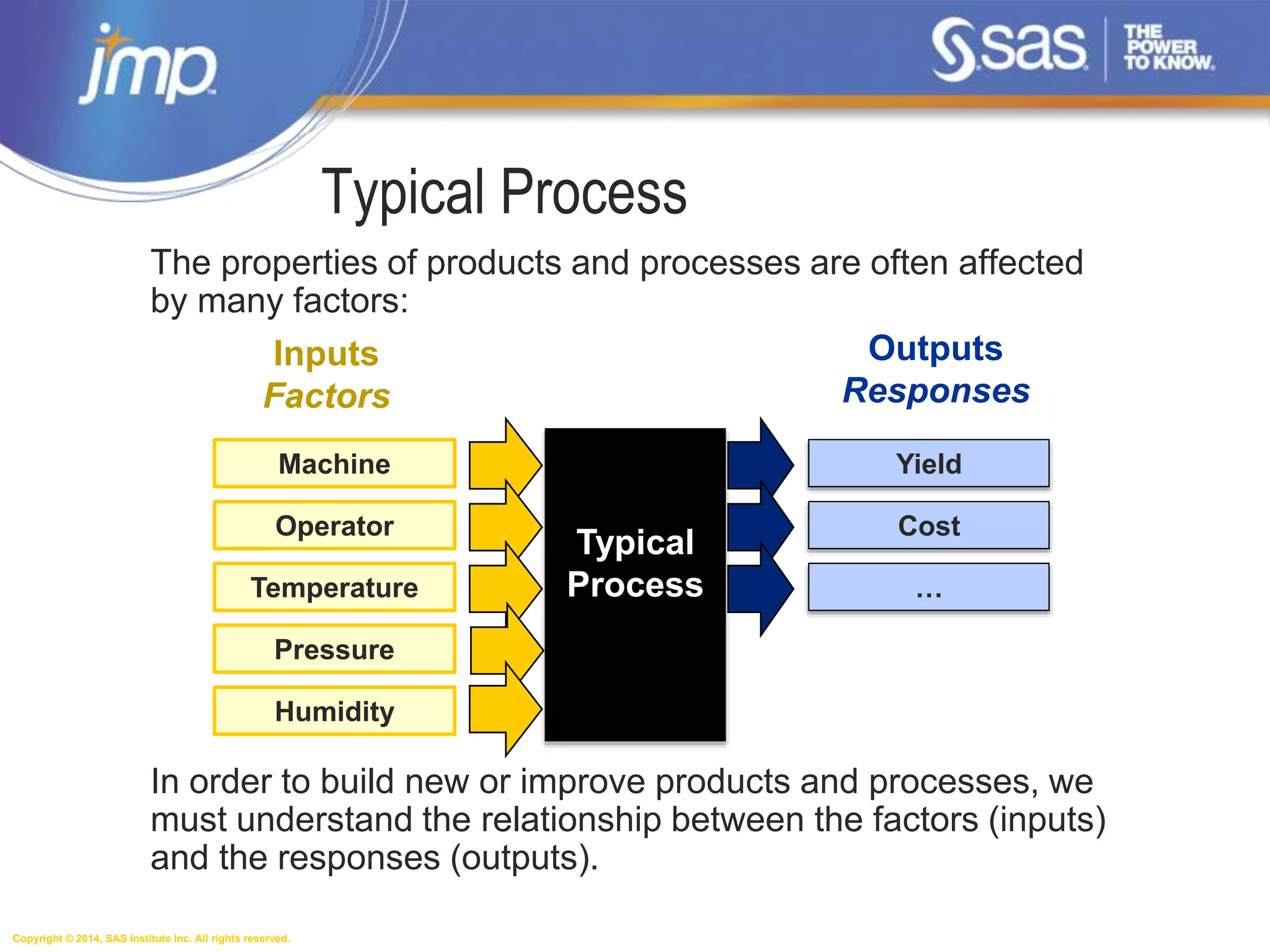

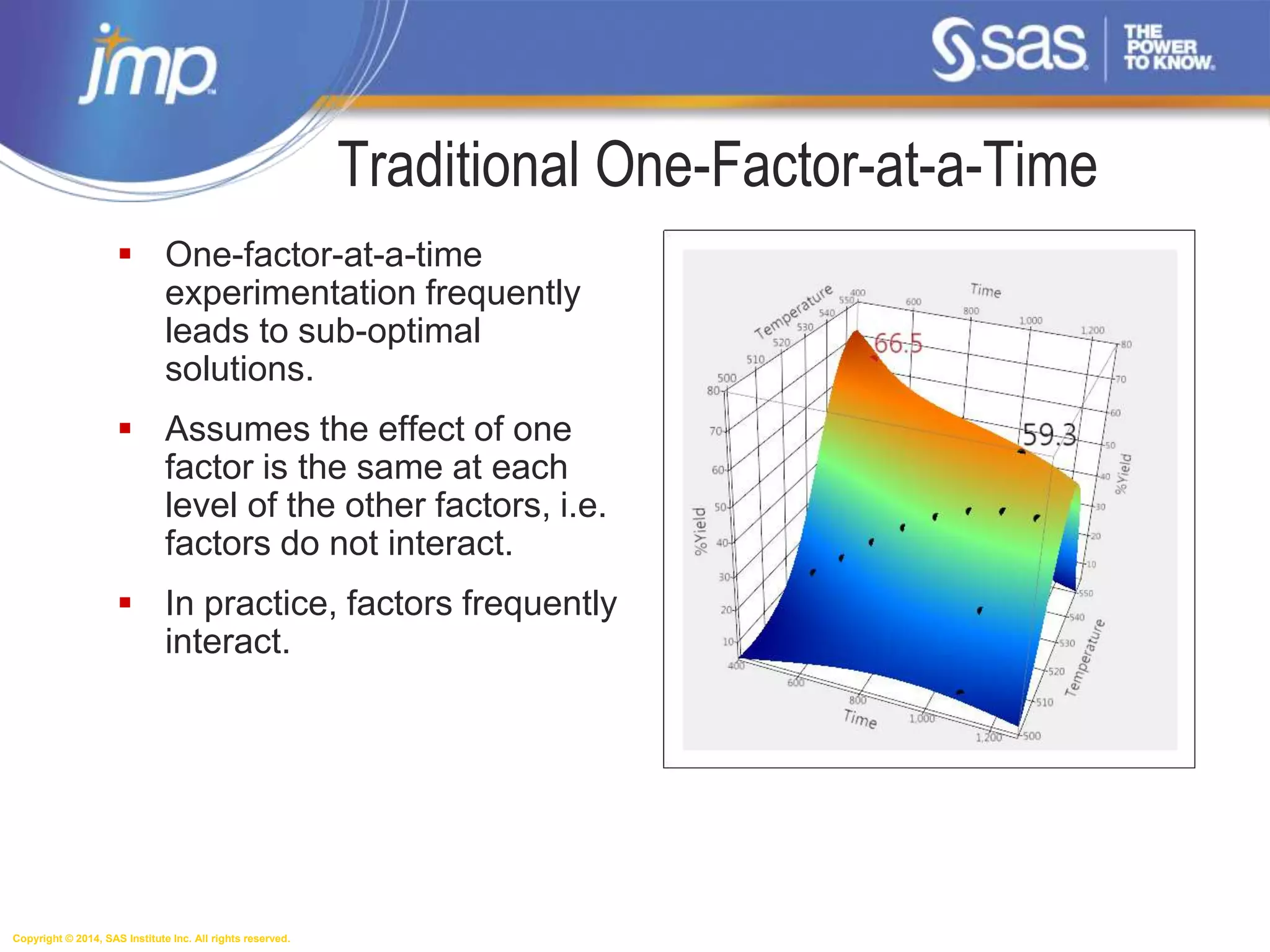

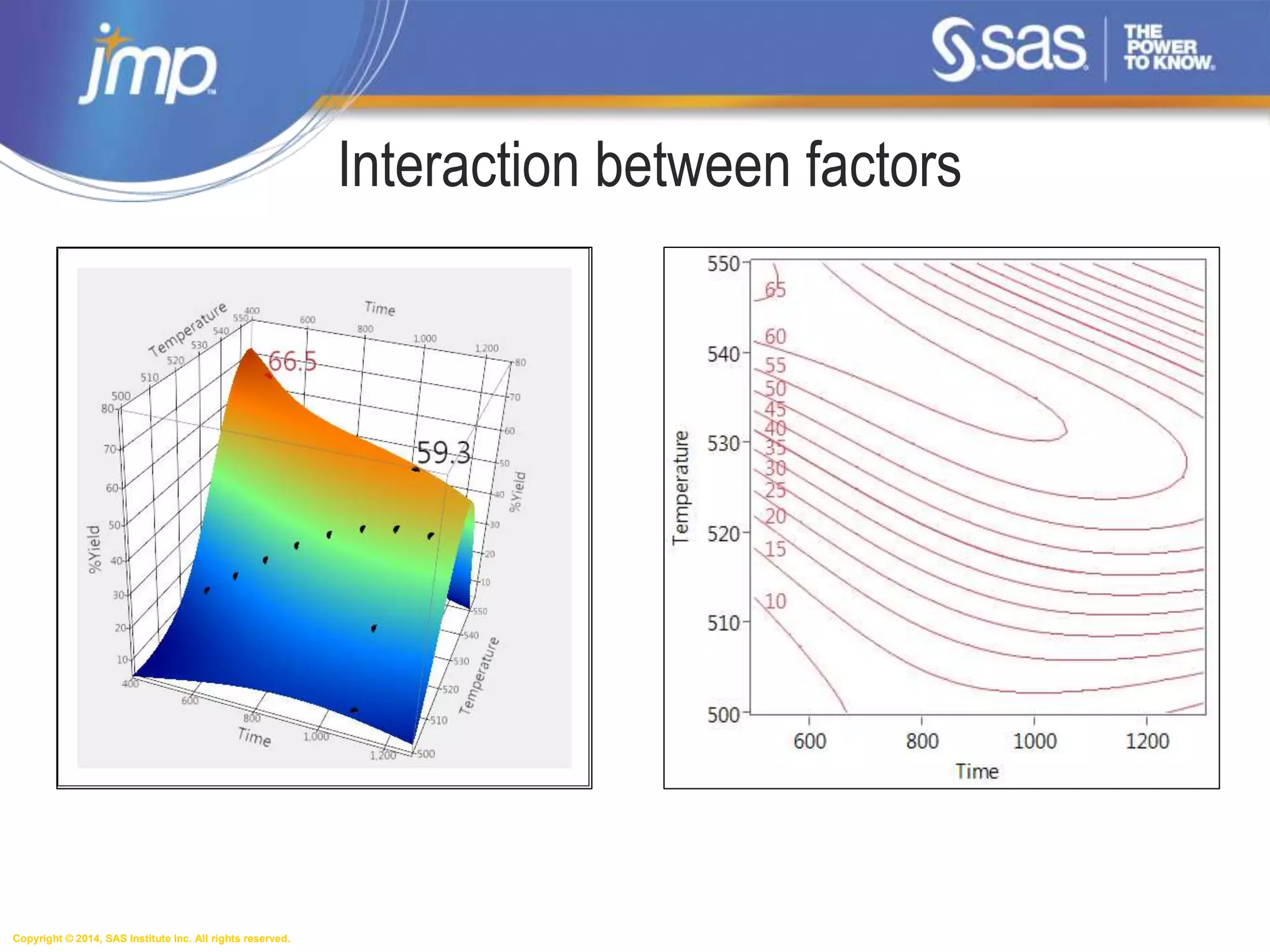

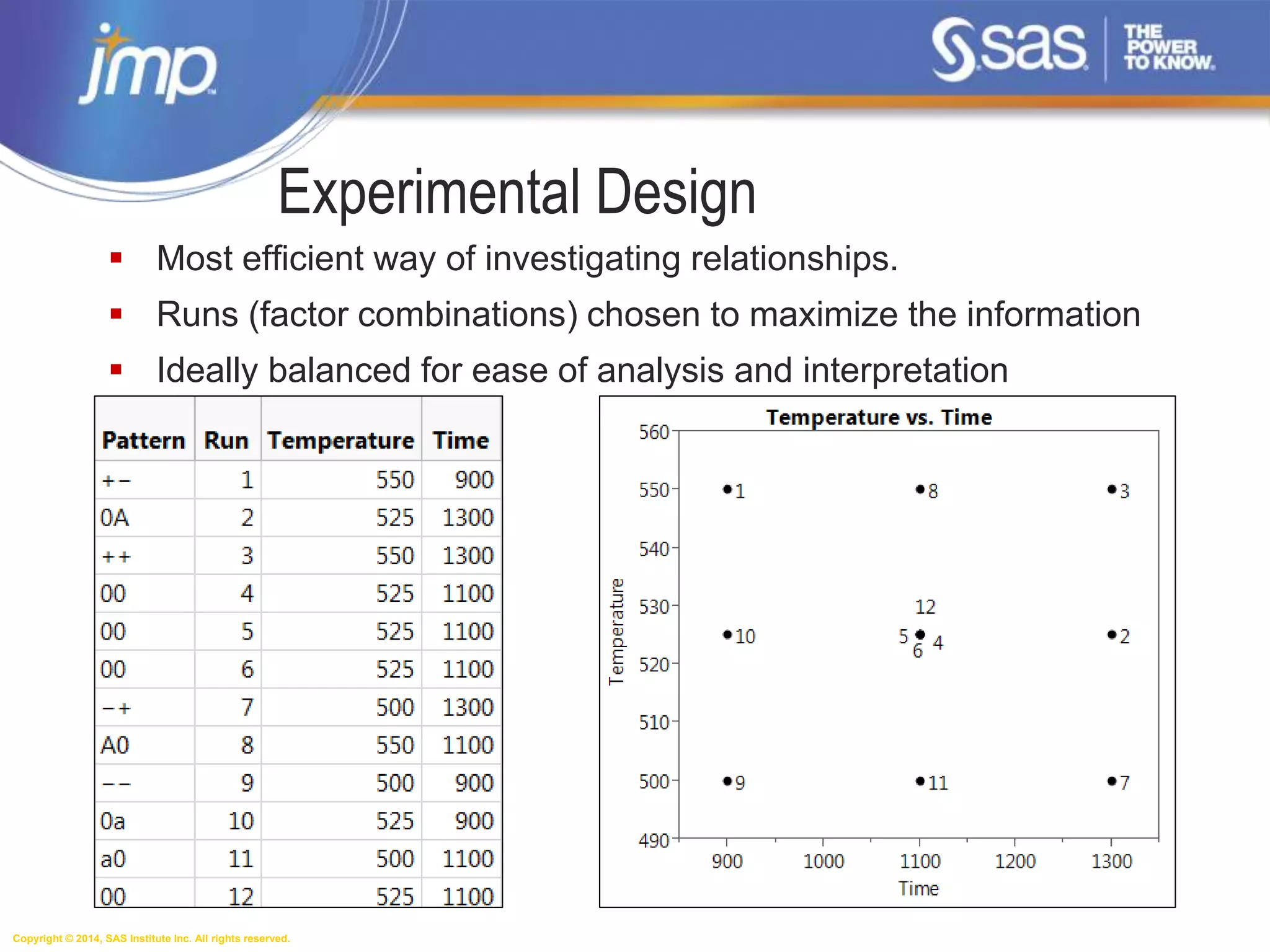

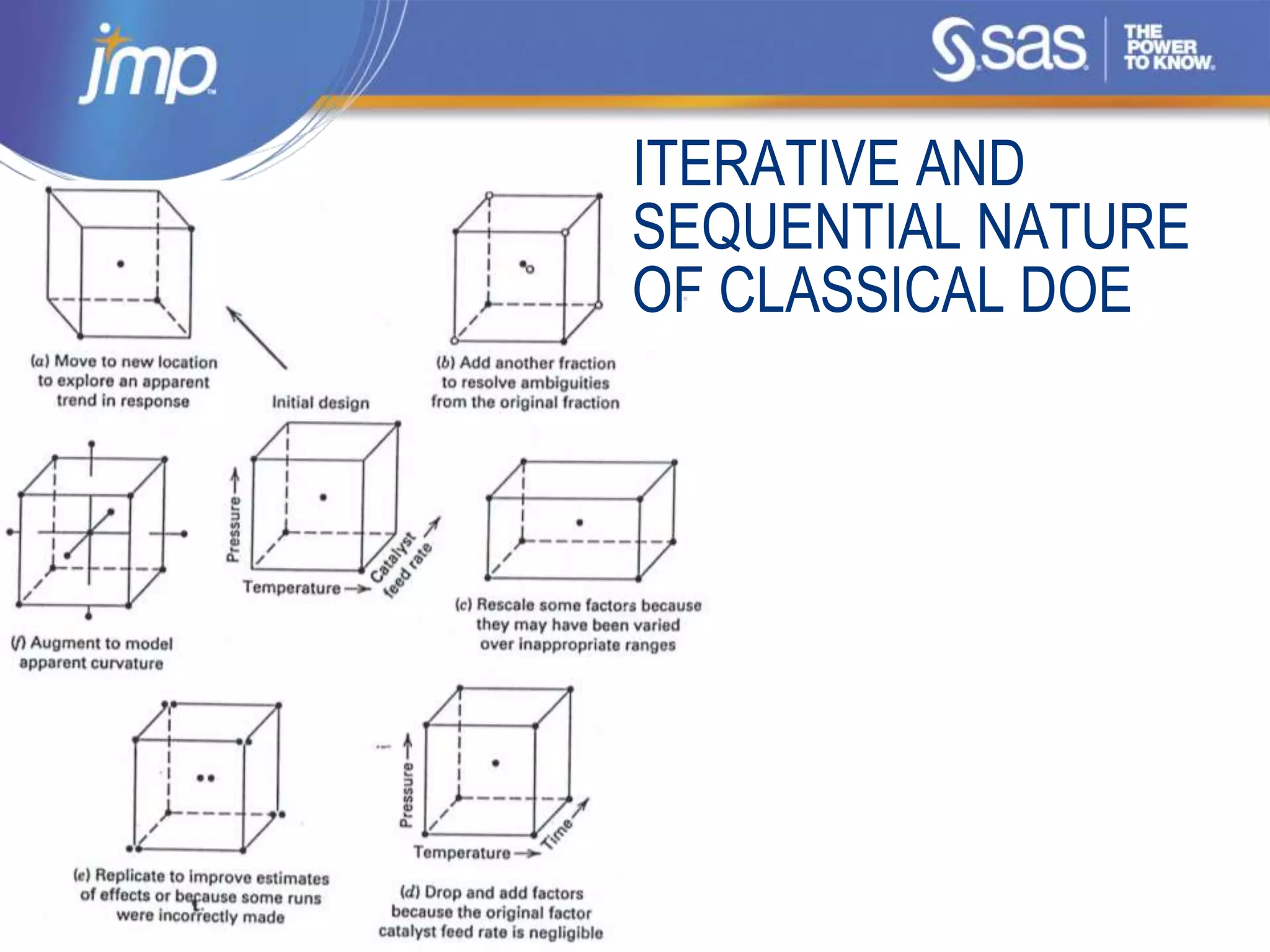

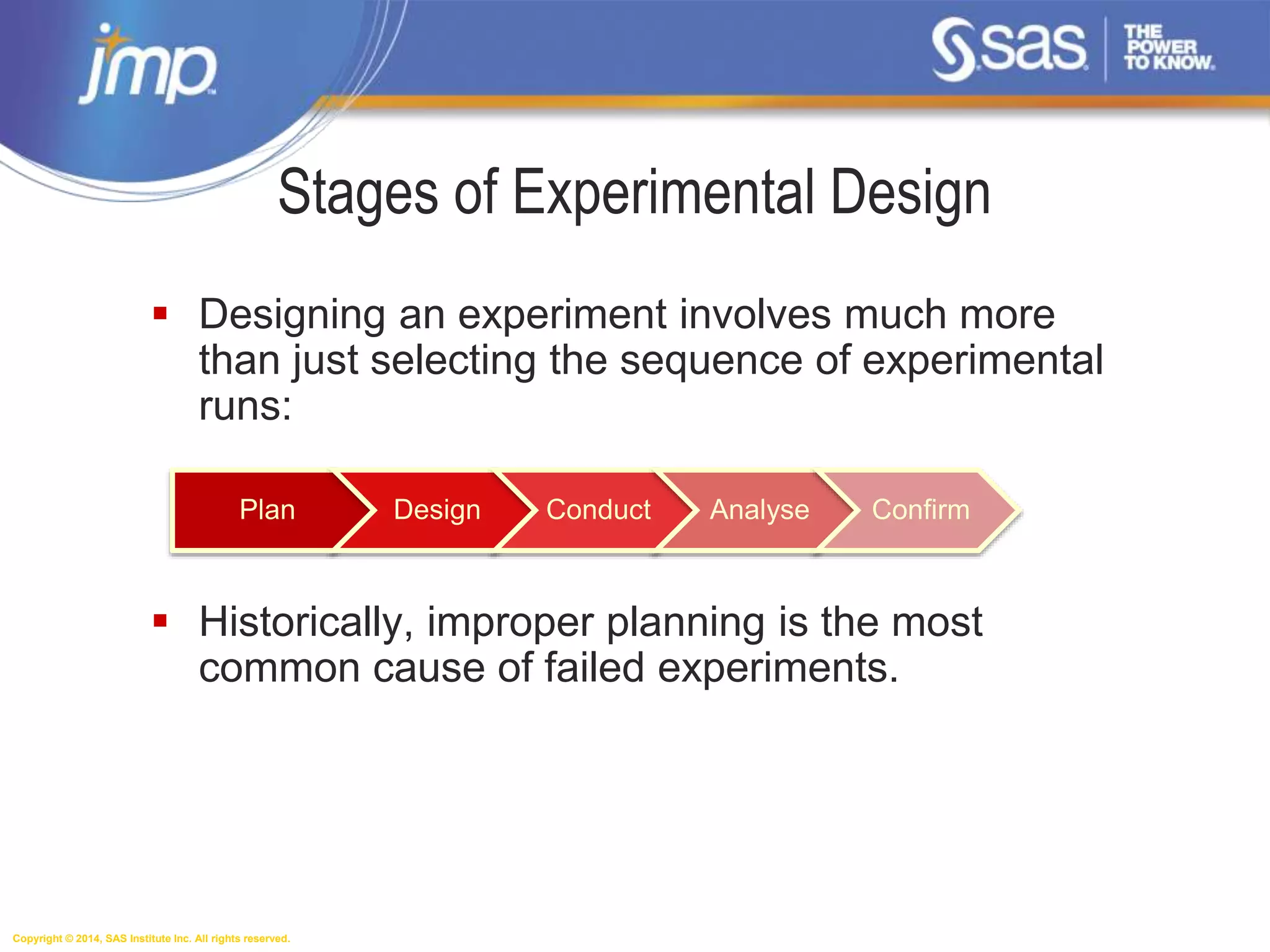

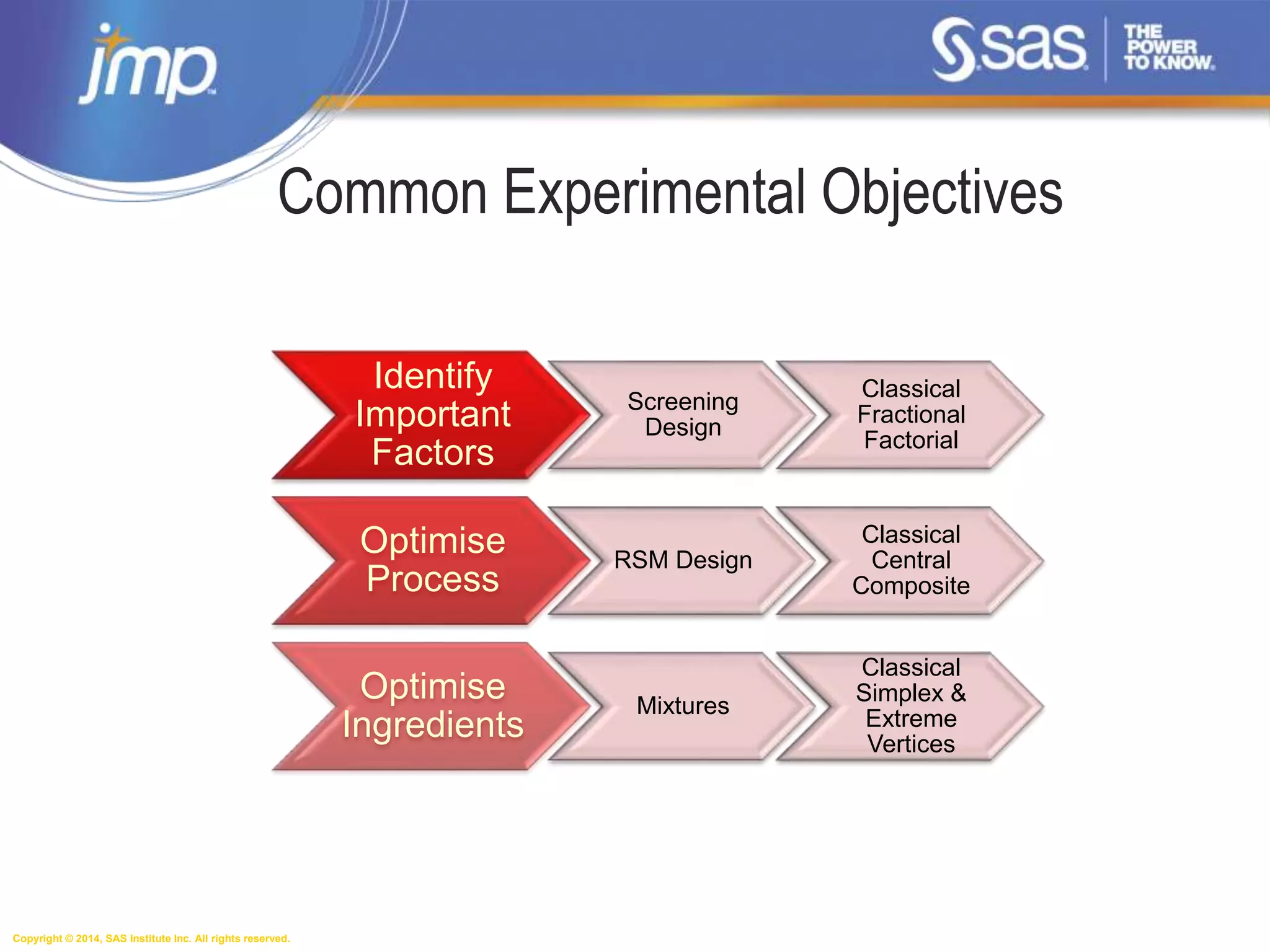

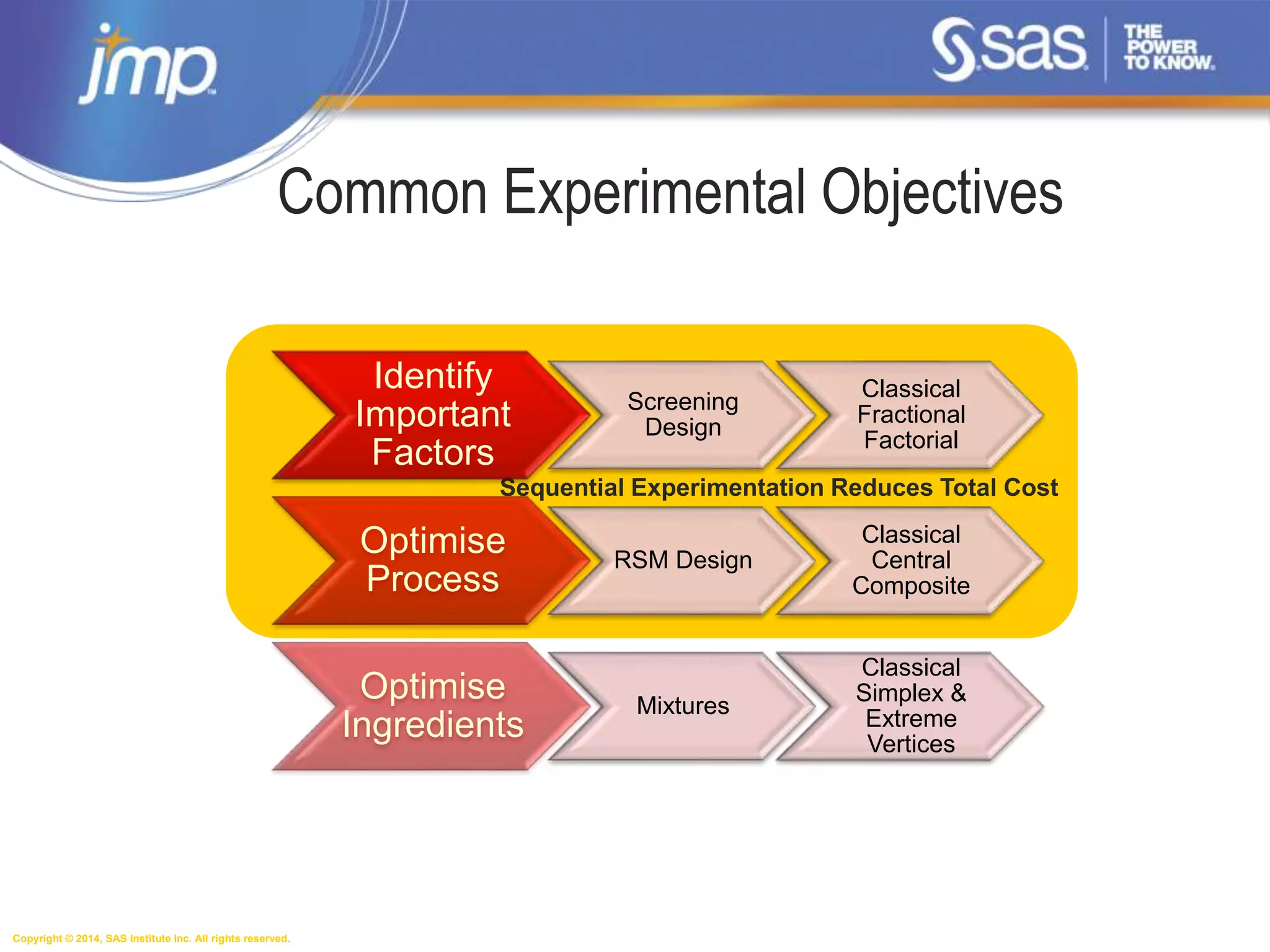

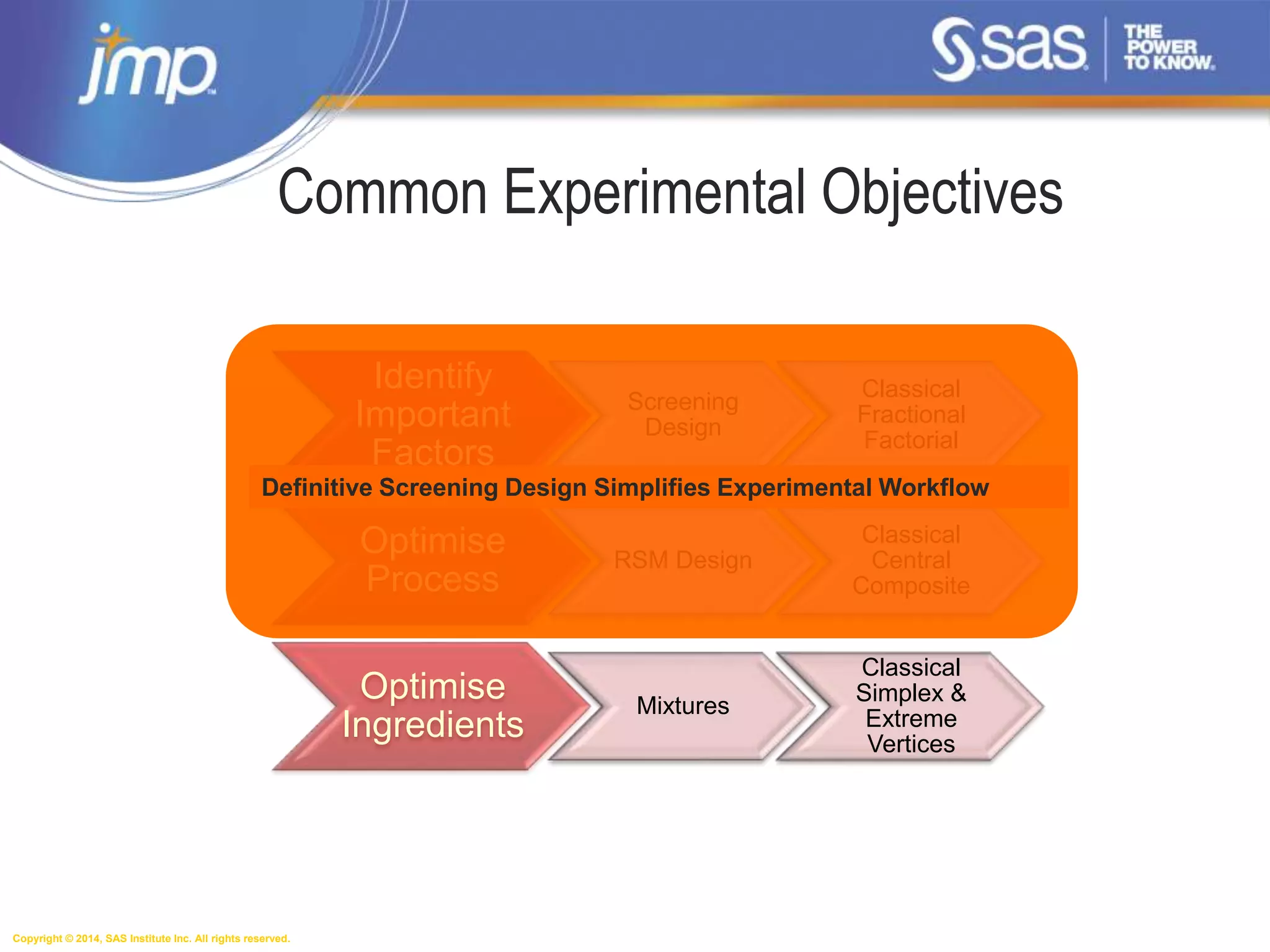

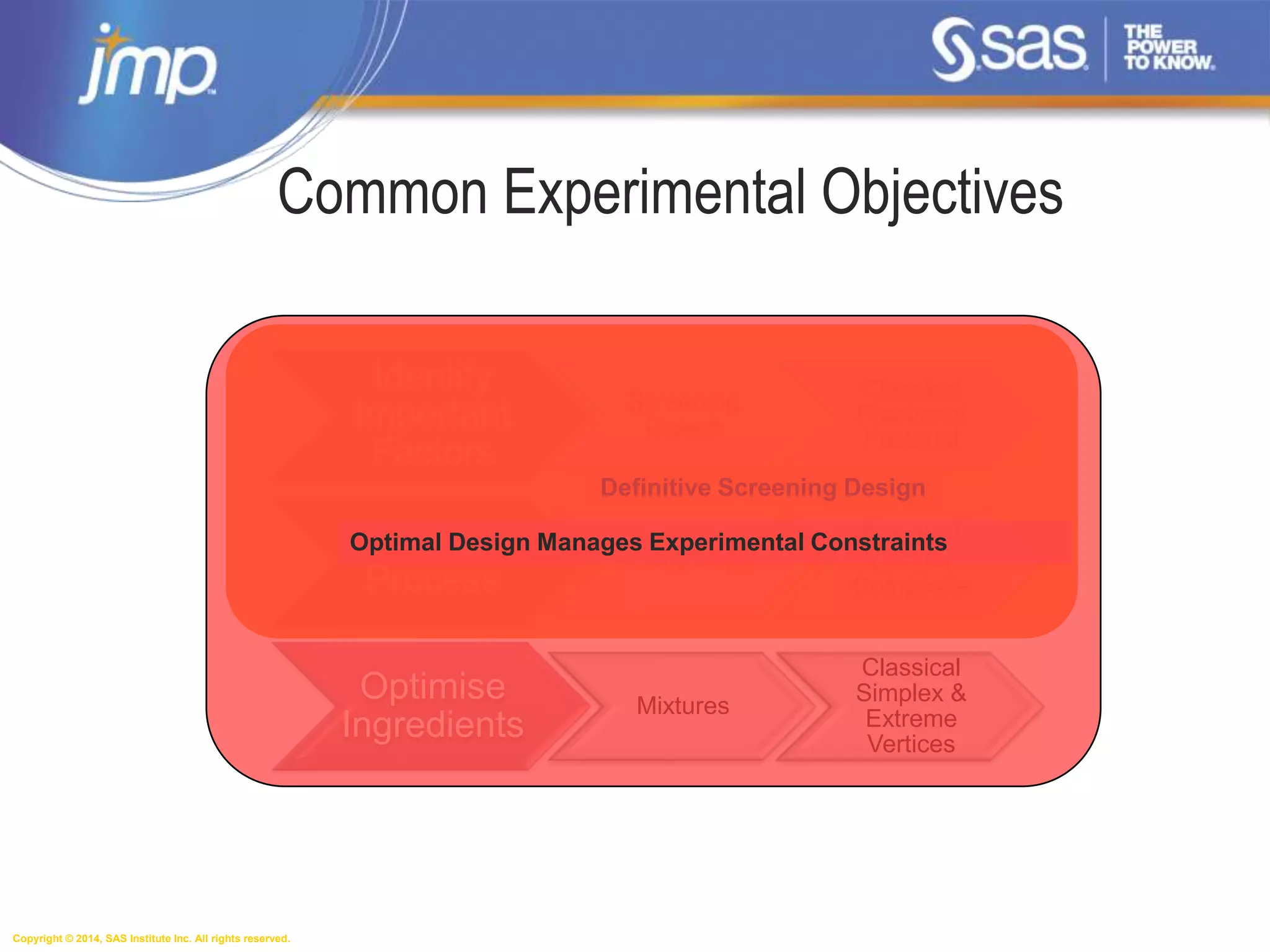

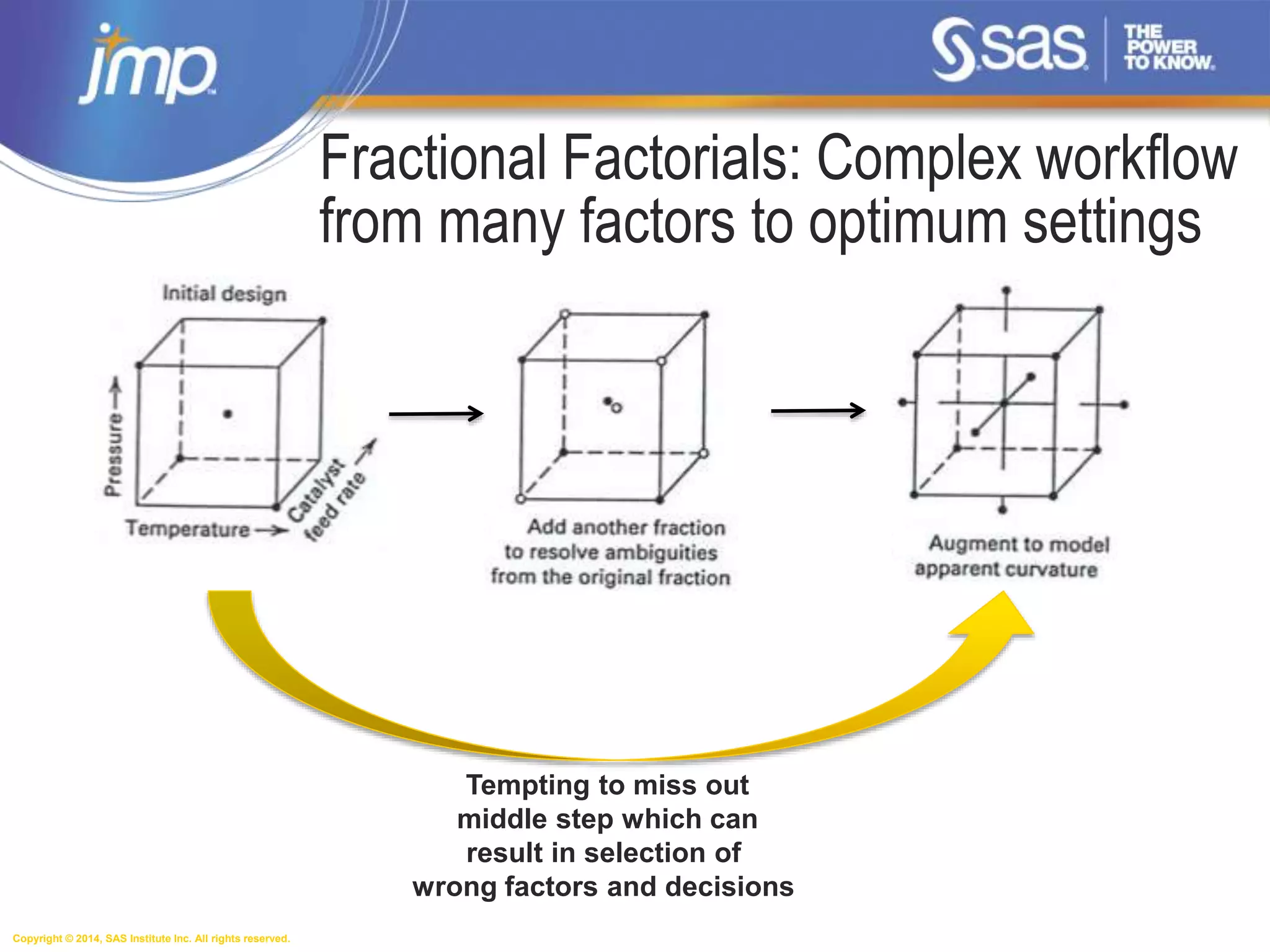

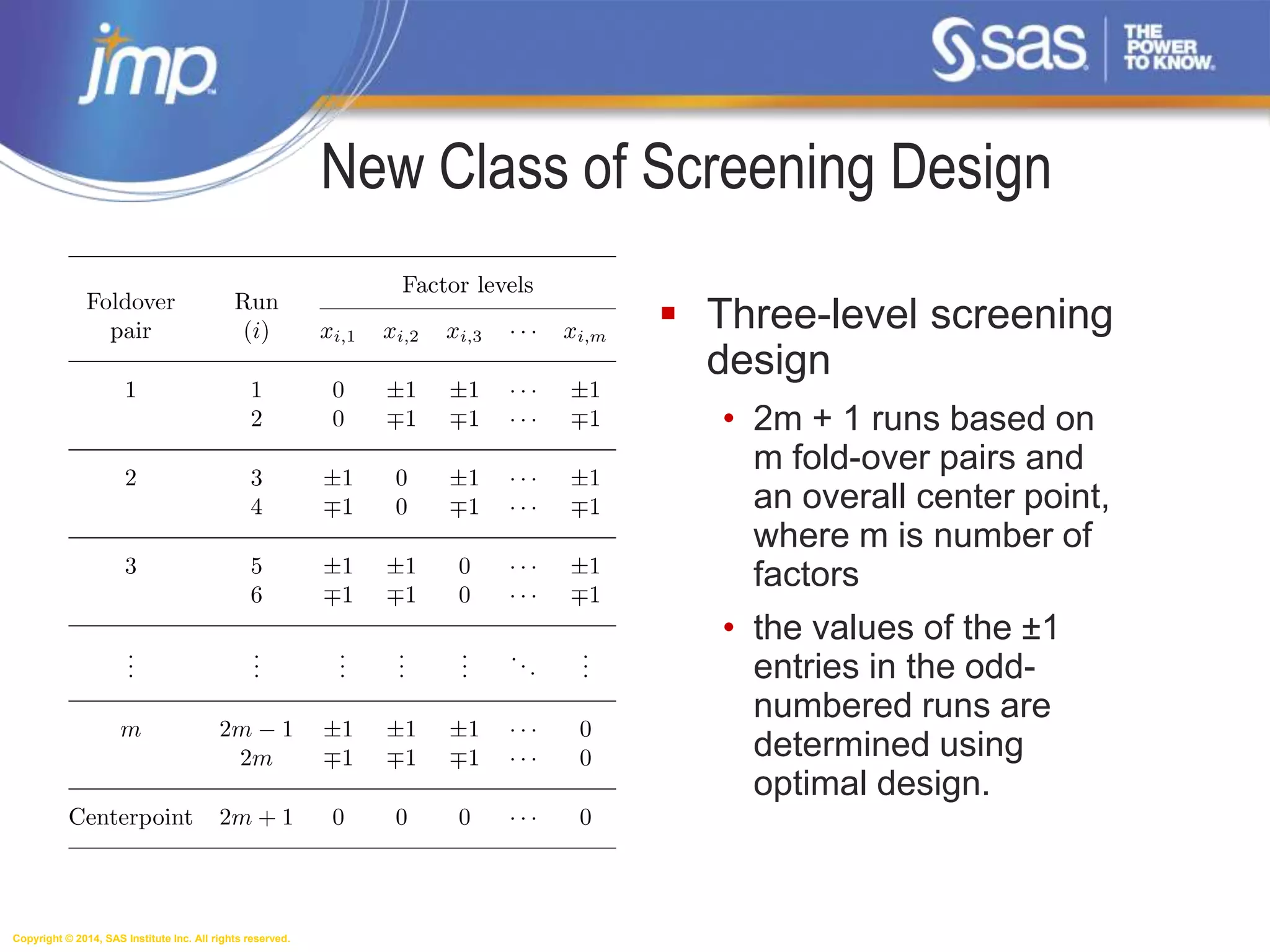

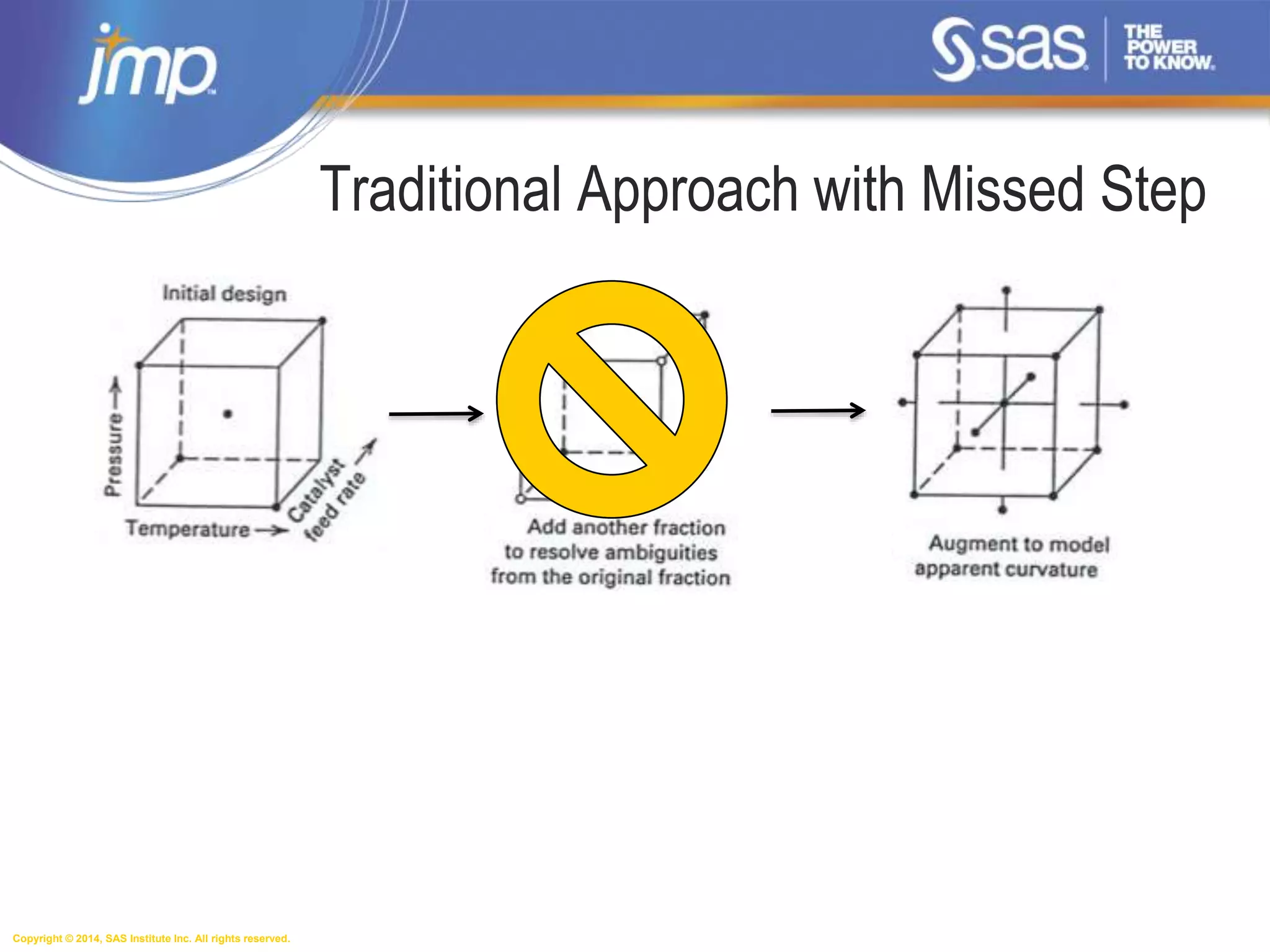

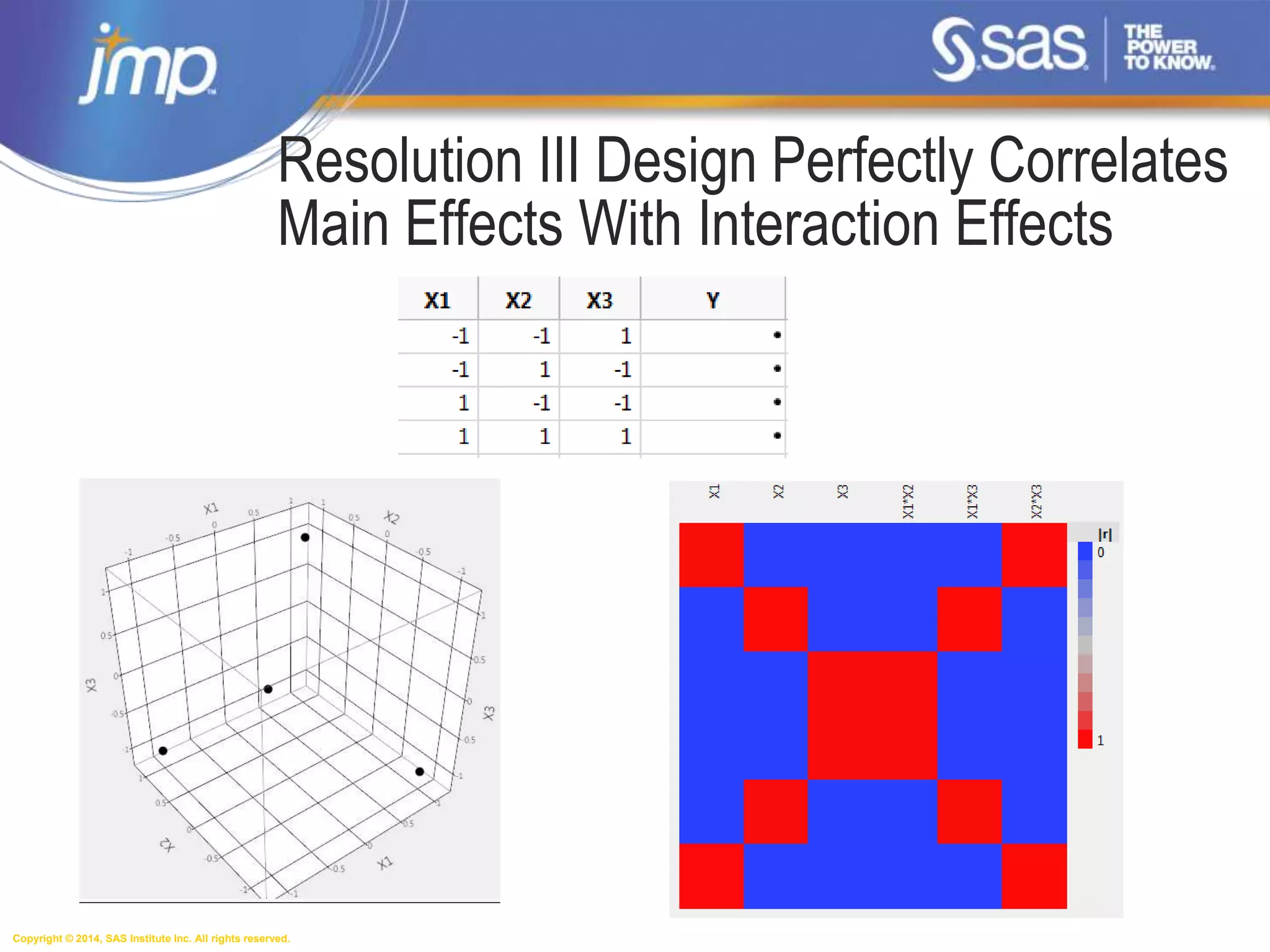

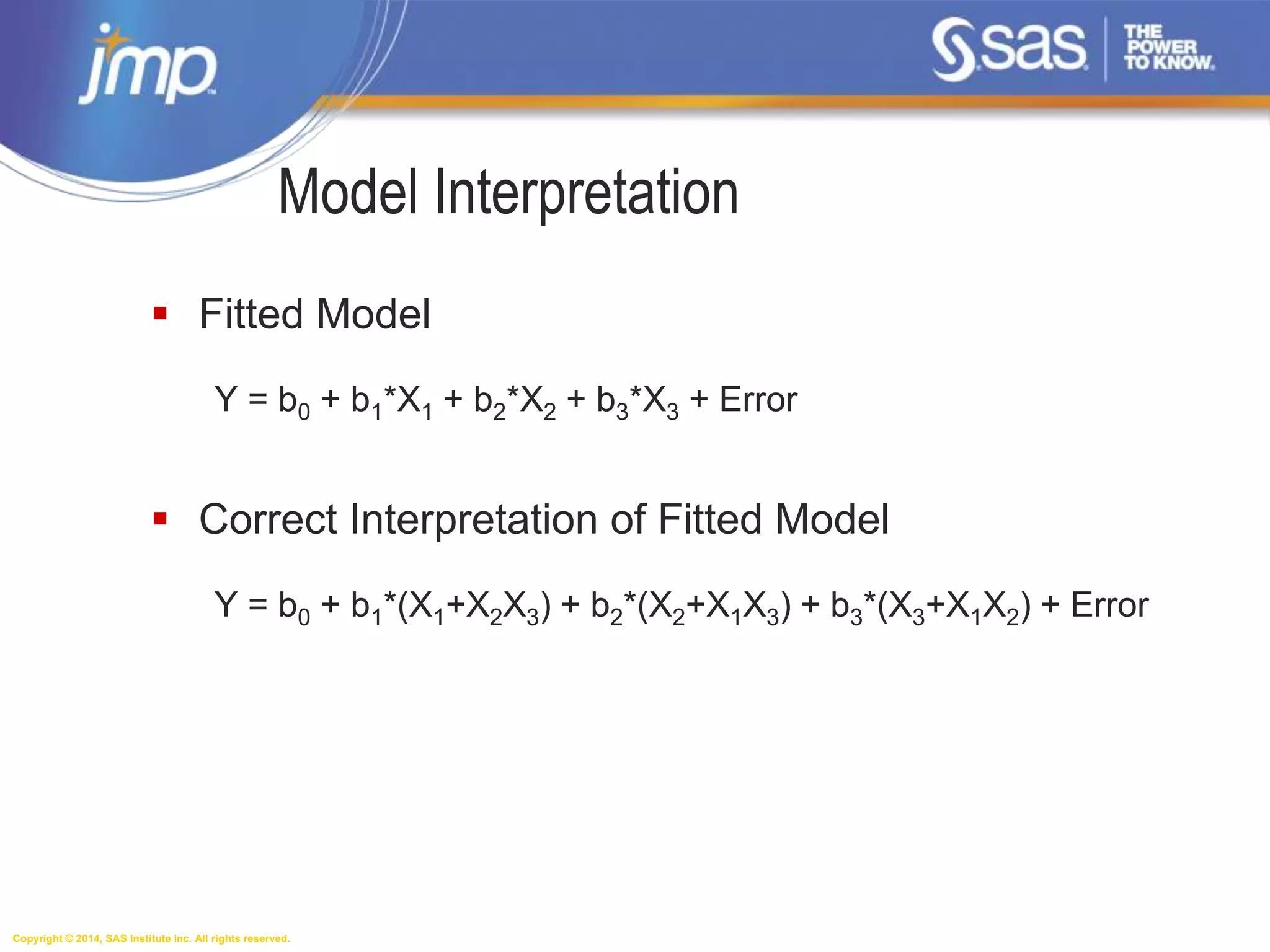

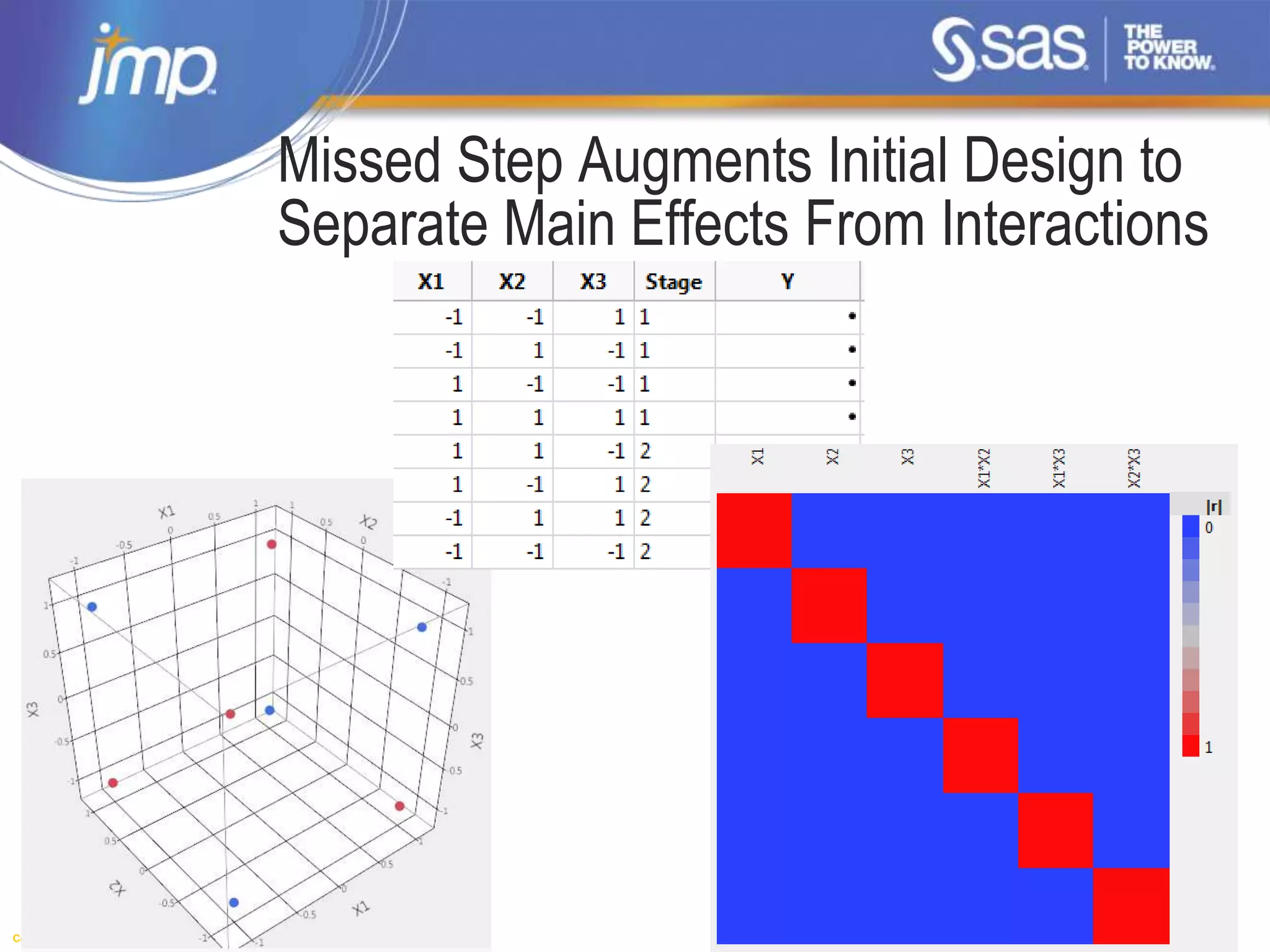

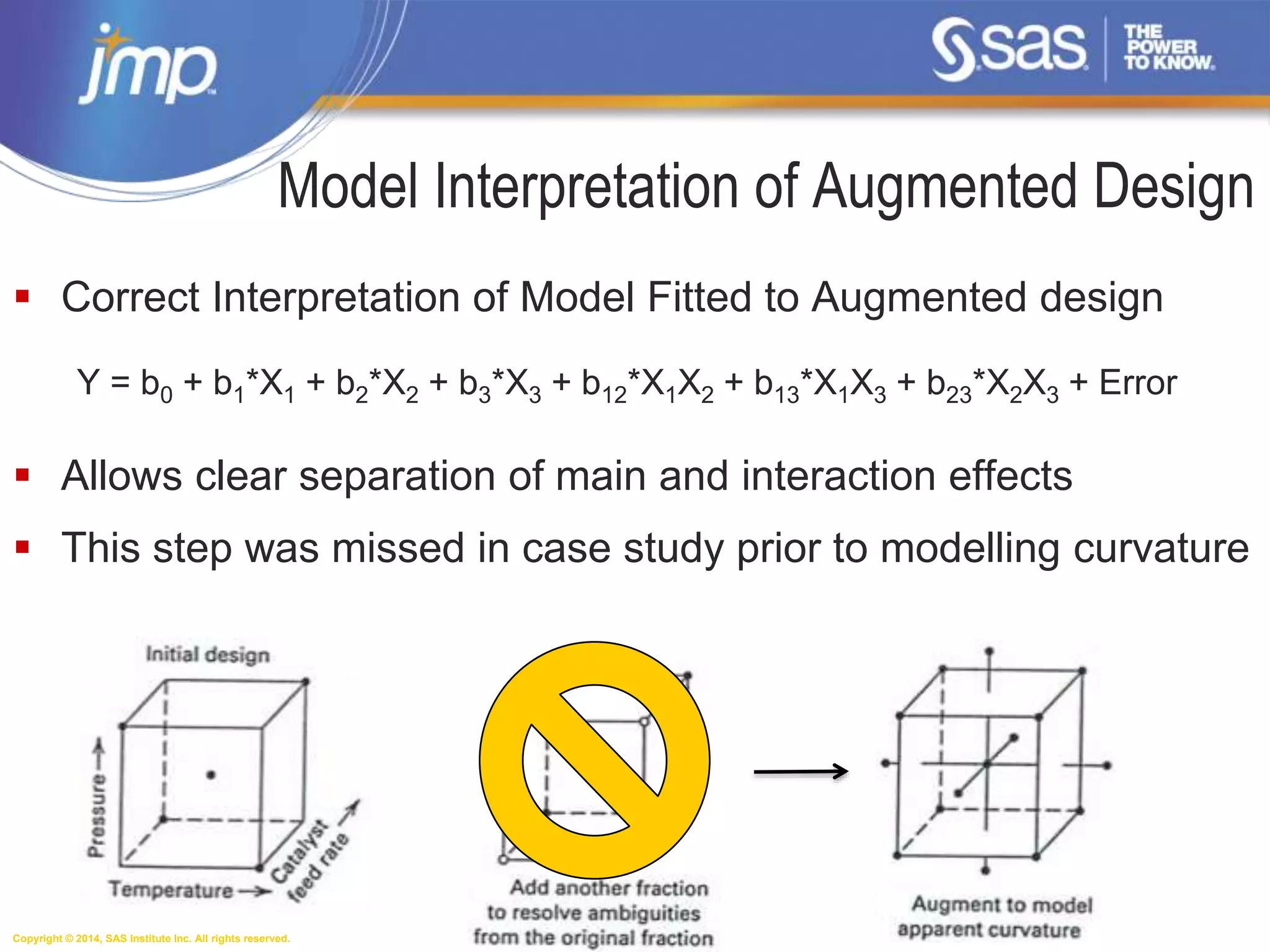

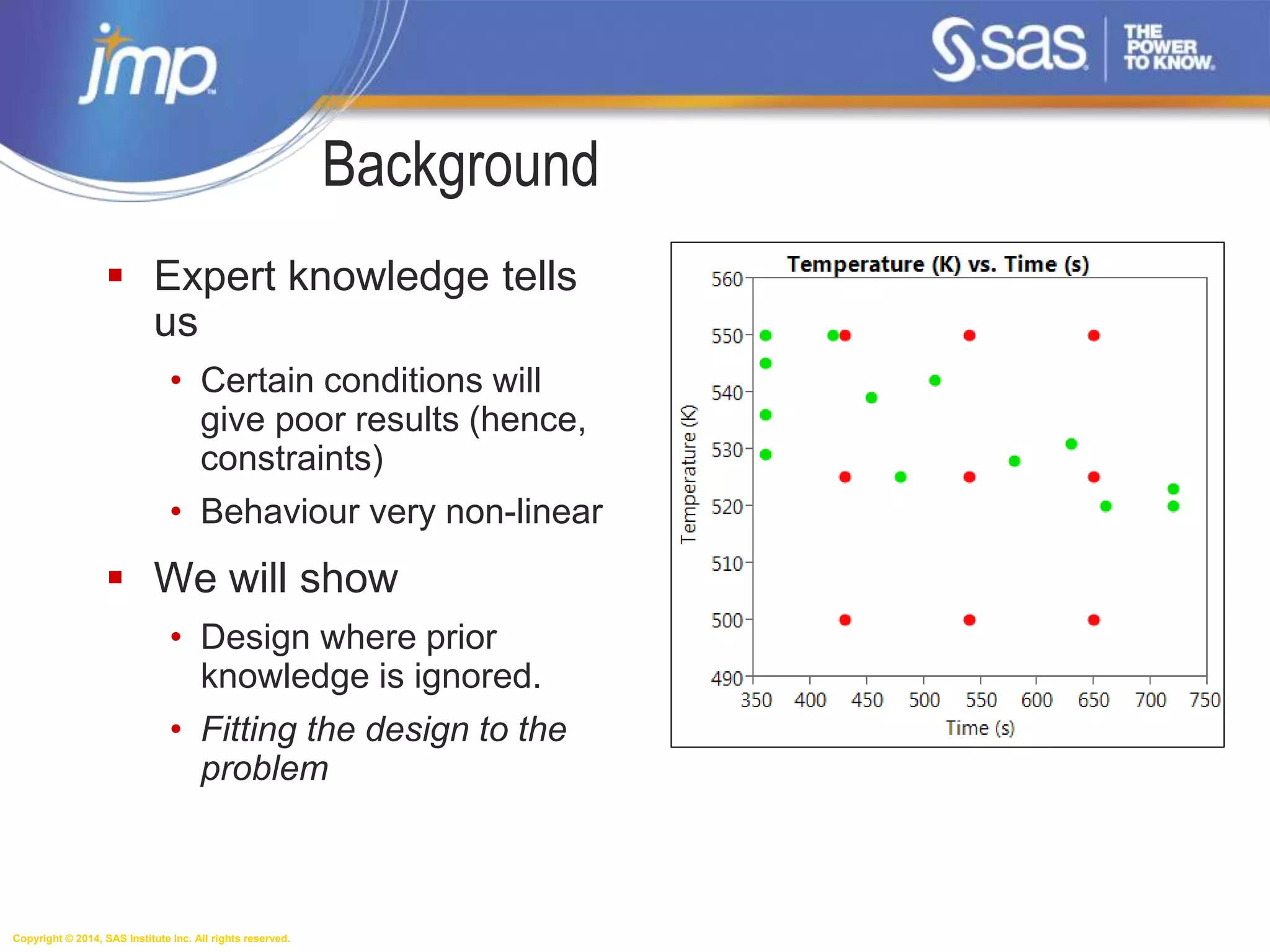

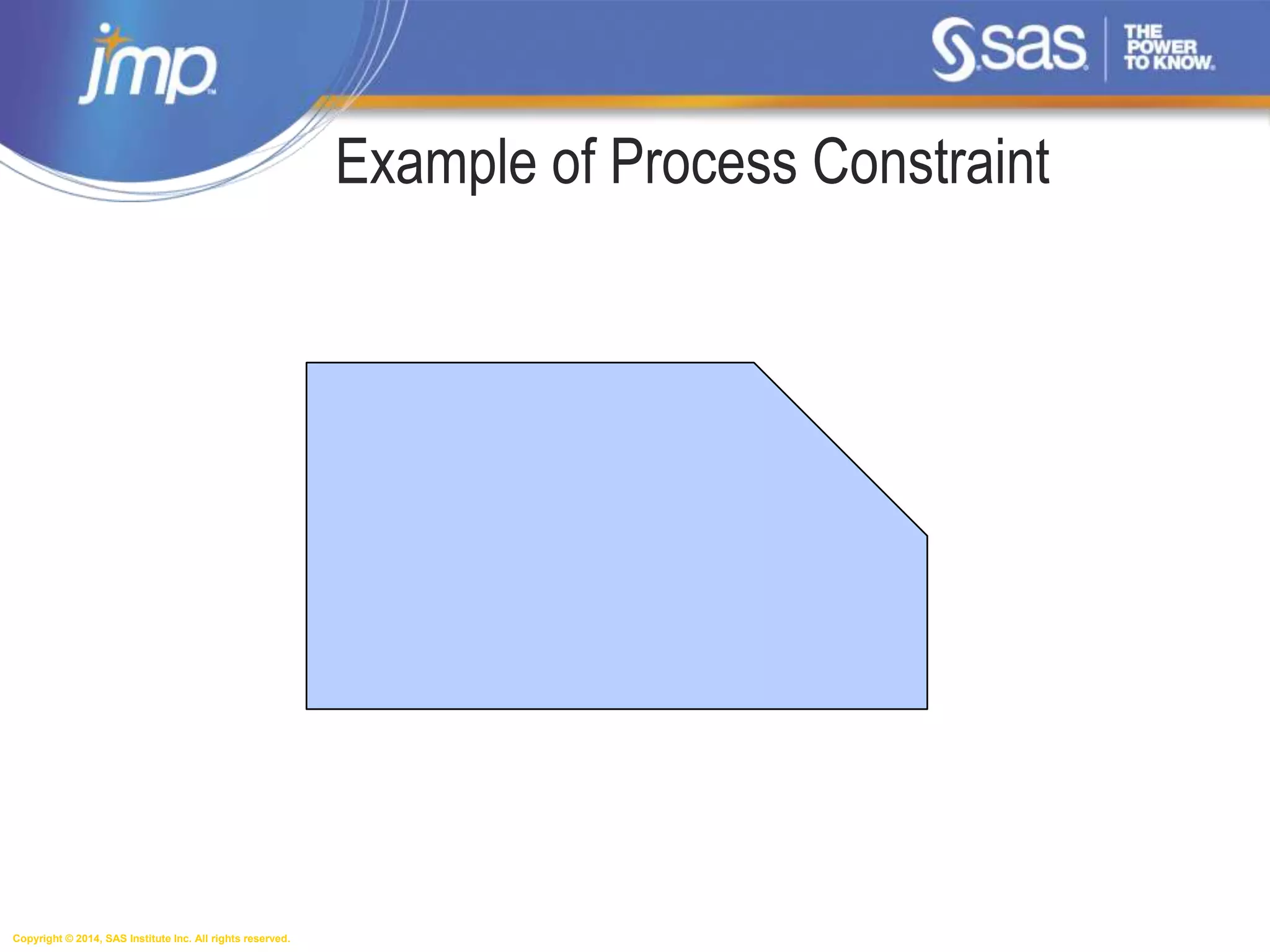

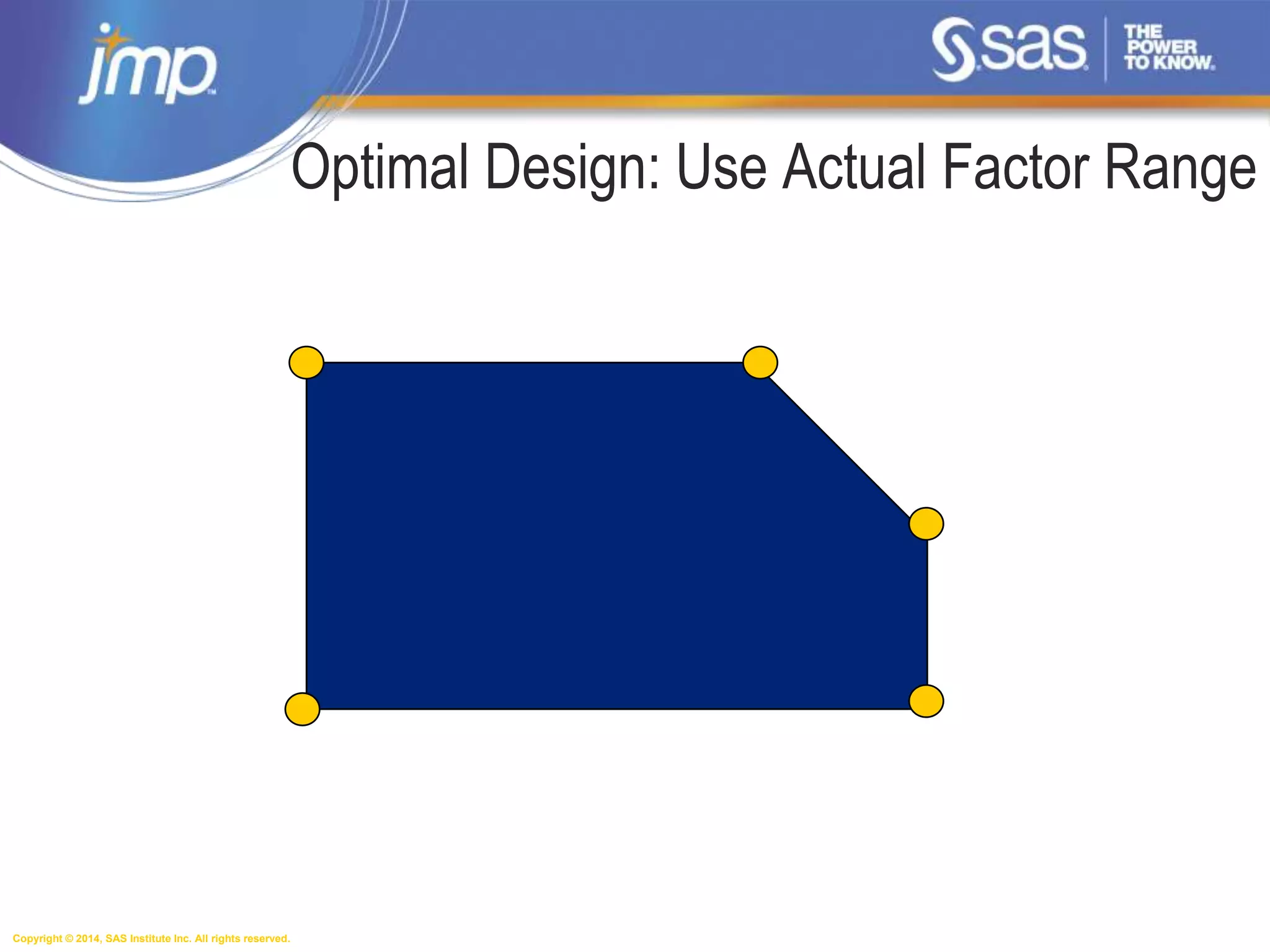

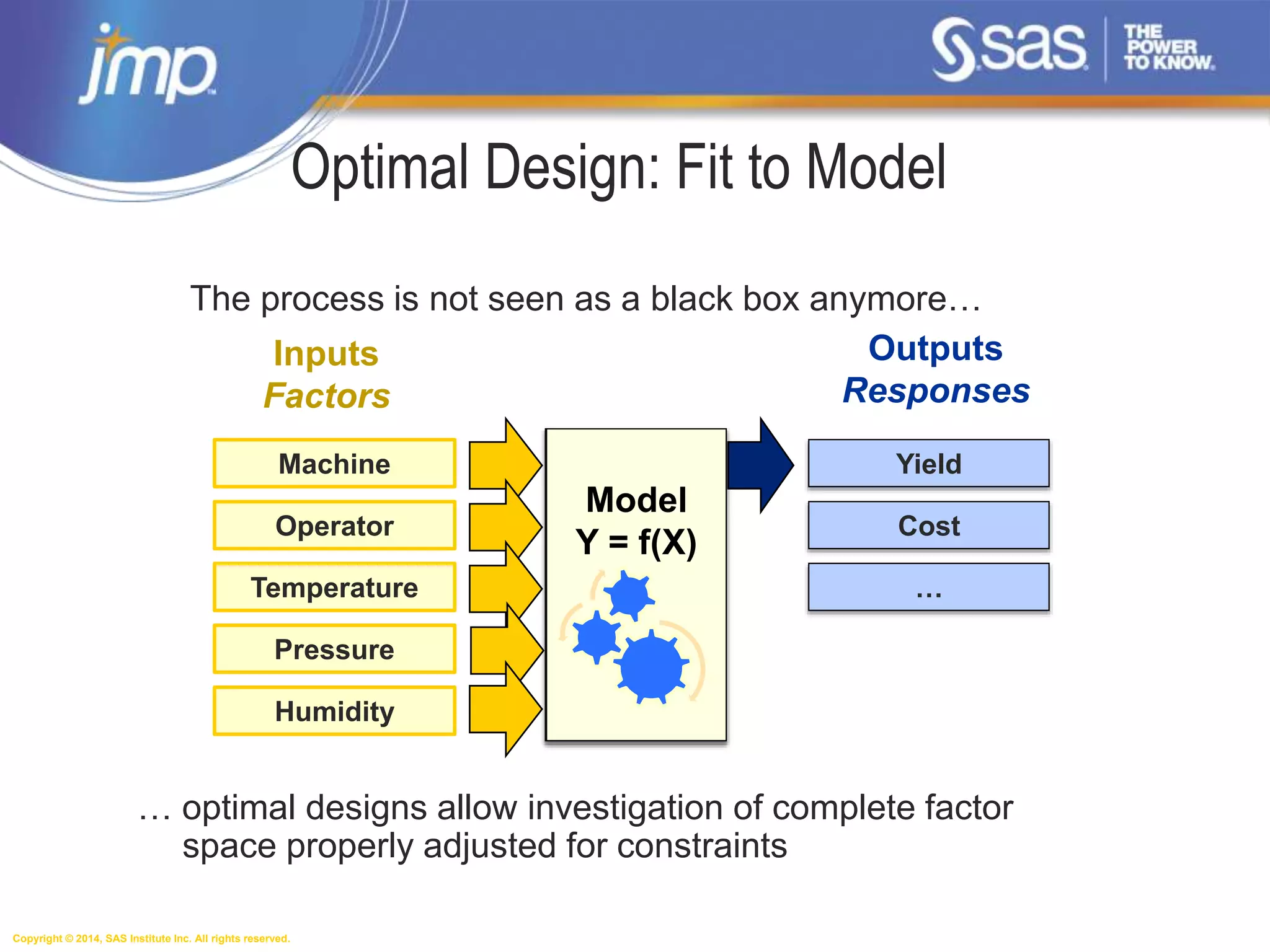

This document discusses best practices in design of experiments (DOE). It covers the history and principles of DOE developed by Ronald Fisher. Case studies demonstrate how definitive screening designs can identify important factors in one step when three or fewer are important, or can be augmented when more factors are important. Optimal designs allow investigation of constrained factor spaces. A holistic approach considers customer preferences in addition to technical factors.