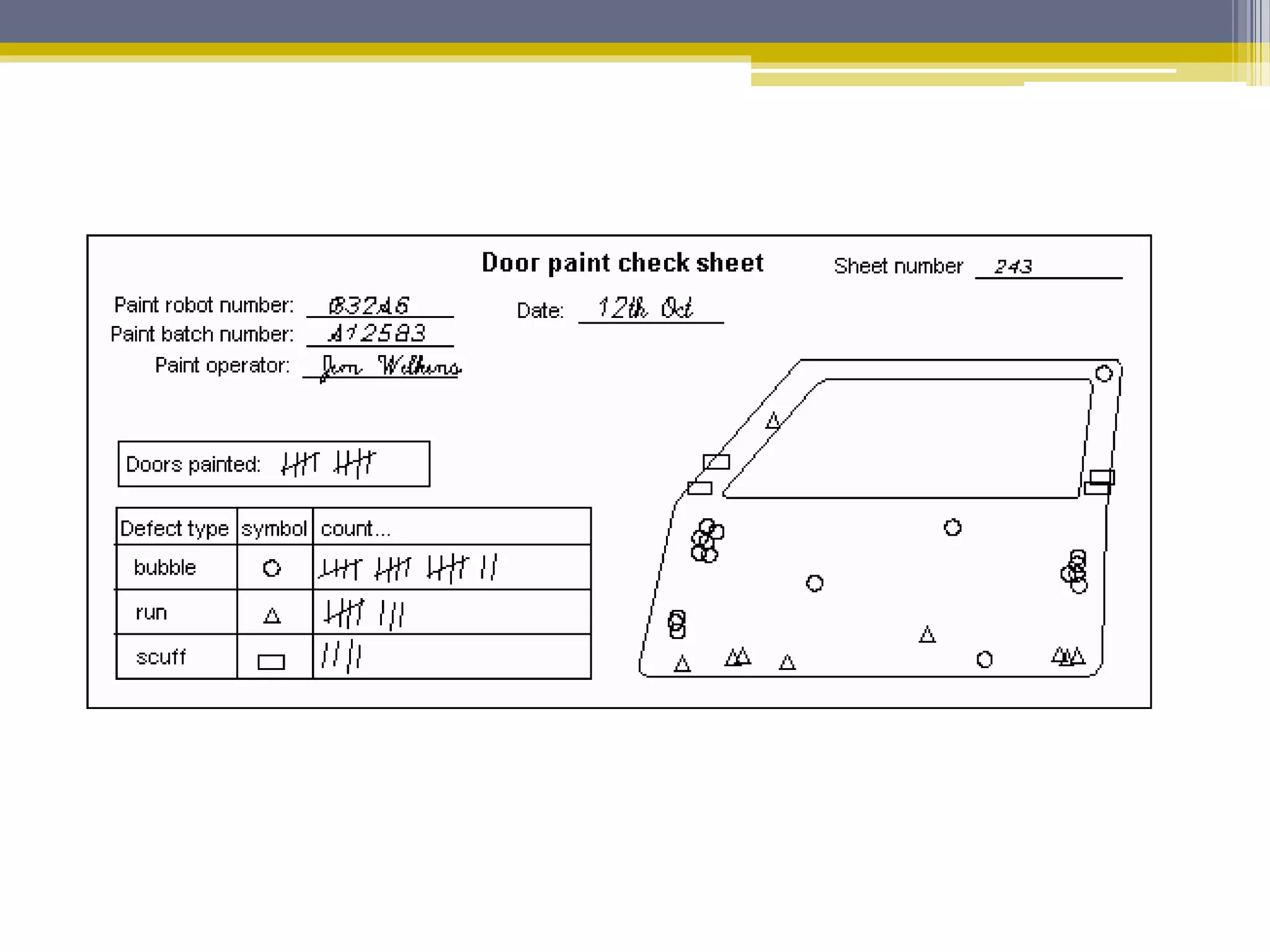

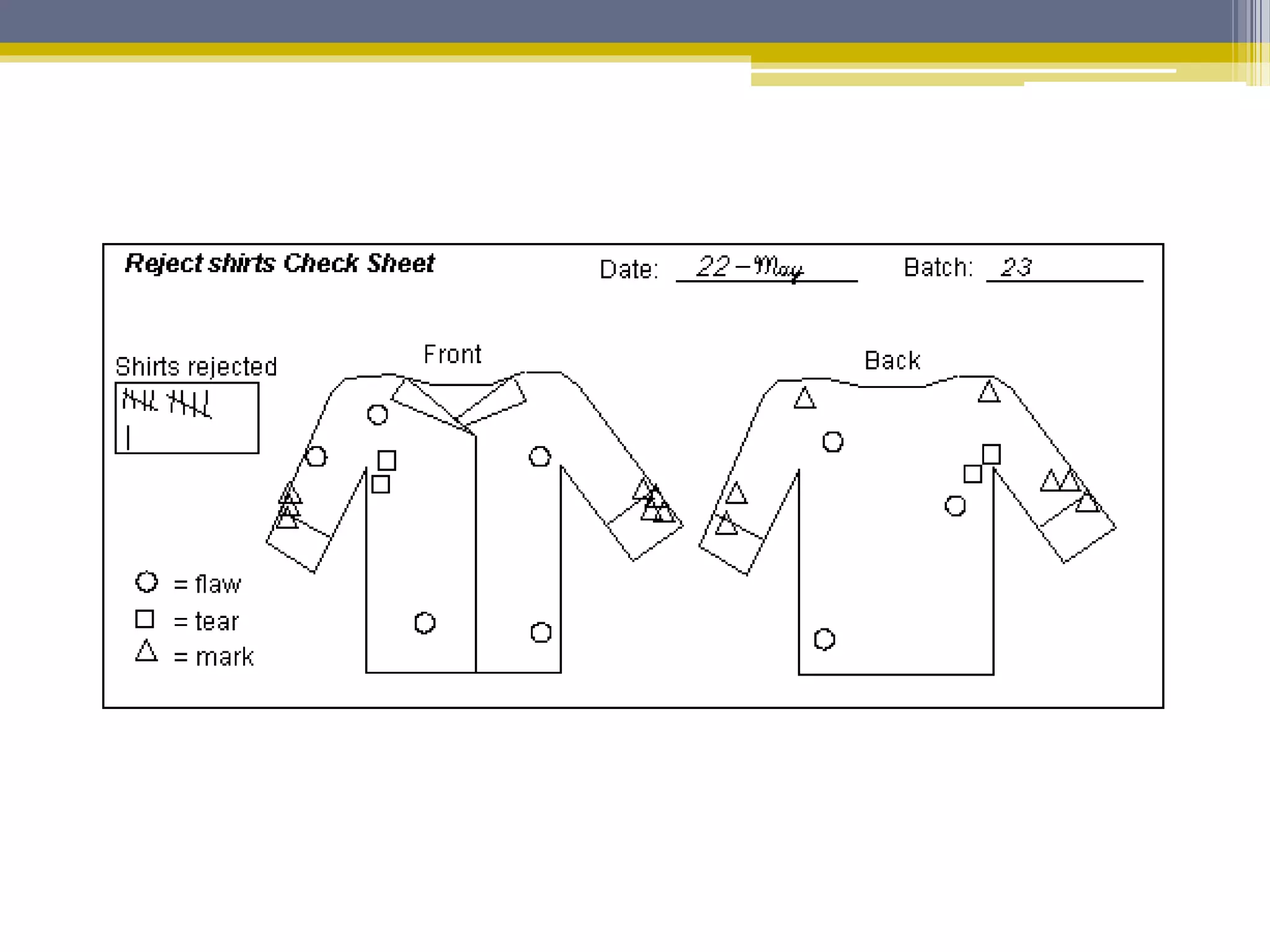

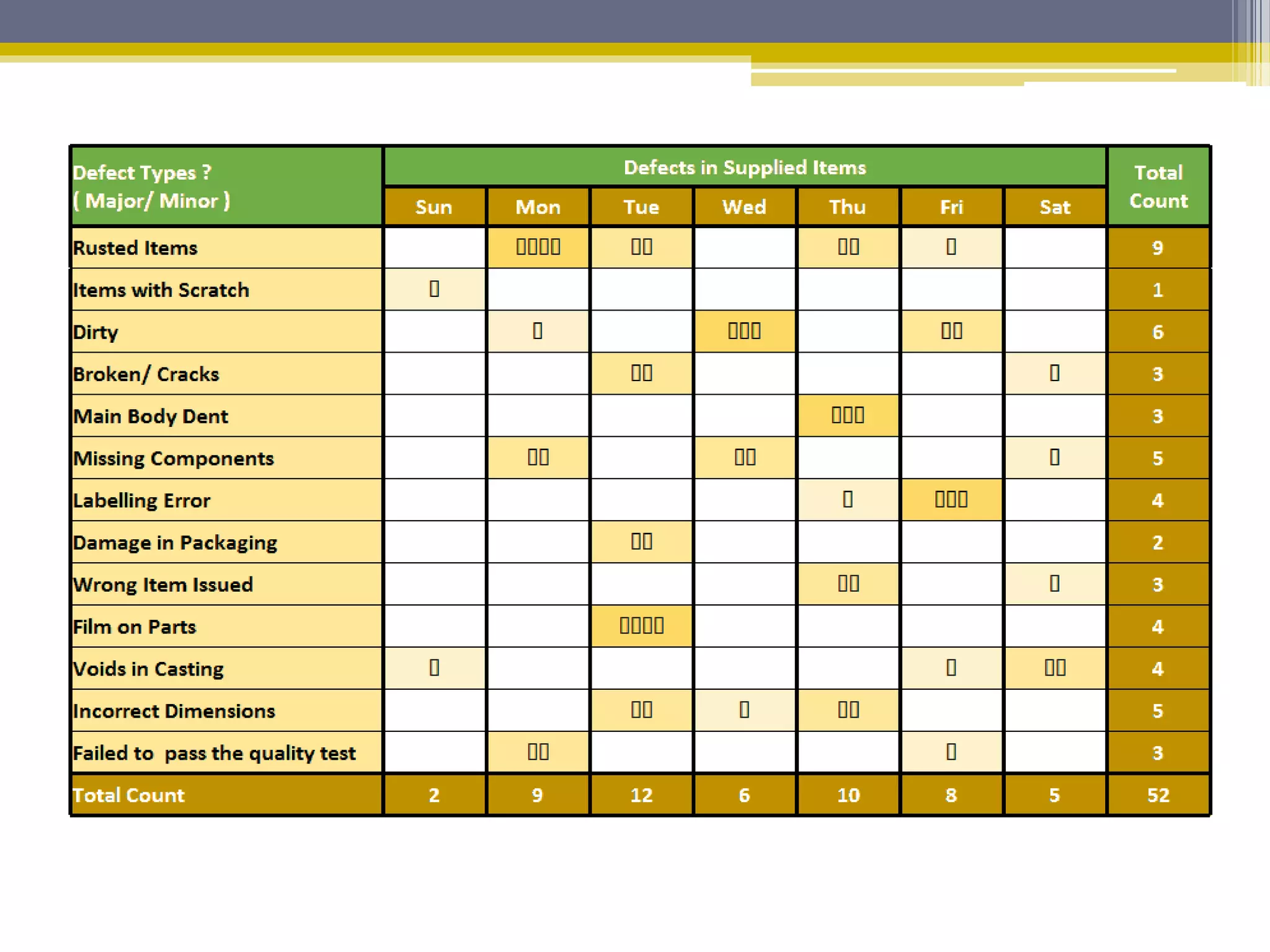

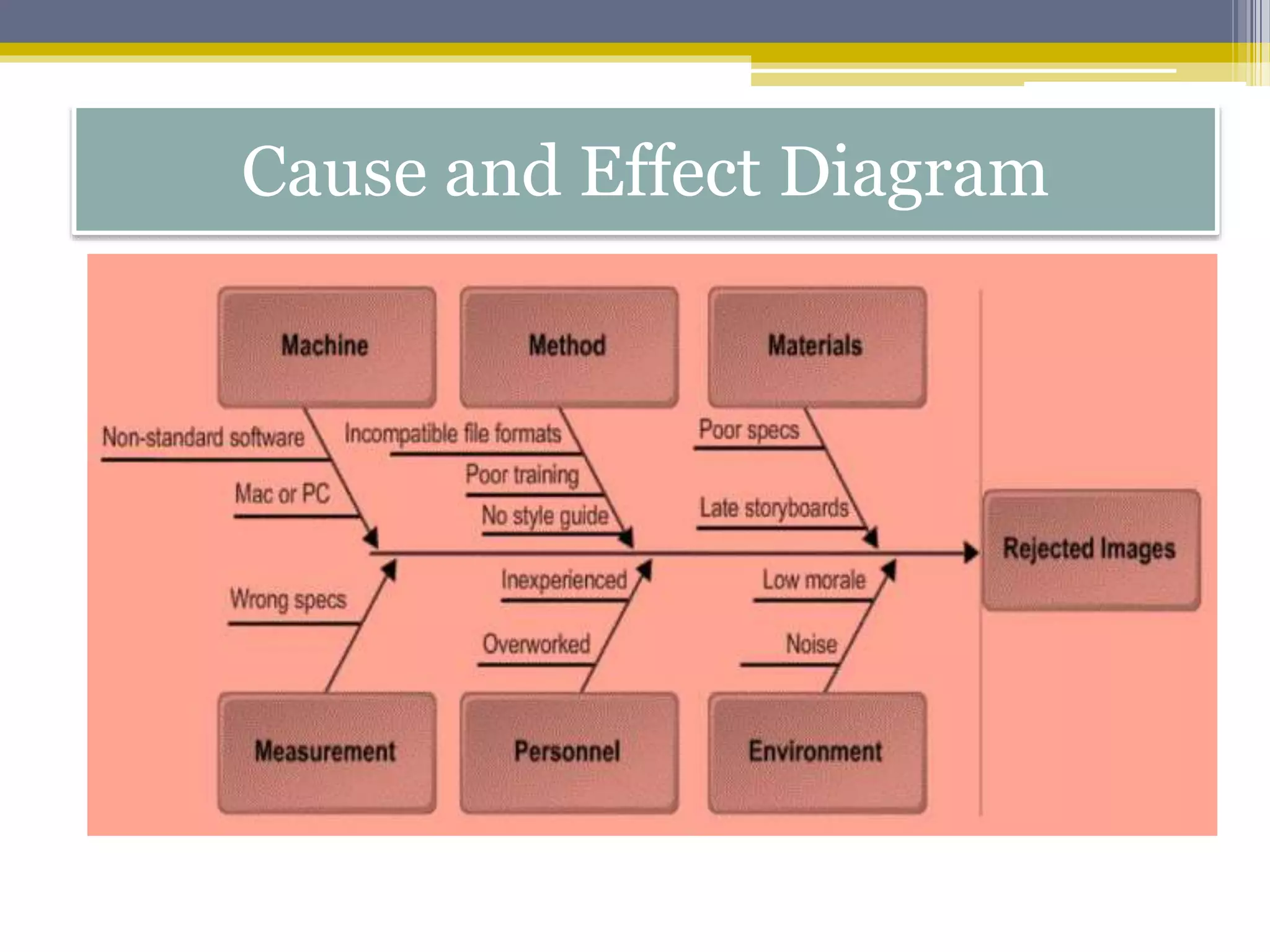

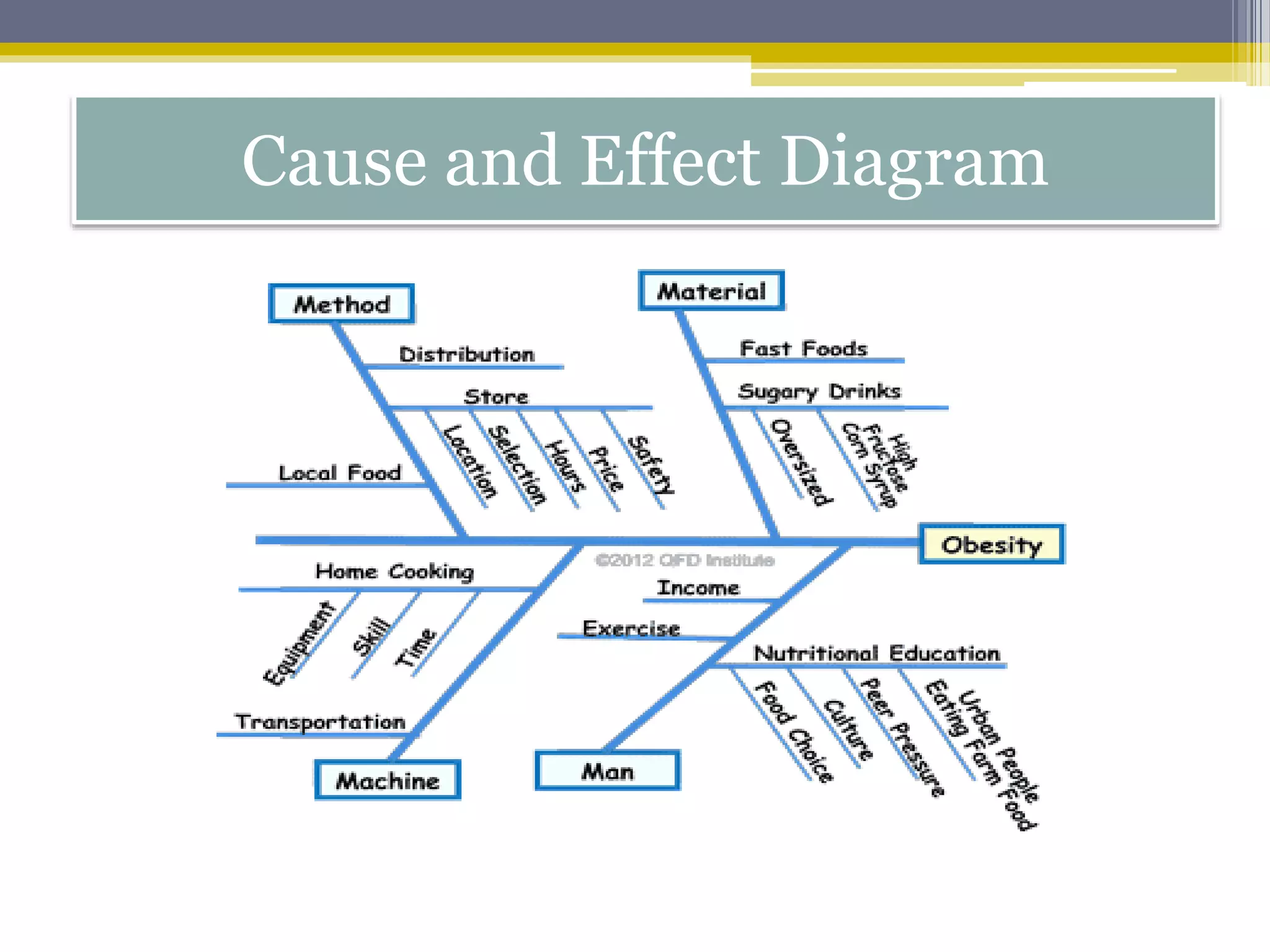

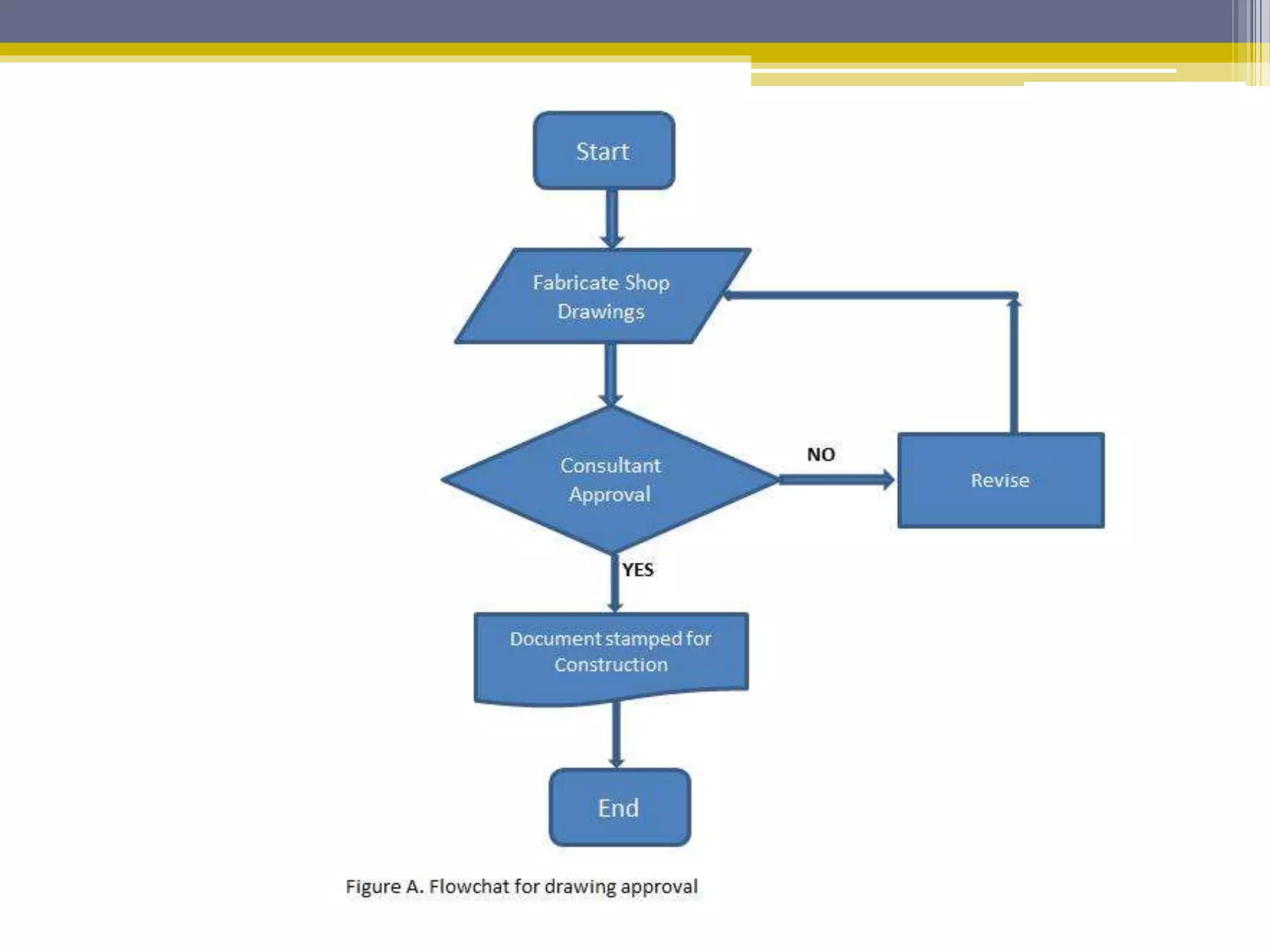

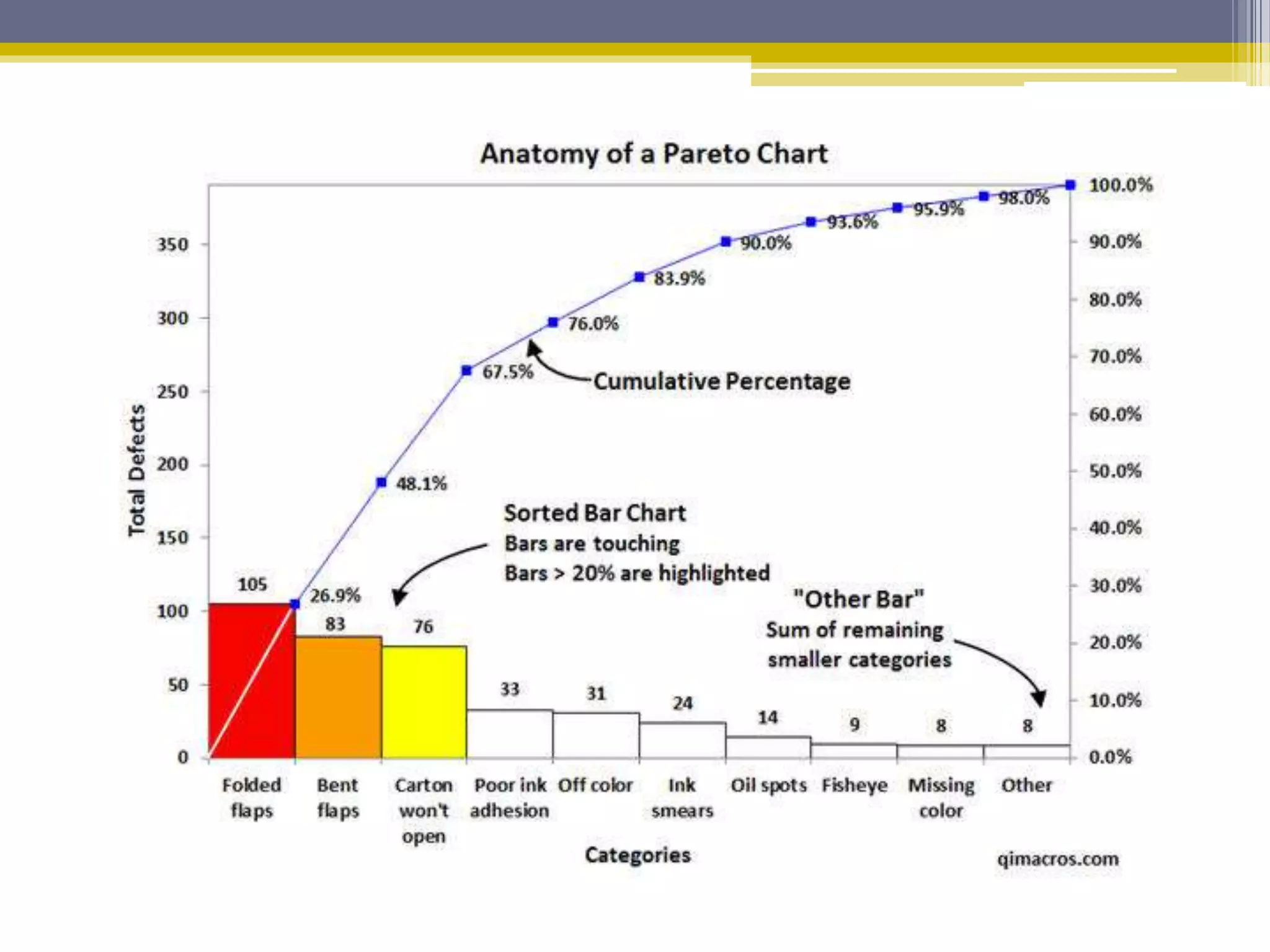

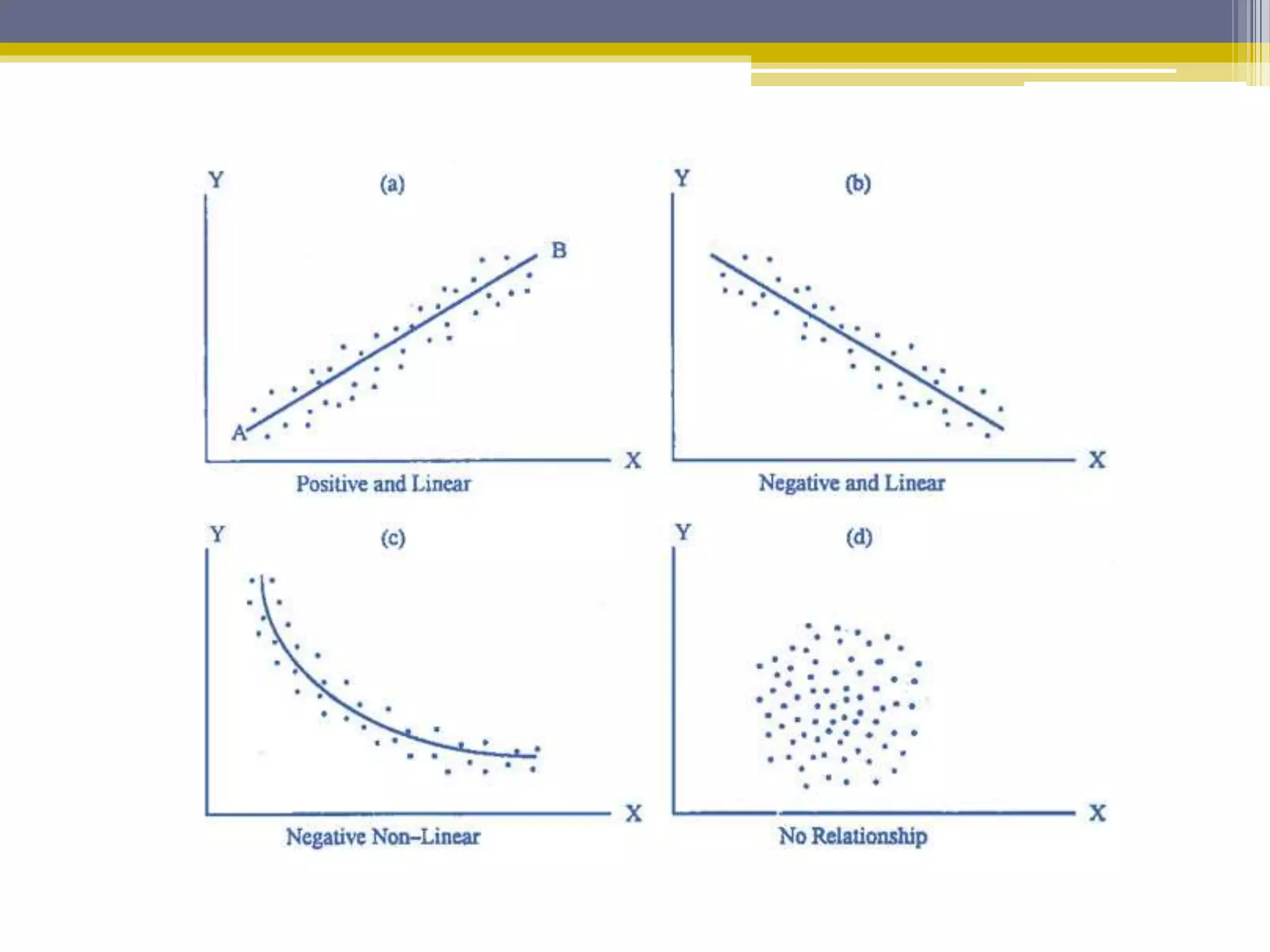

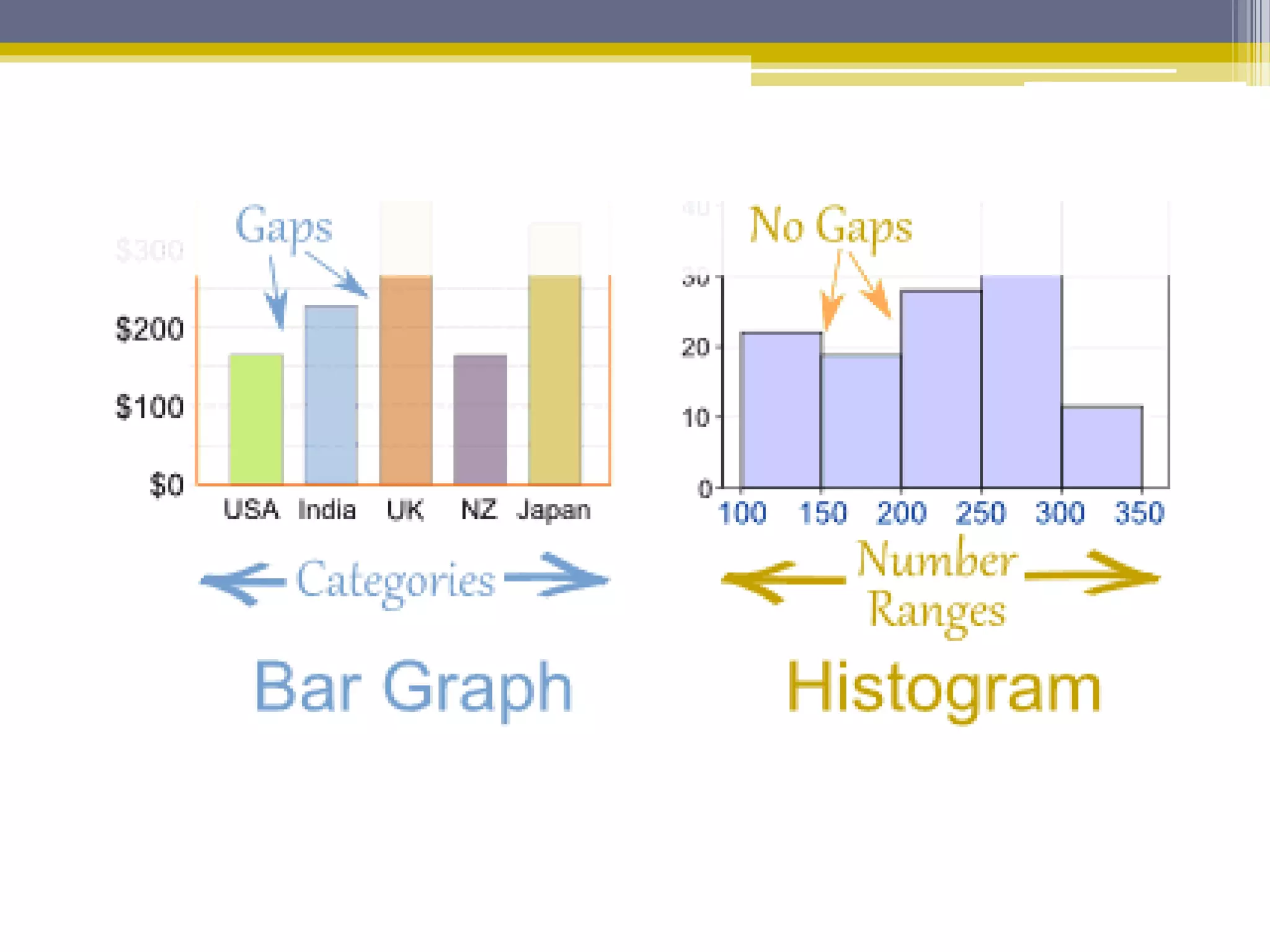

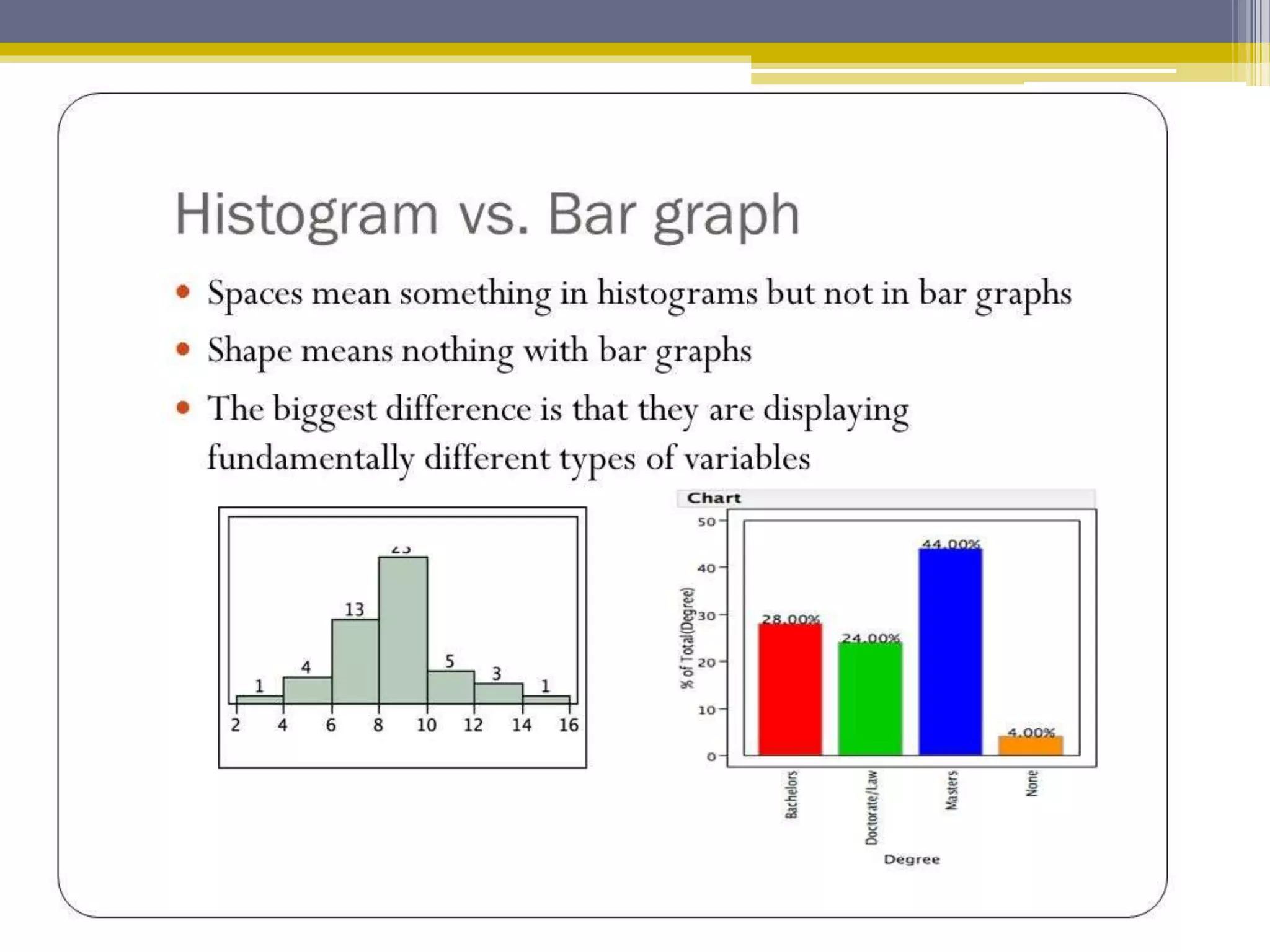

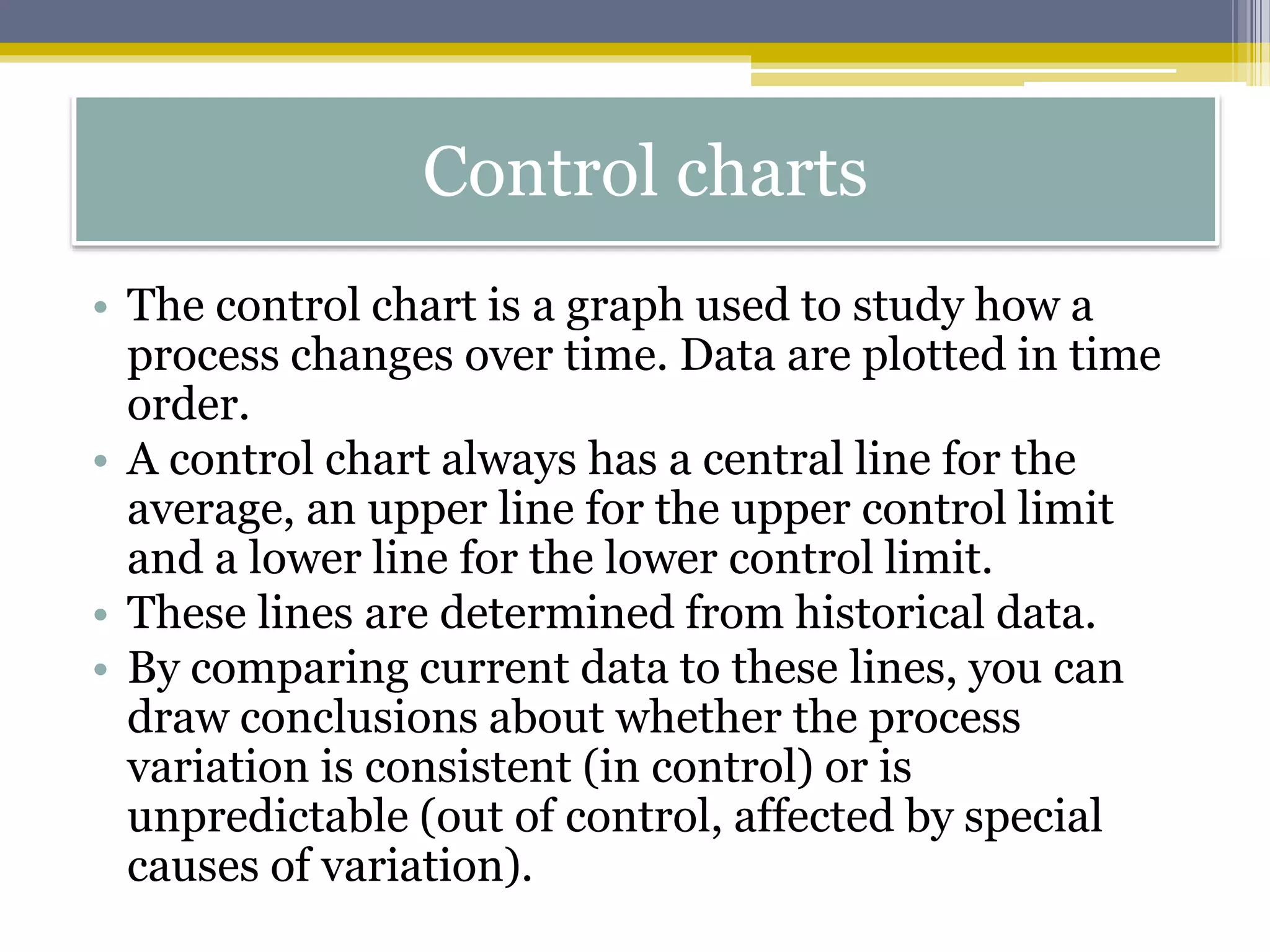

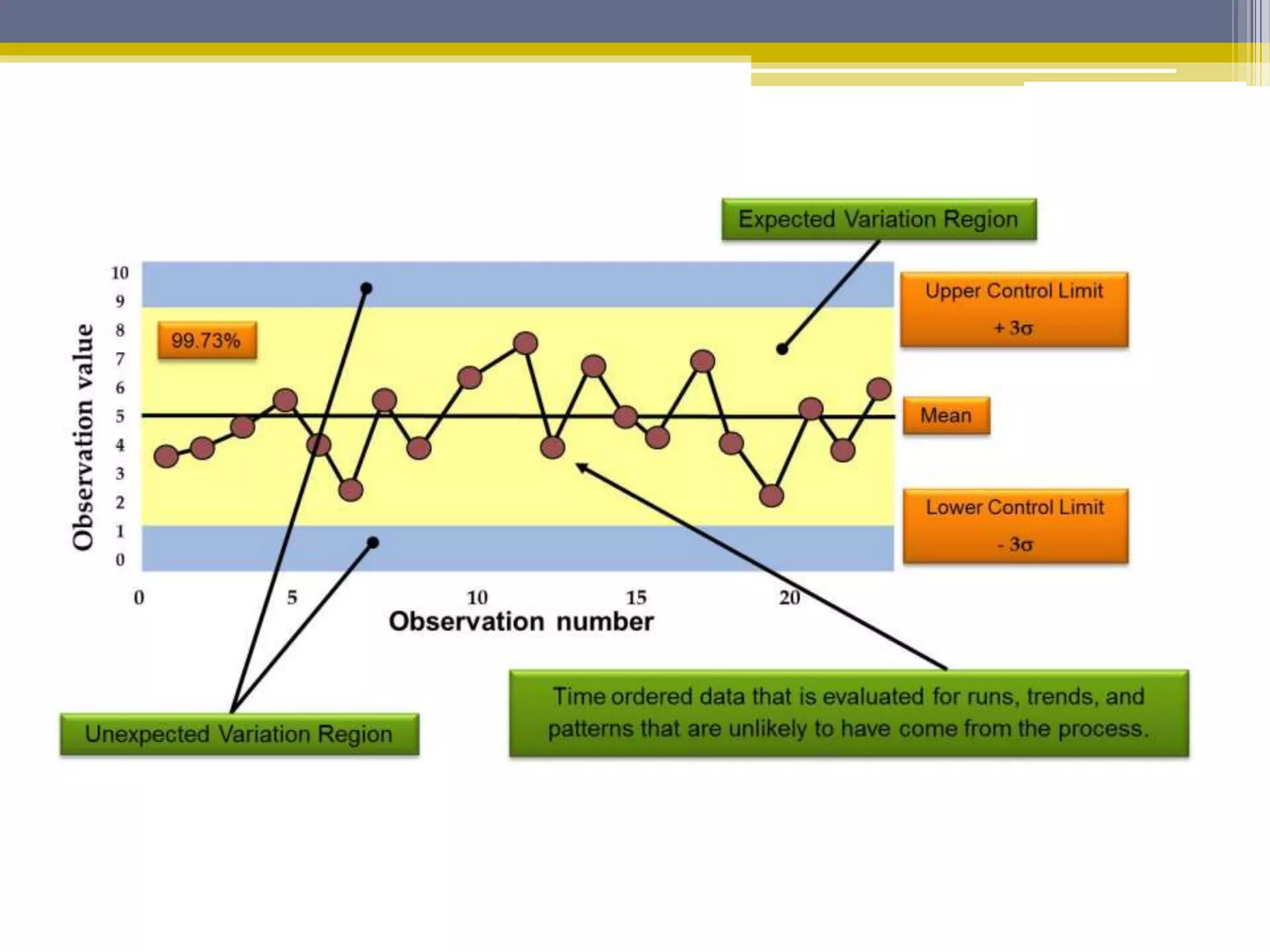

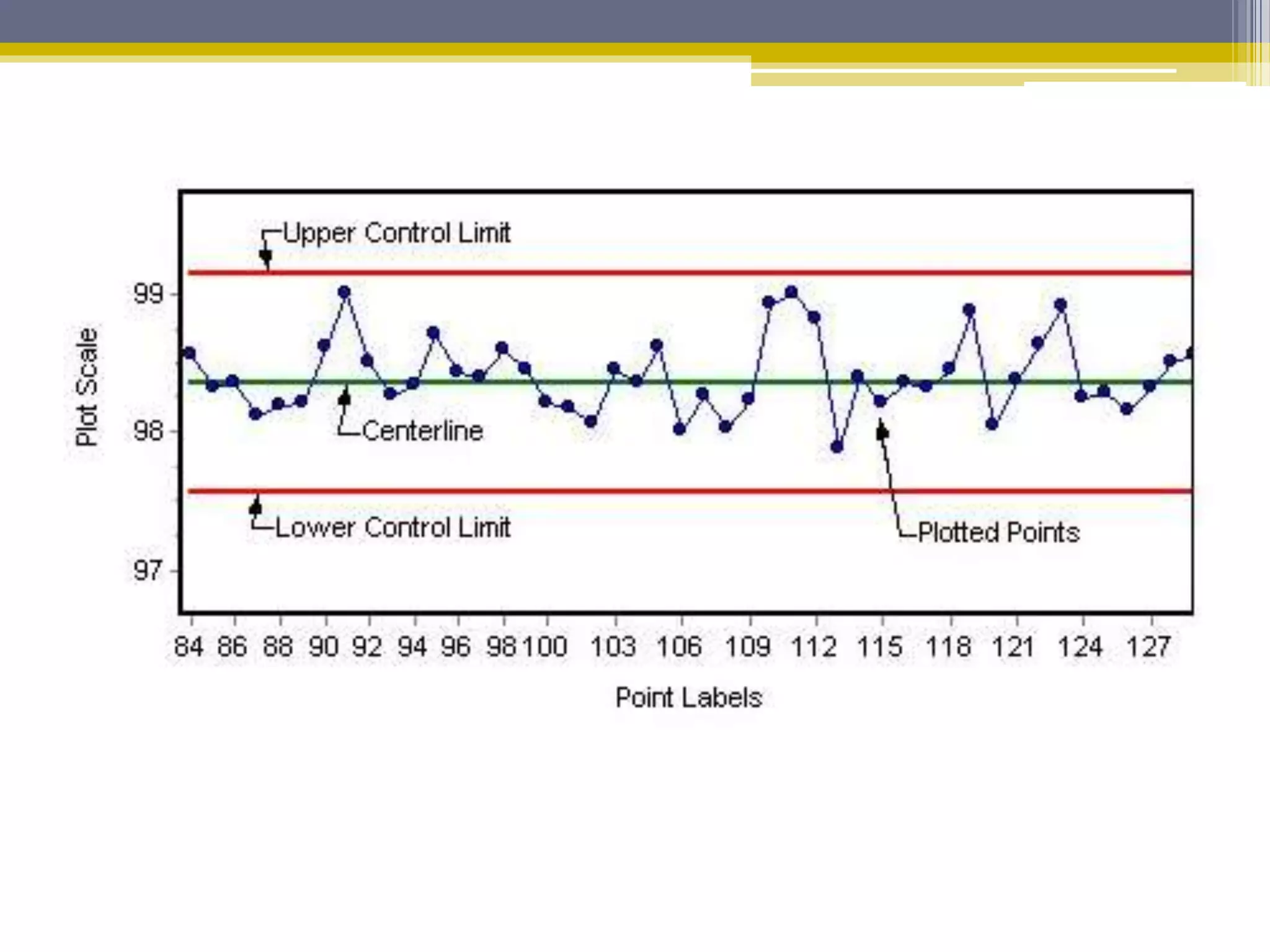

The document discusses various quality improvement tools and techniques. It describes Six Sigma, which aims to minimize process variability through statistical methods. Total Quality Management uses cross-functional teams to solve issues using statistical tools. Additional techniques covered include ISO 9000 quality standards, Quality Control Circles for analyzing work-related problems, and Kaizen for continuous incremental improvement. Quality tools like check sheets, cause-and-effect diagrams, flow charts, Pareto charts, scatter plots, histograms, control charts and brainstorming help organizations understand and improve their processes.