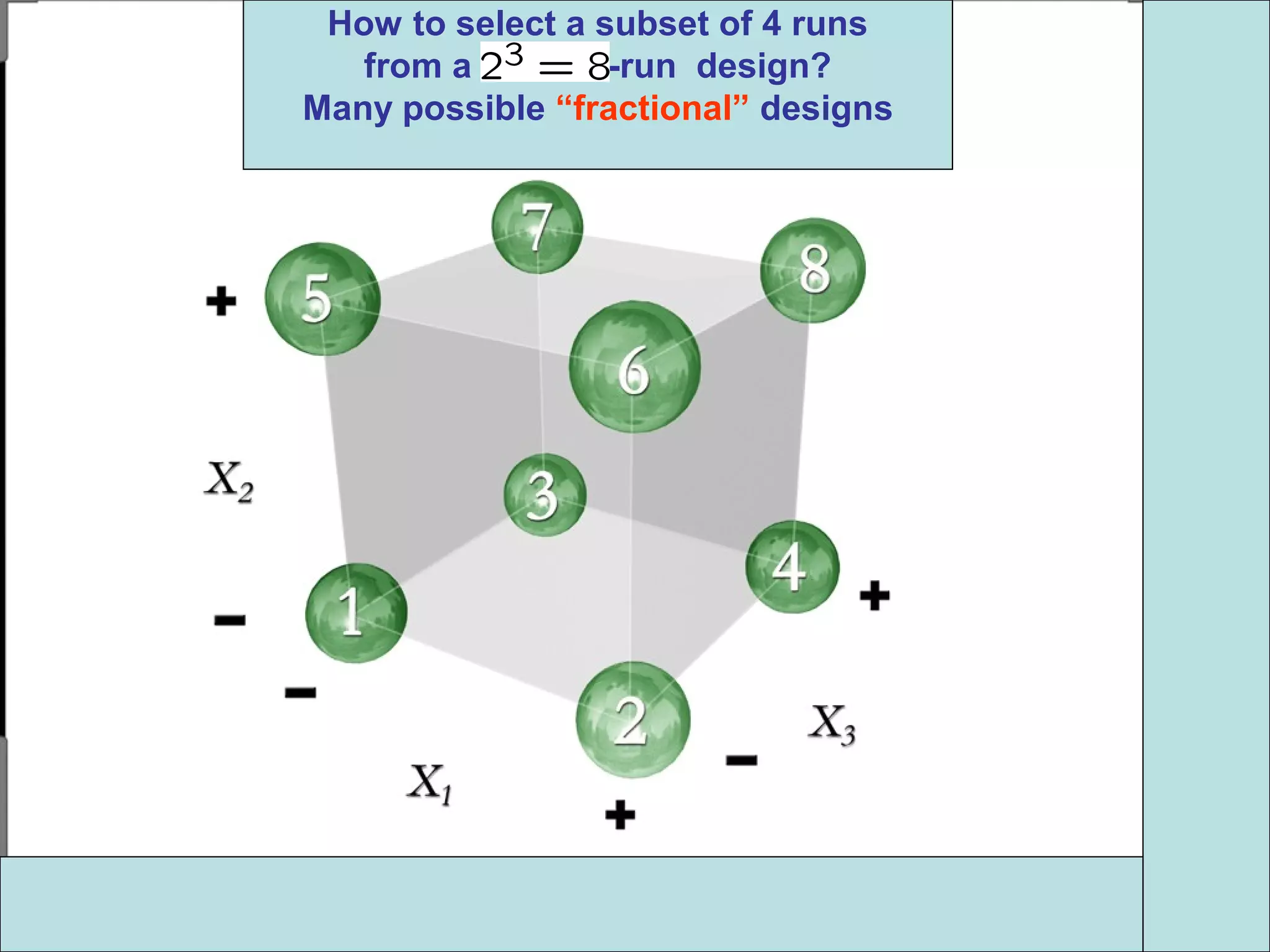

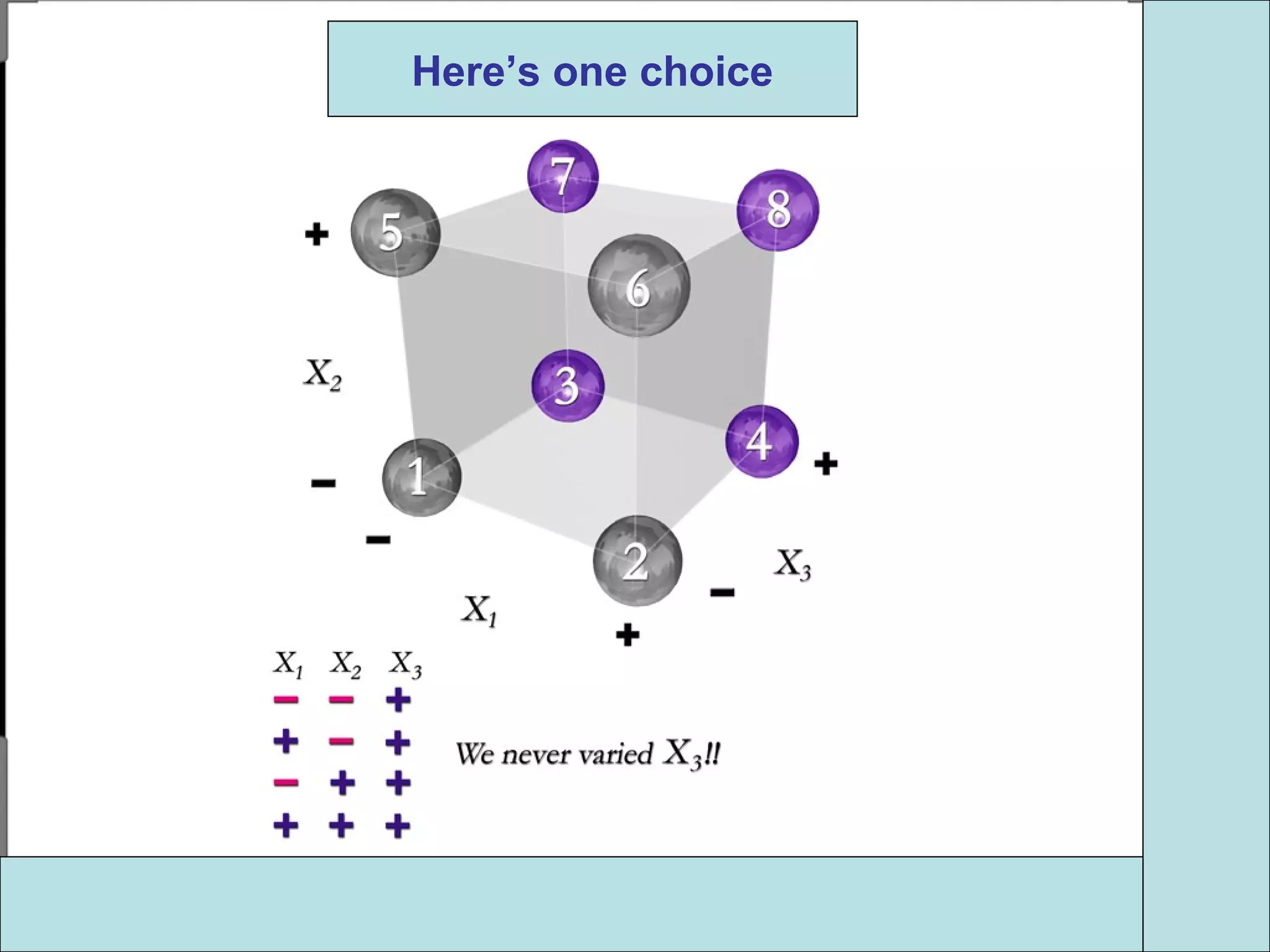

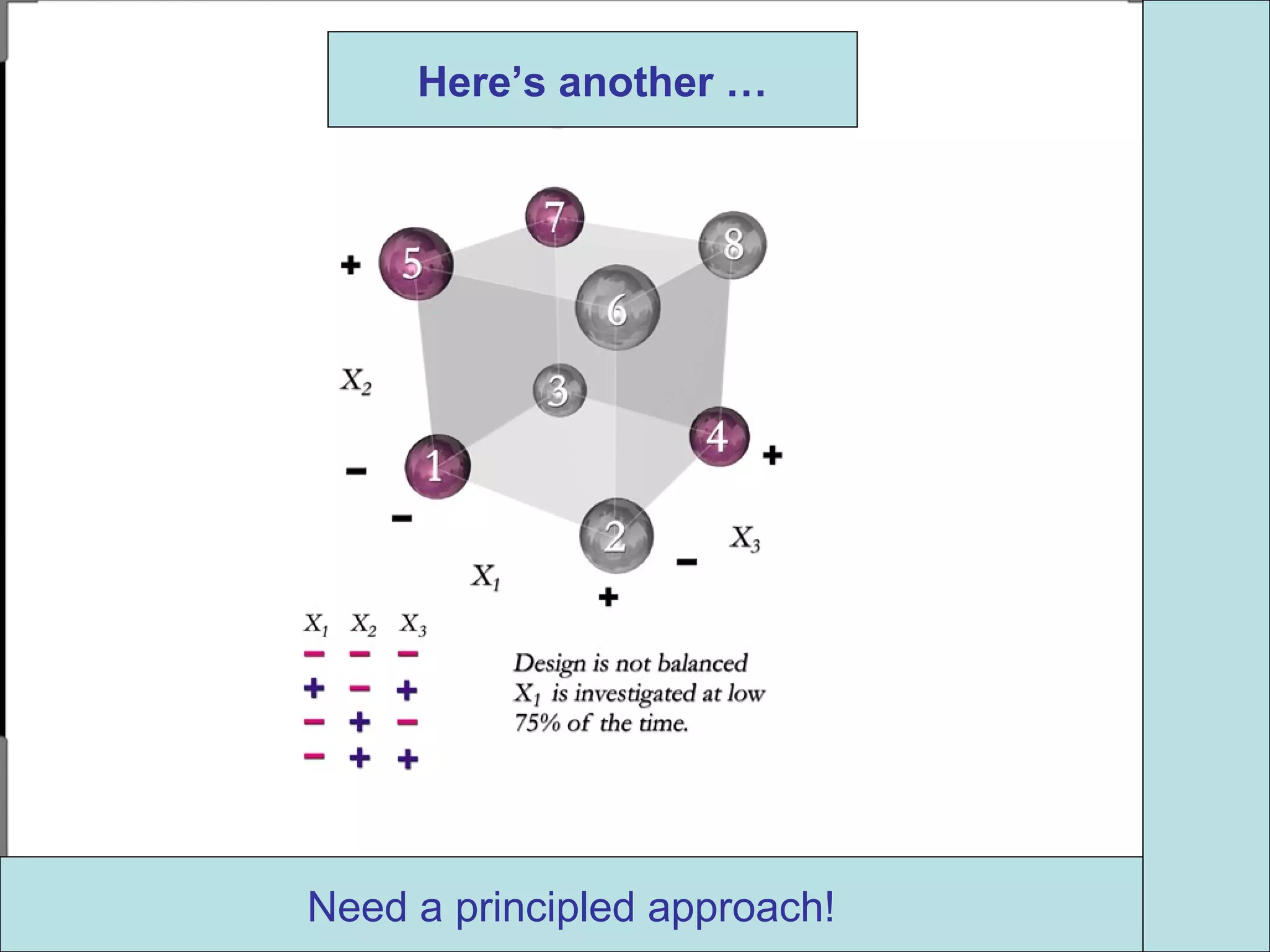

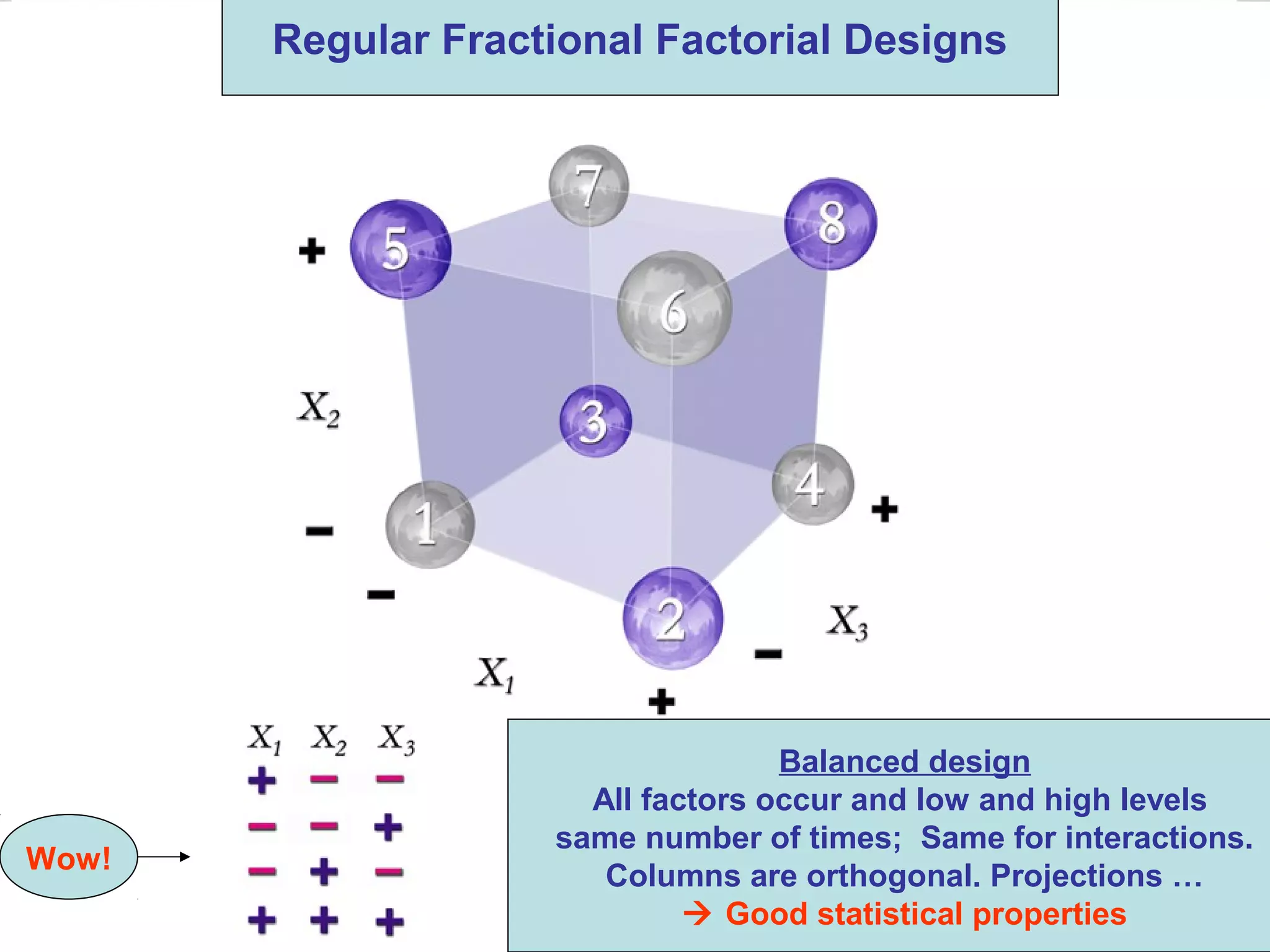

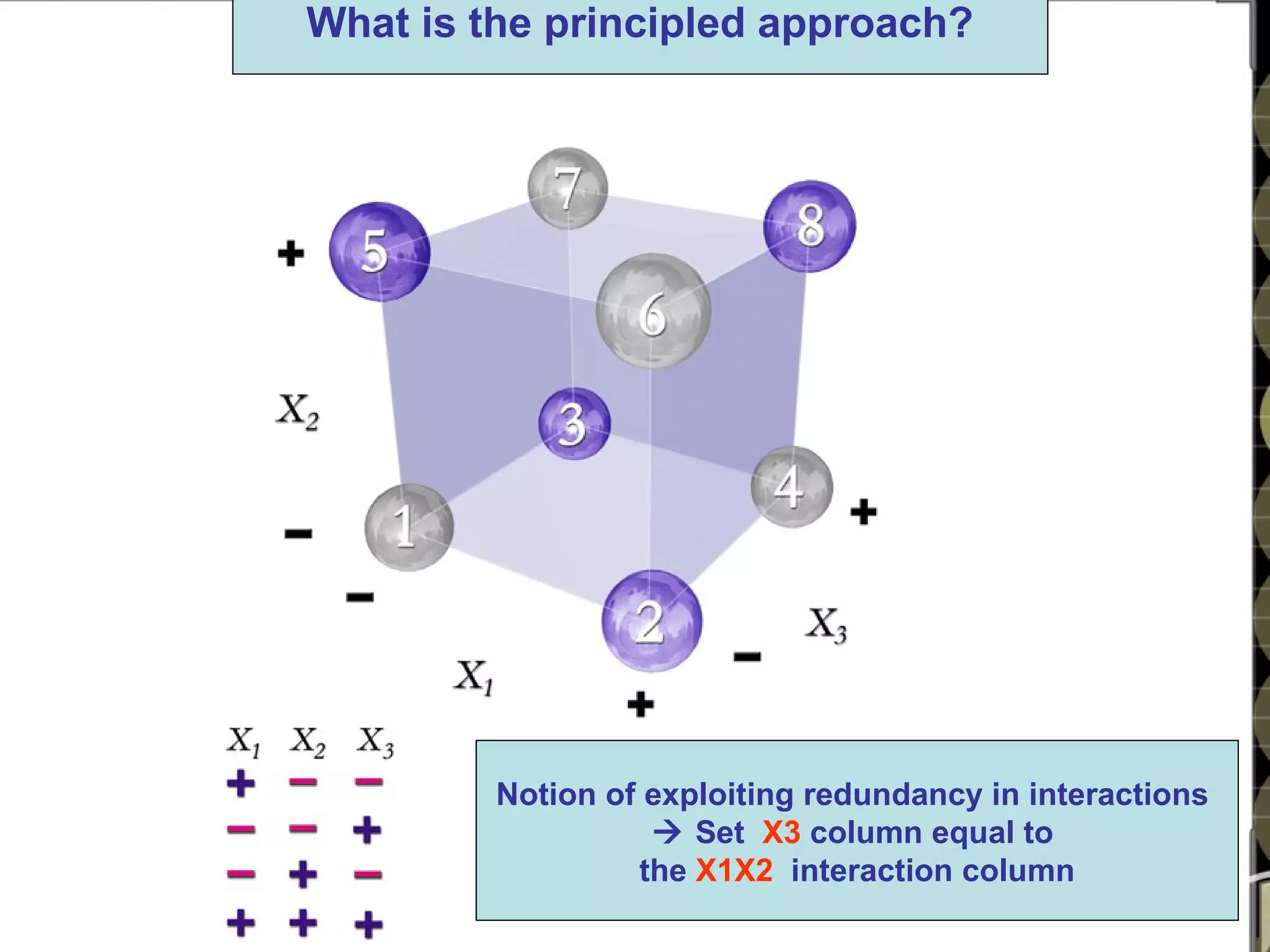

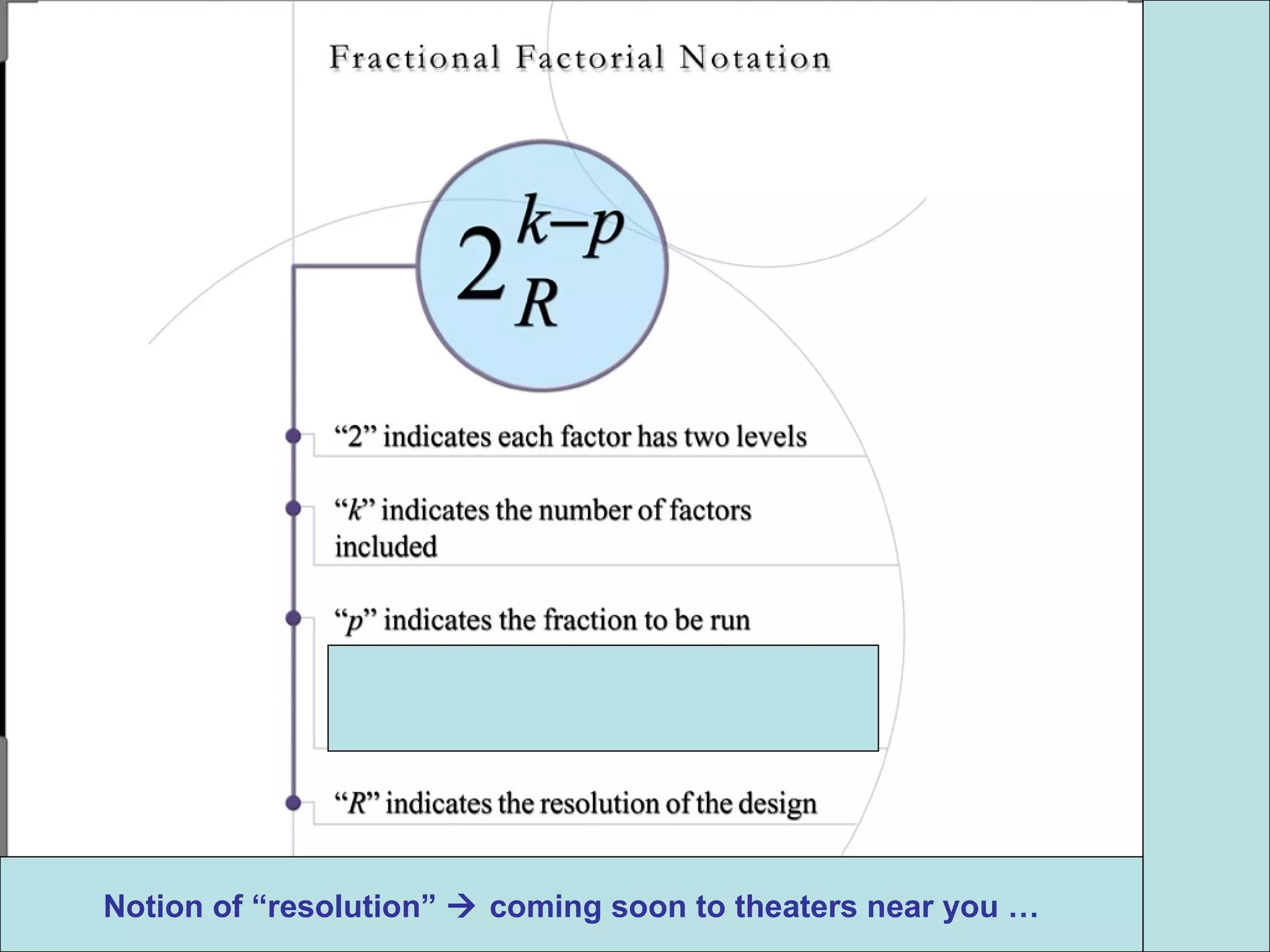

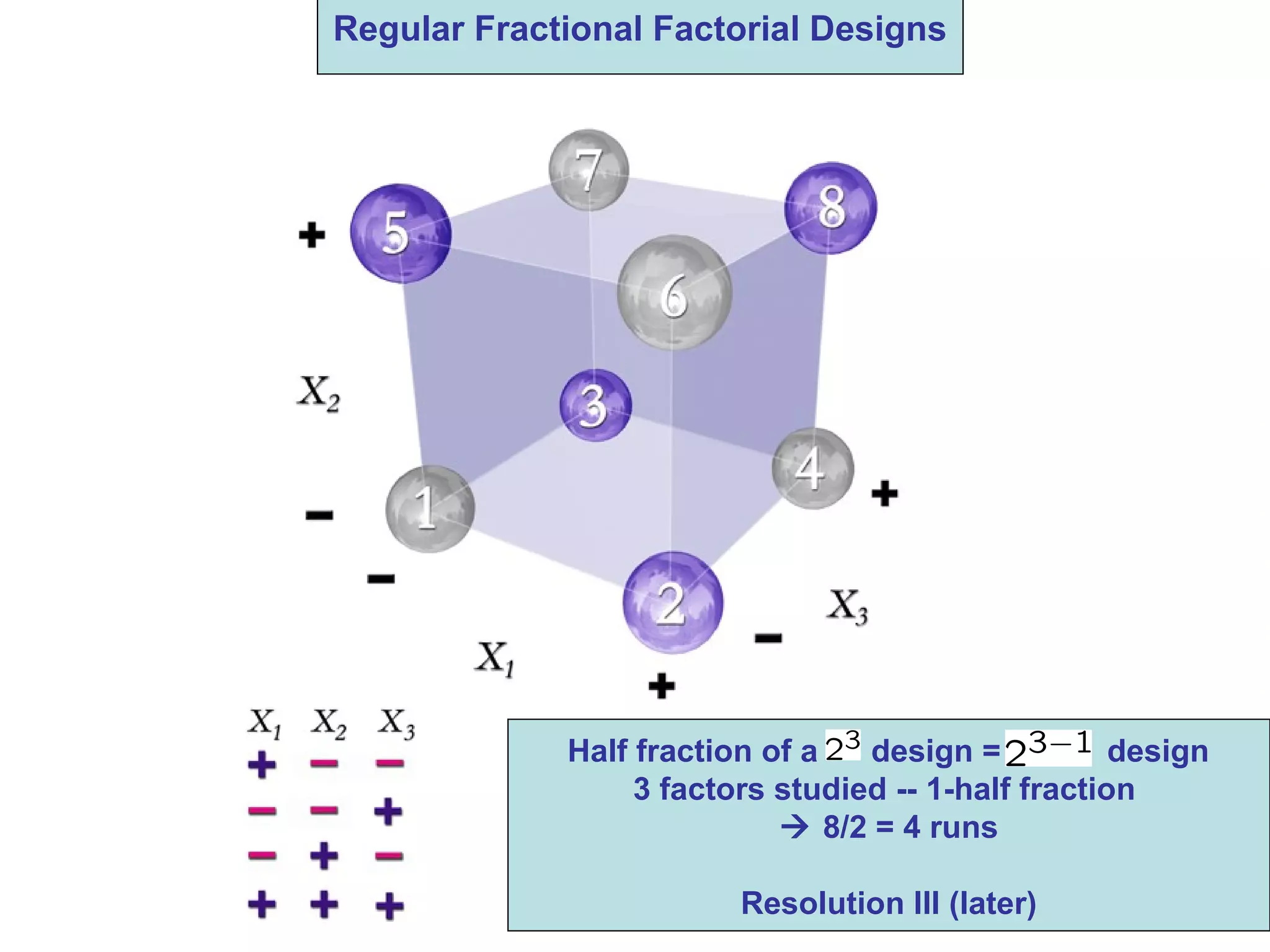

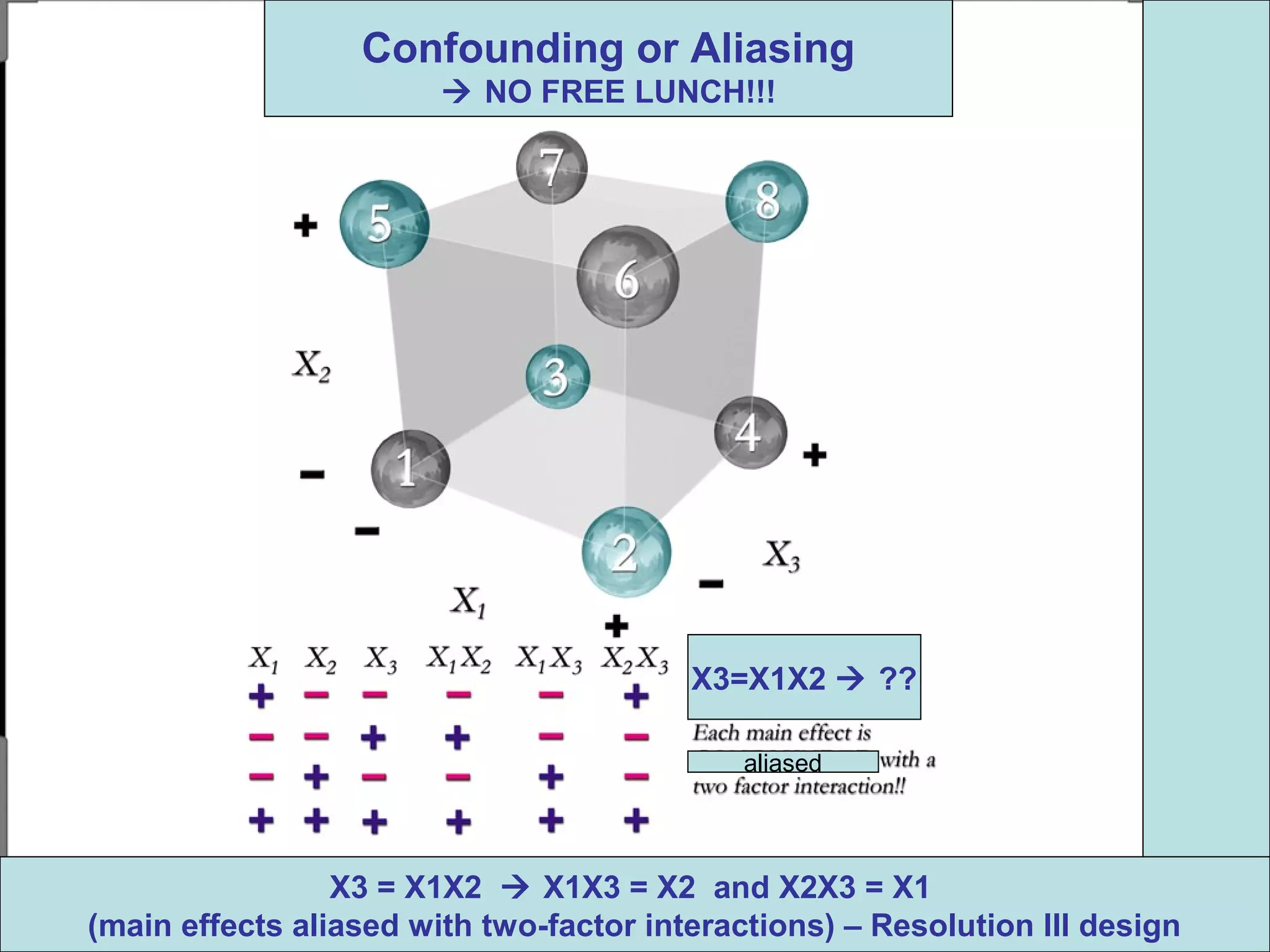

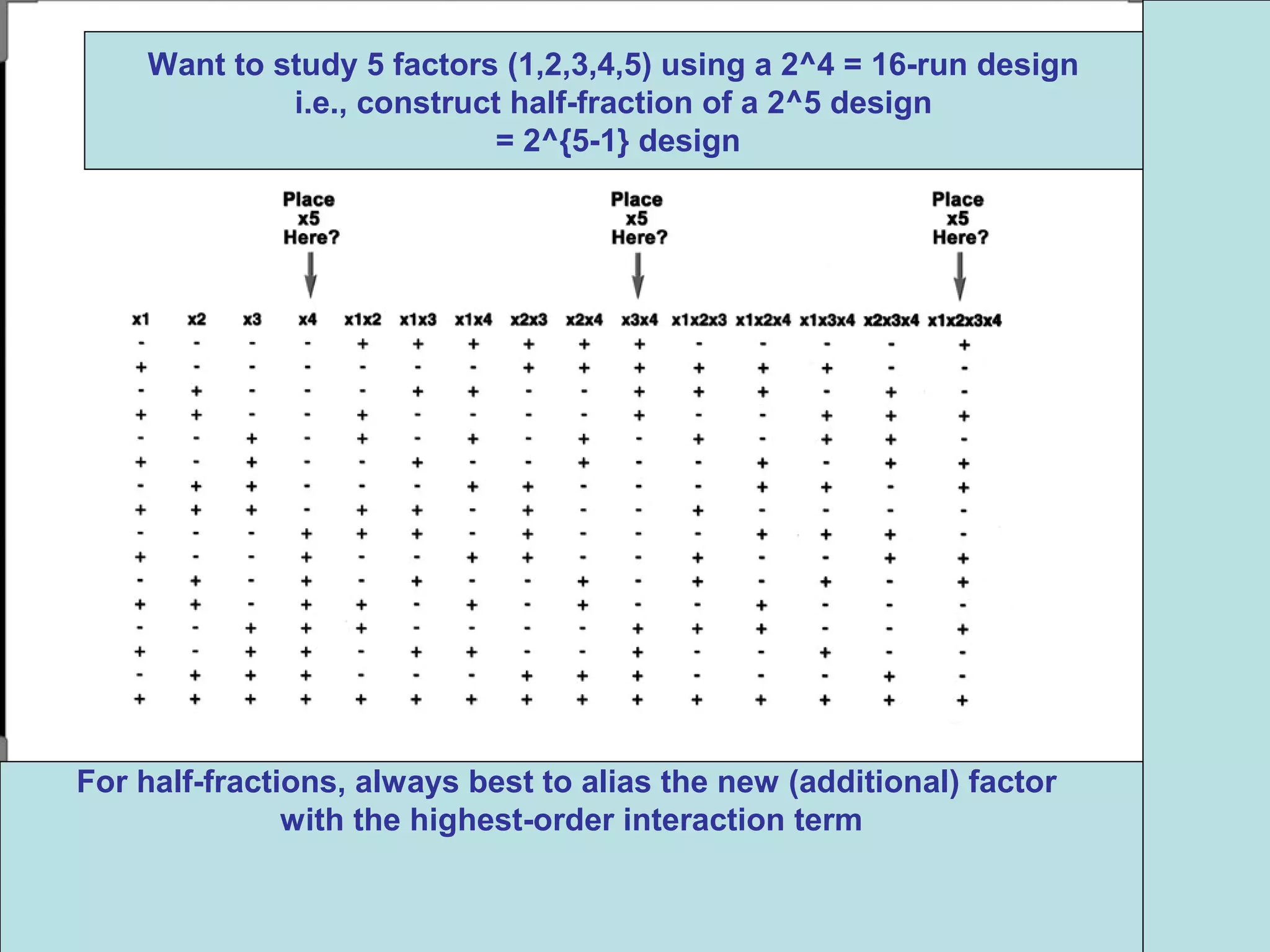

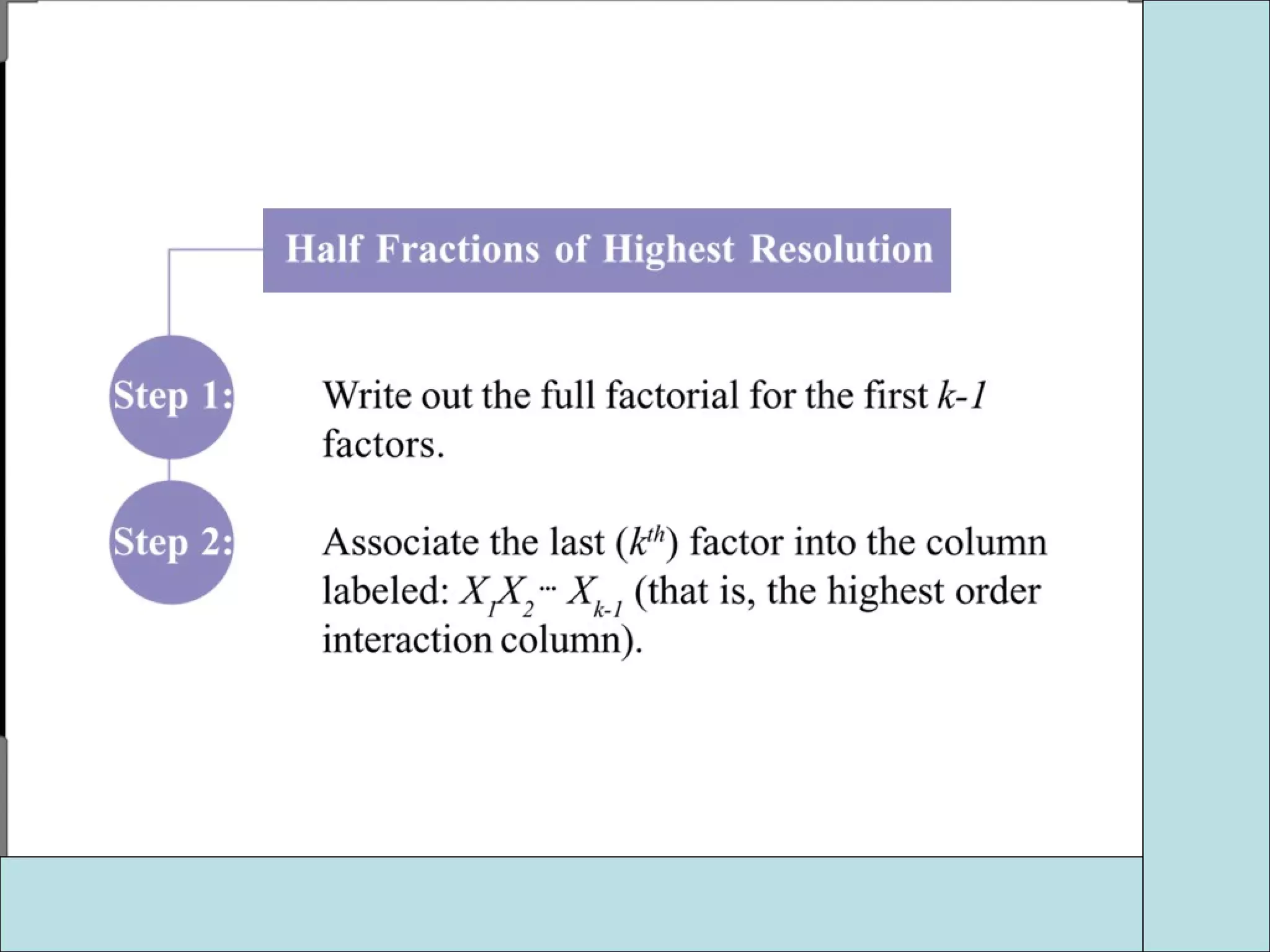

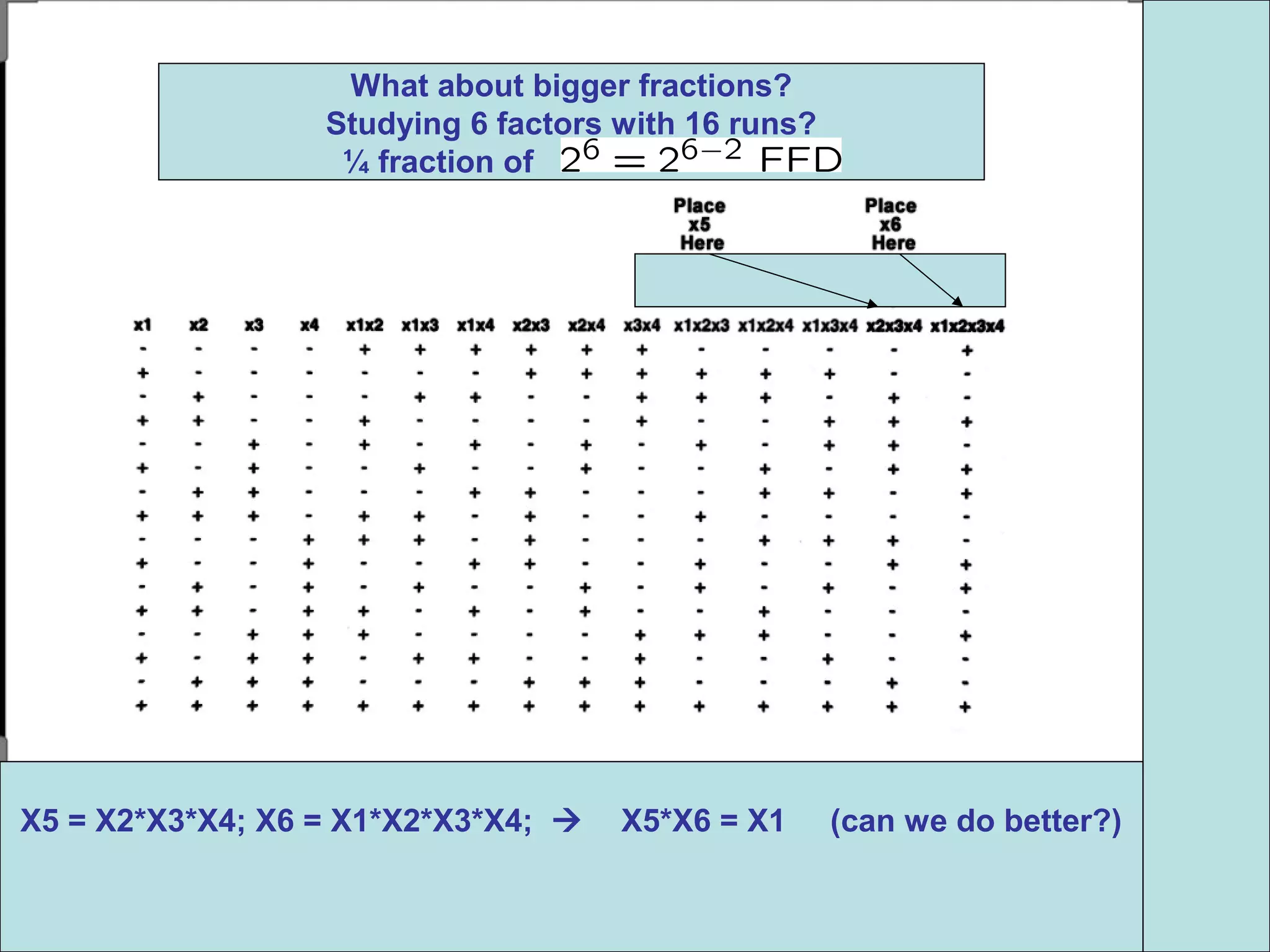

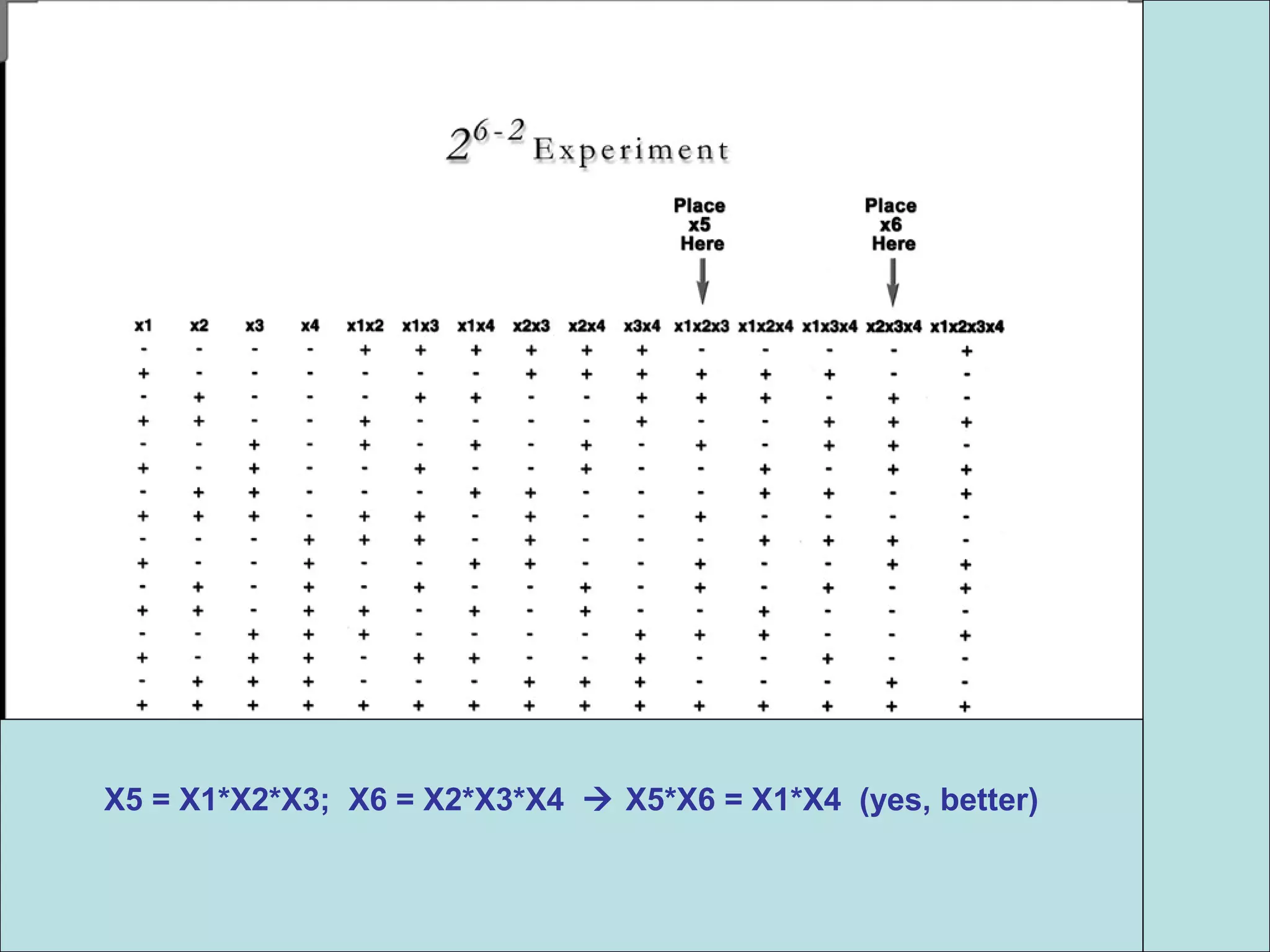

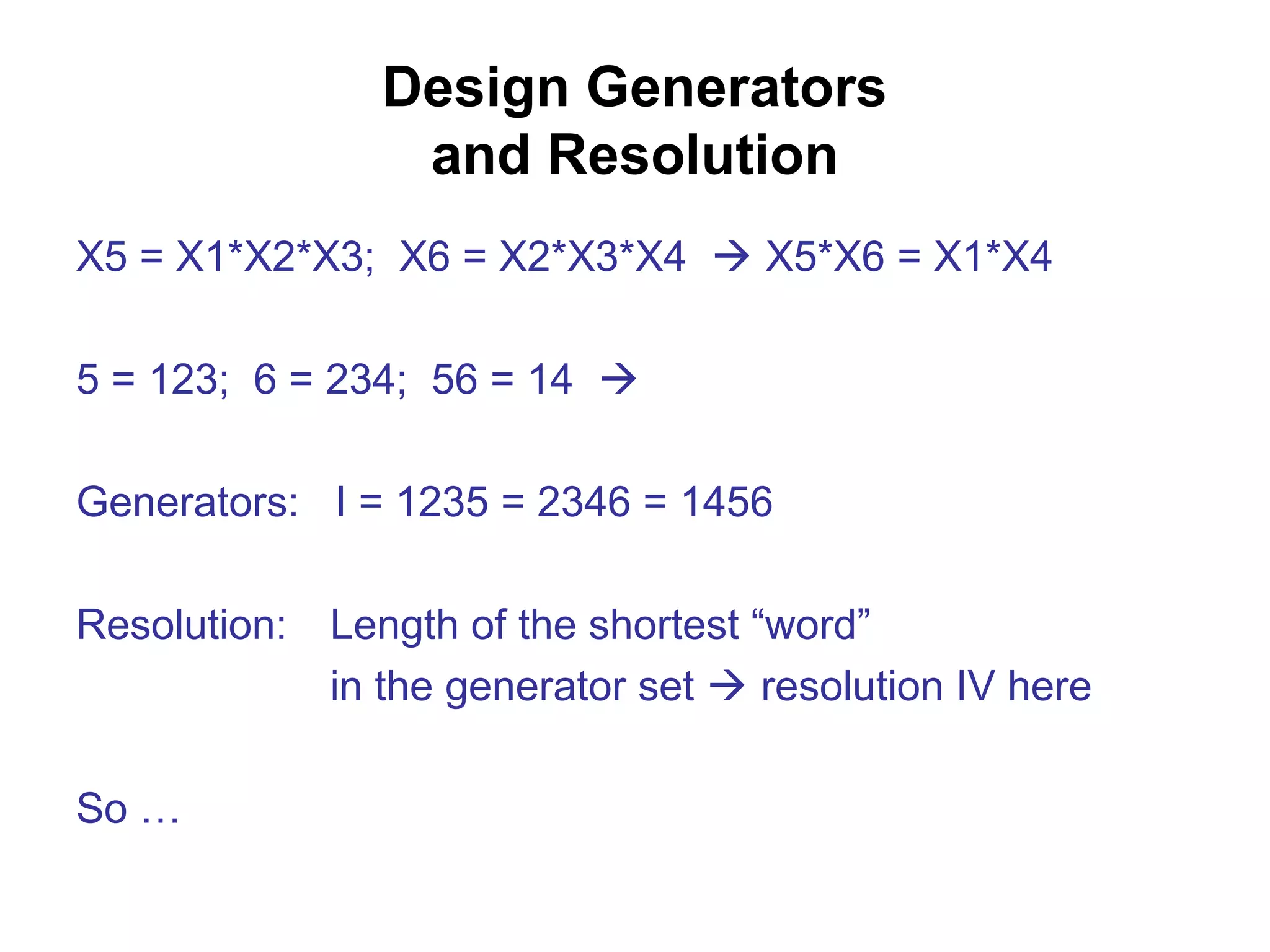

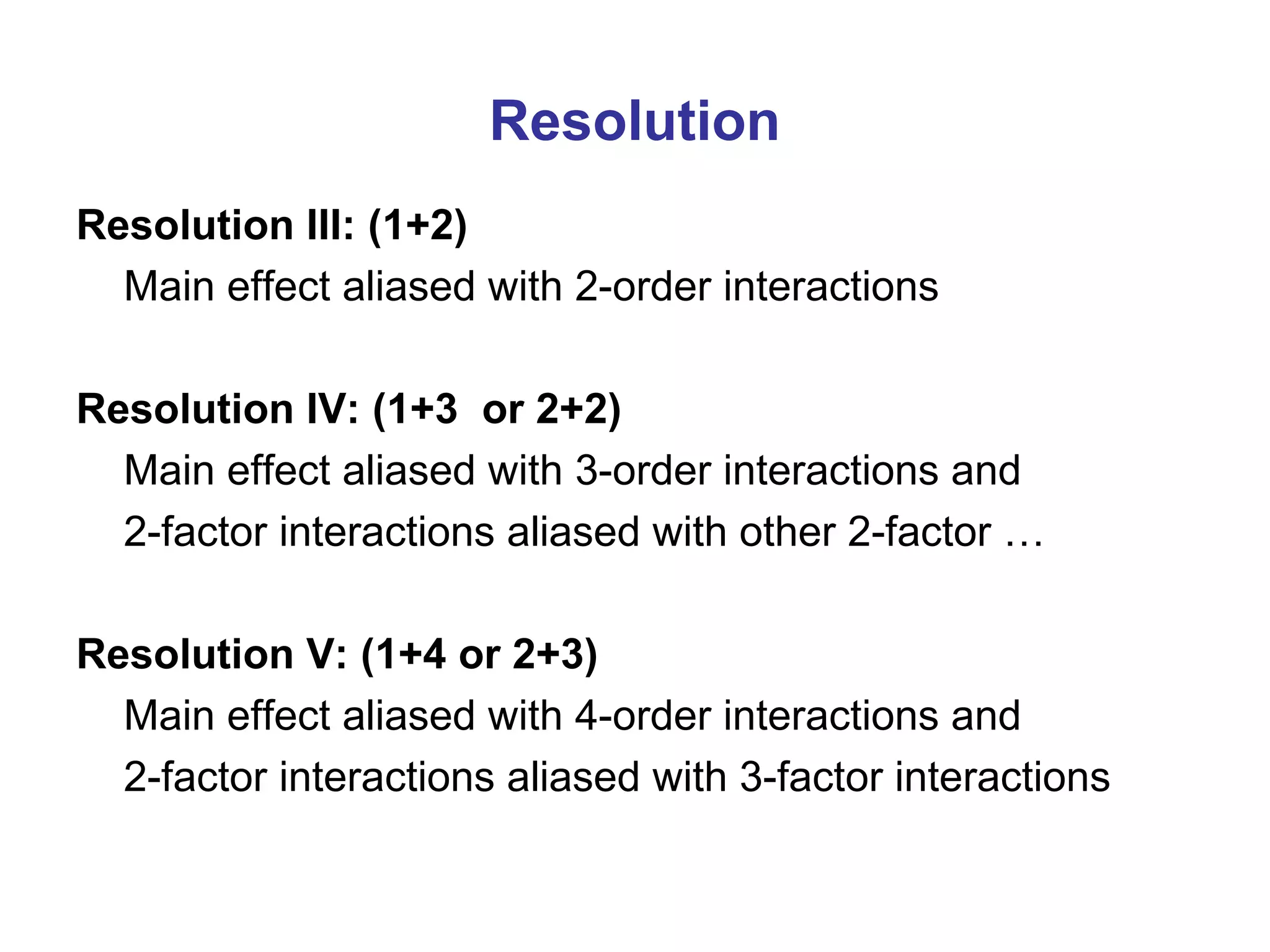

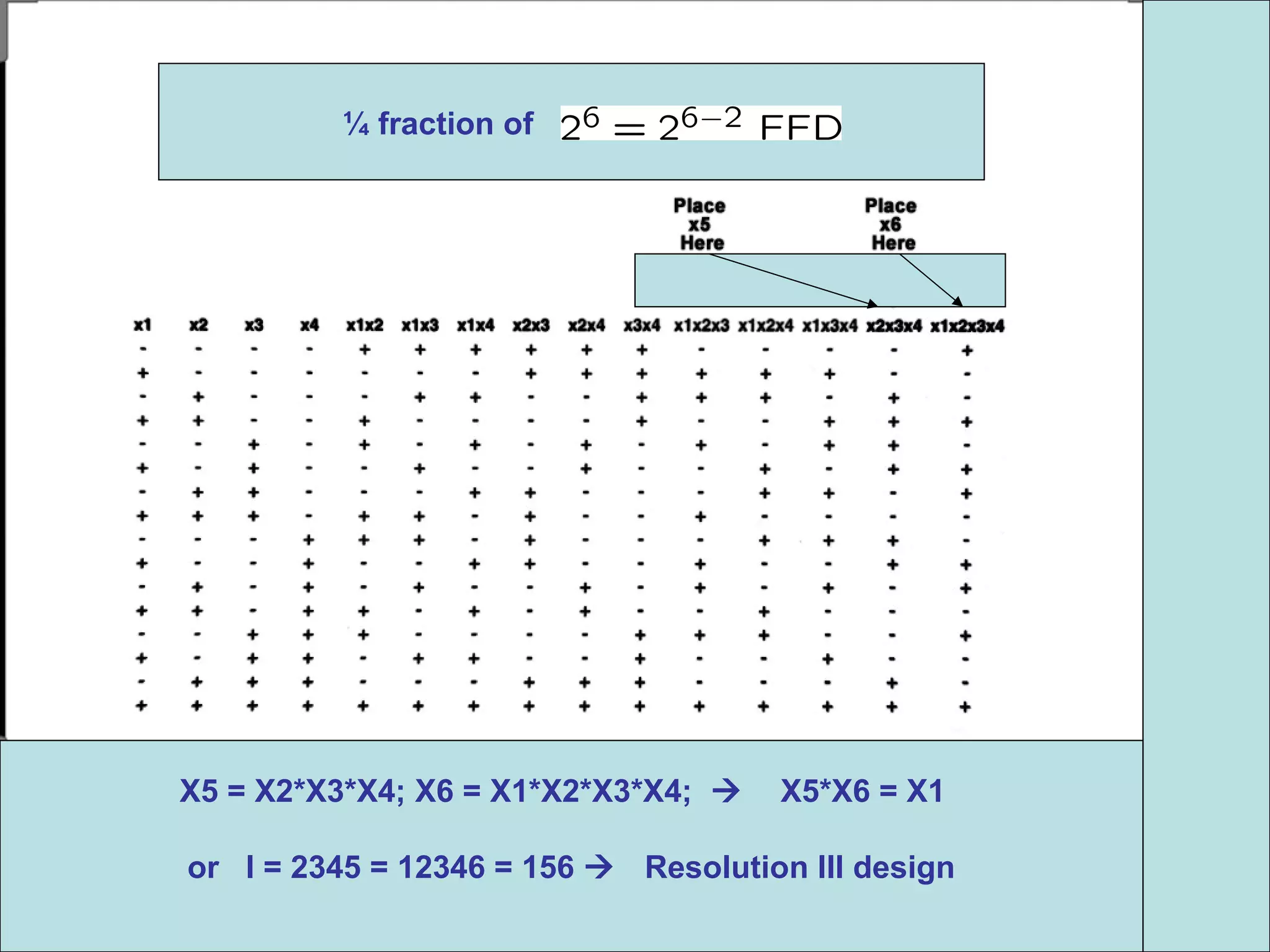

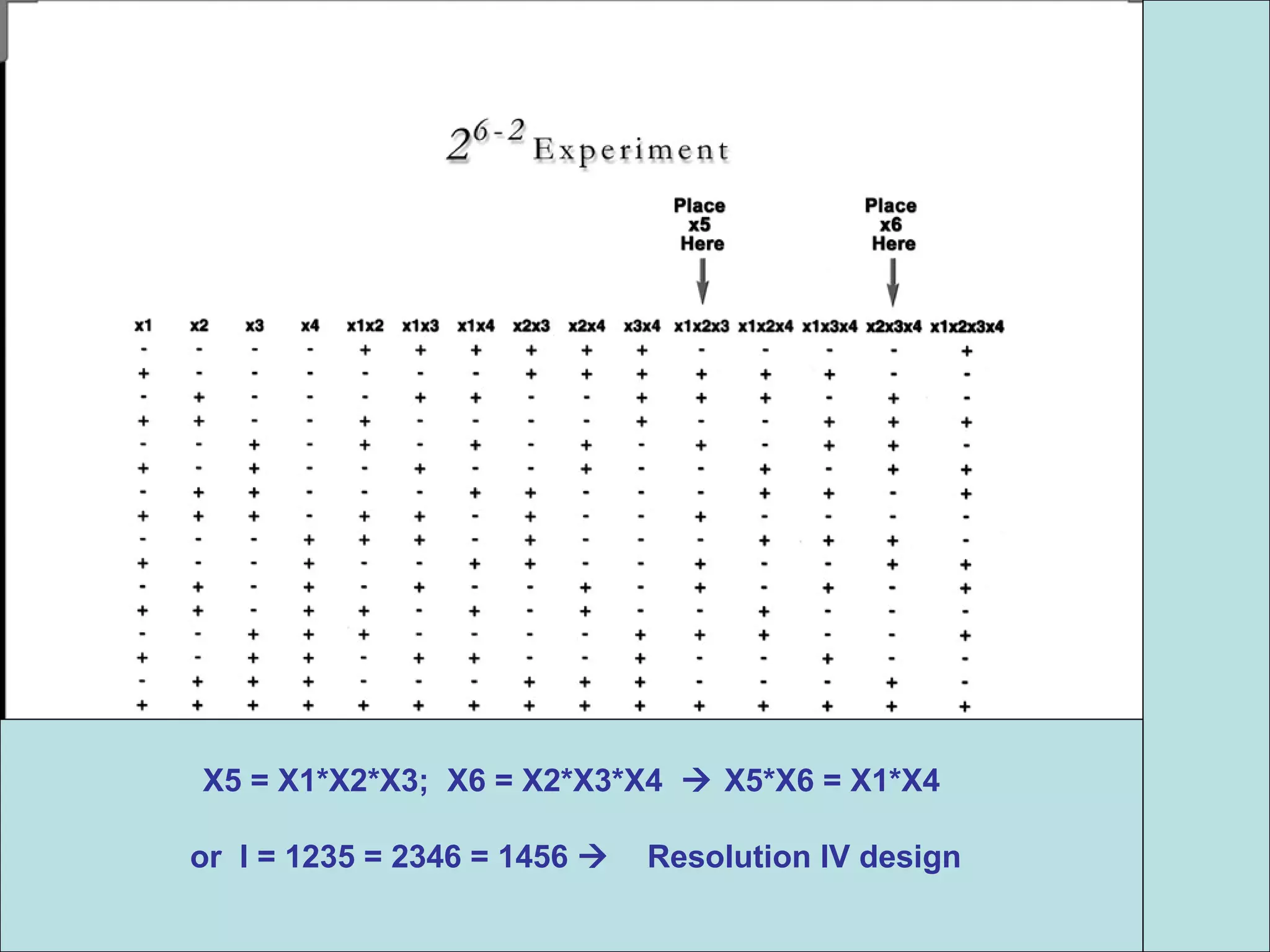

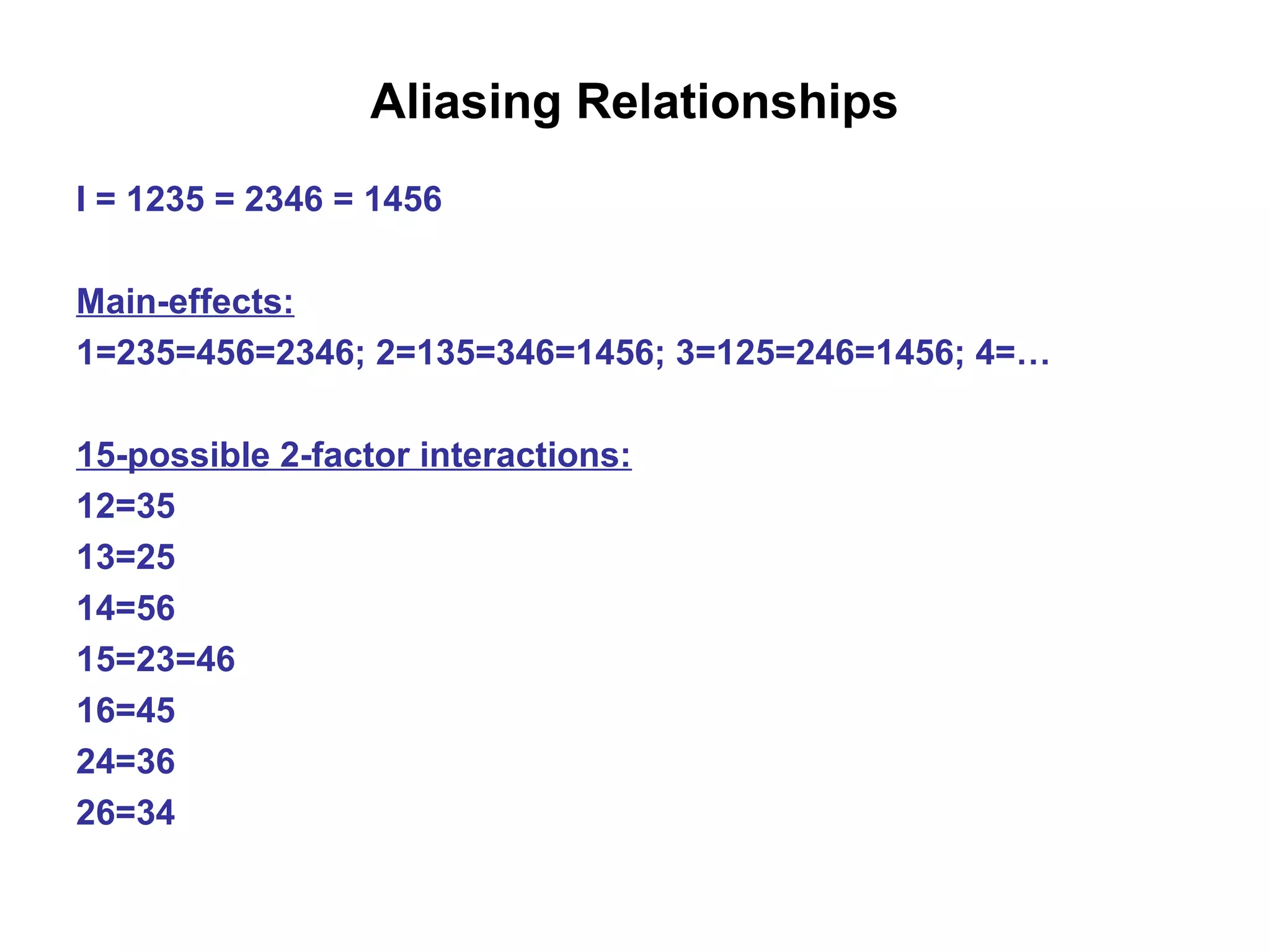

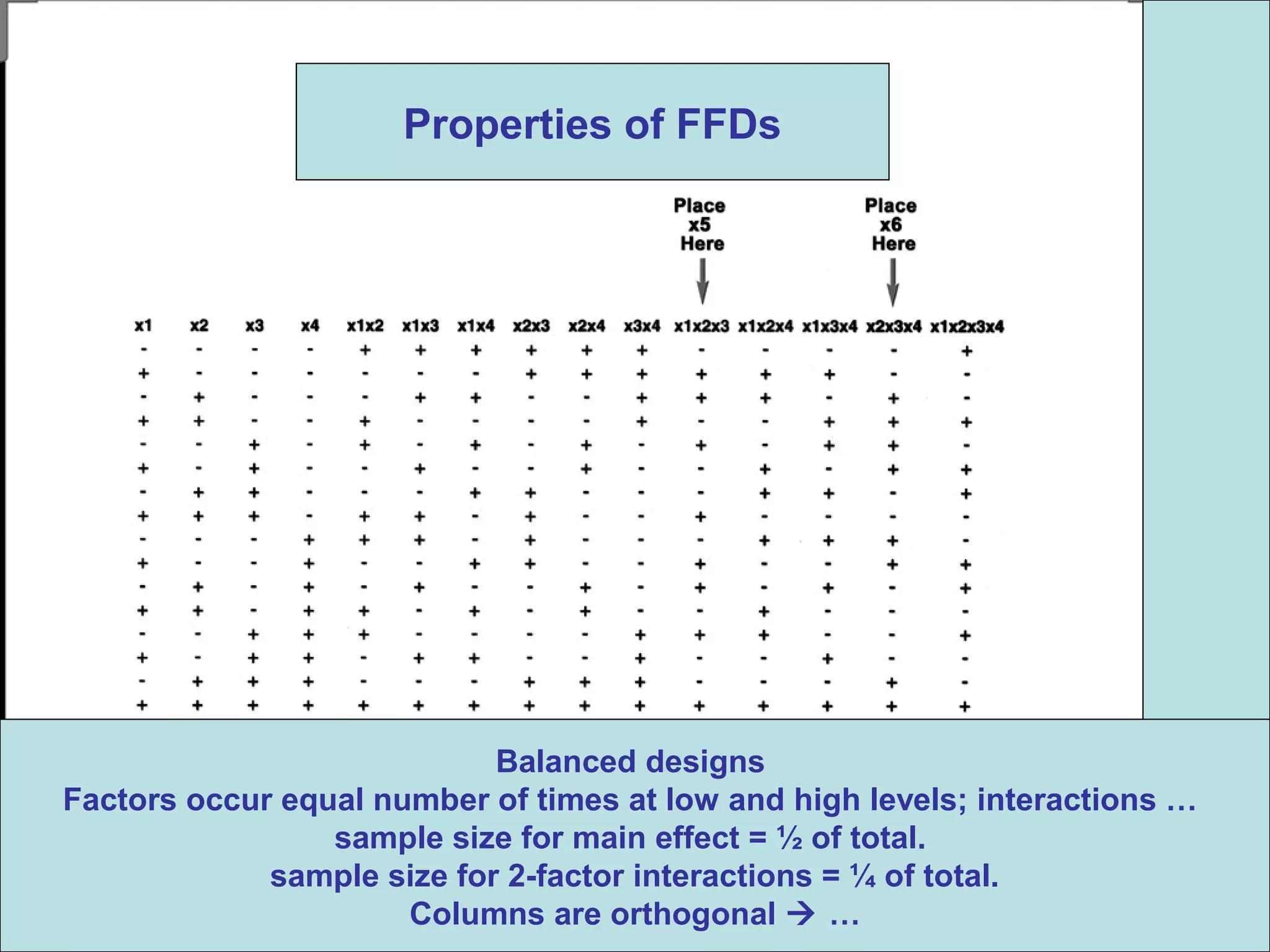

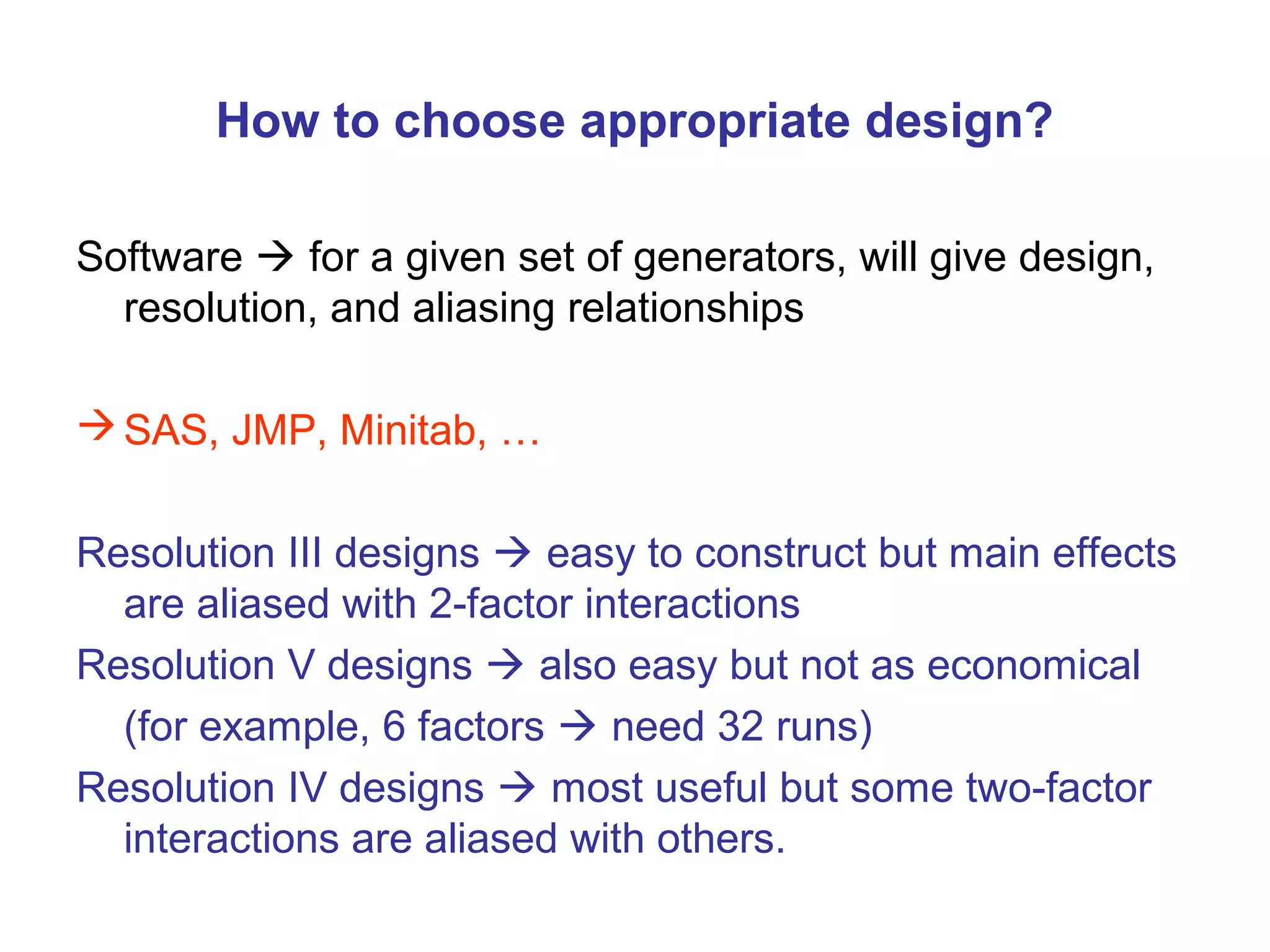

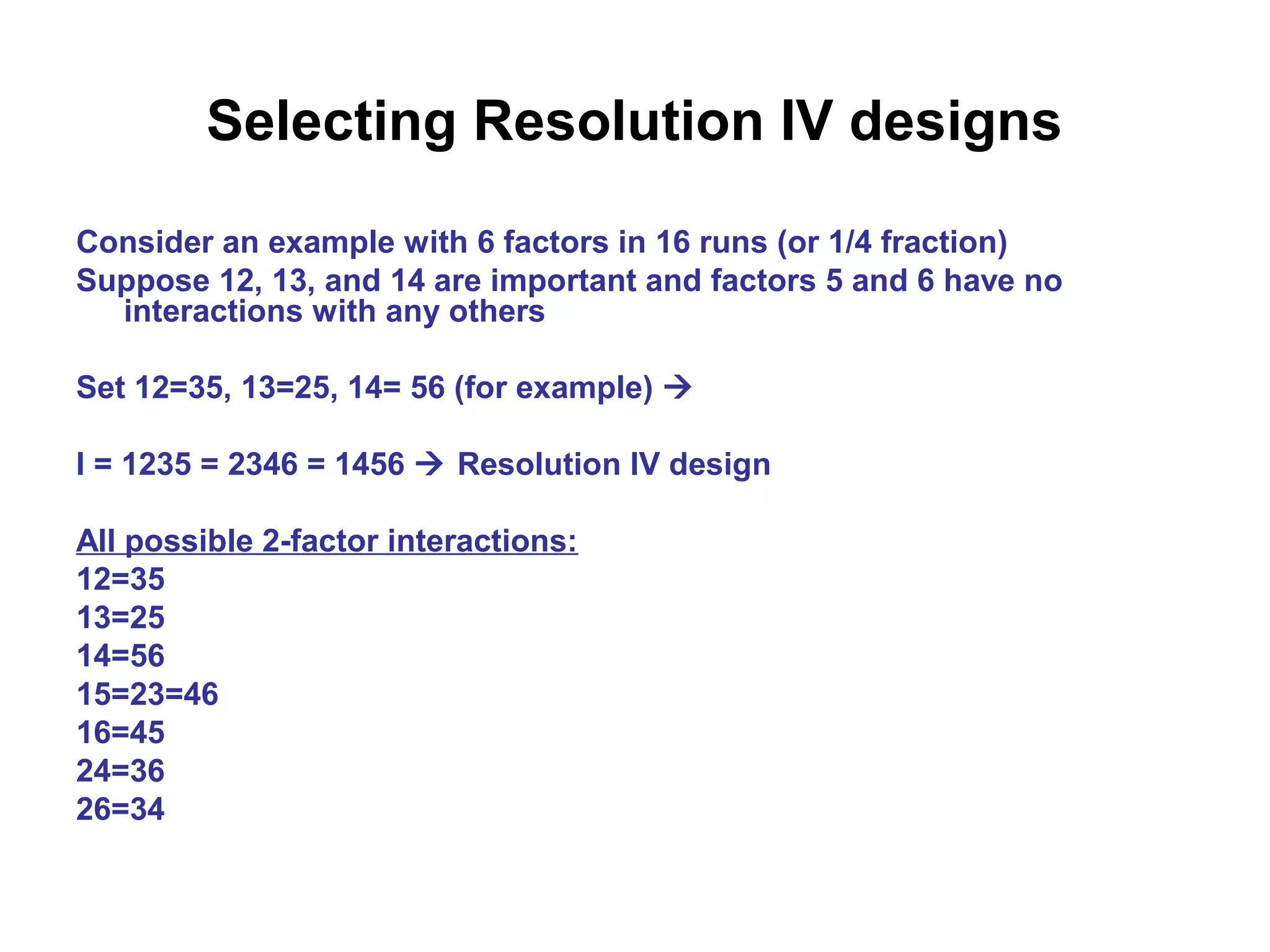

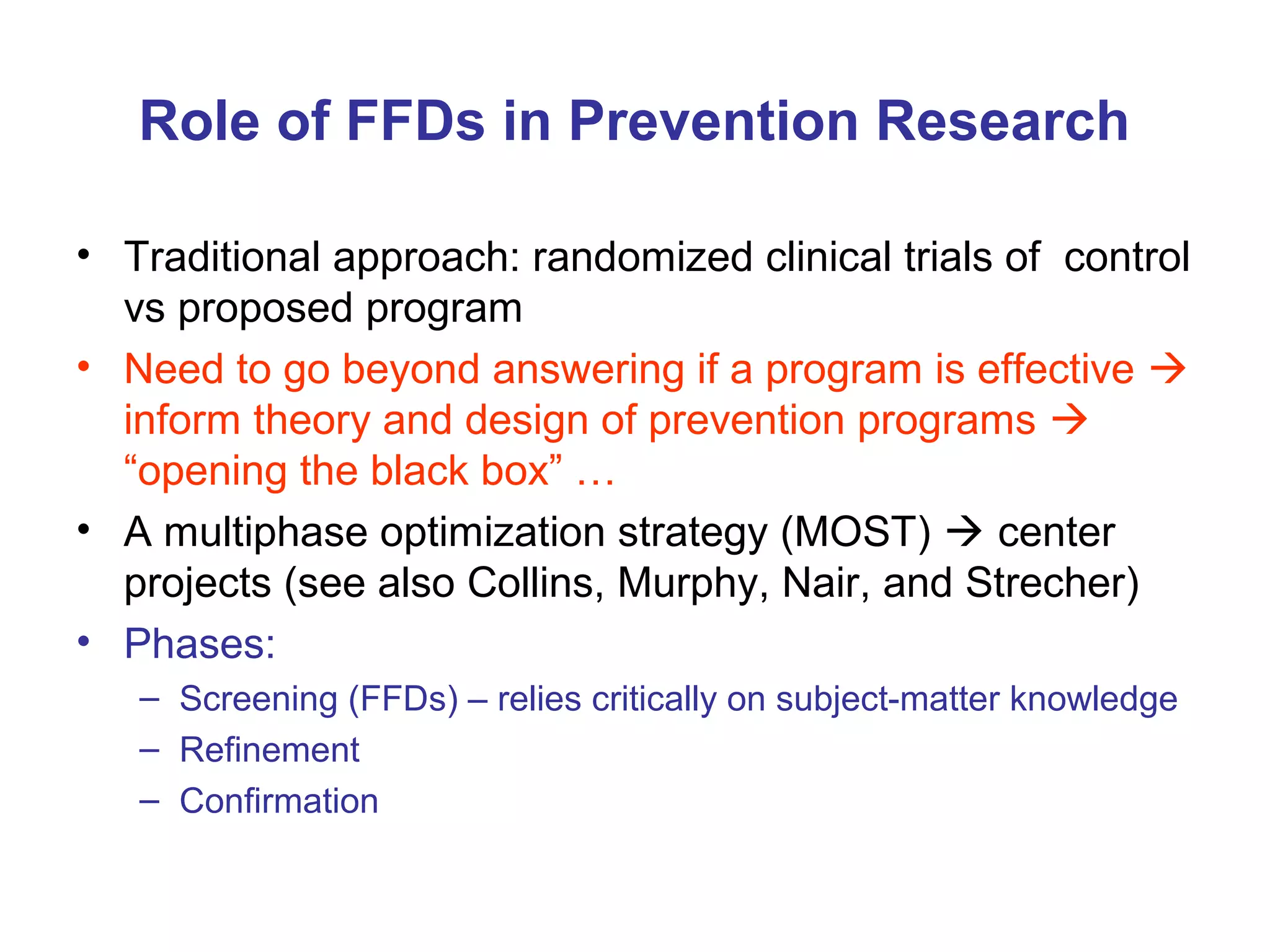

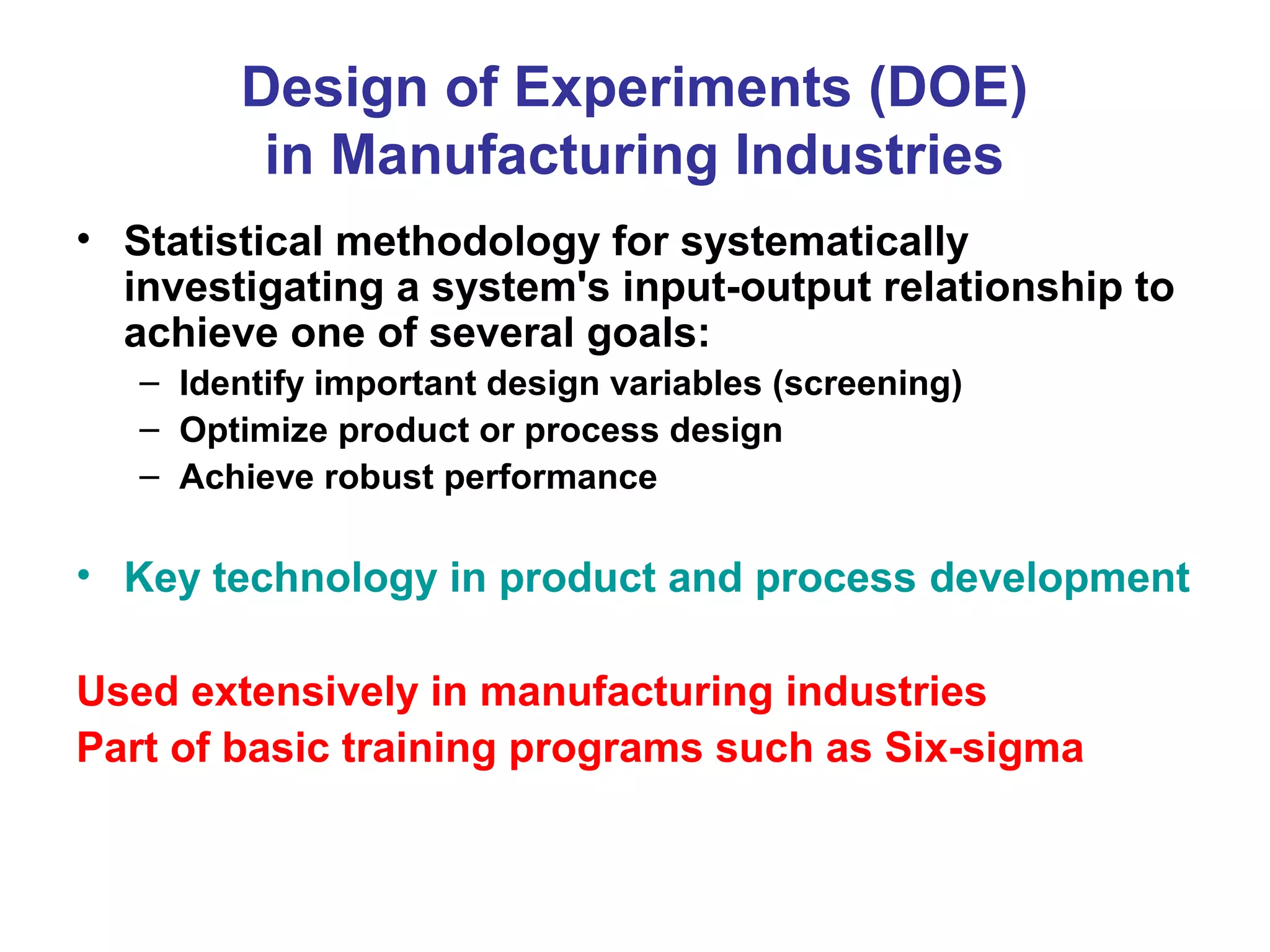

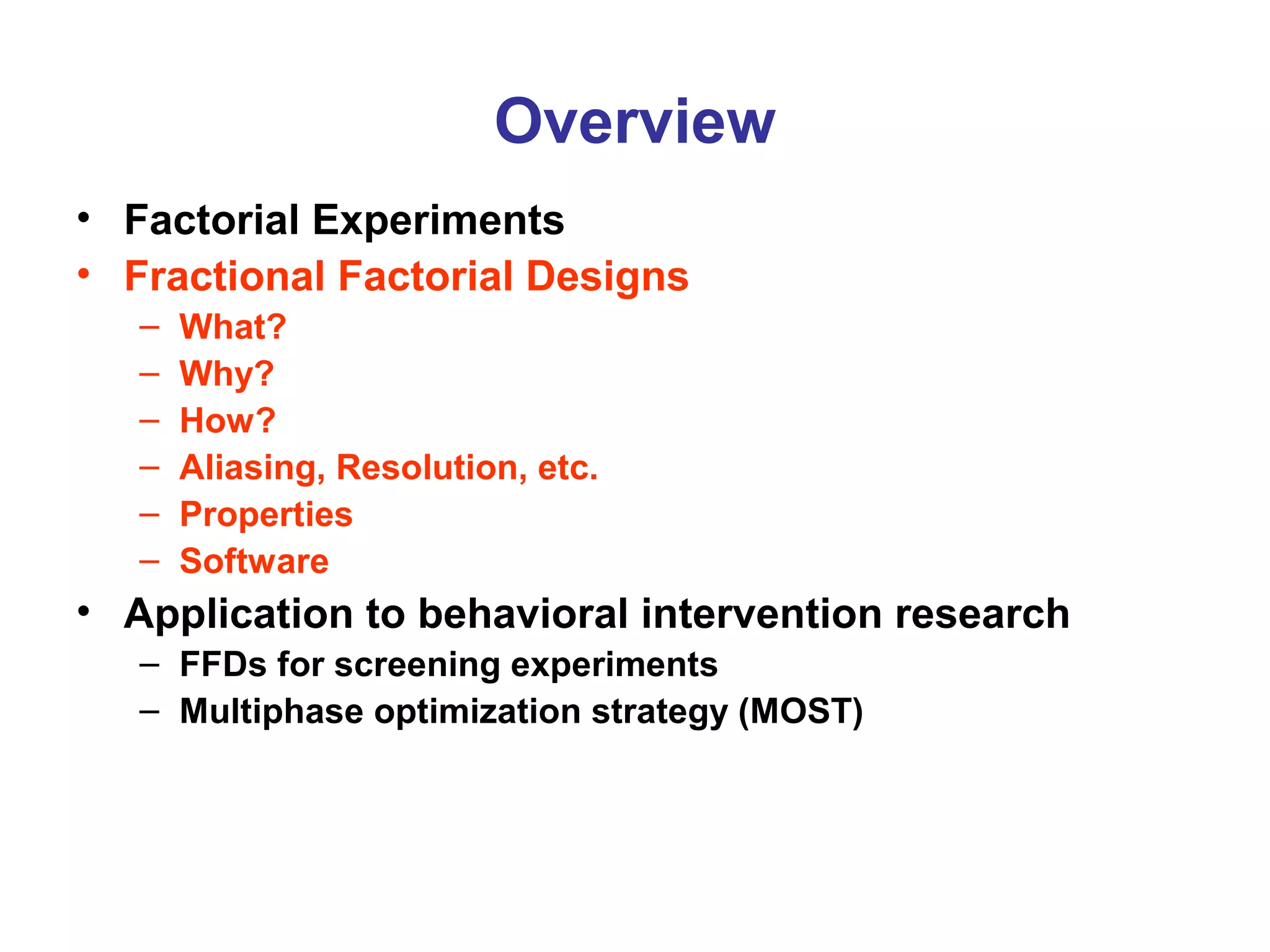

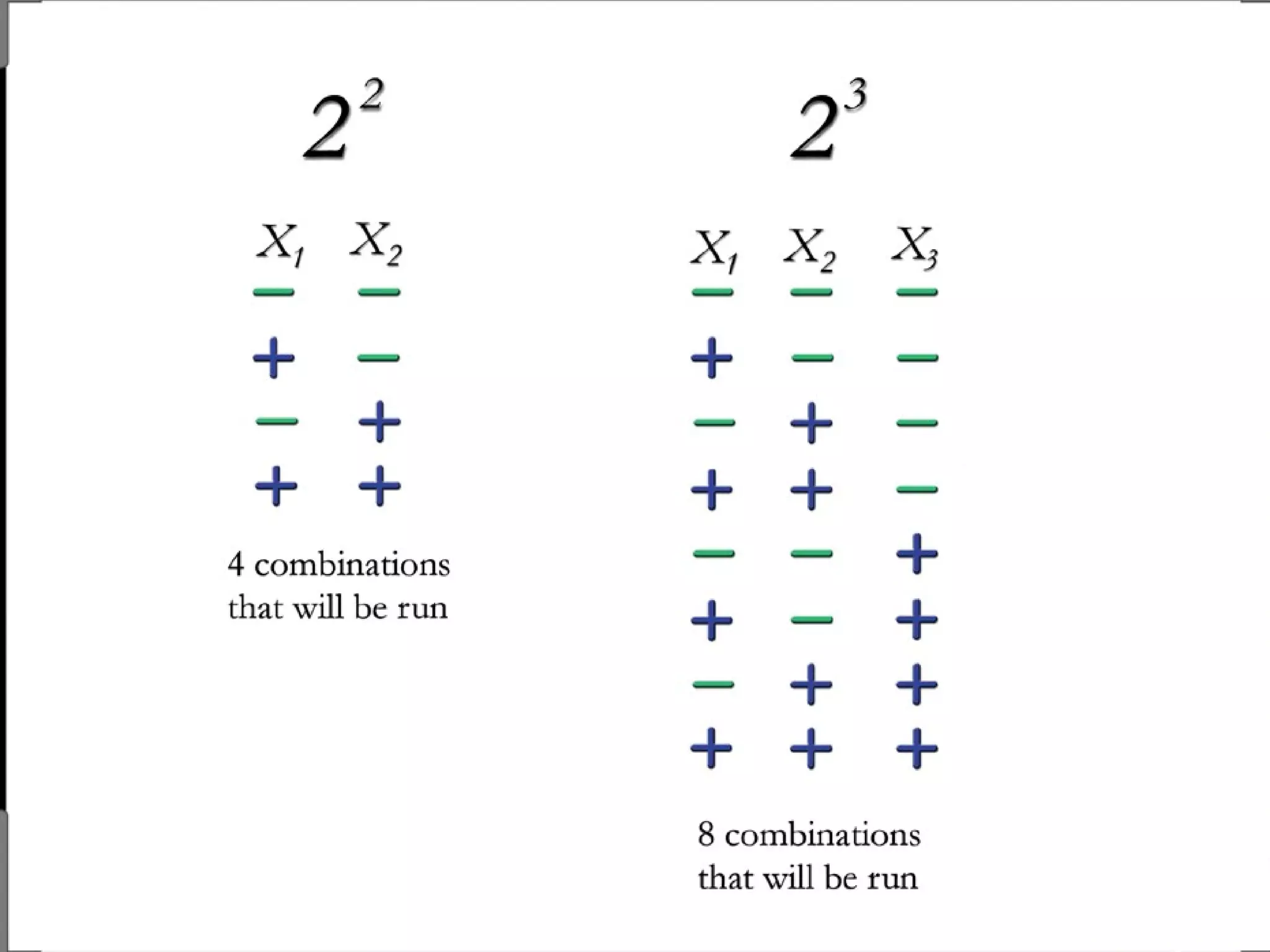

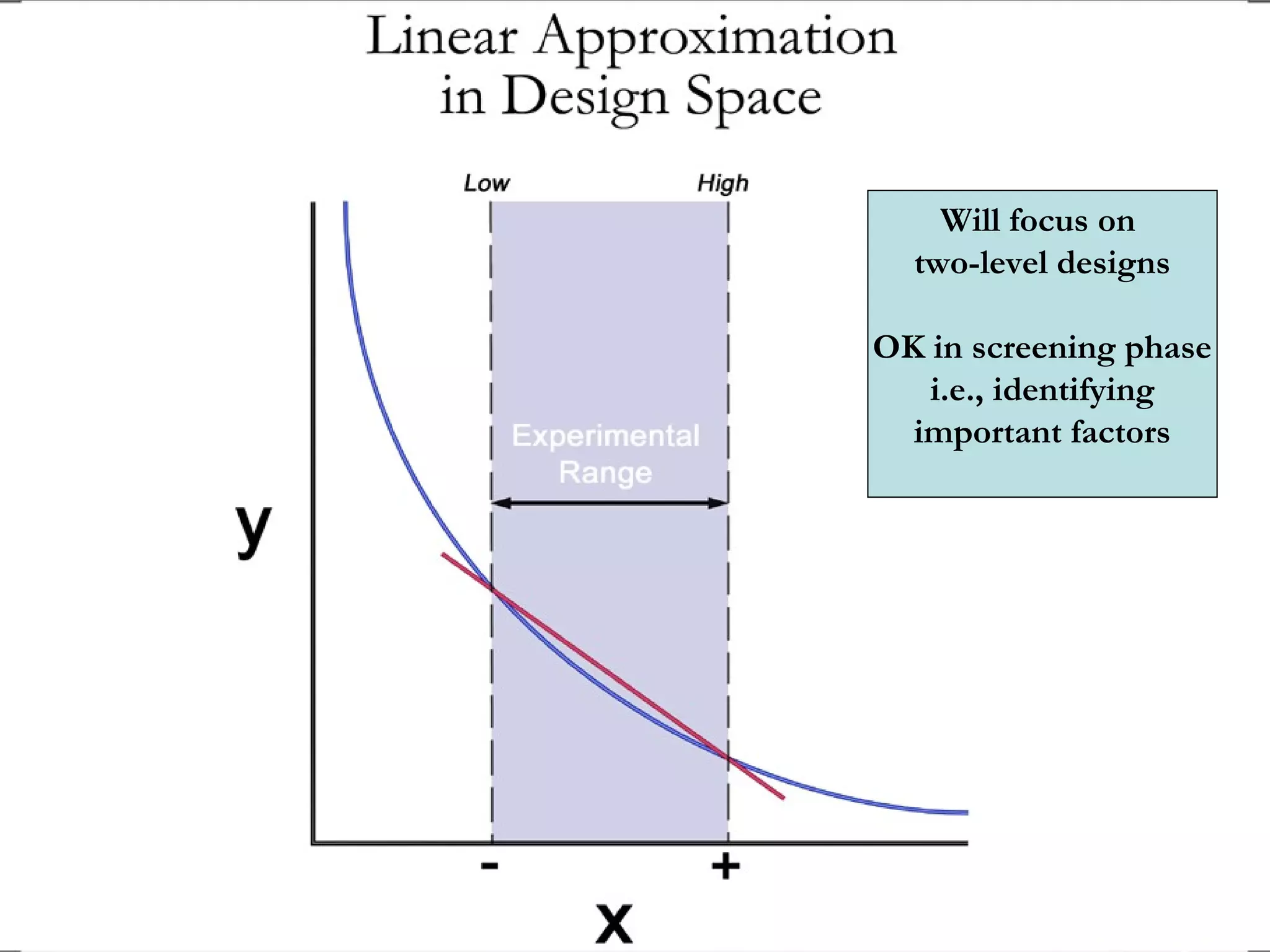

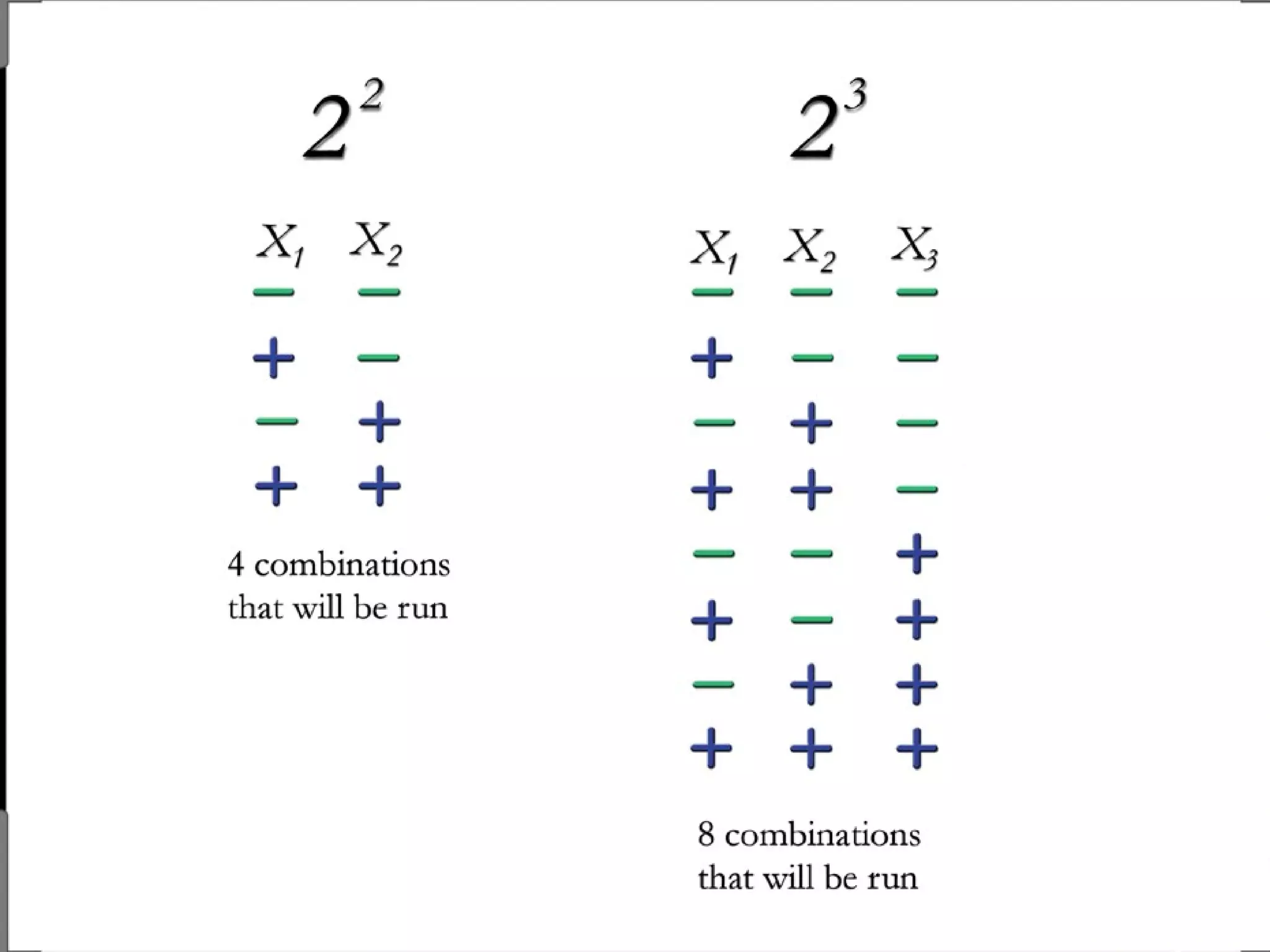

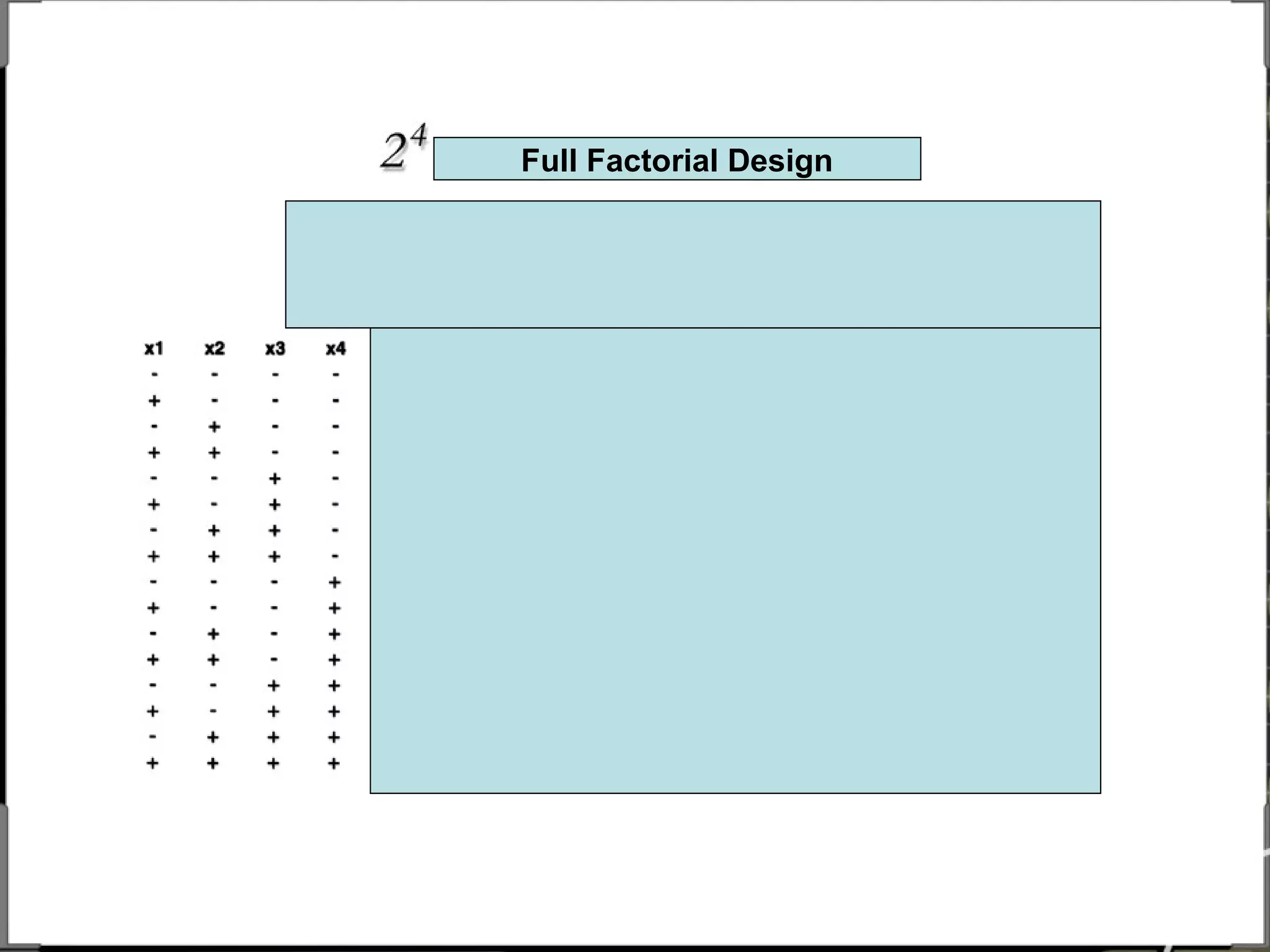

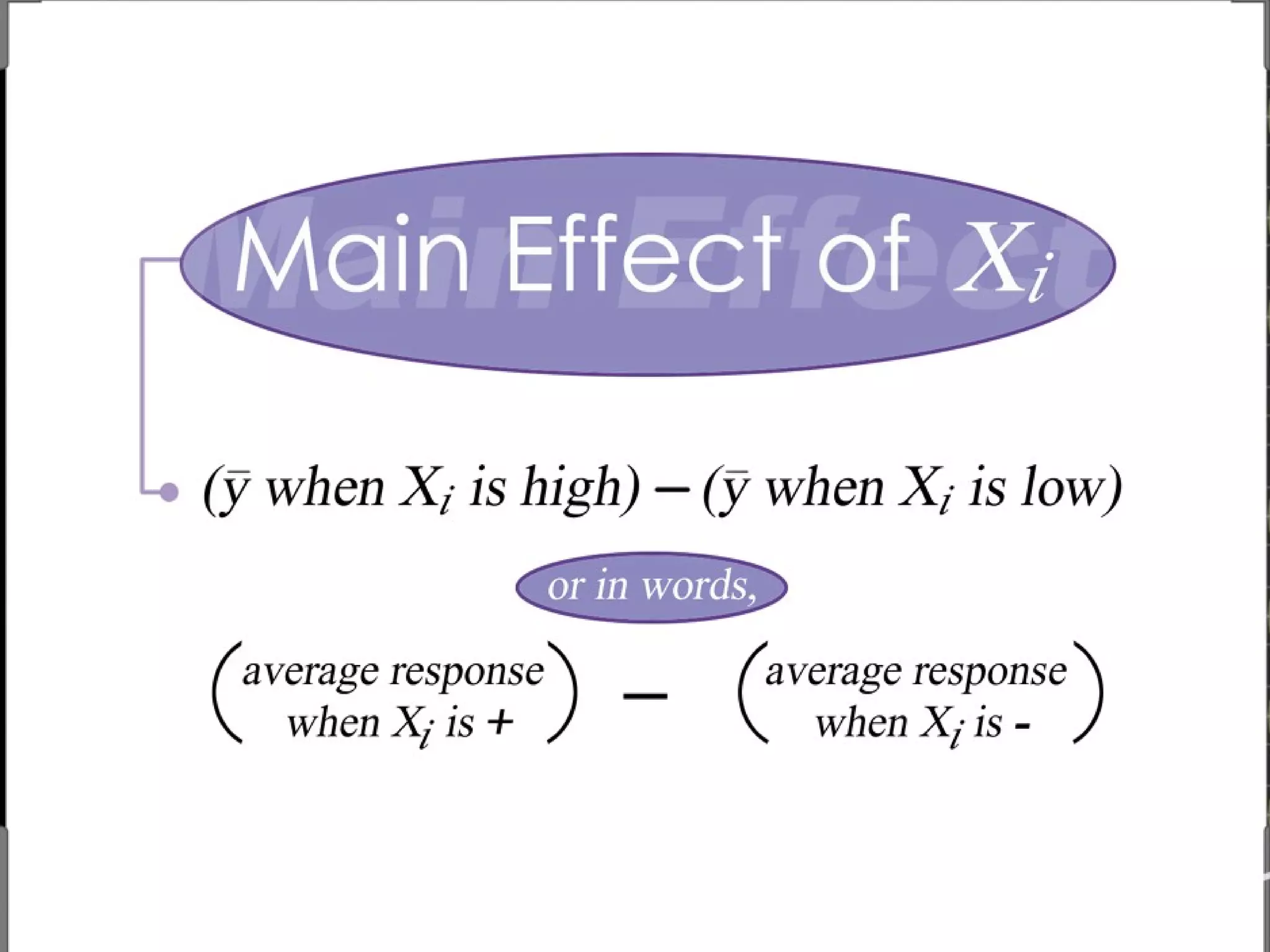

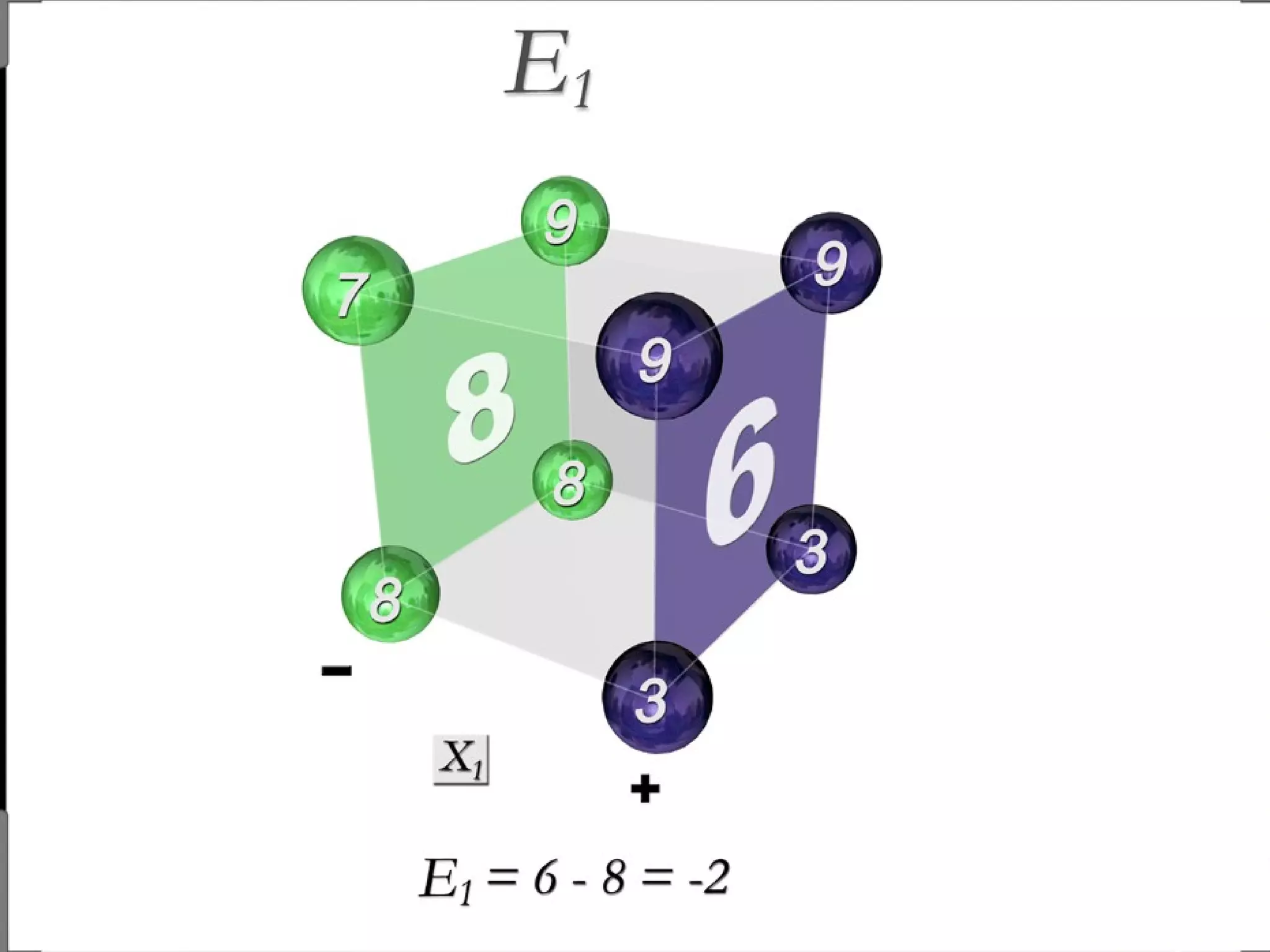

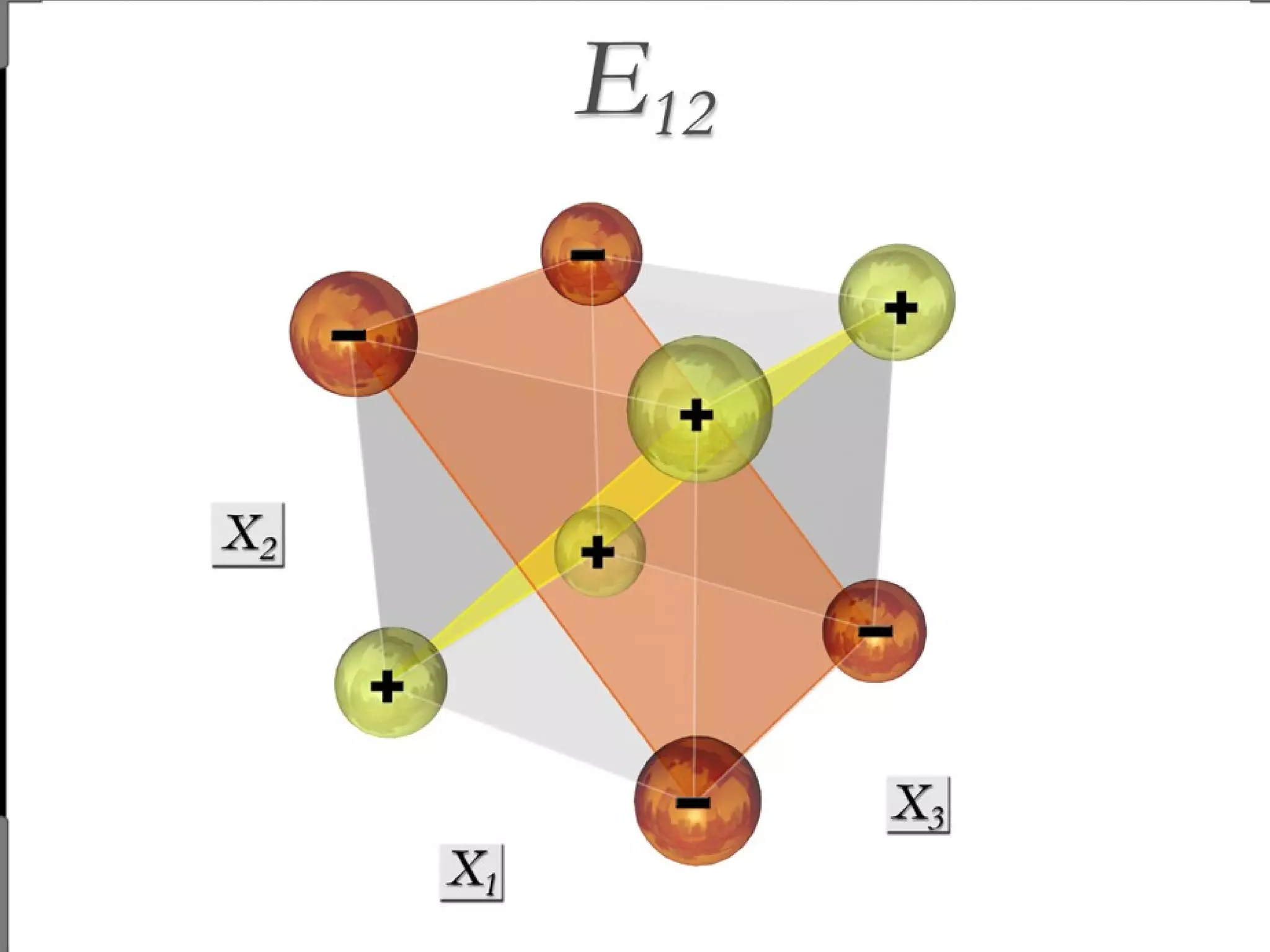

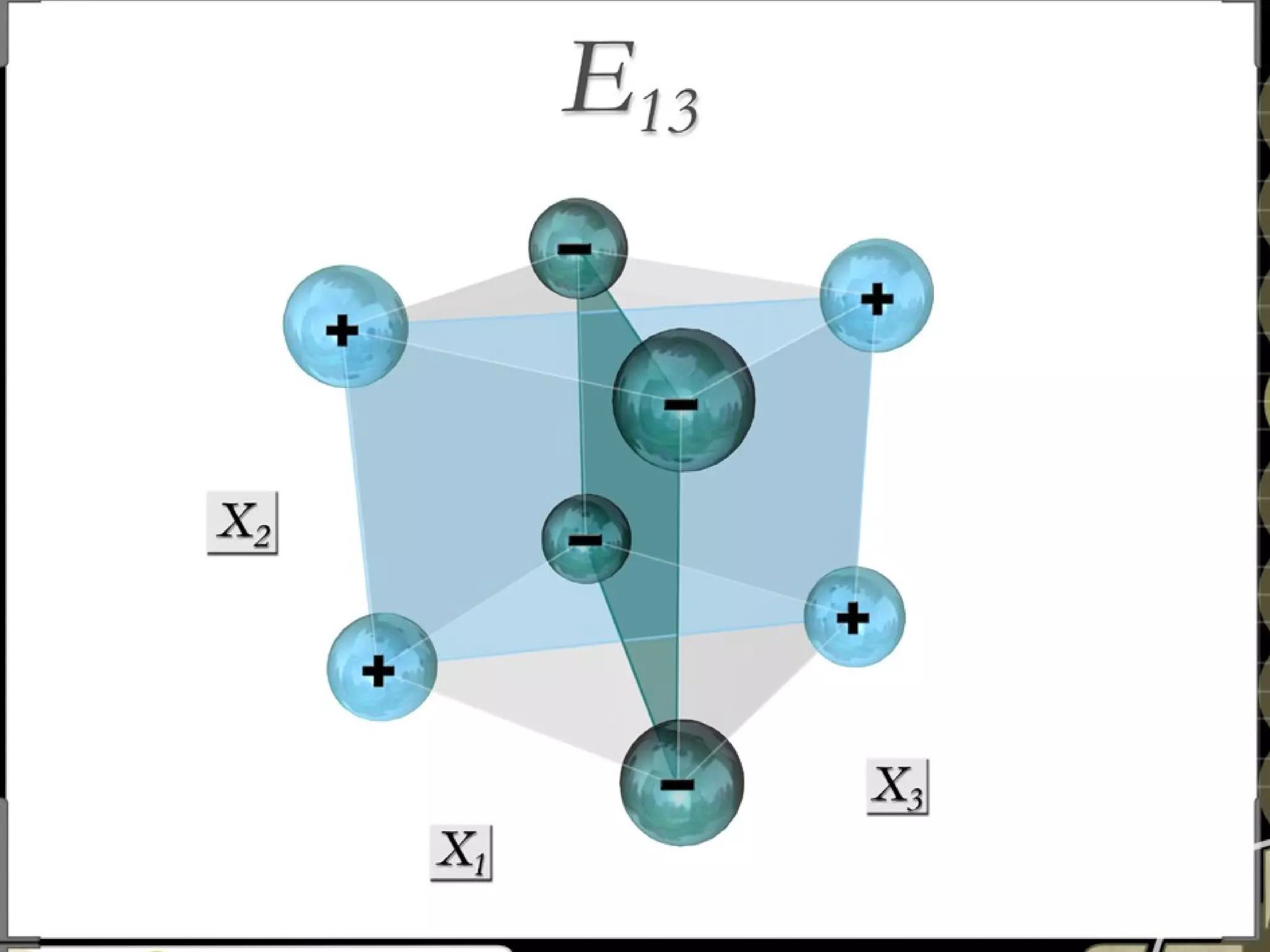

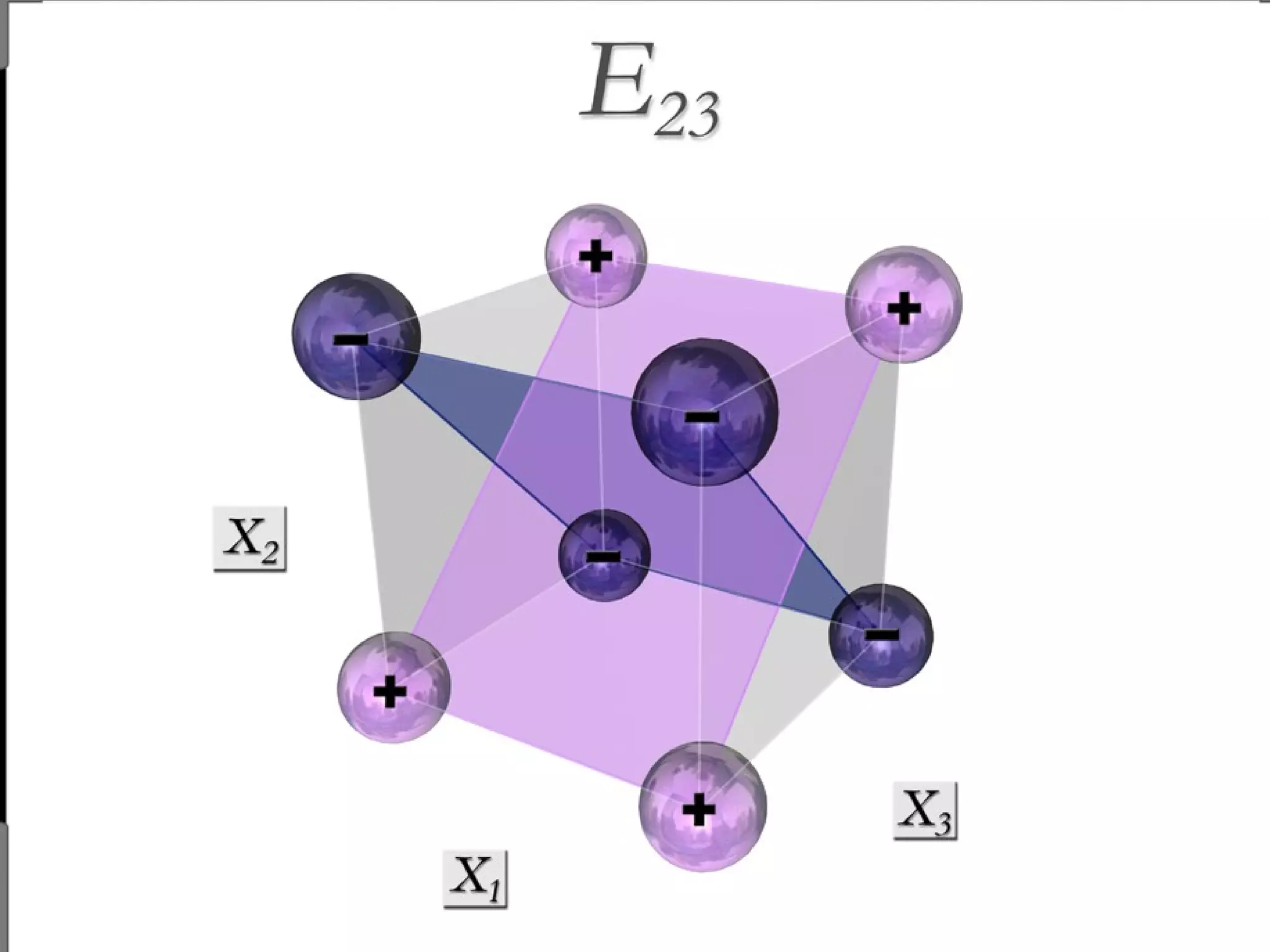

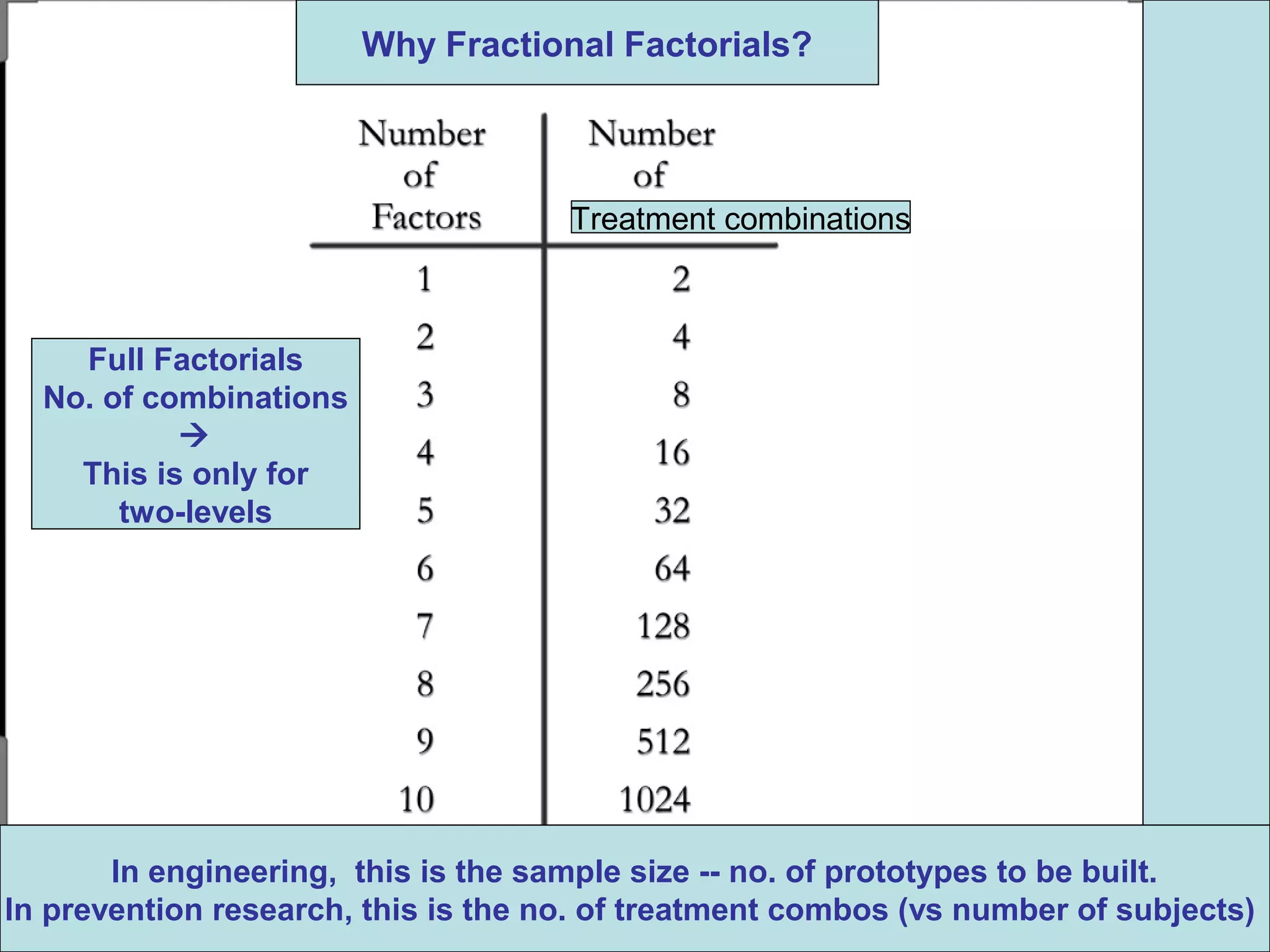

Fractional factorial designs (FFDs) are used to efficiently study many factors using fewer experimental runs than a full factorial design. FFDs exploit redundancy in estimating interactions to select a subset of runs. Regular FFDs have desirable properties like balance and orthogonality. Resolution indicates how interactions are aliased, with higher resolutions preferred. FFDs are useful in screening experiments to identify important factors efficiently before further optimization. Software helps select appropriate FFDs based on desired resolution and aliasing.

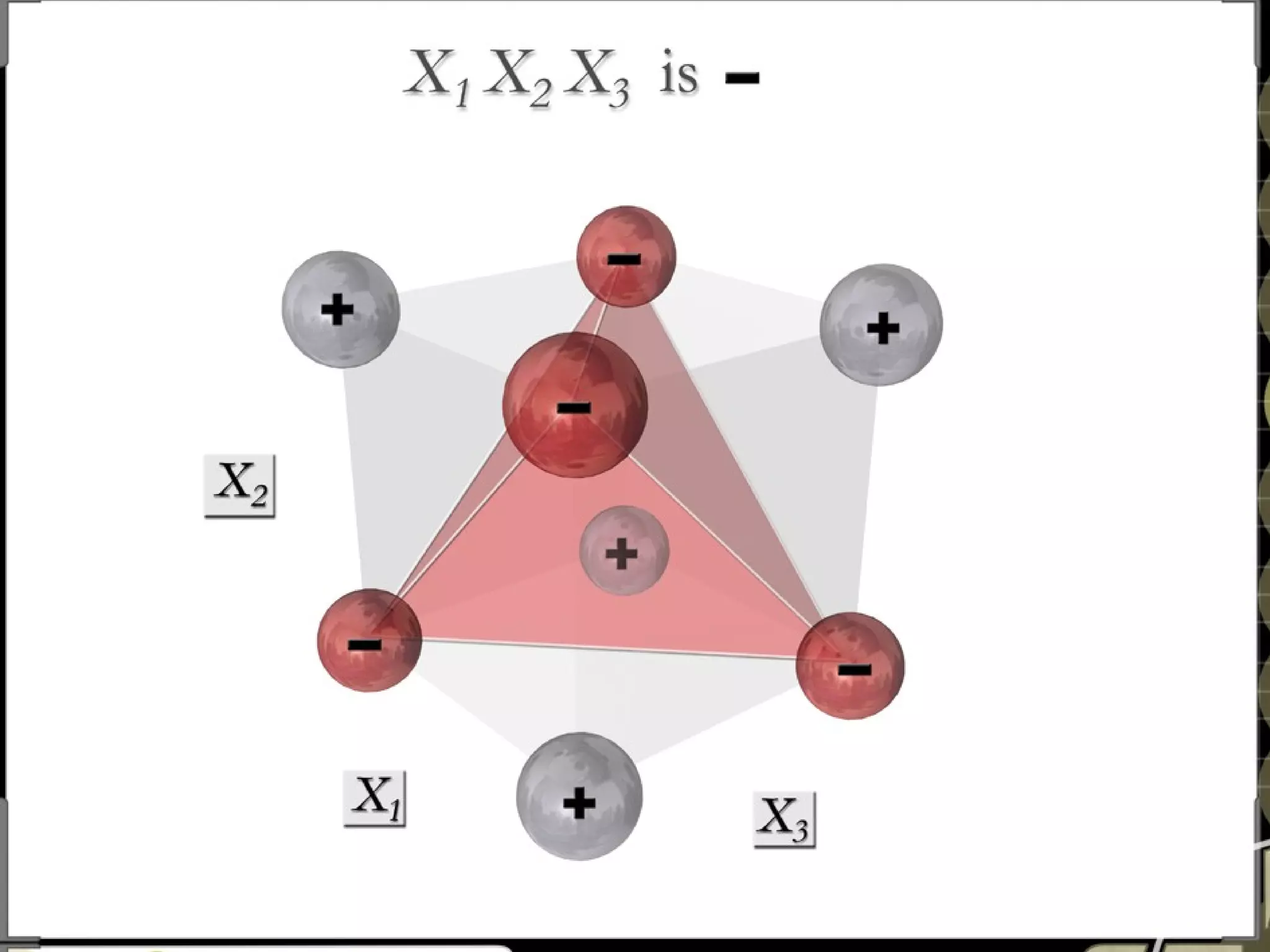

![How?

Box et al. (1978) “There tends to be a redundancy in [full factorial designs]

– redundancy in terms of an excess number of

interactions that can be estimated …

Fractional factorial designs exploit this redundancy …” philosophy](https://image.slidesharecdn.com/ffd-tutorial-121223001122-phpapp01/75/Fractional-factorial-design-tutorial-26-2048.jpg)