100% found this document useful (3 votes)

451 views16 pagesCondition Monitoring - End To End Process

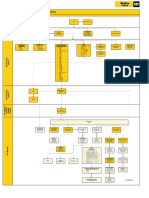

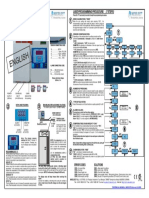

The document outlines steps for condition monitoring and exception analysis to identify equipment issues. It involves analyzing inspection data, wear rates, loads, maintenance history, and electronic data to detect anomalies. If issues are found, repair options are analyzed and presented to the customer.

Uploaded by

enjoythedocsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (3 votes)

451 views16 pagesCondition Monitoring - End To End Process

The document outlines steps for condition monitoring and exception analysis to identify equipment issues. It involves analyzing inspection data, wear rates, loads, maintenance history, and electronic data to detect anomalies. If issues are found, repair options are analyzed and presented to the customer.

Uploaded by

enjoythedocsCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

/ 16