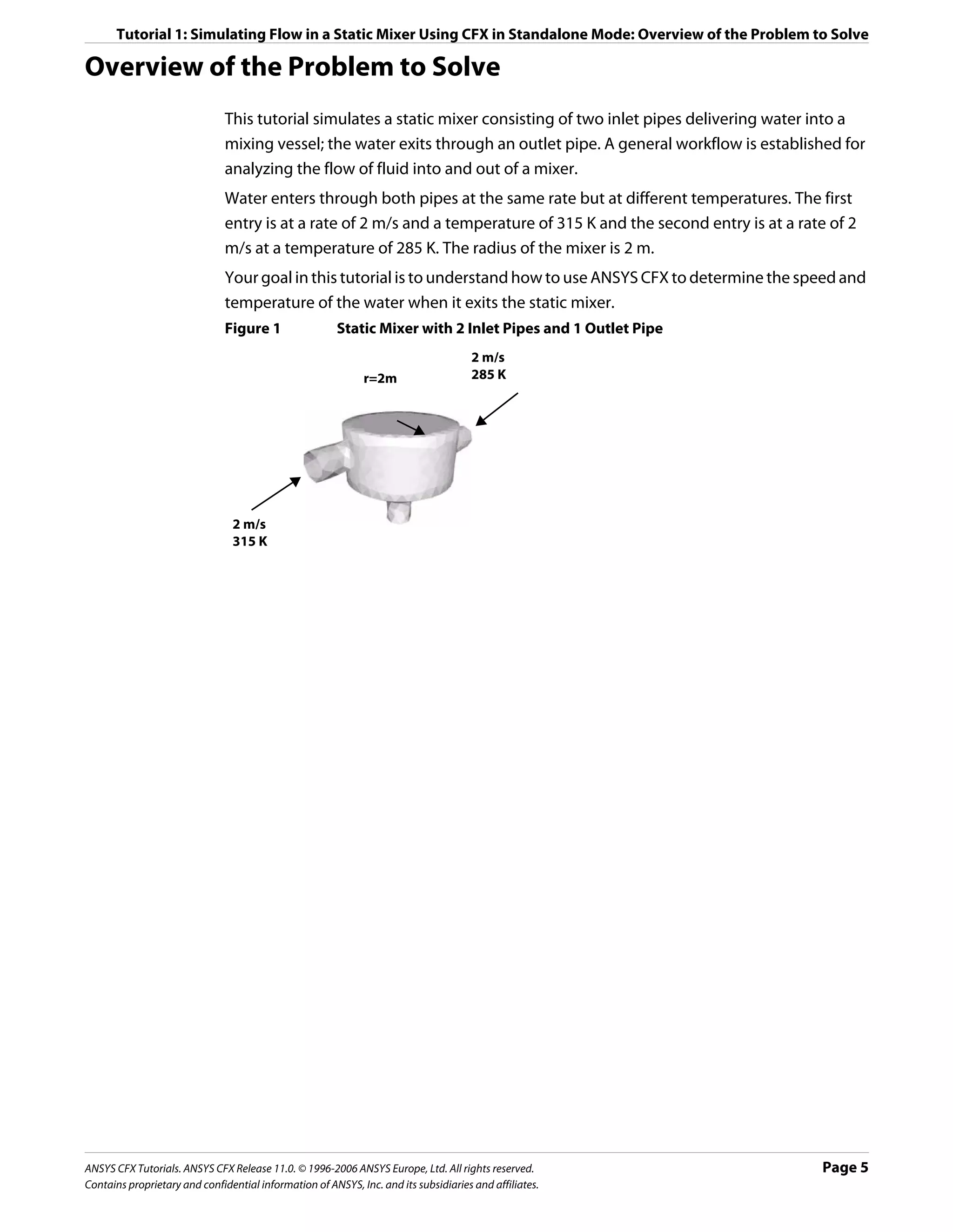

Once boundaries are created, you need to create associated data. Based on Figure 1, you will

define the first inlet boundary condition’s velocity and temperature.

Procedure 1. Ensure that Boundary Data is displayed.

2. Set Boundary Type to Inlet.

3. Set Location to in1.

Setting Flow Specification

Once boundary data is defined, the boundary needs to have the flow specification assigned.

Procedure 1. Ensure that Flow Specification is displayed.

2. Set Option to Normal Speed.

3. Set Normal Speed to 2 [m s^-1].

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 9

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-21-2048.jpg)

![Tutorial 1: Simulating Flow in a Static Mixer Using CFX in Standalone Mode: Defining a Simulation in ANSYS CFX-Pre

Setting Temperature Specification

Once flow specification is defined, the boundary needs to have temperature assigned.

Procedure 1. Ensure that Temperature Specification is displayed.

2. Set Static Temperature to 315 [K].

Reviewing the Boundary Condition Definitions

Defining the boundary condition for in1 required several steps. Here the settings are

reviewed for accuracy.

Based on Figure 1, the first inlet boundary condition consists of a velocity of 2 m/s and a

temperature of 315 K at one of the side inlets.

Procedure 1. Review the boundary in1 settings for accuracy. They should be as follows:

Tab Setting Value

Boundary Data Boundary Type Inlet

Location in1

Flow Specification Option Normal Speed

Normal Speed 2 [m s^-1]

Temperature Specification Static Temperature 315 [K]

Creating the Second Inlet Boundary Definition

Based on Figure 1, you know the second inlet boundary condition consists of a velocity of 2

m/s and a temperature of 285 K at one of the side inlets. You will define that now.

Procedure 1. Under Boundary Definition, right-click in the selector area and select New.

2. Create a new boundary named in2 with these settings:

Tab Setting Value

Boundary Data Boundary Type Inlet

Location in2

Flow Specification Option Normal Speed

Normal Speed 2 [m s^-1]

Temperature Specification Static Temperature 285 [K]

Creating the Outlet Boundary Definition

Now that the second inlet boundary has been created, the same concepts can be applied to

building the outlet boundary.

1. Create a new boundary named out with these settings:

Page 10 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-22-2048.jpg)

![Tutorial 1: Simulating Flow in a Static Mixer Using CFX in Standalone Mode: Defining a Simulation in ANSYS CFX-Pre

Tab Setting Value

Boundary Data Boundary Type Outlet

Location out

Flow Specification Option Average Static Pressure

Relative Pressure 0 [Pa]

2. Click Next.

Moving to General Mode

There are no further boundary conditions that need to be set. All 2D exterior regions that

have not been assigned to a boundary condition are automatically assigned to the default

boundary condition.

Procedure 1. Set Operation to Enter General Mode and click Finish.

The three boundary conditions are displayed in the viewer as sets of arrows at the

boundary surfaces. Inlet boundary arrows are directed into the domain. Outlet

boundary arrows are directed out of the domain.

Setting Solver Control

Solver Control parameters control aspects of the numerical solution generation process.

While an upwind advection scheme is less accurate than other advection schemes, it is also

more robust. This advection scheme is suitable for obtaining an initial set of results, but in

general should not be used to obtain final accurate results.

The time scale can be calculated automatically by the solver or set manually. The Automatic

option tends to be conservative, leading to reliable, but often slow, convergence. It is often

possible to accelerate convergence by applying a time scale factor or by choosing a manual

value that is more aggressive than the Automatic option. In this tutorial, you will select a

physical time scale, leading to convergence that is twice as fast as the Automatic option.

Procedure 1. Click Solver Control .

2. On the Basic Settings tab, set Advection Scheme > Option to Upwind.

3. Set Convergence Control > Fluid Timescale Control > Timescale Control to

Physical Timescale and set the physical timescale value to 2 [s].

4. Click OK.

Writing the Solver (.def) File

The simulation file, StaticMixer.cfx, contains the simulation definition in a format that

can be loaded by ANSYS CFX-Pre, allowing you to complete (if applicable), restore, and

modify the simulation definition. The simulation file differs from the definition file in that it

can be saved at any time while defining the simulation.

Procedure 1. Click Write Solver File .

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 11

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-23-2048.jpg)

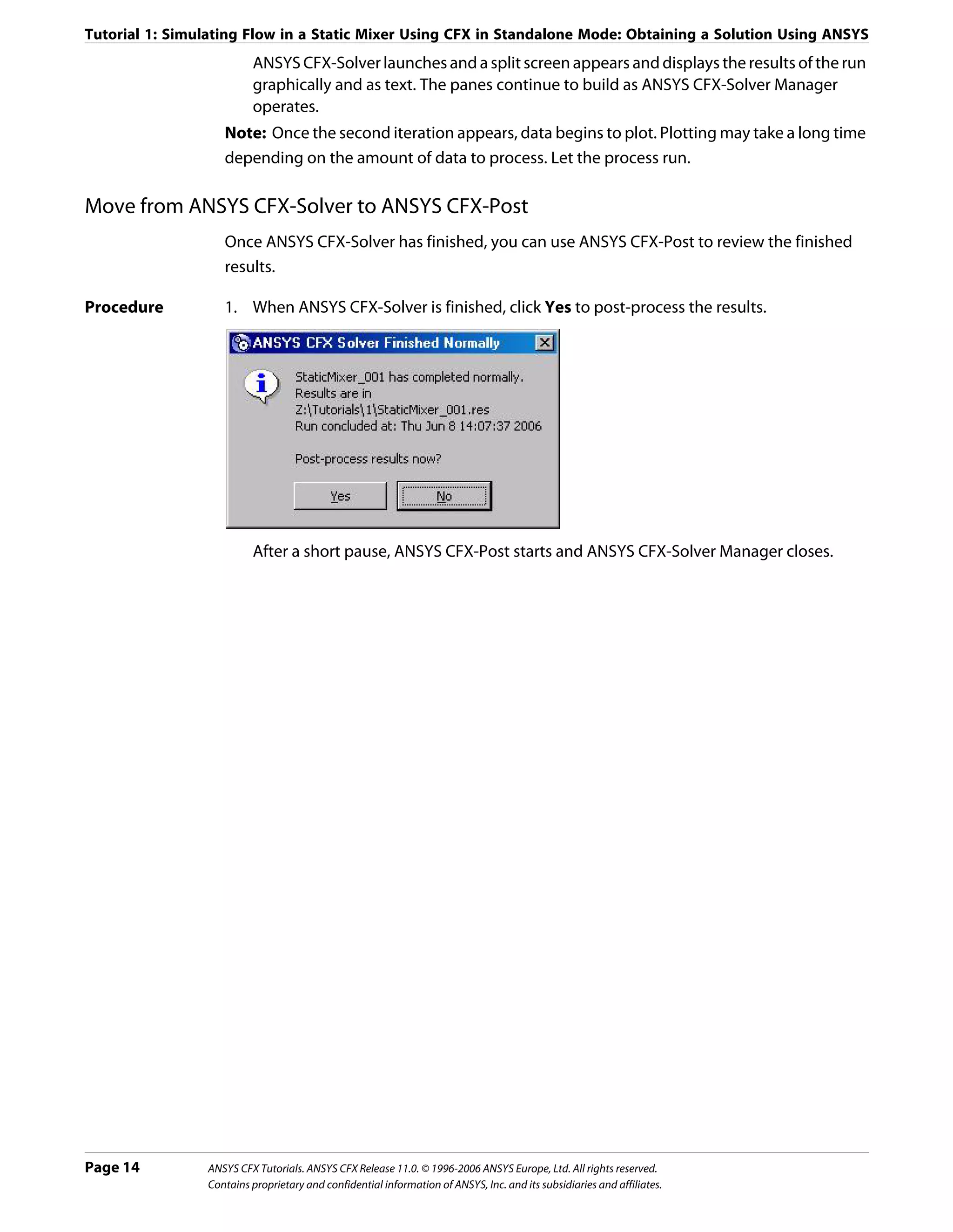

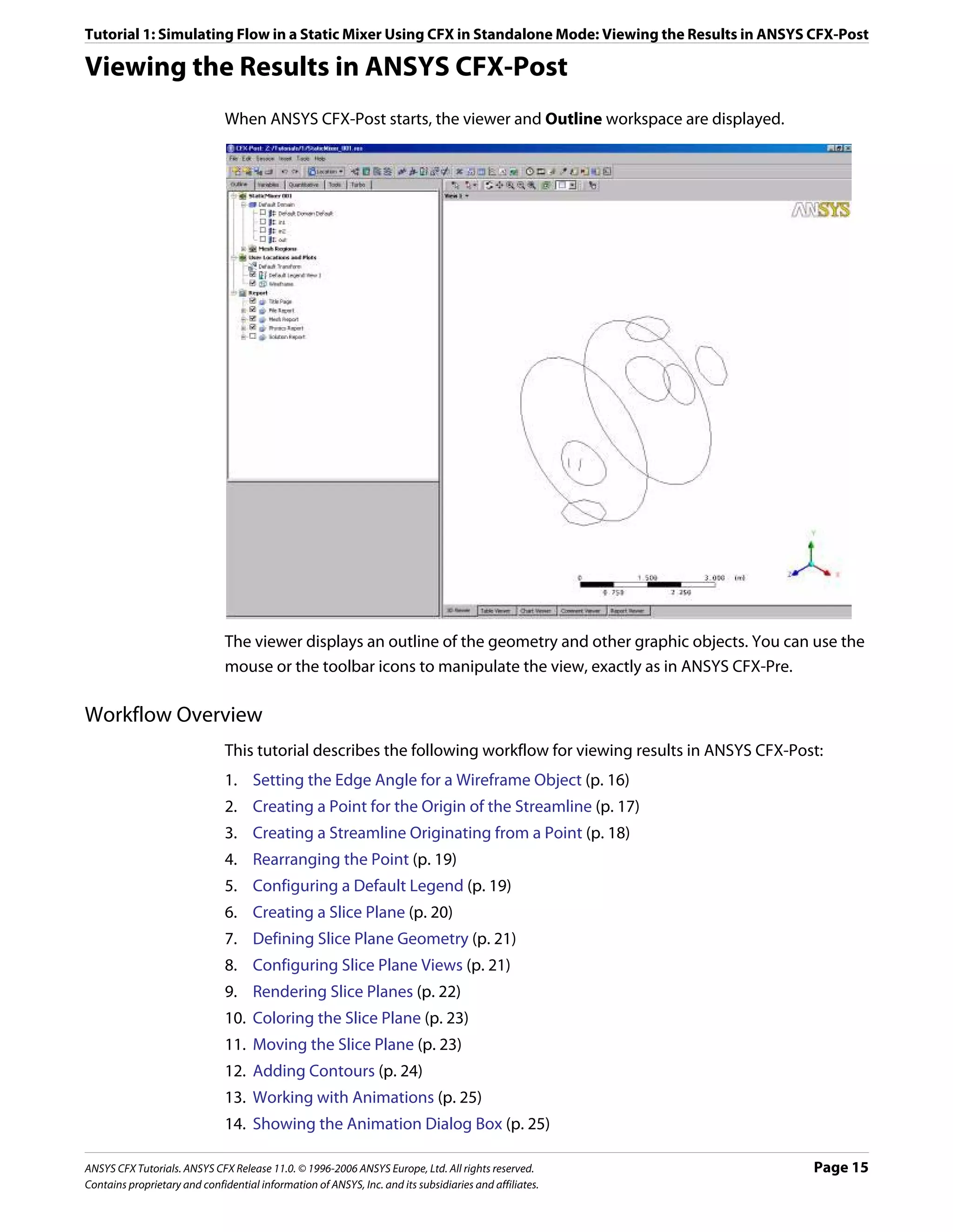

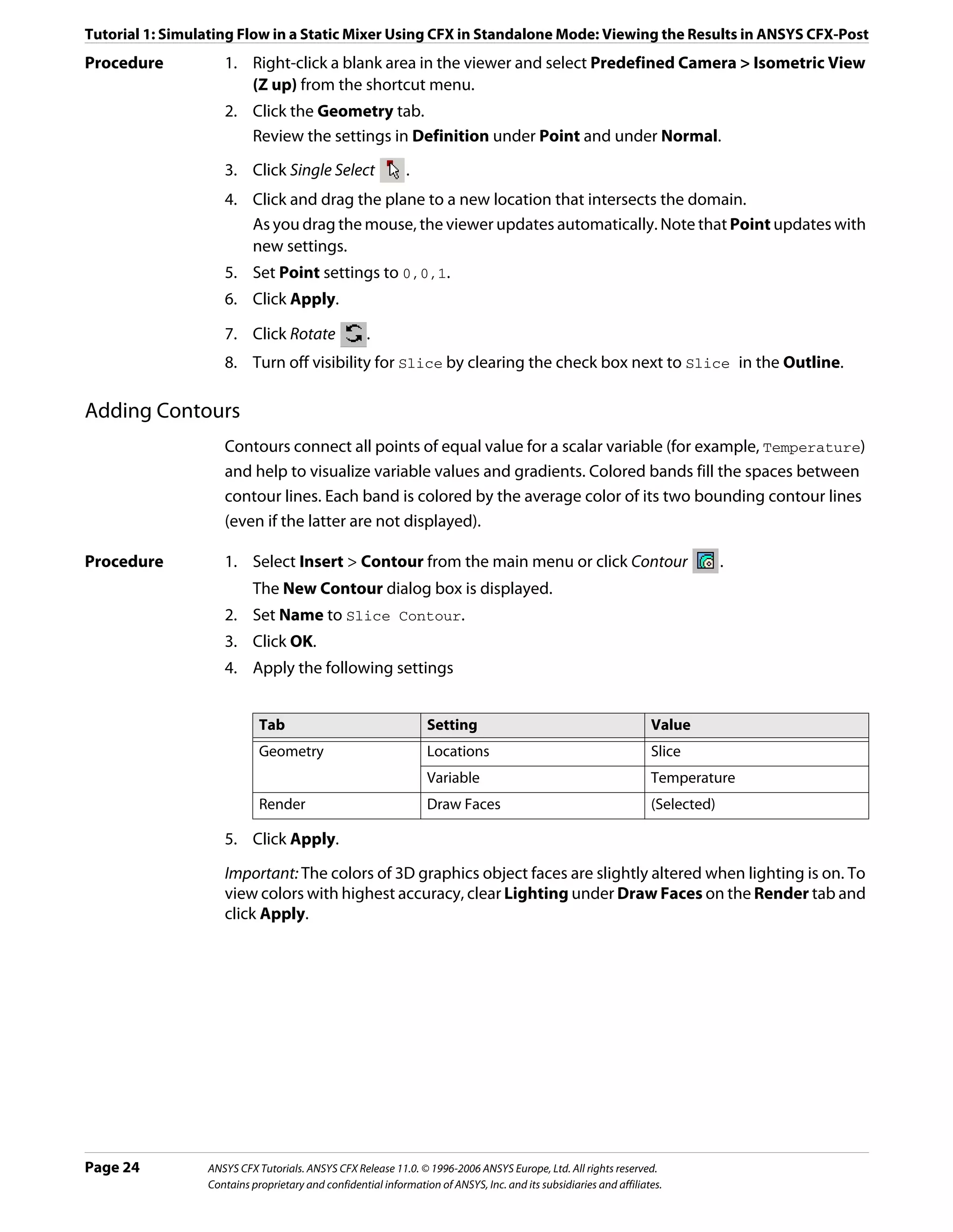

![Tutorial 1: Simulating Flow in a Static Mixer Using CFX in Standalone Mode: Viewing the Results in ANSYS CFX-Post

15. Creating the First Keyframe (p. 26)

16. Creating the Second Keyframe (p. 26)

17. Viewing the Animation (p. 27)

18. Modifying the Animation (p. 28)

19. Saving to MPEG (p. 29)

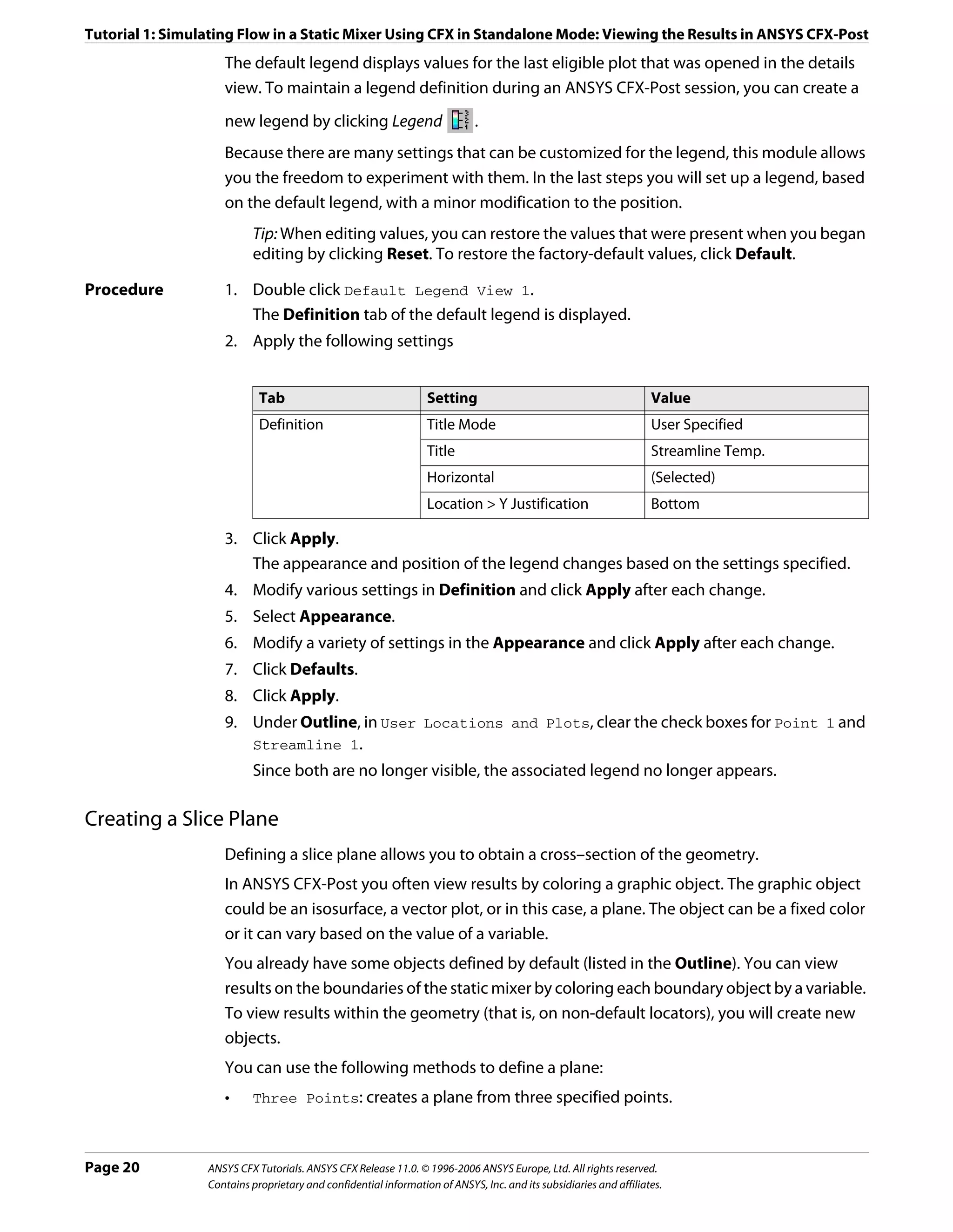

Setting the Edge Angle for a Wireframe Object

The outline of the geometry is called the wireframe or outline plot.

By default, ANSYS CFX-Post displays only some of the surface mesh. This sometimes means

that when you first load your results file, the geometry outline is not displayed clearly. You

can control the amount of the surface mesh shown by editing the Wireframe object listed

in the Outline.

The check boxes next to each object name in the Outline control the visibility of each

object. Currently only the Wireframe and Default Legend objects have visibility selected.

The edge angle determines how much of the surface mesh is visible. If the angle between

two adjacent faces is greater than the edge angle, then that edge is drawn. If the edge angle

is set to 0°, the entire surface mesh is drawn. If the edge angle is large, then only the most

significant corner edges of the geometry are drawn.

For this geometry, a setting of approximately 15° lets you view the model location without

displaying an excessive amount of the surface mesh.

In this module you can also modify the zoom settings and view of the wireframe.

Procedure 1. In the Outline, under User Locations and Plots, double-click Wireframe.

Tip: While it is not necessary to change the view to set the angle, do so to explore the

practical uses of this feature.

2. Right-click on a blank area anywhere in the viewer, select Predefined Camera from the

shortcut menu and select Isometric View (Z up).

3. In the Wireframe details view, under Definition, click in the Edge Angle box.

An embedded slider is displayed.

4. Type a value of 10 [degree].

5. Click Apply to update the object with the new setting.

Page 16 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-28-2048.jpg)

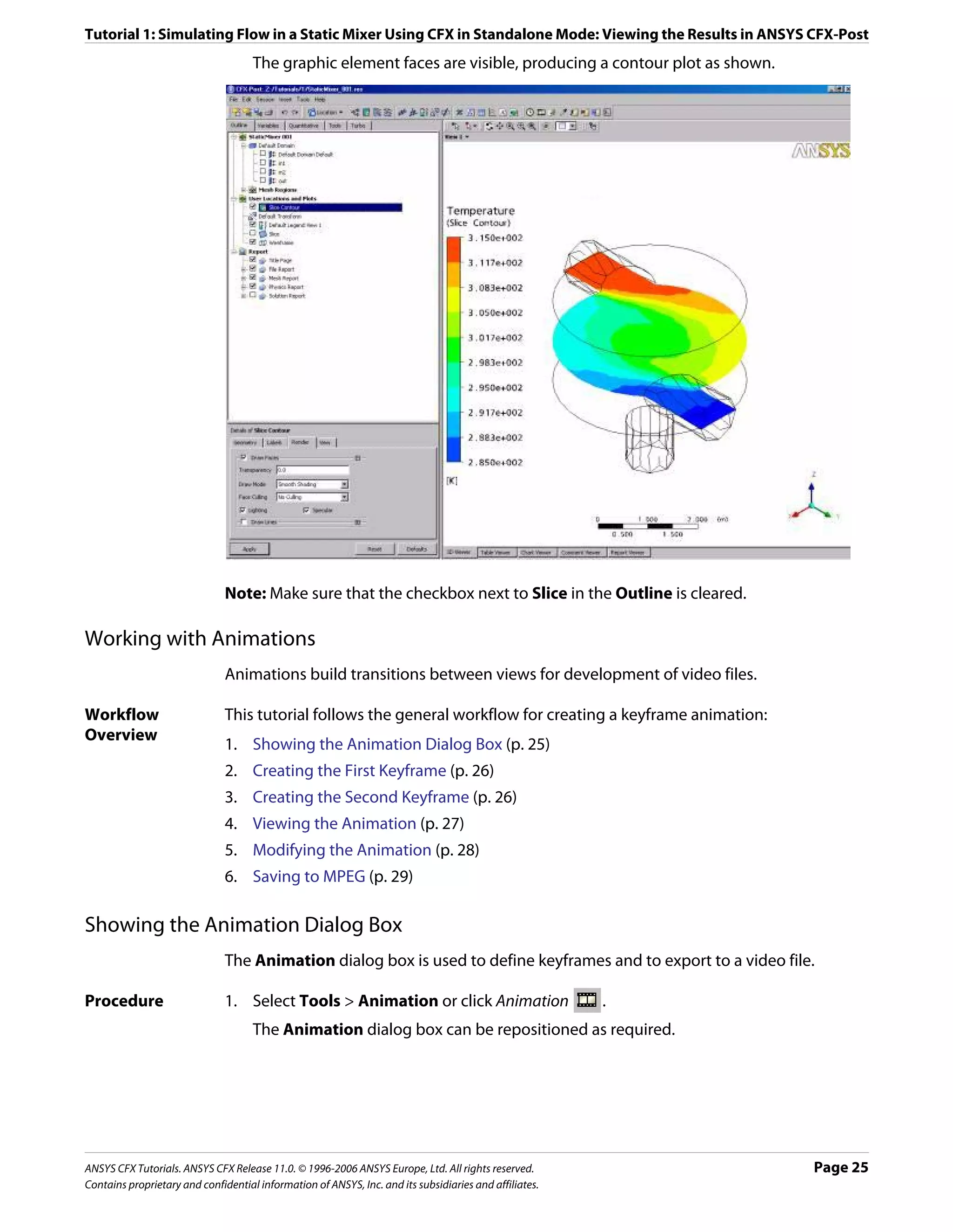

![Tutorial 1: Simulating Flow in a Static Mixer Using CFX in Standalone Mode: Viewing the Results in ANSYS CFX-Post

Notice that more surface mesh is displayed.

6. Drag the embedded slider to set the Edge Angle value to approximately 45 [degree].

7. Click Apply to update the object with the new setting.

Less of the outline of the geometry is displayed.

8. Type a value of 15 [degree].

9. Click Apply to update the object with the new setting.

10. Right-click on a blank area anywhere in the viewer, select Predefined Camera from the

shortcut menu and select View Towards -X.

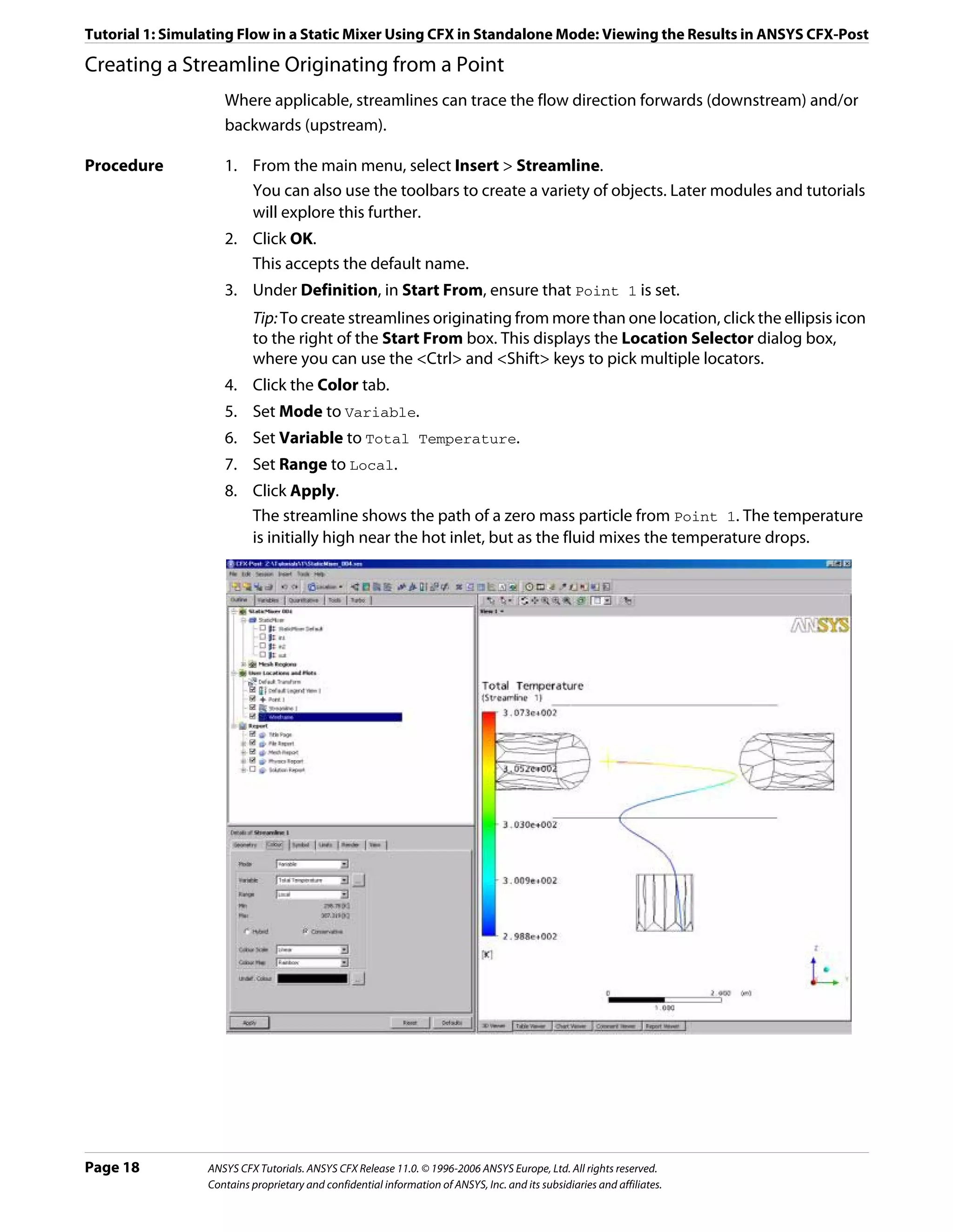

Creating a Point for the Origin of the Streamline

A streamline is the path that a particle of zero mass would follow through the domain.

Procedure 1. Select Insert > Location > Point from the main menu.

You can also use the toolbars to create a variety of objects. Later modules and tutorials

explore this further.

2. Click OK.

This accepts the default name.

3. Under Definition, ensure that Method is set to XYZ.

4. Under Point, enter the following coordinates: -1, -1, 1.

This is a point near the first inlet.

5. Click Apply.

The point appears as a symbol in the viewer as a crosshair symbol.

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 17

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-29-2048.jpg)

![Tutorial 1: Simulating Flow in a Static Mixer Using CFX in Standalone Mode: Viewing the Results in ANSYS CFX-Post

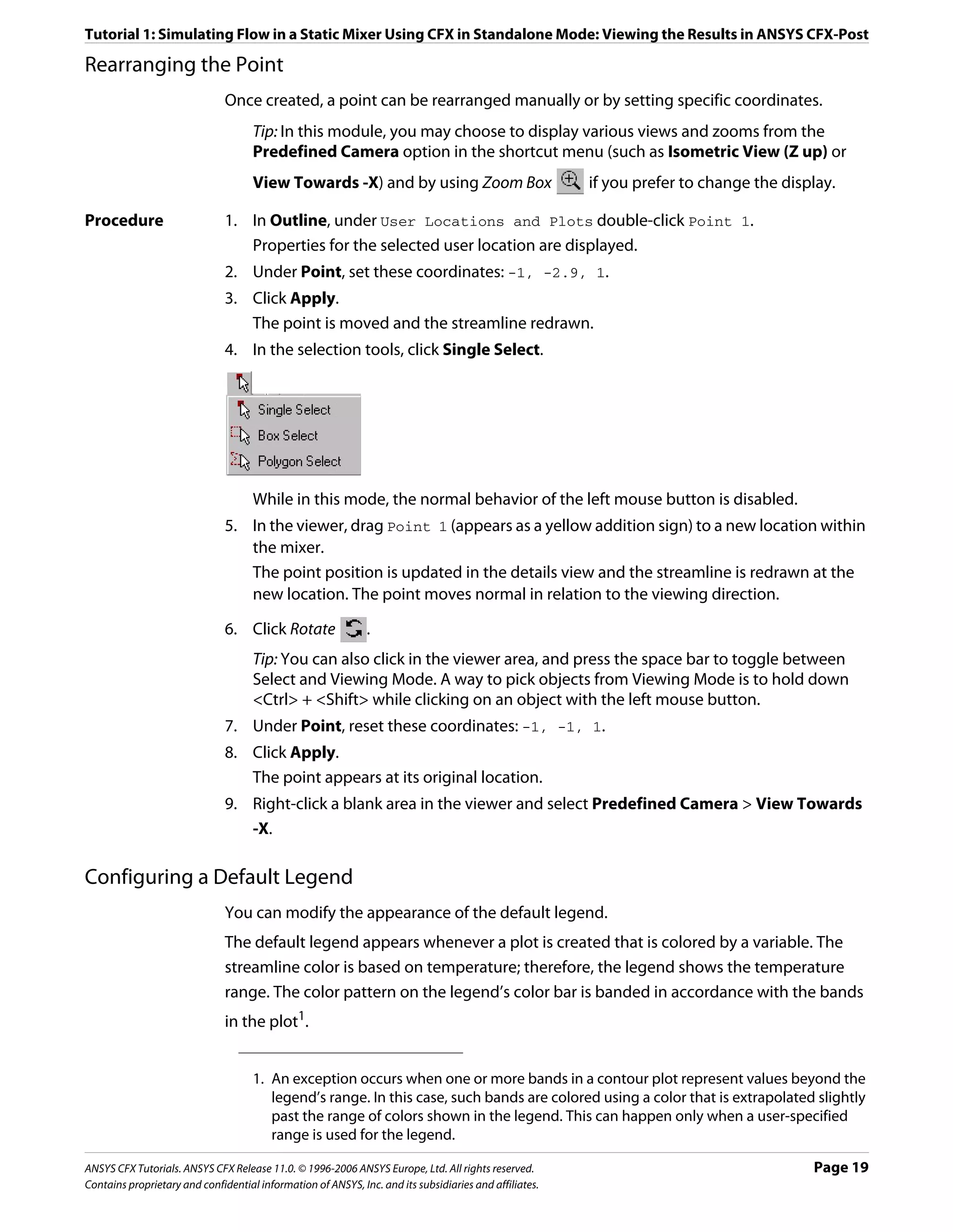

Modifying the Animation

To make the plane sweep through the whole geometry, you will set the starting position of

the plane to be at the top of the mixer. You will also modify the Range properties of the

plane so that it shows the temperature variation better. As the animation is played, you can

see the hot and cold water entering the mixer. Near the bottom of the mixer (where the

water flows out) you can see that the temperature is quite uniform. The new temperature

range lets you view the mixing process more accurately than the global range used in the

first animation.

Procedure 1. Apply the following settings to Slice

Tab Setting Value

Geometry Point 0, 0, 1.99

Color Variable Temperature

Range User Specified

Min 295 [K]

Max 305 [K]

2. Click Apply.

The slice plane moves to the top of the static mixer.

Note: Do not double click in the next step.

3. In the Animation dialog box, single click (do not double-click) KeyframeNo1 to select it.

If you had double-clicked KeyFrameNo1, the plane and viewer states would have been

redefined according to the stored settings for KeyFrameNo1. If this happens, click

Undo and try again to select the keyframe.

4. Click Set Keyframe .

The image in the Viewer replaces the one previously associated with KeyframeNo1.

5. Double-click KeyframeNo2.

The object properties for the slice plane are updated according to the settings in

KeyFrameNo2.

6. Apply the following settings to Slice

Tab Setting Value

Color Variable Temperature

Range User Specified

Min 295 [K]

Max 305 [K]

7. Click Apply.

8. In the Animation dialog box, single-click KeyframeNo2.

9. Click Set Keyframe to save the new settings to KeyframeNo2.

Page 28 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-40-2048.jpg)

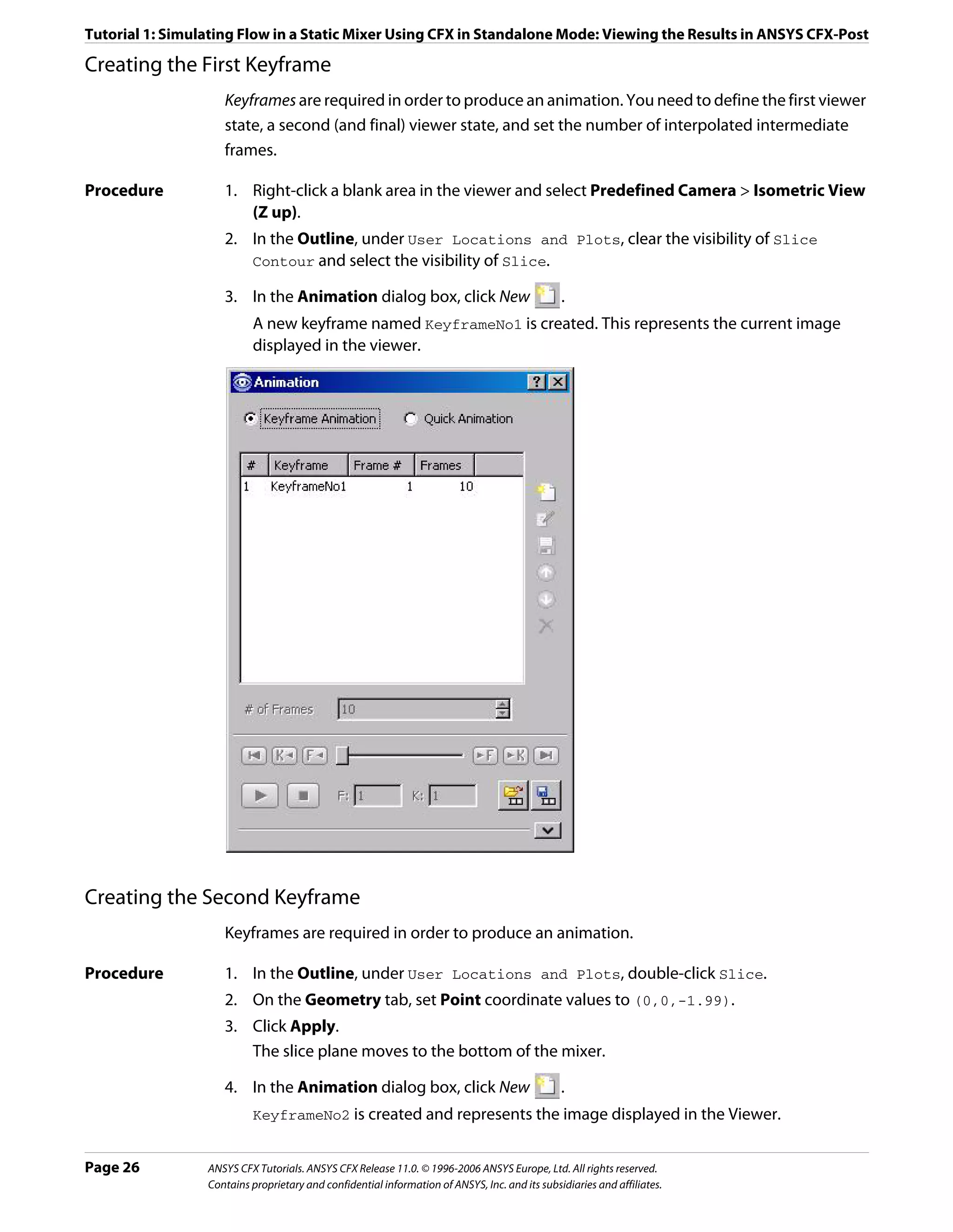

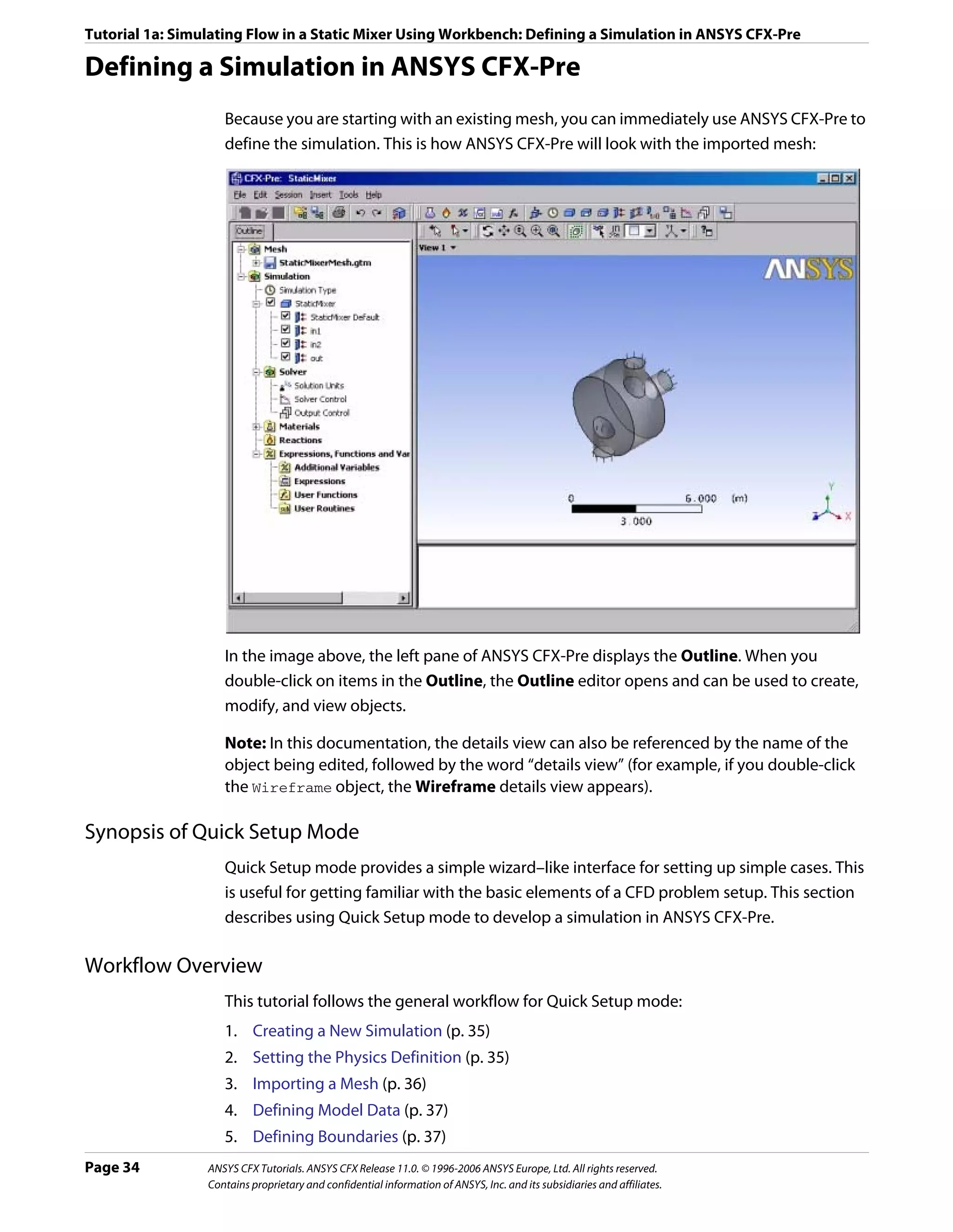

![Tutorial 1a: Simulating Flow in a Static Mixer Using Workbench: Defining a Simulation in ANSYS CFX-Pre

4. Right-click a blank area in the viewer and select Predefined Camera > Isometric View

(Z Up).

A clearer view of the mesh is displayed.

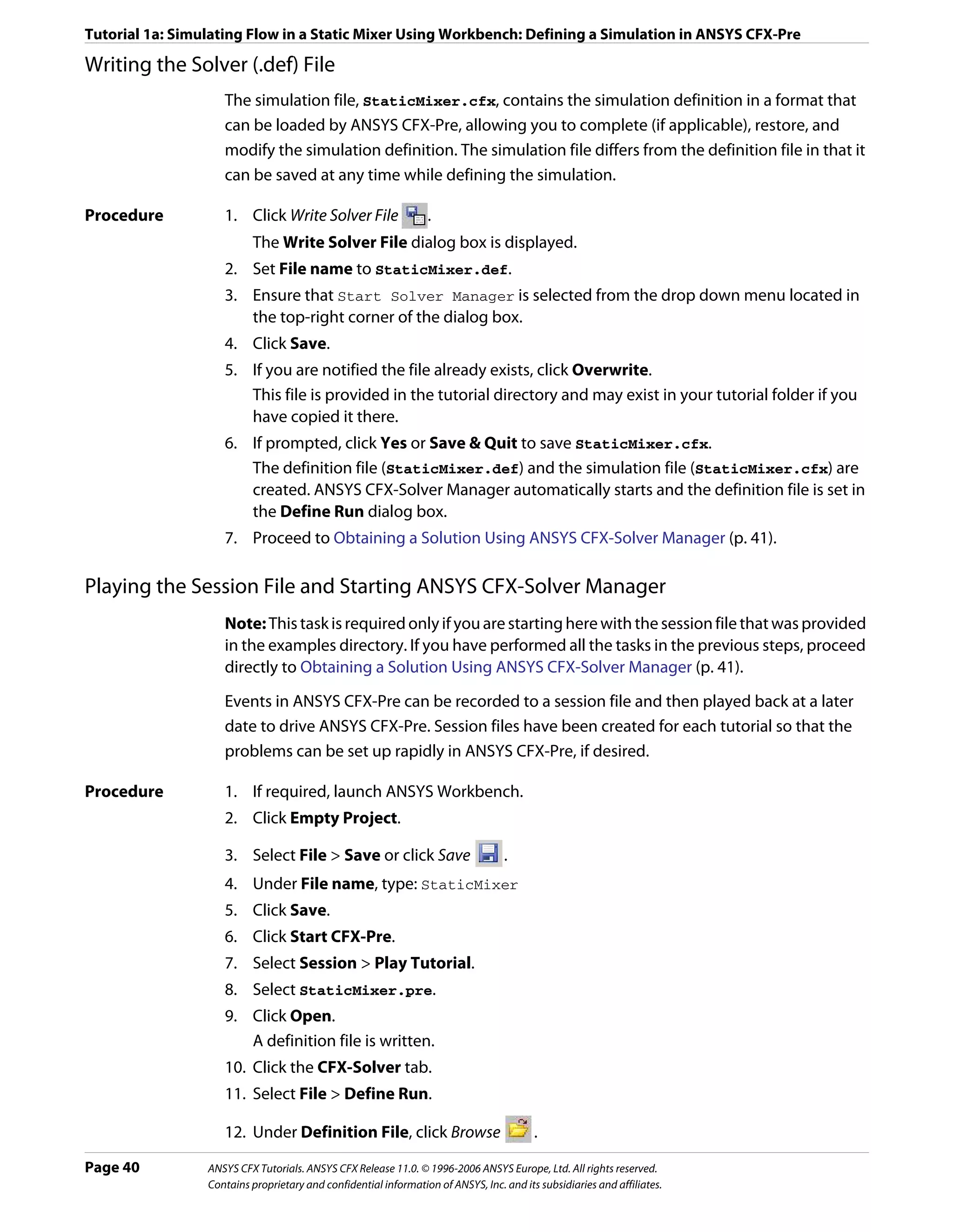

Defining Model Data

You need to define the type of flow and the physical models to use in the fluid domain.

You will specify the flow as steady state with turbulence and heat transfer. Turbulence is

modelled using the k - ε turbulence model and heat transfer using the thermal energy

model. The k - ε turbulence model is a commonly used model and is suitable for a wide

range of applications. The thermal energy model neglects high speed energy effects and is

therefore suitable for low speed flow applications.

Procedure 1. Ensure that Physics Definition is displayed.

2. Under Model Data, set Reference Pressure to 1 [atm].

All other pressure settings are relative to this reference pressure.

3. Set Heat Transfer to Thermal Energy.

4. Set Turbulence to k-Epsilon.

5. Click Next.

Defining Boundaries

The CFD model requires the definition of conditions on the boundaries of the domain.

Procedure 1. Ensure that Boundary Definition is displayed.

2. Delete Inlet and Outlet from the list by right-clicking each and selecting Delete.

3. Right-click in the blank area where Inlet and Outlet were listed, then select New.

4. Set Name to: in1

5. Click OK.

The boundary is created and, when selected, properties related to the boundary are

displayed.

Setting Boundary Data

Once boundaries are created, you need to create associated data. Based on Figure 1, you will

define the first inlet boundary condition to have a velocity of 2 m/s and a temperature of 315

K at one of the side inlets.

Procedure 1. Ensure that Boundary Data is displayed.

2. Set Boundary Type to Inlet.

3. Set Location to in1.

Setting Flow Specification

Once boundary data is defined, the boundary needs to have the flow specification assigned.

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 37

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-49-2048.jpg)

![Tutorial 1a: Simulating Flow in a Static Mixer Using Workbench: Defining a Simulation in ANSYS CFX-Pre

Procedure 1. Ensure that Flow Specification is displayed.

2. Set Option to Normal Speed.

3. Set Normal Speed to 2 [m s^-1].

Setting Temperature Specification

Once flow specification is defined, the boundary needs to have temperature assigned.

Procedure 1. Ensure that Temperature Specification is displayed.

2. Set Static Temperature to 315 [K].

Reviewing the Boundary Condition Definitions

Defining the boundary condition for in1 required several steps. Here the settings are

reviewed for accuracy.

Based on Figure 1, the first inlet boundary condition consists of a velocity of 2 m/s and a

temperature of 315 K at one of the side inlets.

Procedure 1. Review the boundary in1 settings for accuracy. They should be as follows:

Tab Setting Value

Boundary Data Boundary Type Inlet

Location in1

Flow Specification Option Normal Speed

Normal Speed 2 [m s^-1]

Temperature Specification Static Temperature 315 [K]

Creating the Second Inlet Boundary Definition

Based on Figure 1, you know the second inlet boundary condition consists of a velocity of 2

m/s and a temperature of 285 K at one of the side inlets. You will define that now.

Procedure 1. Under Boundary Definition, right-click in the selector area and select New.

2. Create a new boundary named in2 with these settings:

Tab Setting Value

Boundary Data Boundary Type Inlet

Location in2

Flow Specification Option Normal Speed

Normal Speed 2 [m s^-1]

Temperature Specification Static Temperature 285 [K]

Page 38 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-50-2048.jpg)

![Tutorial 1a: Simulating Flow in a Static Mixer Using Workbench: Defining a Simulation in ANSYS CFX-Pre

Creating the Outlet Boundary Definition

Now that the second inlet boundary has been created, the same concepts can be applied to

building the outlet boundary.

1. Create a new boundary named out with these settings:

Tab Setting Value

Boundary Data Boundary Type Outlet

Location out

Flow Specification Option Average Static Pressure

Relative Pressure 0 [Pa]

2. Click Next.

Moving to General Mode

There are no further boundary conditions that need to be set. All 2D exterior regions that

have not been assigned to a boundary condition are automatically assigned to the default

boundary condition.

Procedure 1. Set Operation to Enter General Mode and click Finish.

The three boundary conditions are displayed in the viewer as sets of arrows at the

boundary surfaces. Inlet boundary arrows are directed into the domain. Outlet

boundary arrows are directed out of the domain.

Setting Solver Control

Solver Control parameters control aspects of the numerical solution generation process.

While an upwind advection scheme is less accurate than other advection schemes, it is also

more robust. This advection scheme is suitable for obtaining an initial set of results, but in

general should not be used to obtain final accurate results.

The time scale can be calculated automatically by the solver or set manually. The Automatic

option tends to be conservative, leading to reliable, but often slow, convergence. It is often

possible to accelerate convergence by applying a time scale factor or by choosing a manual

value that is more aggressive than the Automatic option. In this tutorial, you will select a

physical time scale, leading to convergence that is twice as fast as the Automatic option.

Procedure 1. Click Solver Control .

2. On the Basic Settings tab, set Advection Scheme > Option to Upwind.

3. Set Convergence Control > Fluid Timescale Control > Timescale Control to

Physical Timescale and set the physical timescale value to 2 [s].

4. Click OK.

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 39

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-51-2048.jpg)

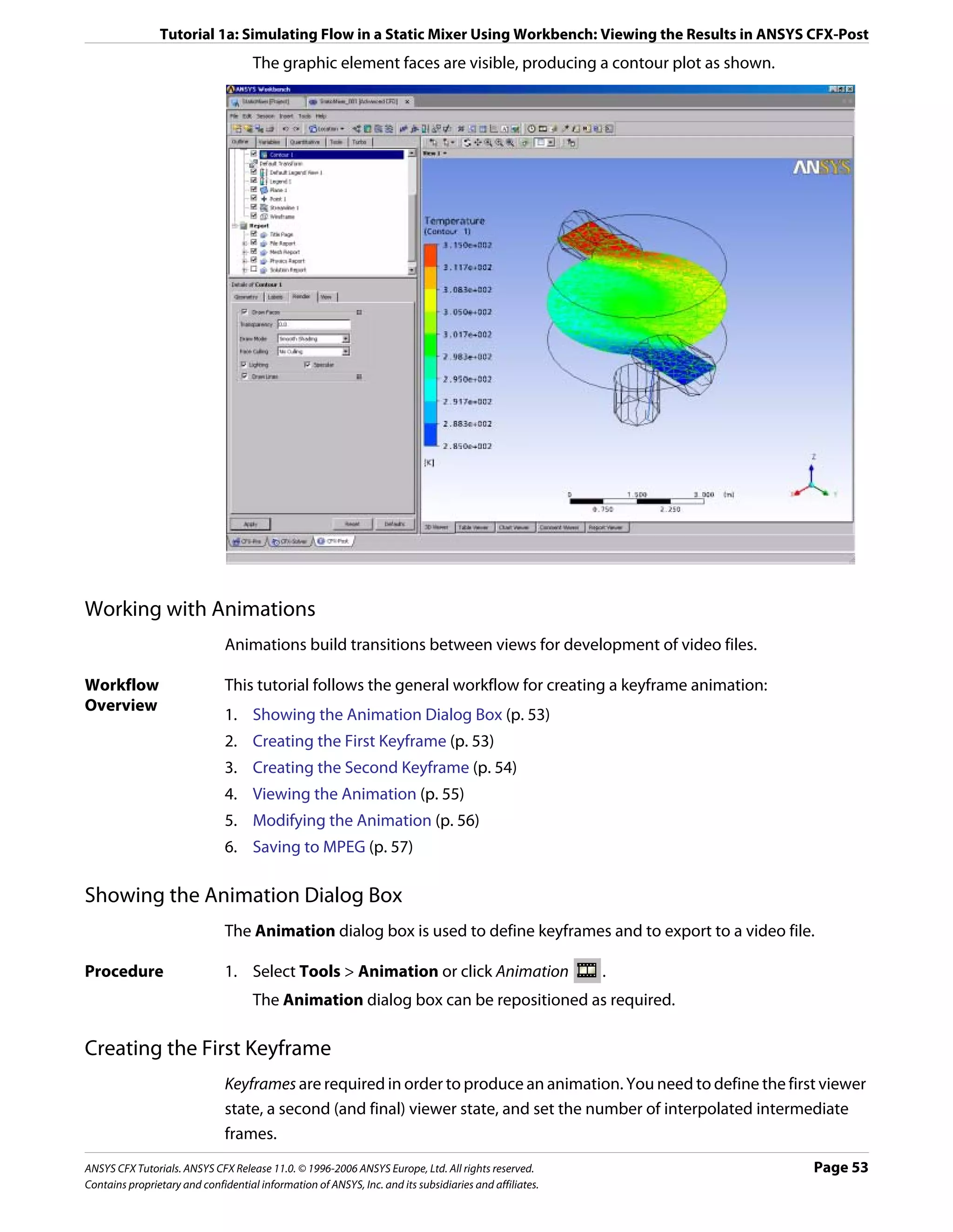

![Tutorial 1a: Simulating Flow in a Static Mixer Using Workbench: Viewing the Results in ANSYS CFX-Post

Setting the Edge Angle for a Wireframe Object

The outline of the geometry is called the wireframe or outline plot.

By default, ANSYS CFX-Post displays only some of the surface mesh. This sometimes means

that when you first load your results file, the geometry outline is not displayed clearly. You

can control the amount of the surface mesh shown by editing the Wireframe object listed

in the Outline.

The check boxes next to each object name in the Outline control the visibility of each

object. Currently only the Wireframe and Default Legend objects have visibility selected.

The edge angle determines how much of the surface mesh is visible. If the angle between

two adjacent faces is greater than the edge angle, then that edge is drawn. If the edge angle

is set to 0°, the entire surface mesh is drawn. If the edge angle is large, then only the most

significant corner edges of the geometry are drawn.

For this geometry, a setting of approximately 15° lets you view the model location without

displaying an excessive amount of the surface mesh.

In this module you can also modify the zoom settings and view of the wireframe.

Procedure 1. In the Outline, under User Locations and Plots, double-click Wireframe.

Tip: While it is not necessary to change the view to set the angle, do so to explore the

practical uses of this feature.

2. Right-click on a blank area anywhere in the viewer, select Predefined Camera from the

shortcut menu and select Isometric View (Z up).

3. In the Wireframe details view, under Definition, click in the Edge Angle box.

An embedded slider is displayed.

4. Type a value of 10 [degree].

5. Click Apply to update the object with the new setting.

Page 44 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-56-2048.jpg)

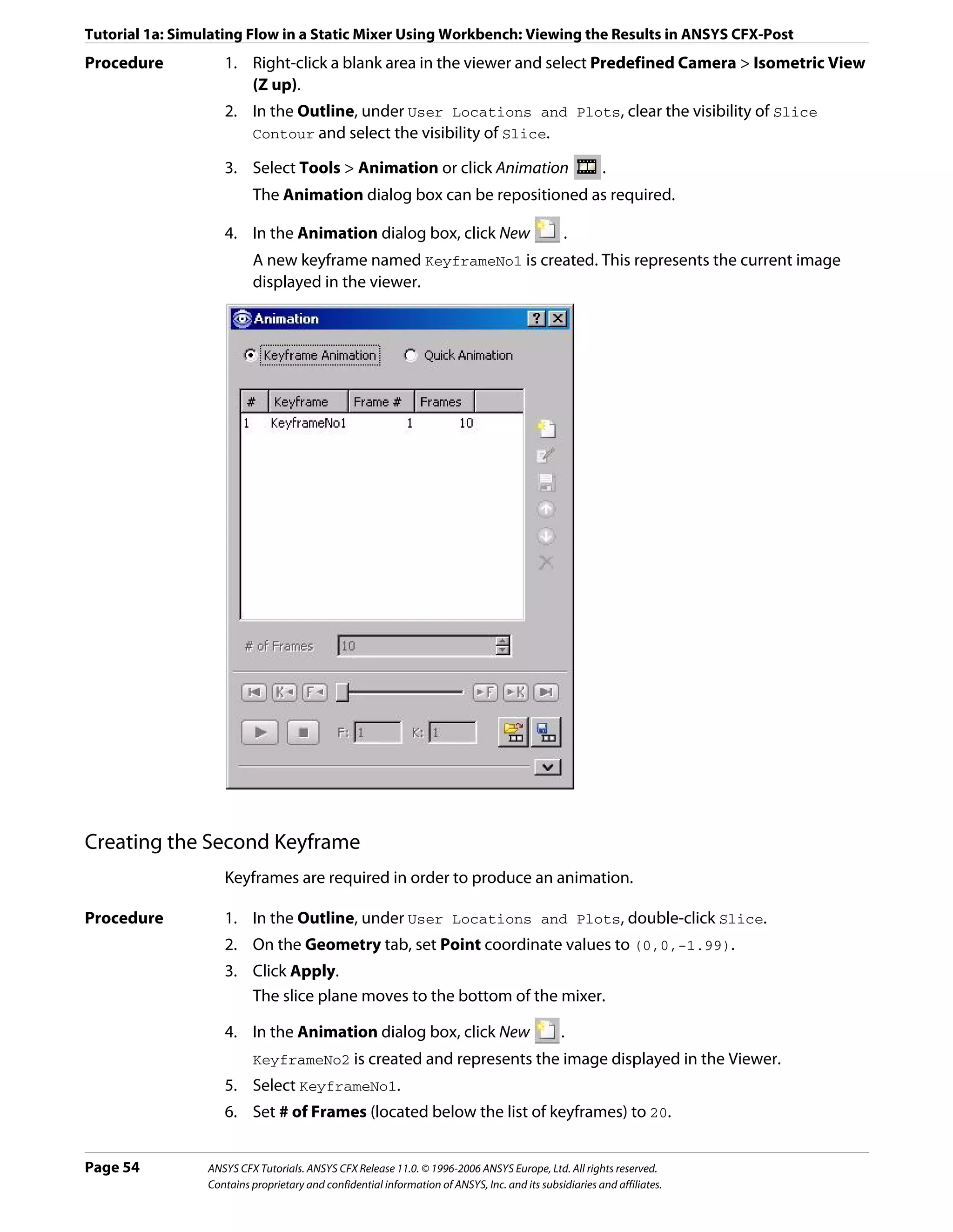

![Tutorial 1a: Simulating Flow in a Static Mixer Using Workbench: Viewing the Results in ANSYS CFX-Post

Notice that more surface mesh is displayed.

6. Drag the embedded slider to set the Edge Angle value to approximately 45 [degree].

7. Click Apply to update the object with the new setting.

Less of the outline of the geometry is displayed.

8. Type a value of 15 [degree].

9. Click Apply to update the object with the new setting.

10. Right-click on a blank area anywhere in the viewer, select Predefined Camera from the

shortcut menu and select View Towards -X.

Creating a Point for the Origin of the Streamline

A streamline is the path that a particle of zero mass would follow through the domain.

Procedure 1. Select Insert > Location > Point from the main menu.

You can also use the toolbars to create a variety of objects. Later modules and tutorials

explore this further.

2. Click OK.

This accepts the default name.

3. Under Definition, ensure that Method is set to XYZ.

4. Under Point, enter the following coordinates: -1, -1, 1.

This is a point near the first inlet.

5. Click Apply.

The point appears as a symbol in the viewer as a crosshair symbol.

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 45

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-57-2048.jpg)

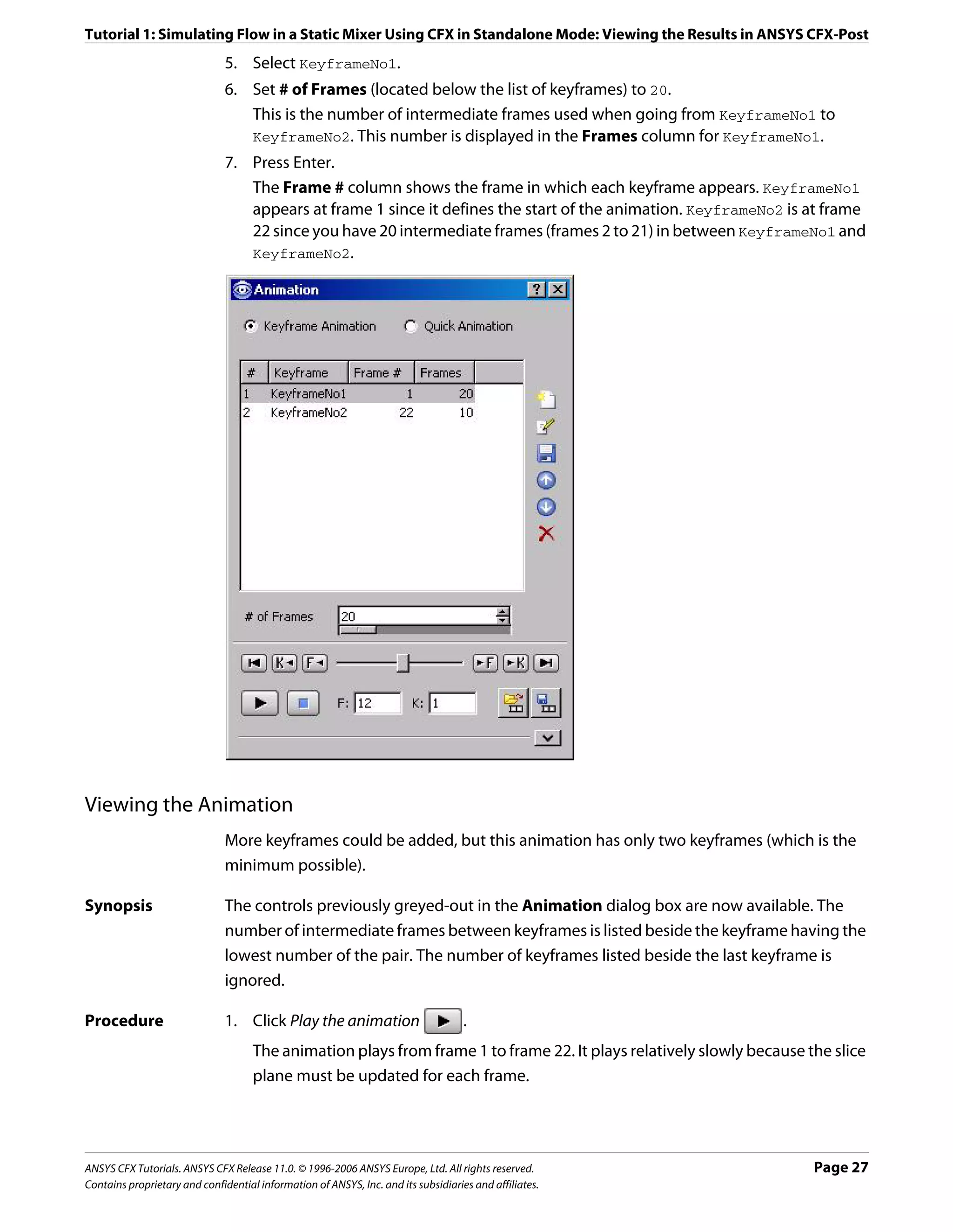

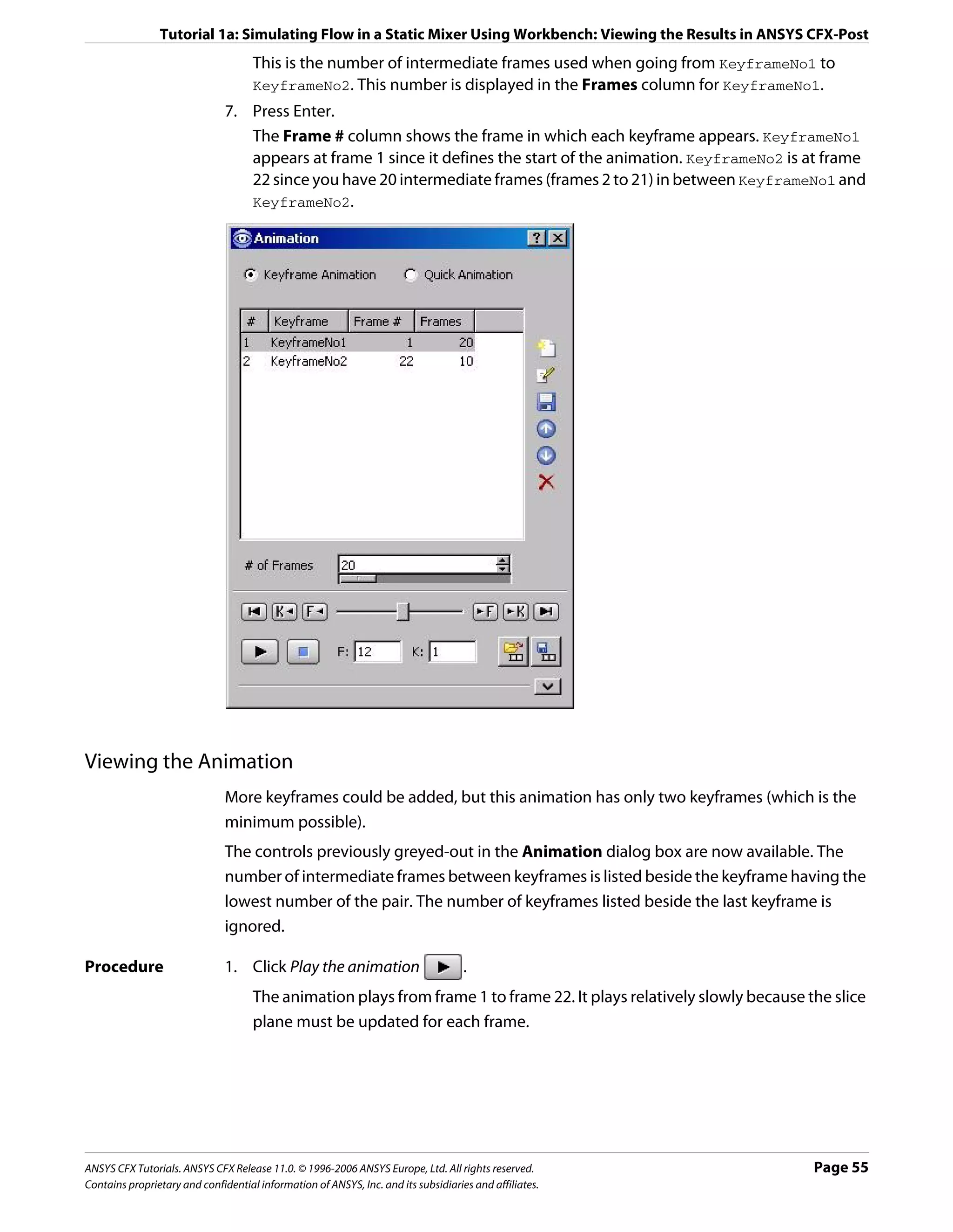

![Tutorial 1a: Simulating Flow in a Static Mixer Using Workbench: Viewing the Results in ANSYS CFX-Post

Modifying the Animation

To make the plane sweep through the whole geometry, you will set the starting position of

the plane to be at the top of the mixer. You will also modify the Range properties of the

plane so that it shows the temperature variation better. As the animation is played, you can

see the hot and cold water entering the mixer. Near the bottom of the mixer (where the

water flows out) you can see that the temperature is quite uniform. The new temperature

range lets you view the mixing process more accurately than the global range used in the

first animation.

Procedure 1. Apply the following settings to Slice

Tab Setting Value

Geometry Point 0, 0, 1.99

Color Mode Variable

Range User Specified

Min 295 [K]

Max 305 [K]

2. Click Apply.

The slice plane moves to the top of the static mixer.

Note: Do not double click in the next step.

3. In the Animation dialog box, single click (do not double-click) KeyframeNo1 to select it.

If you had double-clicked KeyFrameNo1, the plane and viewer states would have been

redefined according to the stored settings for KeyFrameNo1. If this happens, click

Undo and try again to select the keyframe.

4. Click Set Keyframe .

The image in the Viewer replaces the one previously associated with KeyframeNo1.

5. Double-click KeyframeNo2.

The object properties for the slice plane are updated according to the settings in

KeyFrameNo2.

6. Apply the following settings to Slice

Tab Setting Value

Color Mode Variable

Range User Specified

Min 295 [K]

Max 305 [K]

7. Click Apply.

8. In the Animation dialog box, single-click KeyframeNo2.

9. Click Set Keyframe to save the new settings to KeyframeNo2.

Page 56 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-68-2048.jpg)

![Tutorial 2: Flow in a Static Mixer (Refined Mesh): Defining a Simulation using General Mode in ANSYS CFX-Pre

Viewing the Boundary Condition Setting

For the k-epsilon turbulence model, you must specify the turbulent nature of the flow

entering through the inlet boundary. For this simulation, the default setting of Medium

(Intensity = 5%) is used. This is a sensible setting if you do not know the turbulence

properties of the incoming flow.

Procedure 1. Under Default Domain, double-click in1.

2. Click the Boundary Details tab and review the settings for Flow Regime, Mass and

Momentum, Turbulence and Heat Transfer.

3. Click Close.

Defining Solver Parameters

Solver Control parameters control aspects of the numerical-solution generation process.

In Tutorial 1 you set some solver control parameters, such as Advection Scheme and

Timescale Control, while other parameters were set automatically by ANSYS CFX-Pre.

In this tutorial, High Resolution is used for the advection scheme. This is more accurate

than the Upwind Scheme used in Tutorial 1. You usually require a smaller timestep when

using this model. You can also expect the solution to take a higher number of iterations to

converge when using this model.

Procedure 1. Select Insert > Solver > Solver Control from the main menu or click Solver Control .

2. Apply the following Basic Settings

Setting Value

Advection Scheme > Option High Resolution

Convergence Control > Max. Iterations* 150

Convergence Control > Fluid Timescale Control > Physical Timescale

Timescale Control

Convergence Control > Fluid Timescale Control > Physical 0.5 [s]

Timescale

*. If your solution does not meet the convergence criteria after this number of

timesteps, the ANSYS CFX-Solver will stop.

3. Click Apply.

4. Click the Advanced Options tab.

5. Ensure that Global Dynamic Model Control is selected.

6. Click OK.

Writing the Solver (.def) File

Once all boundaries are created you move from ANSYS CFX-Pre into ANSYS CFX-Solver.

Page 64 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-76-2048.jpg)

![Tutorial 2: Flow in a Static Mixer (Refined Mesh): Viewing the Results in ANSYS CFX-Post

After a short pause, ANSYS CFX-Post starts.

Viewing the Results in ANSYS CFX-Post

In the following sections, you will explore the differences between the mesh and the results

from this tutorial and tutorial 1.

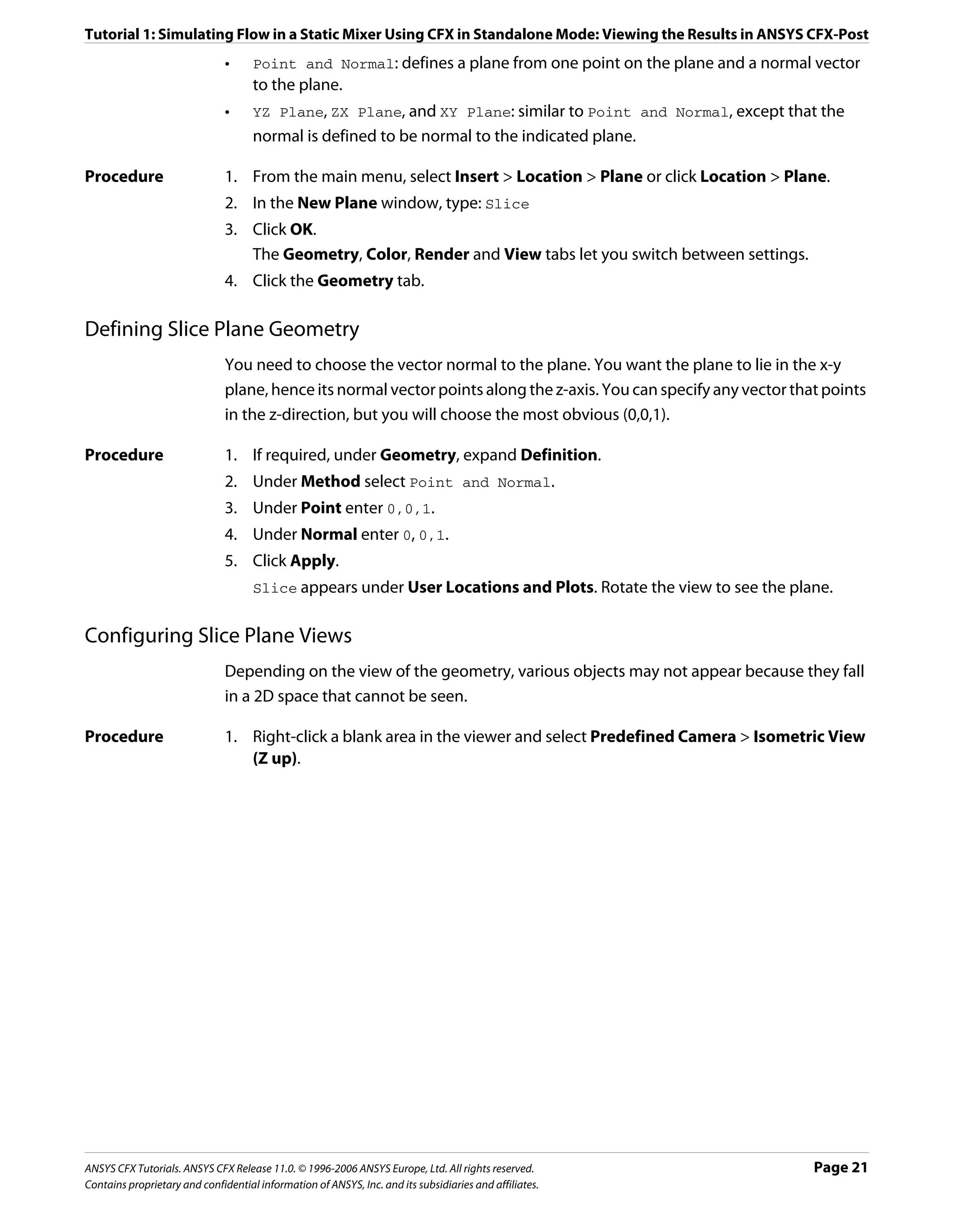

Creating a Slice Plane

More information exists for use by ANSYS CFX-Post in this tutorial than in Tutorial 1 because

the slice plane is more detailed.

Once a new slice plane is created it can be compared with Tutorial 1. There are three

noticeable differences between the two slice planes.

• Around the edges of the mixer geometry there are several layers of narrow rectangles.

This is the region where the mesh contains prismatic elements (which are created as

inflation layers). The bulk of the geometry contains tetrahedral elements.

• There are more lines on the plane than there were in Tutorial 1. This is because the slice

plane intersects with more mesh elements.

• The curves of the mixer are smoother than in Tutorial 1 because the finer mesh better

represents the true geometry.

Procedure 1. Right-click a blank area in the viewer and select Predefined Camera > Isometric View

(Z up).

2. From the main menu, select Insert > Location > Plane or under Location, click Plane.

3. In the Insert Plane dialog box, type Slice and click OK.

The Geometry, Color, Render and View tabs let you switch between settings.

4. Apply the following settings

Tab Setting Value

Geometry Domains Default Domain

Definition > Method XY Plane

Definition > Z 1 [m]

Render Draw Faces (Cleared)

Draw Lines (Selected)

5. Click Apply.

6. Right-click a blank area in the viewer and select Predefined Camera > View Towards

-Z.

7. Click Zoom Box .

8. Zoom in on the geometry to view it in greater detail.

Page 68 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-80-2048.jpg)

![Tutorial 2: Flow in a Static Mixer (Refined Mesh): Viewing the Results in ANSYS CFX-Post

3. On the right side of the dialog box, there are two frames. Under Results file option,

select Add to current results.

4. Select the Offset in Y direction check box.

5. Under Additional actions, ensure that the Clear user state before loading check box

is cleared.

6. Click Open to load the results.

In the tree view, there is now a second group of domains, meshes and boundary

conditions with the heading StaticMixer_001.

7. Double-click the Wireframe object under User Locations and Plots.

8. In the Definition tab, set Edge Angle to 5 [degree].

9. Click Apply.

10. Right-click a blank area in the viewer and select Predefined Camera > Isometric View

(Z up).

Both meshes are now displayed in a line along the Y axis. Notice that one mesh is of a

higher resolution than the other.

11. Set Edge Angle to 30 [degree].

12. Click Apply.

Creating a Second Slice Plane

Procedure 1. In the tree view, right-click the plane named Slice and select Duplicate.

2. Click OK to accept the default name Slice 1.

3. In the tree view, double-click the plane named Slice 1.

4. On the Geometry tab, set Domains to Default Domain 1.

5. On the Color tab, ensure that Range is set to Global.

6. Click Apply.

7. Double-click Slice and make sure that Range is set to Global.

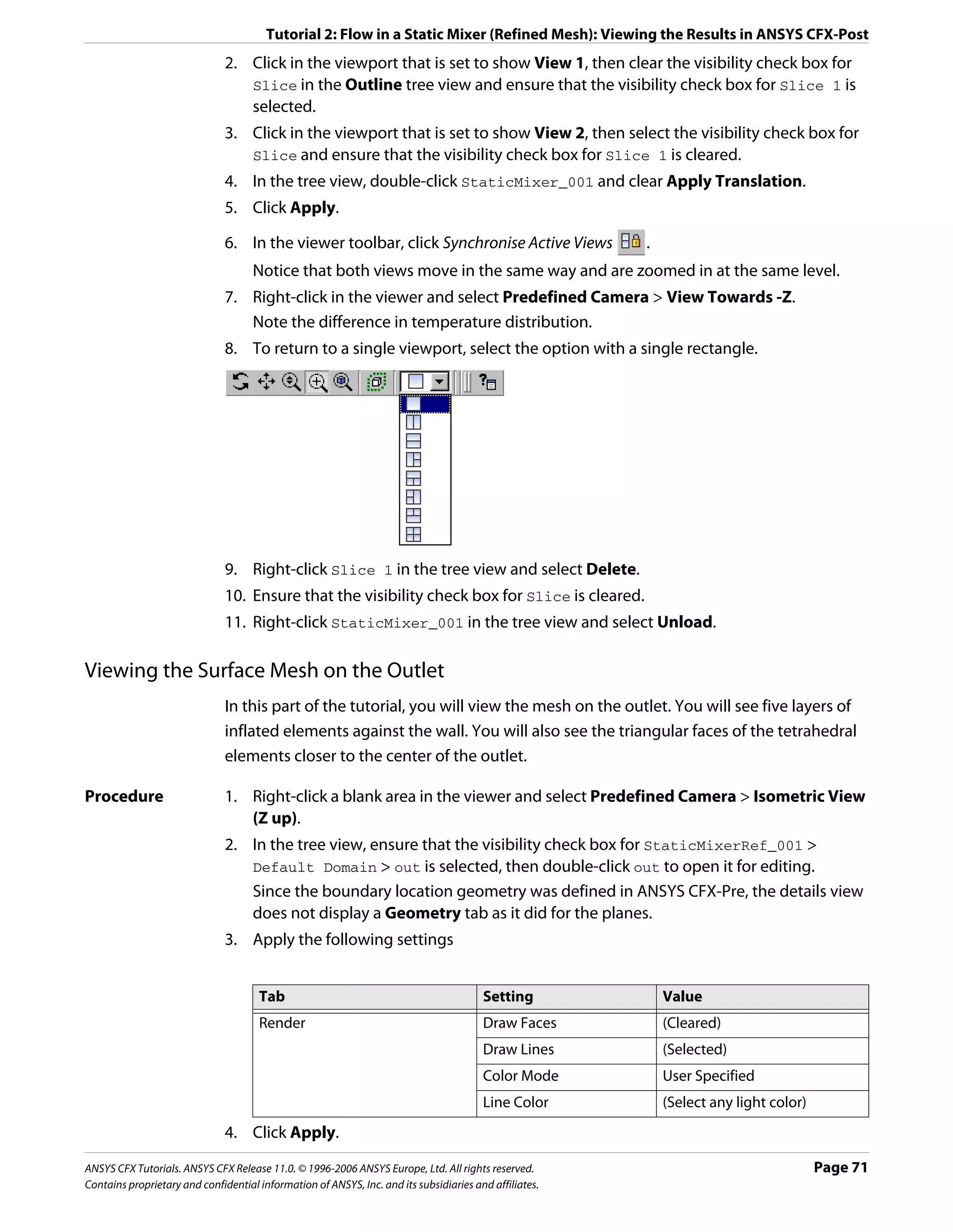

Comparing Slice Planes using Multiple Views

Procedure 1. Select the option with the two vertical rectangles. Notice that the Viewer now has two

separate views.

The visibility status of each object is maintained separately for each view or figure that

can be displayed in a given viewport. This allows some planes to be shown while others

are hidden.

Page 70 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-82-2048.jpg)

![Tutorial 2: Flow in a Static Mixer (Refined Mesh): Viewing the Results in ANSYS CFX-Post

5. Click Zoom Box .

6. Zoom in on the geometry to view out in greater detail.

7. Click Rotate on the Viewing Tools toolbar.

8. Rotate the image as required to clearly see the mesh.

Looking at the Inflated Elements in Three Dimensions

To show more clearly what effect inflation has on the shape of the elements, you will use

volume objects to show two individual elements. The first element that will be shown is a

normal tetrahedral element; the second is a prismatic element from an inflation layer of the

mesh.

Leave the surface mesh on the outlet visible to help see how surface and volume meshes are

related.

Procedure 1. From the main menu, select Insert > Location > Volume or, under Location click

Volume.

2. In the Insert Volume dialog box, type Tet Volume and click OK.

3. Apply the following settings

Tab Setting Value

Geometry Definition > Method Sphere

Definition > Point * 0.08, 0, -2

Definition > Radius 0.14 [m]

Definition > Mode Below Intersection

Inclusive† (Cleared)

Color Color Red

Render Draw Faces > Transparency 0.3

Draw Lines (Selected)

Draw Lines > Line Width 1

Draw Lines > Color Mode User Specified

Draw Lines > Line Color Grey

*. The z slider’s minimum value corresponds to the minimum z value of the entire

geometry, which, in this case, occurs at the outlet.

†. Only elements that are entirely contained within the sphere volume will be

included.

4. Click Apply to create the volume object.

5. Right-click Tet Volume and choose Duplicate.

6. In the Duplicate Tet Volume dialog box, type Prism Volume and click OK.

7. Double-click Prism Volume.

8. Apply the following settings

Page 72 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-84-2048.jpg)

![Tutorial 2: Flow in a Static Mixer (Refined Mesh): Viewing the Results in ANSYS CFX-Post

Tab Setting Value

Geometry Definition > Point -0.22, 0.4, -1.85

Definition > Radius 0.206 [m]

Color Color Orange

9. Click Apply.

Viewing the Surface Mesh on the Mixer Body

Procedure 1. Double-click the Default Domain Default object.

2. Apply the following settings

Tab Setting Value

Render Draw Faces (Selected)

Draw Lines (Selected)

Line Width 2

3. Click Apply.

Viewing the Layers of Inflated Elements on a Plane

You will see the layers of inflated elements on the wall of the main body of the mixer. Within

the body of the mixer, there will be many lines that are drawn wherever the face of a mesh

element intersects the slice plane.

Procedure 1. From the main menu, select Insert > Location > Plane or under Location, click Plane.

2. In the Insert Plane dialog box, type Slice 2 and click OK.

3. Apply the following settings

Tab Setting Value

Geometry Definition > Method YZ Plane

Definition > X 0 [m]

Render Draw Faces (Cleared)

Draw Lines (Selected)

4. Click Apply.

5. Turn off the visibility of all objects except Slice 2.

6. To see the plane clearly, right-click in the viewer and select Predefined Camera > View

Towards -X.

Viewing the Mesh Statistics

You can use the Report Viewer to check the quality of your mesh. For example, you can load

a .def file into ANSYS CFX-Post and check the mesh quality before running the .def file in

the solver.

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 73

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-85-2048.jpg)

![Tutorial 2: Flow in a Static Mixer (Refined Mesh): Viewing the Results in ANSYS CFX-Post

Procedure 1. Click the Report Viewer tab (located below the viewer window).

A report appears. Look at the table shown in the “Mesh Report” section.

2. Double-click Report > Mesh Report in the Outline tree view.

3. In the Mesh Report details view, select Statistics > Maximum Face Angle.

4. Click Refresh Preview.

Note that a new table, showing the maximum face angle for all elements in the mesh,

has been added to the “Mesh Report” section of the report. The maximum face angle is

reported as 148.95°.

As a result of generating this mesh statistic for the report, a new variable, Maximum Face

Angle, has been created and stored at every node. This variable will be used in the next

section.

Viewing the Mesh Elements with Largest Face Angle

In this section, you will visualize the mesh elements that have a Maximum Face Angle value

greater than 140°.

Procedure 1. Click the 3D Viewer tab (located below the viewer window).

2. Right-click a blank area in the viewer and select Predefined Camera > Isometric View

(Z up).

3. In the Outline tree view, select the visibility check box of Wireframe.

4. From the main menu, select Insert > Location > Volume or under Location, click

Volume.

5. In the Insert Volume dialog box, type Max Face Angle Volume and click OK.

6. Apply the following settings

Tab Setting Value

Geometry Definition > Method Isovolume

Definition > Variable Maximum Face Angle*

Definition > Mode Above Value

Definition > Value 140 [degree]

Inclusive† (Selected)

*. Select Maximum Face Angle from the larger list of variables available by clicking

to the right of the Variable box.

†. This includes any elements that have at least one node with a variable value greater

than or equal to the given value.

7. Click Apply.

The volume object appears in the viewer.

Page 74 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-86-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Defining a Simulation using General Mode in ANSYS CFX-Pre

Procedure 1. Select File > Import Mesh.

2. From your tutorial directory, select InjectMixerMesh.gtm.

3. Click Open.

4. Right-click a blank area in the viewer and select Predefined Camera > Isometric View

(Y up) from the shortcut menu.

Setting Temperature-Dependent Material Properties

You will create an expression for viscosity as a function of temperature and then use this

expression to modify the properties of the library material: Water.

Viscosity will be made to vary linearly with temperature between the following conditions:

• µ =1.8E-03 N s m-2 at T=275.0 K

• µ =5.45E-04 N s m-2 at T=325.0 K

The variable T (Temperature) is a ANSYS CFX System Variable recognized by ANSYS CFX-Pre,

denoting static temperature. All variables, expressions, locators, functions, and constants

can be viewed by double-clicking the appropriate entry (such as Additional Variables

or Expressions) in the tree view.

All expressions must have consistent units. You should be careful if using temperature in an

expression with units other than [K].

The Expressions tab lets you define, modify, evaluate, plot, copy, delete and browse

through expressions used within ANSYS CFX-Pre.

Procedure 1. From the main menu, select Insert > Expressions, Functions and Variables >

Expression.

2. In the New Expression dialog box, type Tupper.

3. Click OK.

The details view for the Tupper equation is displayed.

4. Under Definition, type 325 [K].

5. Click Apply to create the expression.

The expression is added to the list of existing expressions.

6. Right-click in the Expressions workspace and select New.

7. In the New Expression dialog box, type Tlower.

8. Click OK.

9. Under Definition, type 275 [K].

10. Click Apply to create the expression.

The expression is added to the list of existing expressions.

11. Create expressions for Visupper, Vislower and VisT using the following values.

Name Definition

Visupper 5.45E-04 [N s m^-2]

Vislower 1.8E-03 [N s m^-2]

VisT Vislower+(Visupper-Vislower)*(T-Tlower)/(Tupper-Tlower)

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 81

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-93-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Defining a Simulation using General Mode in ANSYS CFX-Pre

Plotting an Expression

Procedure 1. Right-click VisT in the Expressions tree view, and then select Edit.

The Expressions details view for VisT appears.

Tip: Alternatively, double-clicking the expression also opens the Expressions details

view.

2. Click the Plot tab and apply the following settings

Tab Setting Value

Plot Number of Points 10

T (Selected)

Start of Range 275 [K]

End of Range 325 [K]

3. Click Plot Expression.

A plot showing the variation of the expression VisT with the variable T is displayed.

Evaluating an Expression

Procedure 1. Click the Evaluate tab.

2. In T, type 300 [K].

This is between the start and end range defined in the last module.

3. Click Evaluate Expression.

The value of VisT for the given value of T appears in the Value field.

Modify Material Properties

Default material properties (such as those of Water) can be modified when required.

Procedure 1. Click the Outline tab.

2. Double click Water under Materials to display the Basic Settings tab.

3. Click the Material Properties tab.

4. Expand Transport Properties.

5. Select Dynamic Viscosity.

6. Under Dynamic Viscosity, click in Dynamic Viscosity.

7. Click Enter Expression .

8. Enter the expression VisT into the data box.

9. Click OK.

Creating the Domain

The domain will be set to use the thermal energy heat transfer model, and the k-ε

(k-epsilon) turbulence model.

Page 82 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-94-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Defining a Simulation using General Mode in ANSYS CFX-Pre

Both General Options and Fluid Models are changed in this module. The Initialization tab

is for setting domain-specific initial conditions, which are not used in this tutorial. Instead,

global initialization is used to set the starting conditions.

Procedure 1. Select Insert > Domain from the main menu or click Domain .

2. In the Insert Domain dialog box, type InjectMixer.

3. Click OK.

4. Apply the following settings

Tab Setting Value

General Options Basic Settings > Location B1.P3

Basic Settings > Fluids List Water

Domain Models > Pressure > 0 [atm]

Reference Pressure

5. Click Fluid Models.

6. Apply the following settings

Setting Value

Heat Transfer > Option Thermal Energy

7. Click OK.

Creating the Side Inlet Boundary Conditions

The side inlet boundary condition needs to be defined.

Procedure 1. Select Insert > Boundary Condition from the main menu or click Boundary Condition

.

2. Set Name to side inlet.

3. Click OK.

4. Apply the following settings

Tab Setting Value

Basic Settings Boundary Type Inlet

Location side inlet

Boundary Details Mass and Momentum > Option Normal Speed

Normal Speed 5 [m s^-1]

Heat Transfer > Option Static Temperature

Static Temperature 315 [K]

5. Click OK.

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 83

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-95-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Defining a Simulation using General Mode in ANSYS CFX-Pre

Creating the Main Inlet Boundary Conditions

The main inlet boundary condition needs to be defined. This inlet is defined using a velocity

profile found in the example directory. Profile data needs to be initialized before the

boundary condition can be created.

You will create a plot showing the velocity profile data, marked by higher velocities near the

center of the inlet, and lower velocities near the inlet walls.

Procedure 1. Select Tools > Initialize Profile Data.

2. Under Data File, click Browse .

3. From your working directory, select InjectMixer_velocity_profile.csv.

4. Click Open.

5. Click OK.

The profile data is read into memory.

6. Select Insert > Boundary Condition from the main menu or click Boundary Condition

.

7. Set name Name to main inlet.

8. Click OK.

9. Apply the following settings

Tab Setting Value

Basic Settings Boundary Type Inlet

Location main inlet

Profile Boundary Conditions (Selected)

> Use Profile Data

Profile Boundary Setup > main inlet

Profile Name

10. Click Generate Values.

This causes the profile values of U, V, W to be applied at the nodes on the main inlet

boundary, and U, V, W entries to be made in Boundary Details. To later modify the

velocity values at the main inlet and reset values to those read from the BC Profile file,

revisit Basic Settings for this boundary condition and click Generate Values.

11. Apply the following settings

Tab Setting Value

Boundary Details Flow Regime > Option Subsonic

Turbulence > Option Medium (Intensity = 5%)

Heat Transfer > Option Static Temperature

Static Temperature 285 [K]

Plot Options Boundary Contour (Selected)

Profile Variable W

12. Click OK.

Page 84 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-96-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Defining a Simulation using General Mode in ANSYS CFX-Pre

13. Zoom into the main inlet to view the inlet velocity contour.

Creating the Main Outlet Boundary Condition

In this module you create the outlet boundary condition. All other surfaces which have not

been explicitly assigned a boundary condition will remain in the InjectMixer Default

object, which is shown in the tree view. This boundary condition uses a No-Slip

Adiabatic Wall by default.

Procedure 1. Select Insert > Boundary Condition from the main menu or click Boundary Condition

.

2. Set Name to outlet.

3. Click OK.

4. Apply the following settings

Tab Setting Value

Basic Settings Boundary Type Outlet

Location outlet

Boundary Details Flow Regime > Option Subsonic

Mass and Momentum > Option Average Static Pressure

Relative Pressure 0 [Pa]

5. Click OK.

Setting Initial Values

Procedure 1. Click Global Initialization .

2. Select Turbulence Eddy Dissipation.

3. Click OK.

Setting Solver Control

Procedure 1. Click Solver Control .

2. Apply the following settings

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 85

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-97-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Defining a Simulation using General Mode in ANSYS CFX-Pre

Tab Setting Value

Basic Settings Advection Scheme > Option Specified Blend Factor

Advection Scheme > Blend 0.75

Factor

Convergence Control > Max. 50

Iterations

Convergence Control > Physical Timescale

Fluid Timescale Control >

Timescale Control

Convergence Control > 2 [s]

Fluid Timescale Control >

Physical Timescale

Convergence Criteria > RMS

Residual Type

Convergence Criteria > 1.E-4*

Residual Target

*. An RMS value of at least 1.E-5 is usually required for adequate convergence, but the

default value is sufficient for demonstration purposes.

3. Click OK.

Writing the Solver (.def) File

Once the problem has been defined you move from General Mode into ANSYS CFX-Solver.

Procedure 1. Click Write Solver File .

The Write Solver File dialog box appears.

2. Apply the following settings:

Setting Value

File name InjectMixer.def

Quit CFX–Pre* (Selected)

*. If using ANSYS CFX-Pre in Standalone Mode.

3. Ensure Start Solver Manager is selected and click Save.

4. If you are notified the file already exists, click Overwrite.

This file is provided in the tutorial directory and may exist in your working folder if you

have copied it there.

5. If prompted, click Yes or Save & Quit to save InjectMixer.cfx.

The definition file (InjectMixer.def), mesh file (InjectMixer.gtm) and the

simulation file (InjectMixer.cfx) are created. ANSYS CFX-Solver Manager

automatically starts and the definition file is set in the Definition File box of Define

Run.

6. Proceed to Obtaining a Solution Using ANSYS CFX-Solver Manager (p. 87).

Page 86 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-98-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Viewing the Results in ANSYS CFX-Post

Moving from ANSYS CFX-Solver Manager to ANSYS CFX-Post

1. Select Tools > Post–Process Results or click Post–Process Results .

2. If using ANSYS CFX-Solver Manager in standalone mode, optionally select Shut down

Solver Manager.

3. Click OK.

Viewing the Results in ANSYS CFX-Post

When ANSYS CFX-Post starts, the viewer and Outline workspace display by default.

Workflow Overview

This section provides a brief summary of the topics to follow as a general workflow:

1. Modifying the Outline of the Geometry (p. 88)

2. Creating and Modifying Streamlines (p. 88)

3. Modifying Streamline Color Ranges (p. 89)

4. Coloring Streamlines with a Constant Color (p. 89)

5. Duplicating and Modifying a Streamline Object (p. 90)

6. Examining Turbulent Kinetic Energy (p. 90)

Modifying the Outline of the Geometry

Throughout this and the following examples, use your mouse and the Viewing Tools

toolbar to manipulate the geometry as required at any time.

Procedure 1. In the tree view, double click Wireframe.

2. Set the Edge Angle to 15 [degree].

3. Click Apply.

Creating and Modifying Streamlines

When you complete this module you will see streamlines (mainly blue and green) starting

at the main inlet of the geometry and proceeding to the outlet. Above where the side pipe

meets the main pipe, there is an area where the flow re-circulates rather than flowing

roughly tangent to the direction of the pipe walls.

Procedure 1. Select Insert > Streamline from the main menu or click Streamline .

2. Under Name, type MainStream.

3. Click OK.

4. Apply the following settings

Page 88 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-100-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Viewing the Results in ANSYS CFX-Post

Tab Setting Value

Geometry Type 3D Streamline

Definition > Start From main inlet

5. Click Apply.

6. Right-click a blank area in the viewer, select Predefined Camera from the shortcut

menu, then select Isometric View (Y up).

The pipe is displayed with the main inlet in the bottom right of the viewer.

Modifying Streamline Color Ranges

You can change the appearance of the streamlines using the Range setting on the Color

tab.

Procedure 1. Under User Locations and Plots, modify the streamline object MainStream by

applying the following settings

Tab Setting Value

Color Range Local

2. Click Apply.

The color map is fitted to the range of velocities found along the streamlines. The

streamlines therefore collectively contain every color in the color map.

3. Apply the following settings

Tab Setting Value

Color Range User Specified

Min 0.2 [m s^-1]

Max 2.2 [m s^-1]

Note: Portions of streamlines that have values outside the range shown in the legend are

colored according to the color at the nearest end of the legend. When using tubes or

symbols (which contain faces), more accurate colors are obtained with lighting turned off.

4. Click Apply.

The streamlines are colored using the specified range of velocity values.

Coloring Streamlines with a Constant Color

1. Apply the following settings

Tab Setting Value

Color Mode Constant

Color (Green)

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 89

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-101-2048.jpg)

![Tutorial 3: Flow in a Process Injection Mixing Pipe: Viewing the Results in ANSYS CFX-Post

Color can be set to green by selecting it from the color pallet, or by repeatedly clicking

on the color box until it cycles through to the default green color.

2. Click Apply.

Duplicating and Modifying a Streamline Object

Any object can be duplicated to create a copy for modification without altering the original.

Procedure 1. Right-click MainStream and select Duplicate from the shortcut menu.

2. In the Name window, type SideStream.

3. Click OK.

4. Double click on the newly created streamline, SideStream.

5. Apply the following settings

Tab Setting Value

Geometry Definition > Start From side inlet

Color Mode Constant

Color (Red)

6. Click Apply.

Red streamlines appear, starting from the side inlet.

7. For better view, select Isometric View (Y up).

Examining Turbulent Kinetic Energy

A common way of viewing various quantities within the domain is to use a slice plane, as

demonstrated in this module.

Note: This module has multiple changes compiled into single steps in preparation for other

tutorials that provide fewer specific instructions.

Procedure 1. Clear visibility for both the MainStream and the SideStream objects.

2. Create a plane named Plane 1 that is normal to X and passing through the X = 0 Point.

To do so, specific instructions follow.

a. From the main menu, select Insert > Location > Plane and click OK.

b. In the Details view set Definition > Method to YZ Plane and X to 0 [m].

c. Click Apply.

3. Color the plane using the variable Turbulence Kinetic Energy, to show regions of

high turbulence. To do so, apply the settings below.

Tab Setting Value

Color Mode Variable

Variable Turbulence Kinetic Energy

4. Click Apply.

Page 90 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-102-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Defining a Steady-State Simulation in ANSYS CFX-Pre

Importing the Mesh

1. Select File > Import Mesh.

2. From your working directory, select CircVentMesh.gtm.

3. Click Open.

4. Right-click a blank area in the viewer and select Predefined Camera > Isometric View

(Z up) from the shortcut menu.

Creating an Additional Variable

In this tutorial, an additional variable (non-reacting scalar component) will be used to model

the dispersion of smoke from the vent.

Note: While smoke is not required for the steady-state simulation, including it here prevents

the user from having to set up timevalue interpolation in the transient simulation.

1. From the main menu, select Insert > Expressions, Functions and Variables >

Additional Variable or click Additional Variable .

2. Under Name, type smoke.

3. Click OK.

4. Under Variable Type, select Volumetric.

5. Set Units to [kg m^-3].

6. Click OK.

Creating the Domain

The fluid domain will be created that includes the additional variable.

To Create a New 1. Select Insert > Domain from the main menu, or click Domain , then set the name to

Domain CircVent and click OK.

2. Apply the following settings

Tab Setting Value

General Options Fluids List Air at 25 C

Reference Pressure 0 [atm]

Fluid Models Heat Transfer > Option None

Additional Variable Details > smoke (Selected)

Additional Variable Details > smoke > (Selected)

Kinematic Diffusivity

Additional Variable Details > smoke > 1.0E-5 [m^2 s^-1]

Kinematic Diffusivity > Kinematic

Diffusivity

3. Click OK.

Page 96 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-108-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Defining a Steady-State Simulation in ANSYS CFX-Pre

Creating the Boundary Conditions

This is an example of external flow, since fluid is flowing over an object and not through an

enclosure such as a pipe network (which would be an example of internal flow). In such

problems, some inlets will be made sufficiently large that they do not affect the CFD

solution. However, the length scale values produced by the Default Intensity and

AutoCompute Length Scale option for turbulence are based on inlet size. They are

appropriate for internal flow problems and particularly, cylindrical pipes. In general, you

need to set the turbulence intensity and length scale explicitly for large inlets in external

flow problems. If you do not have a value for the length scale, you can use a length scale

based on a typical length of the object, over which the fluid is flowing. In this case, you will

choose a turbulence length scale which is one-tenth of the diameter of the vent.

Note: The boundary marker vectors used to display boundary conditions (Inlets, Outlets,

Openings) are normal to the boundary surface regardless of the actual direction

specification. To plot vectors in the direction of flow, select Boundary Vector under the

Plot Options tab for the inlet boundary condition and clear Show Inlet Markers on the

Boundary Marker Options tab of Labels and Markers (accessible by clicking

Label and Marker Visibility ).

For parts of the boundary where the flow direction changes, or is unknown, an opening

boundary condition can be used. An opening boundary condition allows flow to both enter

and leave the fluid domain during the course of the solution.

Inlet Boundary 1. Select Insert > Boundary Condition from the main menu or click Boundary Condition

.

2. Under Name, type Wind.

3. Click OK.

4. Apply the following settings

Tab Setting Value

Basic Settings Boundary Type Inlet

Location Wind

Boundary Details Mass and Momentum > Option Cart. Vel. Components

Mass and Momentum > U 1 [m s^-1]

Mass and Momentum > V 0 [m s^-1]

Mass and Momentum > W 0 [m s^-1]

Turbulence > Option Intensity and Length Scale

Turbulence > Value 0.05

Turbulence > Eddy Len. Scale 0.25 [m]

Additional Variables > smoke > Option Value

Additional Variables > smoke > Value 0 [kg m^-3]

5. Click OK.

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 97

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-109-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Defining a Steady-State Simulation in ANSYS CFX-Pre

Opening 1. Select Insert > Boundary Condition from the main menu or click Boundary Condition

Boundary .

2. Under Name, type Atmosphere.

3. Click OK.

4. Apply the following settings

Tab Setting Value

Basic Settings Boundary Type Opening

Location Atmosphere

Boundary Details Mass and Momentum > Option Opening Pres. and Dirn

Mass and Momentum > Relative Pressure 0 [Pa]

Flow Direction > Option Normal to Boundary

Condition

Turbulence > Option Intensity and Length Scale

Turbulence > Value 0.05

Turbulence > Eddy Len. Scale 0.25 [m]

Additional Variables > smoke > Option Value

Additional Variables > smoke > Value 0 [kg m^-3]

5. Click OK.

Inlet for the 1. Select Insert > Boundary Condition from the main menu or click Boundary Condition

Vent .

2. Under Name, type Vent.

3. Click OK.

4. Apply the following settings

Tab Setting Value

Basic Settings Boundary Type Inlet

Location Vent

Boundary Details Mass and Momentum > Normal Speed 0.01 [m s^-1]

Turbulence > Option Intensity and Eddy Viscosity

Ratio

Additional Variables > smoke > Option Value

Additional Variables > smoke > Value 0 [kg m^-3]

5. Click OK.

Setting Initial Values

1. Click Global Initialization .

2. Select Turbulence Eddy Dissipation.

3. Click OK.

Page 98 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-110-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Defining a Transient Simulation in ANSYS CFX-Pre

Defining a Transient Simulation in ANSYS CFX-Pre

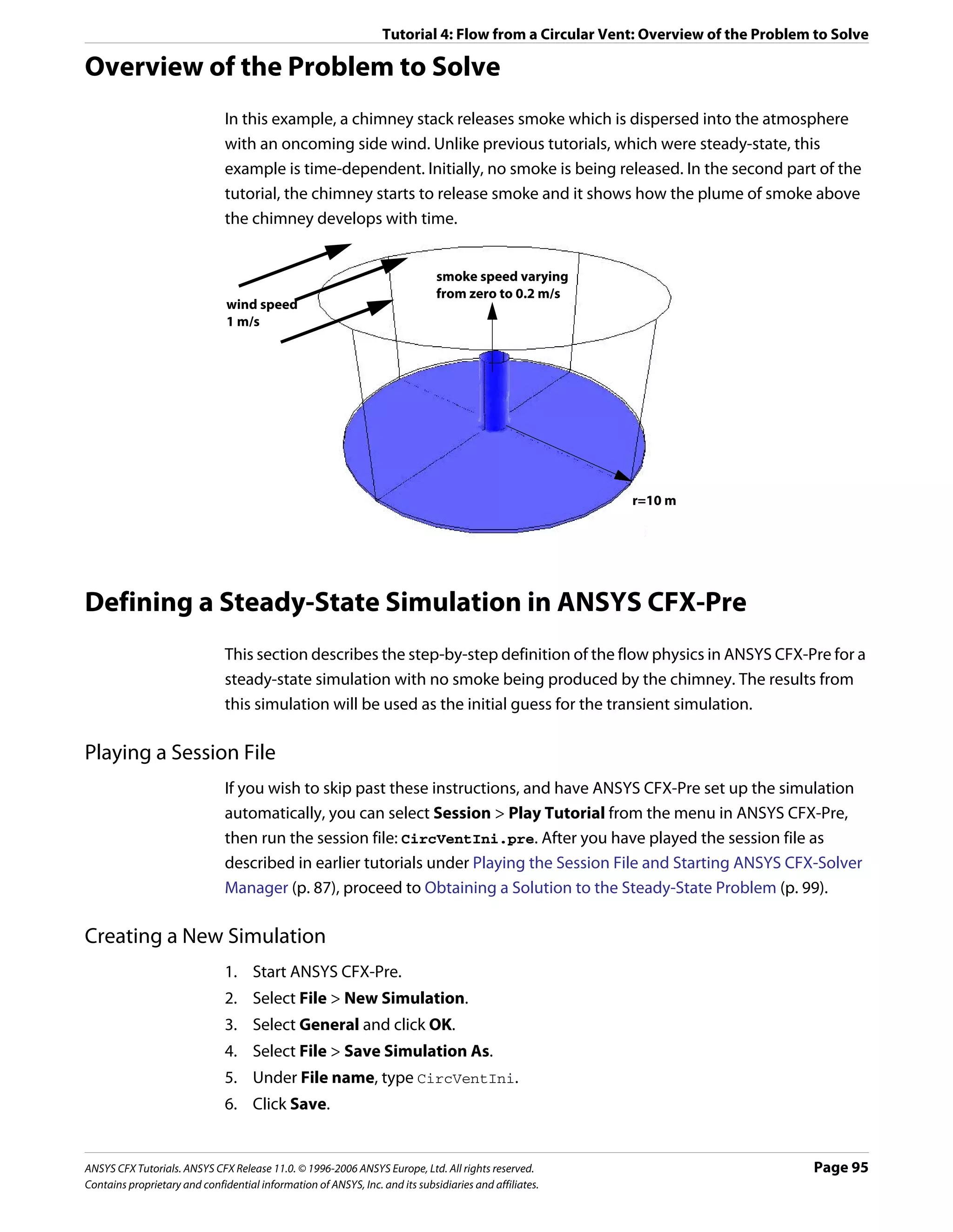

In this part of the tutorial, you alter the simulation settings used for the steady-state

calculation to set up the model for the transient calculation in ANSYS CFX-Pre.

Playing a Session File

If you wish to skip past these instructions, and have ANSYS CFX-Pre set up the simulation

automatically, you can select Session > Play Tutorial from the menu in ANSYS CFX-Pre,

then run the session file: CircVent.pre. After you have played the session file as described

in earlier tutorials under Playing the Session File and Starting ANSYS CFX-Solver Manager

(p. 87), proceed to Obtaining a Solution to the Transient Problem (p. 104).

Opening the Existing Simulation

1. Start ANSYS CFX-Pre.

2. Select File > Open Simulation.

3. If required, set the path location to the tutorial folder.

4. Select the simulation file CircVentIni.cfx.

5. Click Open.

6. Select File > Save Simulation As.

7. Change the name to CircVent.cfx.

8. Click Save.

Modifying the Simulation Type

In this step you will make the problem transient. Later, you will set the concentration of

smoke to rise exponentially with time, so it is necessary to ensure that the interval between

the timesteps is smaller at the beginning of the simulation than at the end.

1. Click Simulation Type .

2. Apply the following settings

Tab Setting Value

Basic Settings Simulation Type > Option Transient

Simulation Type > Time Duration > 30 [s]

Total Time

Simulation Type > Time Steps > 4*0.25, 2*0.5, 2*1.0, 13*2.0 [s]

Timesteps*†

Simulation Type > Initial Time > Time 0 [s]

*. Do NOT click Enter Expression to enter lists of values. Enter the list without the

units, then set the units in the drop-down list.

†. This list specifies 4 timesteps of 0.25 [s], then 2 timesteps of 0.5 [s], etc.

3. Click OK.

Page 100 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-112-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Defining a Transient Simulation in ANSYS CFX-Pre

Modifying the Boundary Conditions

The only boundary condition which needs altering is the Vent boundary condition. In the

steady-state calculation, this boundary had a small amount of air flowing through it. In the

transient calculation, more air passes through the vent and there is a time-dependent

concentration of smoke in the air. This is initially zero, but builds up to a larger value. The

smoke concentration will be specified using the CFX Expression Language.

To Modify the 1. In the Outline workspace, expand the tree to Simulation > CircVent > Vent.

Vent Inlet 2. Right-click Vent and select Edit.

Boundary

Condition 3. Apply the following settings

Tab Setting Value

Boundary Details Mass and Momentum > Normal Speed 0.2 [m s^-1]

Leave the Vent details view open for now.

You are going to create an expression for smoke concentration. The concentration is

zero for time t=0 and builds up to a maximum of 1 kg m^-3.

4. Create a new expression by selecting Insert > Expressions, Functions and Variables

> Expression from the main menu. Set the name to TimeConstant.

5. Apply the following settings

Name Definition

TimeConstant 3 [s]

6. Click Apply to create the expression.

7. Create the following expressions with specific settings, remembering to click Apply

after each is defined.

Name Definition

FinalConcentration 1 [kg m^-3]

ExpFunction * FinalConcentration*abs(1-exp(-t/TimeConstant))

*. When entering this function, you can select most of the required items by

right-clicking in the Definition window in the Expression details view instead of

typing them. The names of the existing expressions are under the Expressions

menu. The exp and abs functions are under Functions > CEL. The variable t is

under Variables.

Note: The abs function takes the modulus (or magnitude) of its argument. Even though the

expression (1- exp (-t/TimeConstant)) can never be less than zero, the abs function is

included to ensure that the numerical error in evaluating it near to zero will never make the

expression evaluate to a negative number.

Next you will visualize how the expressions have scheduled the concentration of smoke

issued from the vent.

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 101

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-113-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Defining a Transient Simulation in ANSYS CFX-Pre

Plotting Smoke 1. Double-click ExpFunction in the Expressions tree view.

Concentration 2. Apply the following settings

Tab Setting Value

Plot t (Selected)

Start of Range 0 [s]

End of Range 30 [s]

3. Click Plot Expression.

The button name then changes to Define Plot, as shown.

As can be seen, the smoke concentration rises exponentially, and reaches 90% of its final

value at around 7 seconds.

4. Click the Boundary: Vent tab.

In the next step, you will apply the expression ExpFunction to the additional variable

smoke as it applies to the boundary Vent.

5. Apply the following settings

Tab Setting Value

Boundary Details Additional Variables > smoke > Option Value

Additional Variables > smoke > Value* ExpFunction

*. Click Enter Expression to enter text.

6. Click OK.

Page 102 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-114-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Defining a Transient Simulation in ANSYS CFX-Pre

Initialization Values

The steady state solution that you have finished calculating is used to supply the initial

values to the ANSYS CFX-Solver. You can leave all of the initialization data set to Automatic

and the initial values will be read automatically from the initial values file. Therefore, there

is no need to revisit the initialization tab.

Modifying the Solver Control

1. Click Solver Control .

2. Set Convergence Control > Max. Coeff. Loops to 3.

3. Leave the other settings at their default values.

4. Click OK to set the solver control parameters.

Output Control

To allow results to be viewed at different timesteps, it is necessary to create transient results

files at specified times. The transient results files do not have to contain all solution data. In

this step, you will create minimal transient results files.

To Create 1. From the main menu, select Insert > Solver > Output Control.

Minimal 2. Click the Trn Results tab.

Transient

Results Files 3. Click Add new item and then click OK to accept the default name for the object.

This creates a new transient results object. Each object can result in the production of

many transient results files.

4. Apply the following settings to Transient Results 1

Setting Value

Option Selected Variables

Output Variables List* Pressure, Velocity, smoke

Output Frequency > Option Time List

Output Frequency > Time List† 1, 2 , 3 [s]

*. Click the ellipsis icon to select items if they do not appear in the drop-down list. Use

the <Ctrl> key to select multiple items.

†. Do NOT click Enter Expression to enter lists of values. Enter the list without the

units, then set the units in the drop-down list.

5. Click Apply.

6. Create a second item with the default name Transient Results 2 and apply the

following settings to that item

Setting Value

Option Selected Variables

Output Variables List Pressure, Velocity, smoke

ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved. Page 103

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-115-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Obtaining a Solution to the Transient Problem

Setting Value

Output Frequency > Option Time Interval

Output Frequency > Time Interval* 4 [s]

*. A transient results file will be produced every 4 s (including 0 s) and at 1 s, 2 s and

3 s. The files will contain no mesh and data for only the three selected variables. This

reduces the size of the minimal results files. A full results file is always written at the

end of the run.

7. Click OK.

Writing the Solver (.def) File

1. Click Write Solver File .

2. Apply the following settings

Setting Value

File name CircVent.def

Quit CFX–Pre * Select

*. If using ANSYS CFX-Pre in Standalone Mode.

3. Ensure Start Solver Manager is selected and click Save.

4. Quit ANSYS CFX-Pre, saving the simulation (.cfx) file at your discretion.

Obtaining a Solution to the Transient Problem

In this tutorial the ANSYS CFX-Solver will read the initial values for the problem from a file.

For details, see Initialization Values (p. 103). You need to specify the file name.

Define Run will be displayed when the ANSYS CFX-Solver Manager launches. Definition

File will already be set to the name of the definition file just written.

Notice that the text output generated by the ANSYS CFX-Solver will be more than you have

seen for steady-state problems. This is because each timestep consists of several inner

(coefficient) iterations. At the end of each timestep, information about various quantities is

printed to the text output area.

The variable smoke is now plotted under the Additional Variables tab.

1. Under Initial Values File, click Browse .

2. Select CircVentIni_001.res, which is the results file of the steady-state problem with

no smoke issuing from the chimney. If you have not run the first part of this tutorial, copy

CircVentIni_001.res from the <CFXROOT>/examples/ directory to your working

directory.

3. Click Open.

4. Click Start Run.

5. You may see a notice that the mesh from the initial values file will be used. This mesh is

the same as in the definition file. Click OK to continue.

Page 104 ANSYS CFX Tutorials. ANSYS CFX Release 11.0. © 1996-2006 ANSYS Europe, Ltd. All rights reserved.

Contains proprietary and confidential information of ANSYS, Inc. and its subsidiaries and affiliates.](https://image.slidesharecdn.com/ansys11tutorial-111218135319-phpapp01/75/Ansys-11-tutorial-116-2048.jpg)

![Tutorial 4: Flow from a Circular Vent: Viewing the Results in ANSYS CFX-Post

ANSYS CFX-Solver runs and attempts to obtain a solution. This can take a long time

depending on your system. Eventually a dialog box is displayed.

6. When ANSYS CFX-Solver has finished, click Yes to post-process the results.

7. If using Standalone Mode, quit ANSYS CFX-Solver Manager.

Viewing the Results in ANSYS CFX-Post

In this tutorial, you will view the dispersion of smoke from the vent over time. When ANSYS

CFX-Post is loaded, the results that are immediately available are those at the final timestep;

in this case, at t = 30 s (this is nominally designated Final State).

Creating an Isosurface

An isosurface is a surface of constant value of a variable. For instance, it could be a surface

consisting of all points where the velocity is 1 [m s^-1]. In this case, you are going to create

an isosurface of smoke density (smoke is the additional variable that you specified earlier).

1. Right-click on a blank area in the viewer and select Predefined Camera > Isometric

View (Z up).