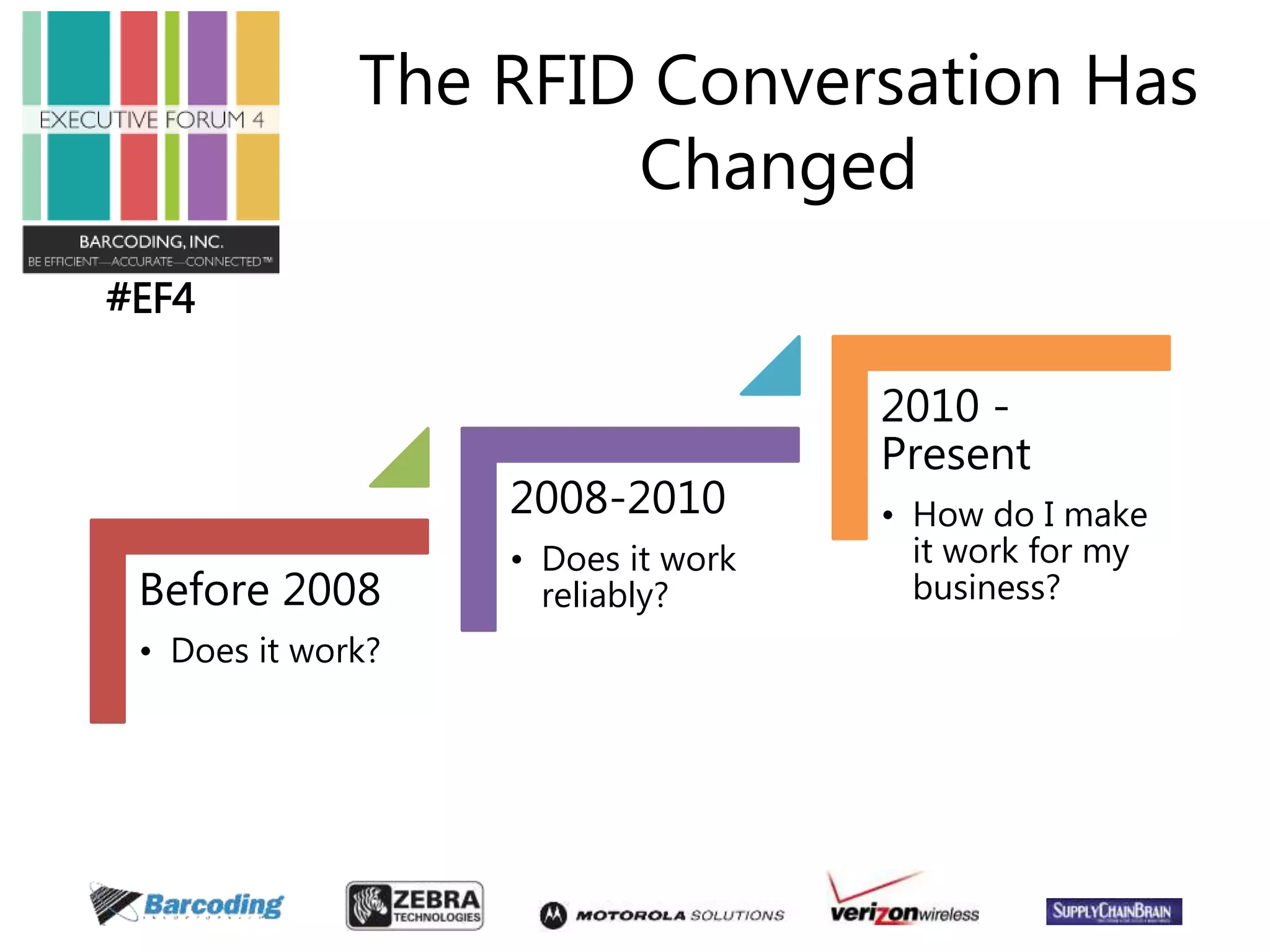

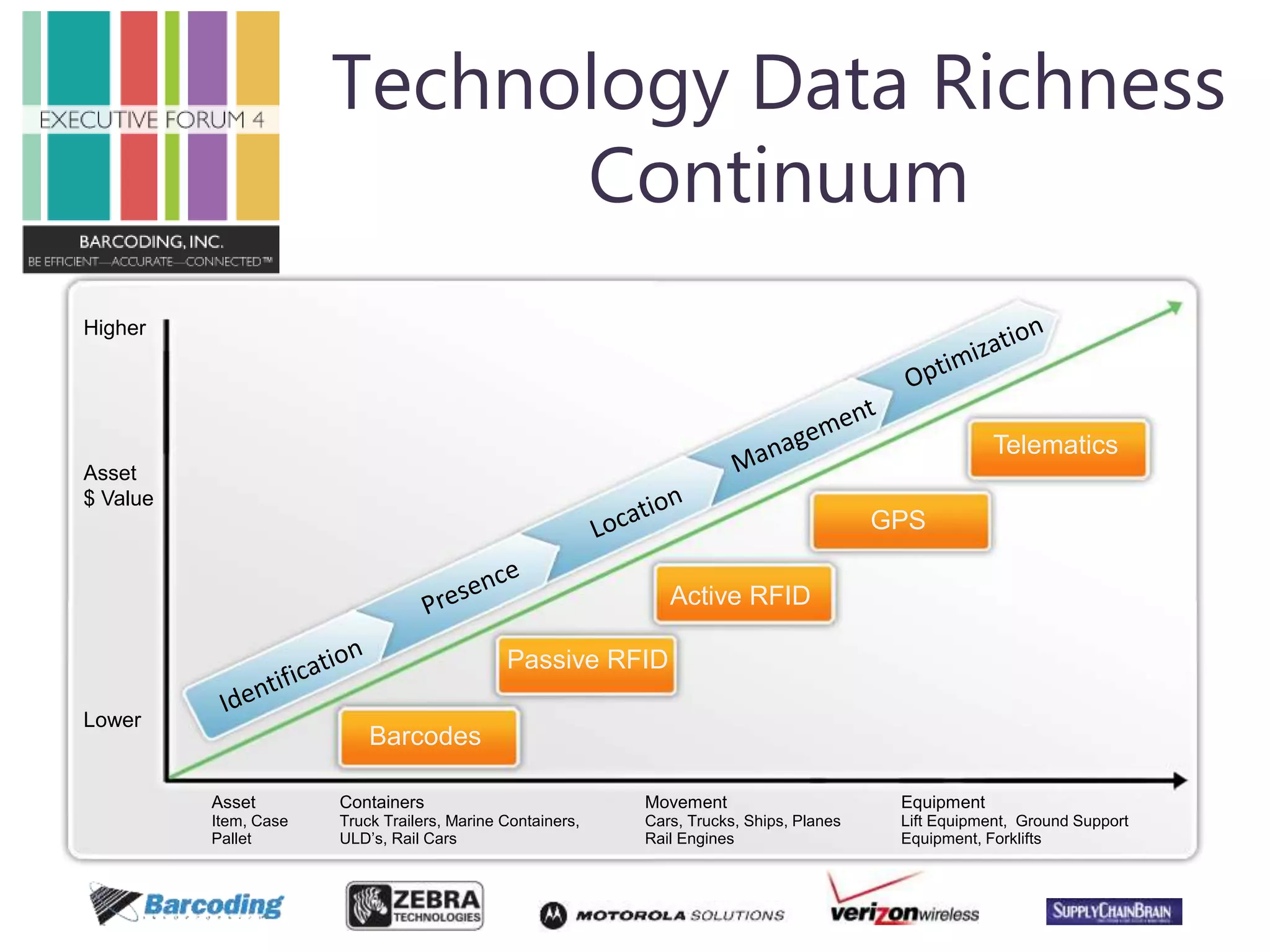

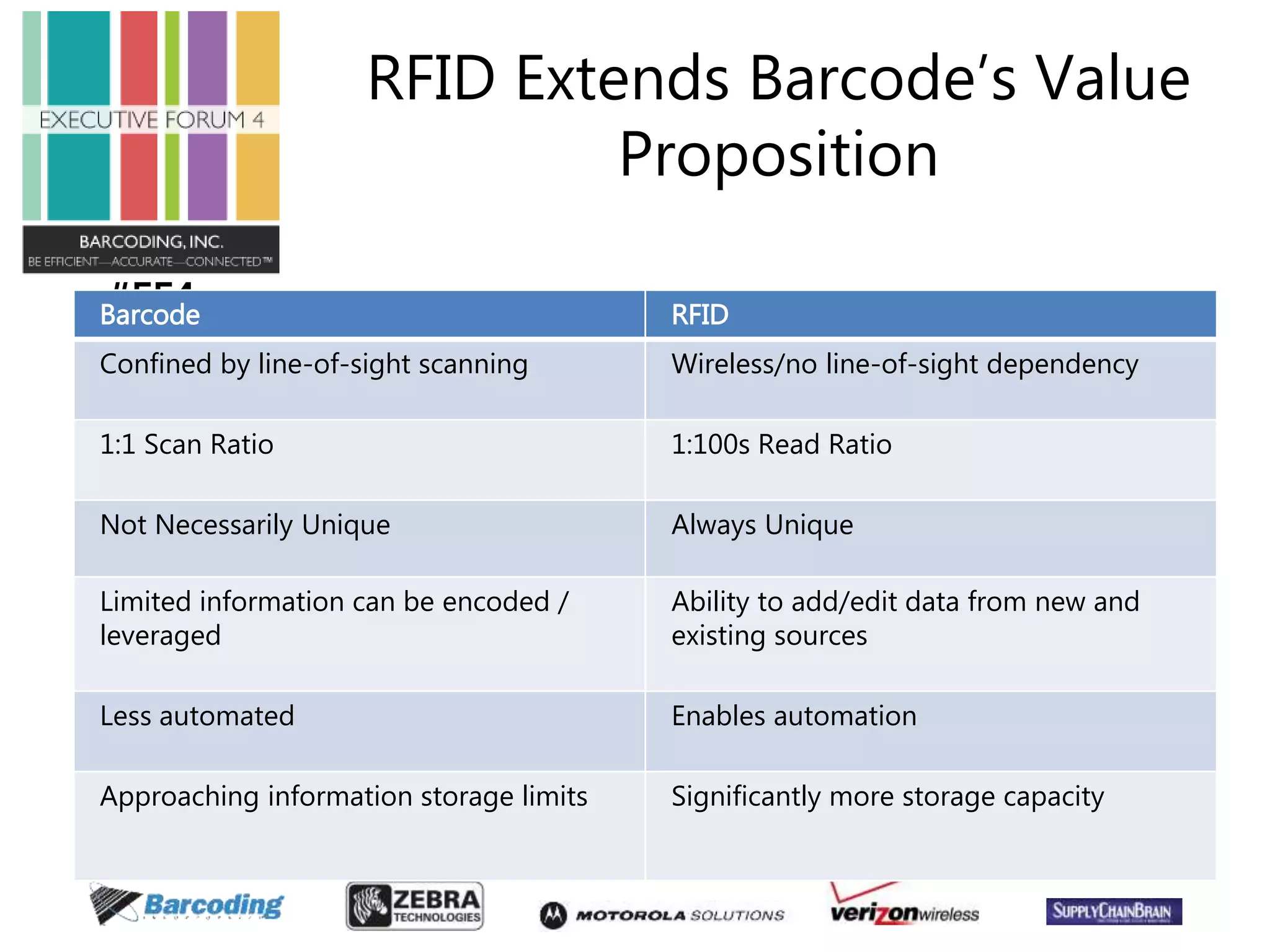

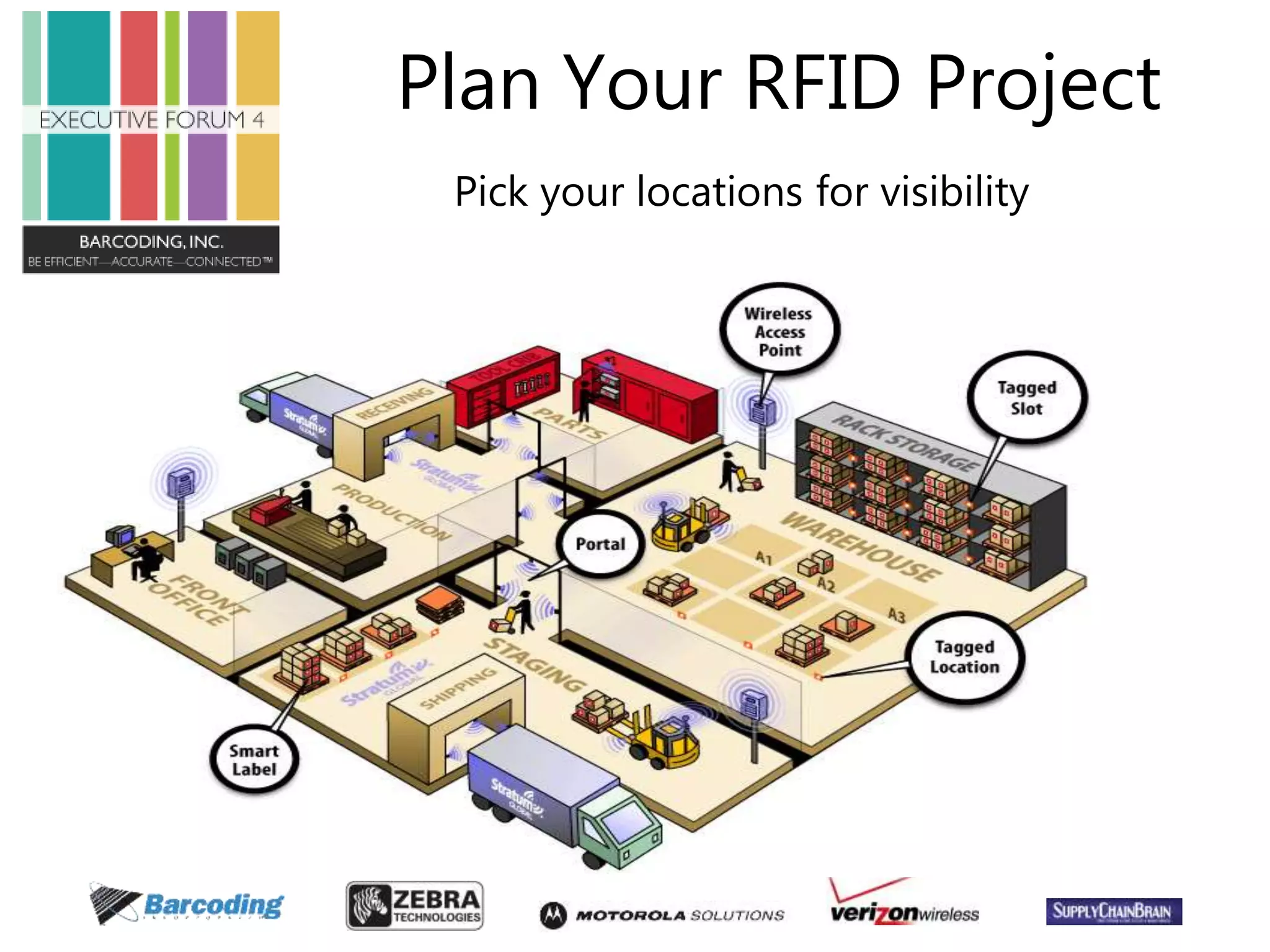

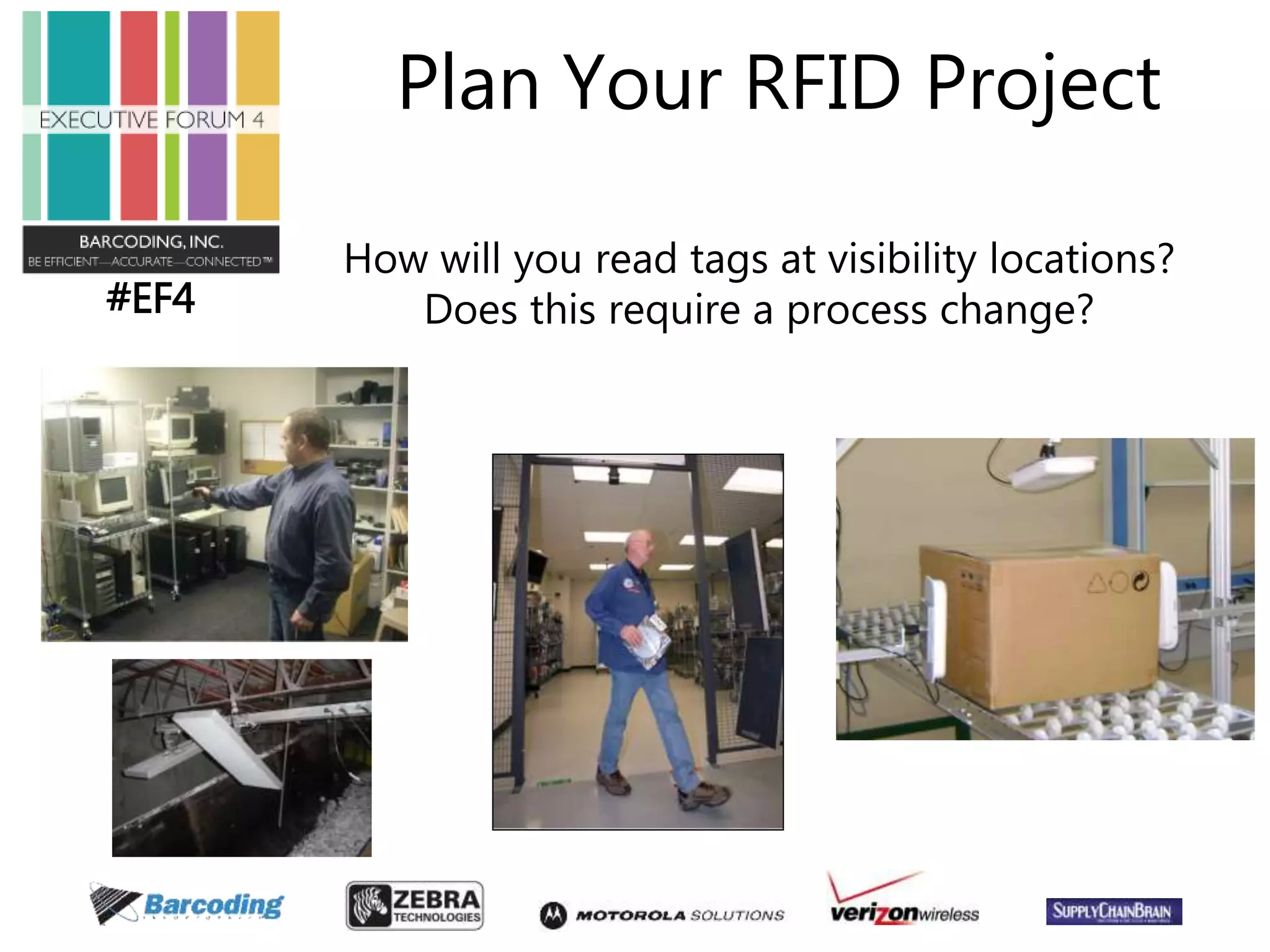

The document discusses the evaluation and implementation of RFID technology in business, emphasizing its benefits in visibility, inventory control, and process automation. Key considerations include selecting appropriate inlays, determining visibility locations, and testing the technology to demonstrate ROI. It highlights the importance of making data-driven decisions and improving efficiency while addressing common supply chain issues.