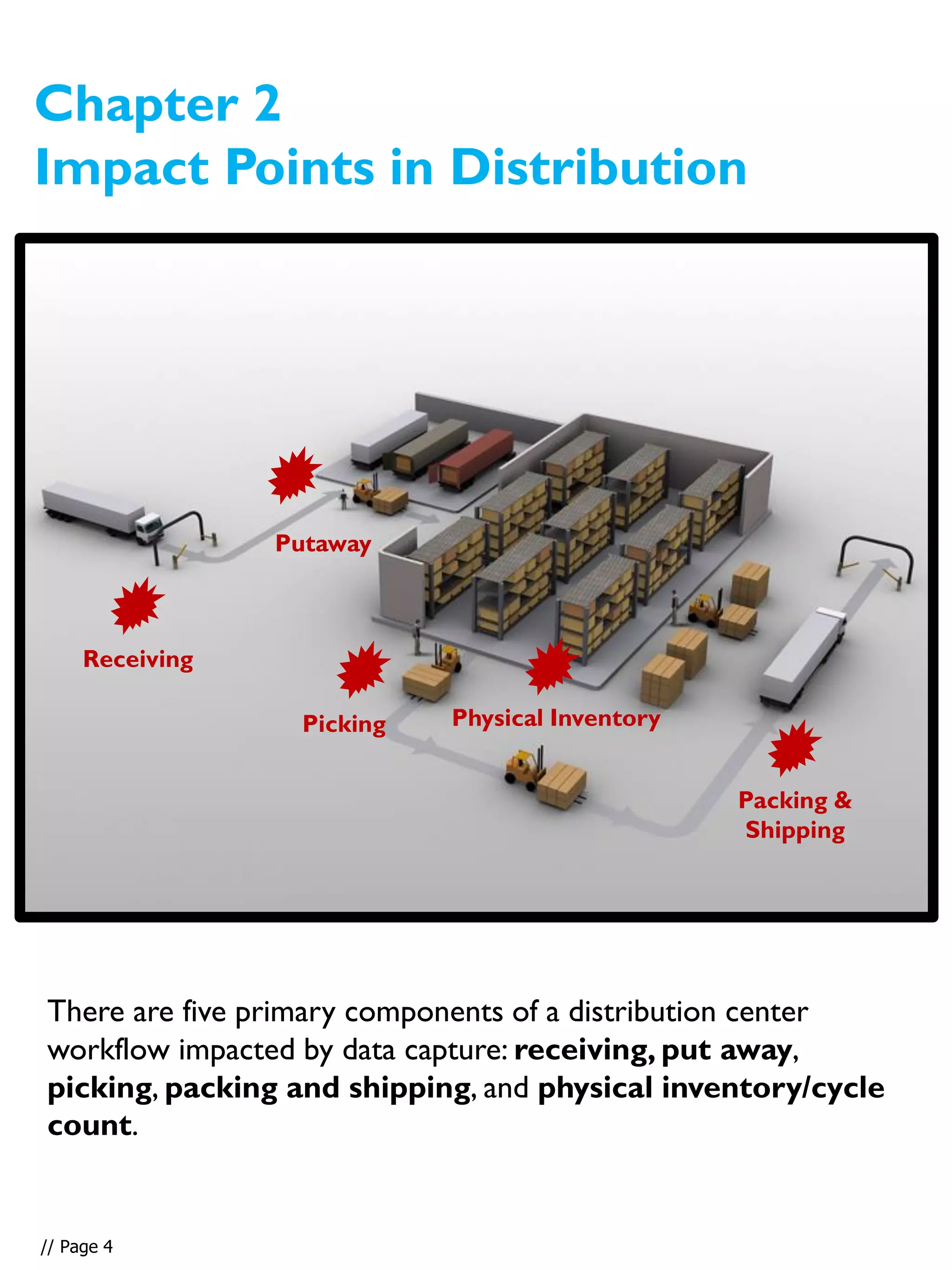

The document discusses how companies can move from manual to automated data capture processes in distribution. It describes leveraging real-time data to improve efficiency, accuracy, and connectivity. The key points are: companies must shift from error-prone manual processes to automated ones using technologies like barcode scanning; implementing wireless networks allows real-time data collection as items move through facilities; and automated data capture benefits areas like receiving, putaway, picking, packing/shipping, and inventory management.