0% found this document useful (0 votes)

189 views38 pagesRisk Assessment & Control Module 3

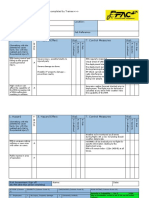

The document discusses methods for assessing risk, including qualitative, semi-quantitative, and quantitative analyses. Qualitative analysis uses words to describe likelihood and severity, while quantitative analysis uses numerical values. Semi-quantitative analysis assigns values to qualitative scales. Risk is determined by estimating the likelihood and potential severity of harm. Various risk assessment techniques are outlined, including what-if analysis, FMEA, HAZOP, fault tree analysis, and event tree analysis. Risk matrices can be used to classify risk levels and determine if further risk controls are needed. The outcome should be a risk control action plan.

Uploaded by

Marvin ReggieCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

189 views38 pagesRisk Assessment & Control Module 3

The document discusses methods for assessing risk, including qualitative, semi-quantitative, and quantitative analyses. Qualitative analysis uses words to describe likelihood and severity, while quantitative analysis uses numerical values. Semi-quantitative analysis assigns values to qualitative scales. Risk is determined by estimating the likelihood and potential severity of harm. Various risk assessment techniques are outlined, including what-if analysis, FMEA, HAZOP, fault tree analysis, and event tree analysis. Risk matrices can be used to classify risk levels and determine if further risk controls are needed. The outcome should be a risk control action plan.

Uploaded by

Marvin ReggieCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPTX, PDF, TXT or read online on Scribd

/ 38