ﺣﺴﺎﺑﺎت ﺣﻤﺎﻣﺎت اﻟﺴﺒﺎﺣﺔ واﻟﻨﻮاﻓﻴﺮ واﻟﺸﻼﻻت

ﻧﻘﻮم اوﻻ ﺑﺎﺳﺘﺨﺮاج اﻟﻤﻌﻠﻮﻣﺎت اﻟﺘﻰ ﺳﻮف ﻧﺴﺘﺨﺪﻣﻬﺎ ﻓﻰ اﻟﺤﺴﺎﺑﺎت ﻣﻦ اﻟﻤﺨﻄﻄﺎت اﻟﻤﻌﻤﺎرﻳﺔ وهﻰ: -1

-1اﻟﺤﺠﻢ Volume

-2اﻟﻤﺤﻴﻂ Perimeter

-3ﻃﺒﻴﻌﺔ اﻻﺳﺘﺨﺪام .Water body loading category

ﻧﻘﻮم ﺑﺤﺴﺎب ) (Turn over timeوﻳﻤﻜﻦ اﻻﺳﺘﻌﺎﻧﺔ ﺑﺎﻟﺠﺪول -2

¾ Code_of_Practice_Aquatic_Facilities , march 2006 p25‐table 4

واﻟﺘﻰ ﻳﻤﻜﻦ ﻣﻦ ﺧﻼل اﻟﺠﺪول اﺳﺘﺨﺮاج اﻟﻘﻴﻤﺔ ﺑﺎﻟﺴﺎﻋﺔ ﻋﻦ ﻃﺮﻳﻖ ﻃﺒﻴﻌﺔ اﻻﺳﺘﺨﺪام وﻳﻌﻄﻰ اﻟﺠﺪول اﻣﺜﻠﺔ ﺗﻮﺿﺢ ﺗﻄﺒﻴﻘﺎت ﻣﻨﺎﺳﺒﺔ ﺣﺴﺐ ﻃﺒﻴﻌﺔ اﻻﺳﺘﺨﺪام.

آﻤﺎ ﻳﻤﻜﻦ اﻳﻀًﺎ اﻻﺳﺘﻌﺎﻧﺔ ﺑﺎﻟﻤﻌﻠﻮﻣﺎت اﻟﻮاردة ﻓﻰ

¾ ASPE data Book , Volume 3,p110

¾ Swimming Pools 4ed ‐ Philip H Perkins, section 8.2.1,p165

¾ PRACTICAL PLUMBING DESIGN GUIDE P 4‐109,110

ﻧﻘﻮم ﺑﺤﺴﺎب ﻣﻌﺪل اﻟﺘﺪوﻳﺮ Total recirculation rateوذﻟﻚ ﺑﻘﺴﻤﺔ اﻟﺤﺠﻢ ﻋﻠﻰ . turn over time -3

ﻧﻘﻮم ﺑﺘﺤﺪﻳﺪ ﻋﺪد اﻟﻤﻀﺨﺎت ﻣﻊ ﻣﺮاﻋﺎة ان ﻳﻜﻮن هﻨﺎك ﻣﻀﺨﺎت ﺑﺪﻳﻠﺔ )( Standby pumpsﻻ ﻳﻘﻞ ﻋﺪدهﺎ ﻋﻦ %25ﻣﻦ ﻋﺪد اﻟﻤﻀﺨﺎت اﻟﻌﺎﻣﻠﺔ ).(Duty pumps -4

ﻣﻦ اﻟﻤﻌﻠﻮﻣﺎت اﻟﺴﺎﺑﻘﺔ ﻳﻤﻜﻦ ﺗﺤﺪﻳﺪ ﻣﻌﺪل اﻟﺘﺪﻓﻖ اﻟﺨﺎص ﺑﺎﻟﻄﻠﻤﺒﺔ اﻟﻮاﺣﺪة وذﻟﻚ ﺑﻘﺴﻤﺔ Total recirculation rateﻋﻠﻰ ﻋﺪد اﻟﻤﻀﺨﺎت اﻟﻌﺎﻣﻠﺔ ).(Duty pumps -5

ﻳﻤﻜﻦ ﺑﻌﺪ ذﻟﻚ ﺗﺤﺪﻳﺪ ﻗﻄﺮ اﻟﻔﻼﺗﺮ ﻣﻊ اﻟﻌﻠﻢ ﺑﺎن ﻋﺪد اﻟﻔﻼﺗﺮ هﻮ ﻧﻔﺲ ﻋﺪد اﻟﻤﻀﺨﺎت اﻟﻌﺎﻣﻠﺔ ) (Duty pumpsوﻳﻤﻜﻦ اﻻﺳﺘﻌﺎﻧﺔ ﺑﺎﻟﻤﻌﻠﻮﻣﺎت اﻟﻮاردة ﻓﻰ -6

¾ ASPE data Book , Volume 3,p112&113

ﻣﻊ ﻣﻼﺣﻈﺔ ان ﻣﻌﺪل اﻟﺘﺪﻓﻖ اﻟﻤﺴﻤﻮح ﺑﻪ ﻟﻞ Cartridge filterﻻ ﻳﺰﻳﺪ ﻋﻦ .( 0.92 m³/ hr/ m² )0.375gpm/ft²

وﻣﻌﺪل اﻟﺘﺪﻓﻖ اﻟﻤﺴﻤﻮح ﺑﻪ ﻟﻞ High rate pressure sand filterﻣﻦ ( 29.32 m³/ hr/ m²) 12gpm/ft²اﻟﻰ.(36.65 m³/ hr/ m²) 15gpm/ft²

أﻣﺎ ﻓﻰ ﺣﺎﻟﺔ Gravity or low velocity sand filtersﻓﻬﻰ ﺗﻌﻤﻞ ﺑﻤﻌﺪل (4.88:7.3 m³/ hr/ m²) 2:3gpm/ft²راﺟﻊ . ASPE data Book , Volume 3, P132

وﻓﻰ ﺣﺎﻟﺔ ) Diatomaceous earth filter (pressure or vacuumﻓﺈن ﻣﻌﺪل اﻟﺘﺪﻓﻖ 1 gpm/ft²ﻃﺒﻘﺎ ل ASPE data Book , Volume 3,P 139وﻳﻜﻮن ﺑﺤﺪ أﻗﺼﻰ2.5gpm/ft²

) (6.1 m³/m²/hrراﺟﻊ ASPE data Book , Volume 3, P134

ﻣﻊ ﻣﺮاﻋﺎة اذا زاد ﻣﻌﺪل اﻟﺘﺪوﻳﺮ ﻋﻦ 120gpmﻳﺠﺐ اﺧﺘﻴﺎر ﻋﺪد 2ﻓﻠﺘﺮ ﻋﻠﻰ اﻻﻗﻞ.

وﻳﺘﻢ ﺣﺴﺎب ﻣﺴﺎﺣﺔ اﻟﻔﻠﺘﺮة اﻟﻜﻠﻴﺔ Total filtration areaﻋﻦ ﻃﺮﻳﻖ ﻗﺴﻤﺔ ﻣﻌﺪل اﻟﺘﺪوﻳﺮ Total recirculation rateﻋﻠﻰ 0.375ﻟﻞ Cartridge filterو 12او 15ﻟﻞ

High pressure sand filterو2أو 3ﻟﻞ Gravity or low velocity sand filterو 2.5ﻟﻞ) Diatomaceous earth filter (pressure or vacuumوﺑﻘﺴﻤﺔ ﻣﺴﺎﺣﺔ اﻟﻔﻠﺘﺮة ﻋﻠﻰ ﻋﺪد

اﻟﻔﻼﺗﺮ ﻧﺤﺼﻞ ﻋﻠﻰ ﻣﺴﺎﺣﺔ اﻟﻔﻠﺘﺮة ﻟﻠﻔﻠﺘﺮ اﻟﻮاﺣﺪ.

¾ Swimming Pools 4ed ‐ Philip H Perkins, section 8.2.1, p175&176

ﻳﻼﺣﻆ هﻨﺎ ان اﻟﻜﻮد اوﺻﻰ ﺑﺎن ﻳﺘﻢ ﺗﺮآﻴﺐ ال High rate pressure sand filterﻓﻰ اﻟﻨﻮادى واﻟﻔﻨﺎدق واﻟﺤﻤﺎﻣﺎت اﻟﺨﺎﺻﺔ وﻳﻜﻮن ﻣﻌﺪل اﻟﺘﺪﻓﻖ ﻣﻦ12.3gpm/ft²

)(30 m³/ hr/ m²ال ( 50 m³/ hr/ m²) 20.5gpm/ft²ﻓﻰ ﺣﻴﻦ ﻳﺴﺘﺨﺪم ال Medium rate pressure sand filterﻓﻰ اﻟﺤﻤﺎﻣﺎت اﻟﻌﺎﻣﺔ واﻟﻤﺪارس

1|Page

� وﻳﻜﻮن ﻣﻌﺪل اﻟﺘﺪﻓﻖ ﻣﻦ (20 m³/ hr/ m²) 8.2gpm/ft²اﻟﻰ.( 30 m³/ hr/ m²) 12.3gpm/ft²

¾ PRACTICAL PLUMBING DESIGN GUIDE P 4‐113,114

ﻳﻼﺣﻆ ان هﺬا اﻟﻤﺮﺟﻊ ﻳﺬآﺮ ان High rate pressure sand filterﻳﻌﻤﻞ ﺑﻤﻌﺪل (36.65 m³/ hr/ m²) 15gpm/ft²و Rapid sand filterوهﻮ ﻣﺎ ﻳﻤﺎﺛﻞ ال

low velocity sand filtersﻓﻰ آﻮد ال ASPEوﻳﻌﻤﻞ ﺑﻤﻌﺪل (7.3 m³/ hr/ m²) 3gpm/ft²و Vacuum diatomite filterوﻳﻌﻤﻞ ﺑﻤﻌﺪل .(4.88 m³/ hr/ m²) 2gpm/ft²

-7ﻧﻘﻮم اﻻن ﺑﺤﺴﺎب ﺣﺠﻢ ال Compensation tankآﺎﻟﺘﺎﻟﻰ:

-1ﻧﻘﻮم ﺑﺤﺴﺎب آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﻨﺎﺗﺠﺔ ﻋﻦ ﻋﻤﻠﻴﺔ اﻟﻐﺴﻴﻞ اﻟﻌﻜﺴﻰ Back washوﻳﻤﻜﻦ ﺣﺴﺎﺑﻬﺎ ﺑﺎﻻﺳﺘﻌﺎﻧﺔ ب

¾ ASPE data Book , Volume 3, P113

¾ واﻟﺬى ﻳﻮﺿﺢ اﻧﻪ ﻋﻠﻰ اﻟﺮﻏﻢ ﻣﻦ ان اﻟﺰﻣﻦ اﻻﻗﺼﻰ اﻟﻼزم ﻟﻌﻤﻞ اﻟﻐﺴﻴﻞ اﻟﻌﻜﺴﻰ 5دﻗﺎﺋﻖ اﻻ اﻧﻬﺎ ﺗﺴﺘﻬﻠﻚ آﻤﻴﺔ آﺒﻴﺮة ﻣﻦ اﻟﻤﻴﺎﻩ ﺗﺼﻞ اﻟﻰ ( 48.87 m³/ hr/ m²) 20gpm/ft²ﻣﻦ ﻣﺴﺎﺣﺔ

اﻟﻔﻠﺘﺮة وذﻟﻚ ﺑﺎﻟﻨﺴﺒﺔ High‐rate pressure sand filtersوﻳﺬآﺮ ﻧﻔﺲ اﻟﻜﻮد أن ﻣﺪة اﻟﻐﺴﻴﻞ اﻟﻌﻜﺴﻰ 2.5دﻗﻴﻘﺔ ﻟﻠﺤﻤﺎﻣﺎت اﻟﻌﺎﻣﺔ . ASPE data Book , Volume 3,P 139

أﻣﺎ ﻓﻰ ﺣﺎﻟﺔ Gravity or low velocity sand filtersﻓﺎن اﻟﻤﻌﺪل ﺧﻼل اﻟﻐﺴﻴﻞ اﻟﻌﻜﺴﻰ ﻣﻦ

(29.32 m³/ hr/ m²) 12gpm/ft²اﻟﻰ (36.65 m³/ hr/ m²) 15gpm/ft²وﻟﻤﺪة 2.5دﻗﻴﻘﺔ وهﻮ ﻣﺎهﻮ واﺿﺢ ﻓﻰ ASPE data Book , Volume 3, P132و

ASPE data Book , Volume 3,P 139

أﻣﺎ ﻓﻰ ﺣﺎﻟﺔ ) Diatomaceous earth filter (pressure or vacuumﻓﻴﻤﻜﻦ اﻋﺘﺒﺎر ﻣﻌﺪل اﻟﺘﺸﻐﻴﻞ ASPE data Book , Volume 3, P134 (6.1 m³/ hr/ m²) 2.5gpm/ft²هﻮ

ﻣﻌﺪل اﻟﻐﺴﻴﻞ اﻟﻌﻜﺴﻰ ﻟﻤﺪة 3دﻗﺎﺋﻖ)آﻤﺎ هﻮ وارد ﻓﻰ ( ASPE data Book , Volume 3,P 139ﻣﻊ ﻣﻼﺣﻈﺔ ان اﻟﻨﻮع ال vacuumﻻ ﻳﺘﻢ ﻟﻪ backwashﺣﻴﺚ ﻳﺘﻢ ﺗﻨﻈﻴﻔﻪ ﻳﺪوﻳ ًﺎ.

وﻳﻤﻜﻦ اﻳﻀ ًﺎ اﻻﺳﺘﻌﺎﻧﺔ ب

¾ Swimming Pools 4ed ‐ Philip H Perkins, section 8.2.1, p176

واﻟﺬى ﻳﻮﺿﺢ ان اﻟﺰﻣﻦ اﻟﻼزم ﻟﻌﻤﻞ اﻟﻐﺴﻴﻞ اﻟﻌﻜﺴﻰ 8دﻗﺎﺋﻖ ﺑﻤﻌﺪل ﺗﺪﻓﻖ .( 25 m³/ hr/ m²) 10.23gpm/ft²

-2ﻧﻘﻮم ﺑﺤﺴﺎب آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﻨﺎﺗﺠﺔ ﻋﻦ ازاﺣﺔ ﻣﺴﺘﺨﺪﻣﻮ اﻟﺤﻤﺎم ﻟﻠﻤﻴﺎﻩ وﻧﺒﺪأ اوﻻ ﺑﺤﺴﺎب ﻋﺪد اﻻﺷﺨﺎص اﻟﻠﺬﻳﻦ ﻳﺴﺘﻌﻤﻠﻮن اﻟﺤﻤﺎم وﻳﻤﻜﻦ اﻻﺳﺘﻌﺎﻧﺔ ب

¾ Code_of_Practice_Aquatic_Facilities , march 2006 p51‐table 10

او

¾ Swimming Pools 4ed ‐ Philip H Perkins, section 1.3.3&8.24, p18&p168

أو

¾ ASPE data Book , Volume 3, P143

ﺑﻌﺪ ﺗﺤﺪﻳﺪ ﻋﺪد اﻻﺷﺨﺎص ﻧﻘﻮم ﺑﺤﺴﺎب آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﻼزﻣﺔ ﻋﻦ ﻃﺮﻳﻖ ﺿﺮب ﻋﺪد اﻻﺷﺨﺎص ﻓﻰ اﻟﻜﻤﻴﺔ اﻟﻼزﻣﺔ ﻟﻠﺸﺨﺺ اﻟﻮاﺣﺪ واﻟﺘﻰ ﻳﻤﻜﻦ اﻟﺤﺼﻮل ﻋﻠﻴﻬﺎ ﻋﻦ ﻃﺮﻳﻖ ﻣﺎﻳﻠﻰ:

¾ ASPE data Book , Volume 3, P143

¾

-3ﻧﻘﻮم ﺑﺤﺴﺎب آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﻨﺎﺗﺠﺔ ﻋﻦ اﻟﺒﺨﺮ وذﻟﻚ ﻓﻰ ﺣﺎﻟﺔ اﻟﺤﻤﺎﻣﺎت اﻟﺨﺎرﺟﻴﺔ وﻳﺘﻢ ذﻟﻚ ﻋﻦ ﻃﺮﻳﻖ اﺳﺘﺨﺪام اﻟﻤﻌﺎدﻟﺔ اﻟﻤﺴﺘﺨﺪﻣﺔ ﻓﻰ آﻮد : ASHRAE

¾ ASHRAE2007,HVAC APPLICATIONS,CHAPTER 4, P4.6

wp = 4 × 10^(-5)A( pw – pa) Fa:

where

wp = evaporation of water, kg/s

A = area of pool surface, m2

2|Page

�pw = saturation vapor pressure taken at surface water temperature, kPa

pa = saturation pressure at room air dew point, kPa

Fa =typical activation factor

و ﻳﺘﻢ اﻟﺤﺼﻮل ﻋﻠﻰ ﻗﻴﻢ pwﻣﻦ :

¾ ASHRAE 2005 HANDBOOK,FUNDAMENTALS(SI) ,CH06,P06,TABLE 3وذﻟﻚ ﺑﺎﺳﺘﺨﺪام درﺟﺔ اﻟﺤﺮارة ﻣﻦ ﺟﺪول )(1

وﻳﺘﻢ اﻟﺤﺼﻮل ﻋﻠﻰ ﻗﻴﻢ paﻣﻦ:

PSYCROMETRIC CHARTﺑﺎﺳﺘﺨﺪام Relative humidityو Surface water temperatureﻣﻦ ﺟﺪول ).(1

ﻣﻊ ﻣﻼﺣﻈﺔ اﻧﻪ ﻟﻠﺤﺼﻮل ﻋﻠﻰ ﺣﺠﻢ اﻟﻤﻴﺎﻩ اﻟﻨﺎﺗﺠﺔ ﻋﻦ اﻟﺘﺒﺨﺮ ﻳﺠﺐ ﺿﺮب ﻗﻴﻤﺔ wpﻓﻰ ) ( 60*60*24ﻟﻠﺤﺼﻮل ﻋﻠﻰ آﺘﻠﺔ اﻟﻤﻴﺎﻩ اﻟﻴﻮﻣﻴﺔ وﻟﻠﺤﺼﻮل ﻋﻠﻰ اﻟﺤﺠﻢ ﻧﻘﺴﻢ اﻟﻔﻴﻤﺔ اﻟﻴﻮﻣﻴﺔ ﻋﻠﻰ آﺜﺎﻓﺔ

اﻟﻤﻴﺎﻩ). (1000

-4ﻧﻘﻮم ﺑﺠﻤﻊ اﻟﻘﻴﻢ اﻟﺴﺎﺑﻘﺔ ﻣﻌًﺎ ﻟﻠﺤﺼﻮل ﻋﻠﻰ ﺣﺠﻢ ﺧﺰان اﻟﺘﻌﻮﻳﺾ ﻣﻊ ﻣﻼﺣﻈﺔ ان ﻣﺮﺟﻊ PRACTICAL PLUMBING DESIGN GUIDE P 4‐110ﻳﻮﺻﻰ ﺑﺄن ﻳﻜﻮن ﺣﺠﻢ ﺧﺰان اﻟﺘﻌﻮﻳﺾ ﻣﻦ

0.5:1 gallon/ft²ﻣﻦ ﻣﺴﺎﺣﺔ ﺣﻤﺎم اﻟﺴﺒﺎﺣﺔ.

-8ﻧﻘﻮم اﻻن ﺑﺤﺴﺎب راﻓﻊ Headﻃﻠﻤﺒﺔ اﻟﺘﺪوﻳﺮ ال

= HSTATICاﻟﻤﺴﺎﻓﺔ اﻟﺮأﺳﻴﺔ ﺑﻴﻦ اﻟﻄﻠﻤﺒﺔ وﻣﺪاﺧﻞ اﻟﻤﻴﺎﻩ ﻟﻠﺤﻤﺎم. .1

= HRESIDEULEﻳﻤﻜﻦ ان ﺗﻘﺪر ب 0.3ﺑﺎر ) 3ﻣﺘﺮ(. .2

. HMAJORS+HMINORS (FRICTION) = HLOSSES .3

= HMAJORSوهﻰ اﻟﺨﺎﺻﺔ ﺑﺎﻟﻔﻼﺗﺮ وهﻰ ﺗﻘﺪر ب 25psiﺑﺎﻟﻨﺴﺒﺔ ﻟﻠﻔﻼﺗﺮ اﻟﺮﻣﻠﻴﺔ ASPE data Book, Volume 3,P 139أو 20psiﻃﺒﻘﺎ ﻟﻠﻤﺮﺟﻊ .4

. PRACTICAL PLUMBING DESIGN GUIDE P 4‐130

=HMINORS (FRICTION) .5وهﻰ اﻟﻨﺎﺗﺠﺔ ﻋﻦ اﻻﺣﺘﻜﺎك ﻓﻰ اﻟﻤﻮاﺳﻴﺮ واﻟﻘﻄﻊ واﻟﻜﺘﺎﻟﻮج اﻻﺗﻰ ﺑﻪ ﻗﻴﻢ اﻟﻔﻘﺪ ﻋﻦ ﻃﺮﻳﻖ اﻻﺣﺘﻜﺎك ﻟﻤﺎدﺗﻰ George Fischer catalogue PVC&CPVC

-9ﻟﻌﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻞ over flowاﻟﺨﺎص ﺑﺎﻟﺤﻤﺎم ﻳﻮﺻﻰ آﻮد ASPE data Book, Volume 3,P 142و ASPE data Book , Volume 3,p110ﺑﺎن اﻟﻤﺴﺎﻓﺔ ﺑﻴﻦ آﻞ ﻧﻘﻄﺘﻴﻦ ﺻﺮف 4.6ﻣﺘﺮ آﺤﺪ

اﻗﺼﻰ ﻓﻰ ﺣﺎﻟﺔ اﺳﺘﺨﺪام اﻟﻨﻮع ال Gutterوﻟﺘﺼﻤﻴﻢ ﻗﻄﺮ اﻟﻤﻮاﺳﻴﺮ ﻳﺮاﻋﻰ ان ﻳﻜﻮن ﻣﻌﺪل آﻤﻴﺔ اﻟﻤﻴﺎﻩ هﻮ ﻧﻔﺲ اﻟﻤﻌﺪل اﻟﺨﺎص ﺑﺎﻟﻔﻠﺘﺮة turnover rateوﺑﺴﺮﻋﺔ ﻣﻦ (0.6m/s:3m/s) 2ft/s:10ft/s

ﻋﻠﻰ اﻻﻳﻘﻞ ﻗﻄﺮ اﻟﻤﺎﺳﻮرة ﻋﻦ " 2ﻓﻰ ﺣﺎﻟﺔ ﺣﻤﺎﻣﺎت اﻟﺴﺒﺎﺣﺔ اﻟﻌﺎﻣﺔ اﻣﺎ ﻓﻰ ﺣﺎﻟﺔ اﺳﺘﺨﺪام ال Skimmerﻓﺎن اﻟﻮاﺣﺪ ﻳﺨﺪم ﻣﻦ ( 37.2m²:46.5m²) 400 ft²:500ft²وﻳﺘﻢ ﺗﺼﻤﻴﻢ ﻣﻘﺎﺳﺎت اﻟﻤﻮاﺳﻴﺮ

ﻋﻠﻰ اﺳﺎس ﻣﻌﺪل ﺗﺪﻓﻖ ﻣﻦ 80%:100%ﻣﻦ اﻟﻤﻌﺪل اﻟﺨﺎص ﺑﺎﻟﻔﻠﺘﺮة turnover rateأو (1.9l/s) 30 gpmأو ) (9.3 l/s/m) 3.75gpm/inﻣﻦ ﻃﻮل اﻟﺸﻼل (weir lengthﻓﻰ ﺣﻴﻦ ﻳﺬآﺮ

ﻣﺮﺟﻊ PRACTICAL PLUMBING DESIGN GUIDE P 4‐110ان ﻳﺘﻢ اﻟﺘﺼﻤﻴﻢ ﻋﻠﻰ اﺳﺎس ﻣﻌﺪل ﺗﺪﻓﻖ ﻣﻦ 50%:100%ﻣﻦ اﻟﻤﻌﺪل اﻟﺨﺎص ﺑﺎﻟﻔﻠﺘﺮة . turnover rate

-10ﻟﻌﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻞ inletsاﻟﺨﺎﺻﺔ ﺑﺎﻟﺤﻤﺎم ﻳﻮﺻﻰ آﻮد ASPE data Book, Volume 3,P 143ﺑﺎن اﻟﻤﺪﺧﻞ اﻟﻮاﺣﺪ ﻳﺨﺪم ) 10000 GPM(37850 Lﻣﻊ ﻣﺮاﻋﺎة ان ﻳﺘﻢ ﺗﻮزﻳﻊ اﻟﻤﺪاﺧﻞ ﺑﺸﻜﻞ هﻨﺪﺳﻰ

ﻋﻠﻰ ان ﻳﺮاﻋﻰ اﻻ ﻳﺒﻌﺪ اﻗﺮب ﻣﺪﺧﻞ ﻣﻦ اﻟﻜﻮرﻧﺮ ﻋﻦ ) 20ft(6 mو) 5ft(1.5 mوﻋﻨﺪ ﻋﻤﻞ اﻟﺘﺼﻤﻴﻢ ﻟﻤﻮاﺳﻴﺮ اﻟﺘﻐﺬﻳﺔ ﻳﺮاﻋﻰ ان ﺗﻜﻮن ﺳﺮﻋﺔ اﻟﻤﻮاﺳﻴﺮ اﻟﻘﺼﻮى ) 5 fps(1.5m/sﻓﻰ ﺣﻴﻦ ﻳﻮﺻﻰ

ﻣﺮﺟﻊ PRACTICAL PLUMBING DESIGN GUIDE P 4‐110ﺑﺎن ﺗﻜﻮن اﻟﻤﺴﺎﻓﺔ اﻟﻘﺼﻮى ﺑﻴﻦ اى ﻣﺪﺧﻠﻴﻦ ) 20ft(6mﻋﻠﻰ ان ﻳﺮاﻋﻰ اﻻ ﻳﺒﻌﺪ اﻗﺮب ﻣﺪﺧﻞ ﻣﻦ اﻟﻜﻮرﻧﺮ ﻋﻦ ).5ft(1.5 m

-11ﻟﻌﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻞ main drainاﻟﺨﺎص ﺑﺎﻟﺤﻤﺎم ﻳﻮﺻﻰ آﻮد ASPE data Book, Volume 3,P 143ﺑﺎن ﻳﺘﻢ اﺳﺘﺨﺪام وﺣﺪﺗﻴﻦ ﻣﻨﻔﺼﻠﺘﻴﻦ وان ﻳﺘﻢ ﻋﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻘﻄﺮ اﻟﻤﻮاﺳﻴﺮ ﻋﻠﻰ اﺳﺎس ﻣﻌﺪل

ﺗﺪﻓﻖ 100%ﻣﻦ اﻟﻤﻌﺪل اﻟﺨﺎص ﺑﺎﻟﻔﻠﺘﺮة turnover rateوان ﻳﺮاﻋﻰ ان ﺗﻜﻮن اﻟﻤﺴﺎﻓﺔ اﻟﻘﺼﻮى ﻋﻦ اﻗﺮب ﺣﺎﺋﻂ ﻻ ﺗﺘﺠﺎوز ) 15ft(4.6 mوأن ﺗﻜﻮن اﻟﻤﺴﺎﻓﺔ اﻟﻘﺼﻮى ﺑﻴﻦ وﺣﺪﺗﻰ اﻟﺼﺮف

) 30ft(9.2 mوان ﺗﻜﻮن اﻗﻞ ﻣﺴﺎﻓﺔ ﺑﻴﻦ وﺣﺪﺗﻰ اﻟﺼﺮف ) ASPE data Book , Volume 3,p110 4ft(1.2 mوﻧﻔﺲ هﺬﻩ اﻟﻤﻌﻠﻮﻣﺎت ﻣﺬآﻮرة ﻓﻰ

PRACTICAL PLUMBING DESIGN GUIDE P 4‐110

-12ﻟﻌﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻞ vacuumاﻟﺨﺎص ﺑﺎﻟﺤﻤﺎم ﻳﻮﺻﻰ آﻮد ASPE data Book, Volume 3,P 144و PRACTICAL PLUMBING DESIGN GUIDE P 4‐111ﺑﺎن ﺗﻜﻮن اﻟﻤﺴﺎﻓﺔ ﺑﻴﻦ آﻞ ﻧﻘﻄﺘﻴﻦ

) 50ft(15 mوﺑﻘﻄﺮ " 2وذﻟﻚ ﻓﻰ ﺣﺎﻟﺔ اﺳﺘﺨﺪام . Gutter overflowآﻤﺎ ﻳﺠﺐ ﻣﻼﺣﻈﺔ ان اﻟﻜﻮد ﻳﺬآﺮ ان ﺳﺮﻋﺔ اﻟﻤﺎء ﻟﻞ Supplyو ال Returnﻣﻦ ) 5:6 fps(1.5:1.8m/sﻓﻰ ﺣﻴﻦ ﻳﺬآﺮ

3|Page

� ﻧﻔﺲ اﻟﻜﻮد اﻟﺴﺮﻋﺎت اﻟﻘﺼﻮى اﻟﻤﻮﺻﻰ ﺑﻬﺎ ﻓﻰ ﺣﺎﻟﺔ اﻟﻨﻮاﻓﻴﺮ ASPE data Book, Volume 3,P 117ﻓﻰ ﺣﻴﻦ ﻳﺬآﺮ ﻣﺮﺟﻊ PRACTICAL PLUMBING DESIGN GUIDE P 4‐126ﺳﺮﻋﺎت

ﻣﺨﺘﻠﻔﺔ .

-13ﻟﻌﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻞ heaterاﻟﺨﺎص ﺑﺎﻟﺤﻤﺎم ﻳﻮﺻﻰ آﻮد ASHRAE2007,HVAC APPLICATIONS,CHAPTER 49, P22,23ﺑﺎﺳﺘﺨﺪام ﻣﻌﺎدﻟﺘﻴﻦ رﻗﻢ 21,22ﻣﻊ ﻣﻼﺣﻈﺔ ان اﻟﻜﻮد ﻳﻮﺻﻰ ﺑﺎن

ﺗﺆﺧﺬ ) 27°C(80°Fﻓﻰ ﺣﻴﻦ ﻳﻮﺻﻰ ﻣﺮﺟﻊ PRACTICAL PLUMBING DESIGN GUIDE P 4‐111ﺑﺎن ﺗﻜﻮن درﺟﺔ اﻟﺤﺮارة ). 24.5:25.5°C(76:78°F

-14ﻟﻌﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻠﻄﻠﻤﺒﺔ اﻟﻐﺎﻃﺴﺔ اﻟﺨﺎﺻﺔ ﺑﺎل Pump roomﻳﻤﻜﻦ ﺣﺴﺎب آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﻤﺮاد رﻓﻌﻬﺎ آﺎﻟﺘﺎﻟﻰ:

.1آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﻨﺎﺗﺠﺔ ﻣﻦ ﻋﻤﻠﻴﺔ اﻟﻐﺴﻴﻞ اﻟﻌﻜﺴﻰ واﻟﺘﻰ ﺗﻢ ﺗﻮﺿﻴﺢ آﻴﻔﻴﺔ ﺣﺴﺎﺑﻬﺎ ﺳﺎﺑﻘ ًﺎ.

.2آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﻨﺎﺗﺠﺔ ﻋﻦ اى ﺗﺴﺮﻳﺐ ﻟﻠﻤﻴﺎﻩ ﻣﺤﺘﻤﻞ وﻳﻤﻜﻦ ﺗﻘﺪﻳﺮﻩ ﺑﺤﺠﻢ اﻟﻤﻴﺎﻩ اﻟﻨﺎﺗﺠﺔ ﻋﻦ ﺗﺮاآﻢ اﻟﻤﻴﺎﻩ ﺑﺎرﺗﻔﺎع 10 cmداﺧﻞ ﻏﺮﻓﺔ اﻟﻄﻠﻤﺒﺎت .

وﺑﻔﺮض ﻗﻴﺎم اﻟﻄﻠﻤﺒﺔ ﺑﺮﻓﻊ اﻟﻤﻴﺎﻩ ﺧﻼل 10دﻗﺎﺋﻖ ﻳﻤﻜﻦ ﻗﺴﻤﺔ آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﻜﻠﻴﺔ ﻋﻠﻰ زﻣﻦ اﻟﺮﻓﻊ) 10دﻗﺎﺋﻖ( ﻟﻠﺤﺼﻮل ﻋﻠﻰ ﻣﻌﺪل ﺗﺪﻓﻖ اﻟﻄﻠﻤﺒﺔ اﻟﻐﺎﻃﺴﺔ

وﻳﻤﻜﻦ ﺣﺴﺎب راﻓﻊ اﻟﻄﻠﻤﺒﺔ ﺑﻨﻔﺲ اﻟﻄﺮﻳﻘﺔ اﻟﺘﻰ ﺗﻢ ﺑﻬﺎ ﺣﺴﺎب راﻓﻊ ﻃﻠﻤﺒﺔ اﻟﺘﺪوﻳﺮ

-15ﻟﻌﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻠﻄﻠﻤﺒﺔ اﻟﺨﺎﺻﺔ ﺑﺎﻟﻨﻮاﻓﻴﺮ JET PUMPﻳﺠﺐ اﻟﺮﺟﻮع اﻟﻰ اﻟﻤﻌﻠﻮﻣﺎت اﻟﻔﻨﻴﺔ اﻟﻤﺘﻮﻓﺮة ﻟﺪى اﻟﻤﺼﻨﻊ ﻟﻠﻨﺎﻓﻮرة واﻟﺬى ﻳﺤﺪد ﻓﻴﻬﺎ ﻣﻌﺪل اﻟﺘﺪﻓﻖ واﻟﻀﻐﻂ اﻟﻤﻄﻠﻮﺑﻴﻦ ﻋﻨﺪ ﻣﺨﺮج اﻟﻨﺎﻓﻮرة ﻣﻊ

ﻣﺮاﻋﺎة ﺣﺴﺎب آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﺨﺎرﺟﺔ ﻣﻦ الnozzlesاﻟﺨﺎﺻﺔ ﺑﺎﻟﻨﺎﻓﻮرة وذﻟﻚ ﺑﺎﺳﺘﺨﺪام اﻟﻤﻌﺎدﻟﺔ ) t(sec)=d(m) /v(m/secوﺑﺎﻋﺘﺒﺎر v=1m/secﺣﻴﺚ dهﻮ ارﺗﻔﺎع اﻟﻤﻴﺎﻩ اﻟﺨﺎرﺟﺔ ﻣﻦ اﻟﻨﺎﻓﻮرة

ﺑﻀﺮب اﻟﺰﻣﻦ ﻓﻰ ﻣﻌﺪل ﺗﺪﻓﻖ اﻟﻤﻴﺎﻩ ﻳﺘﻢ اﻟﺤﺼﻮل ﻋﻠﻰ آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﺨﺎﺻﺔ ﺑﺎﻟﻨﺎﻓﻮرة ﻟﻴﺘﻢ اﺿﺎﻓﺔ هﺬﻩ اﻟﻜﻤﻴﺔ اﻟﻰ ﺣﺠﻢ ﺧﺰان اﻟﺘﻌﻮﻳﺾ .

-16ﻓﻰ ﺣﺎﻟﺔ وﺟﻮد ﺷﻼل weirﻳﺠﺐ ﻣﺮاﻋﺎة اﻻﺗﻰ:

¾ ﻳﺘﻢ ﺣﺴﺎب آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﺨﺎﺻﺔ ﺑﺎﻟﺸﻼل وذﻟﻚ ﺣﺘﻰ ﻳﻤﻜﻦ اﺿﺎﻓﺘﻬﺎ اﻟﻰ ﺣﺠﻢ ﺧﺰان اﻟﺘﻌﻮﻳﺾ وﻳﻜﻮن ذﻟﻚ ﻋﻦ ﻃﺮﻳﻖ اﻟﺤﺼﻮل ﻣﻦ اﻟﺮﺳﻮﻣﺎت اﻟﻤﻌﻤﺎرﻳﺔ ﻋﻠﻰ ﺳﻤﻚ اﻟﺸﻼل وﻋﺮﺿﻪ وارﺗﻔﺎﻋﻪ

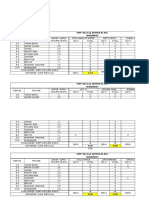

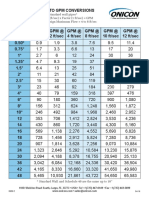

وﺑﺎﺳﺘﺨﺪام PRACTICAL PLUMBING DESIGN GUIDE P 4‐122ﻳﺘﻢ اﻟﺤﺼﻮل ﻋﻠﻰ ﻣﻌﺪل ﺗﺪﻓﻖ اﻟﻤﻴﺎﻩ) (gpm/ftﺑﻤﻌﻠﻮﻣﻴﺔ ﺳﻤﻚ اﻟﺸﻼل وﺑﻀﺮب اﻟﻜﻤﻴﺔ اﻟﺴﺎﺑﻘﺔ ﻓﻰ ﻋﺮض اﻟﺸﻼل ﻳﺘﻢ

اﻟﺤﺼﻮل ﻋﻠﻰ ﻣﻌﺪل ﺗﺪﻓﻖ اﻟﺸﻼل ) (gpmوﺑﺎﺳﺘﺨﺪام اﻟﻤﻌﺎدﻟﺔ t(sec)=d(m) /v(m/sec):وﺑﺎﻋﺘﺒﺎر v=1m/secﺣﻴﺚ dهﻮ ارﺗﻔﺎع اﻟﺸﻼل ﻳﻤﻜﻦ اﻟﺤﺼﻮل ﻋﻠﻰ اﻟﺰﻣﻦ اﻟﻼزم ﻟﺘﺪﻓﻖ اﻟﺸﻼل

وﺑﻀﺮب ﻣﻌﺪل ﺗﺪﻓﻖ اﻟﺸﻼل ﻓﻰ زﻣﻦ ﺗﺪﻓﻖ اﻟﺸﻼل ﻳﺘﻢ اﻟﺤﺼﻮل ﻋﻠﻰ آﻤﻴﺔ اﻟﻤﻴﺎﻩ اﻟﺨﺎﺻﺔ ﺑﺎﻟﺸﻼل .

¾ ﻳﺠﺐ ﻣﺮاﻋﺎة ان دﺧﻮل اﻟﻤﻴﺎﻩ ﻓﻰ ﺣﺎﻟﺔ اﻟﺸﻼل ﻳﺠﺐ ان ﻳﻜﻮن ﺑﺒﻂء ﺷﺪﻳﺪ وﺑﺘﻮزﻳﻊ ﻣﺘﺠﺎﻧﺲ وذﻟﻚ ﻟﻀﻤﺎن اﻧﺴﻴﺎﺑﻴﺔ ﺗﺪﻓﻖ اﻟﺸﻼل وﻳﻜﻮن ذﻟﻚ ﺑﺎﺳﺘﺨﺪام ﻣﺎﺳﻮرة ﻣﺜﻘﺒﺔ ﺣﻴﺚ ﻳﻜﻮن ﺳﺮﻋﺔ اﻟﻤﻴﺎﻩ

) 2fps(0.6m/sوﺑﻤﻌﻠﻮﻣﻴﺔ ﻣﻌﺪل ﺗﺪﻓﻖ اﻟﺸﻼل ﻳﻤﻜﻦ اﻟﺤﺼﻮل ﻋﻠﻰ اﻟﻤﺴﺎﺣﺔ اﻟﻜﻠﻴﺔ ﻟﻠﺜﻘﻮب ﻋﻦ ﻃﺮﻳﻖ اﻟﻤﻌﺎدﻟﺔ Q=A*Vوﻣﻨﻬﺎ ﻳﻤﻜﻦ اﻟﺤﺼﻮل ﻋﻠﻰ ﻋﺪد اﻟﺜﻘﻮب ﻋﻦ ﻃﺮﻳﻖ اﻟﻤﻌﺎدﻟﺔ

وﻳﻤﻜﻦ ﻓﺮض ﻗﻄﺮ اﻟﻘﺐ اﻟﻮاﺣﺪ 8mmوﻳﻤﻜﻦ ﻋﻤﻞ هﺬﻩ اﻟﺜﻘﻮب ﻓﻰ ﺻﻮرة ﺣﻠﻘﺎت وﻳﻤﻜﻦ ﻓﺮض ﻋﺪد اﻟﺤﻠﻘﺎت 10 ringsوﺑﺬﻟﻚ ﻳﻤﻜﻦ اﻟﺤﺼﻮل ﻋﻠﻰ ﻋﺪد No.of holes=Atot/Aone hole

اﻟﺜﻘﻮب ﻓﻰ اﻟﺤﻠﻘﺔ اﻟﻮاﺣﺪة وذﻟﻚ ﺑﻘﺴﻤﺔ ﻋﺪد اﻟﺜﻘﻮب اﻟﻜﻠﻴﺔ ﻋﻠﻰ 10واﻟﻤﺴﺎﻓﺔ ﺑﻴﻦ آﻞ ﺣﻠﻘﺘﻴﻦ وذﻟﻚ ﺑﻤﻌﻠﻮﻣﻴﺔ ﻃﻮل اﻟﻤﺎﺳﻮرة وﺑﻔﺮض ان رﺑﻊ اﻟﻤﺎﺳﻮرة اﻟﻌﻠﻮى ﻻ ﻳﺘﻢ ﻓﻴﻪ ﺛﻘﻮب ﻳﻤﻜﻦ اﻟﺤﺼﻮل ﻋﻠﻰ اﻟﻤﺴﺎﻓﺔ

ﺑﻴﻦ آﻞ ﺛﻘﺒﻴﻦ ﻋﻦ ﻃﺮﻳﻖ اﻟﻤﻌﺎدﻟﺔ

) 0.75Πd/2=No.holes*(d+Dﺣﻴﺚ Dاﻟﻤﺴﺎﻓﺔ ﺑﻴﻦ اﻟﺜﻘﻮب و dهﻰ ﻗﻄﺮ اﻟﺜﻘﺐ اﻟﻮاﺣﺪة.

¾ ﻟﻌﻤﻞ ﺗﺼﻤﻴﻢ ﻟﻠﻄﻠﻤﺒﺔ اﻟﺨﺎﺻﺔ ﺑﺎﻟﺸﻼل Display pumpﻳﺮاﻋﻰ ان ﻳﻜﻮن ﻣﻌﺪل اﻟﺘﺪﻓﻖ هﻮ ﻧﻔﺲ ﻣﻌﺪل اﻟﺘﺪﻓﻖ اﻟﺬى ﺗﻢ ﺣﺴﺎﺑﻪ ﻣﻦ ﻗﺒﻞ آﻤﺎ ﻳﺮاﻋﻰ اﺛﻨﺎء ﺣﺴﺎب ﺿﻐﻂ اﻟﻄﻠﻤﺒﺔ ان ال Hresiduleﻳﻜﻮن

. ASPE data Book, Volume 3,P 115 10ft

4|Page