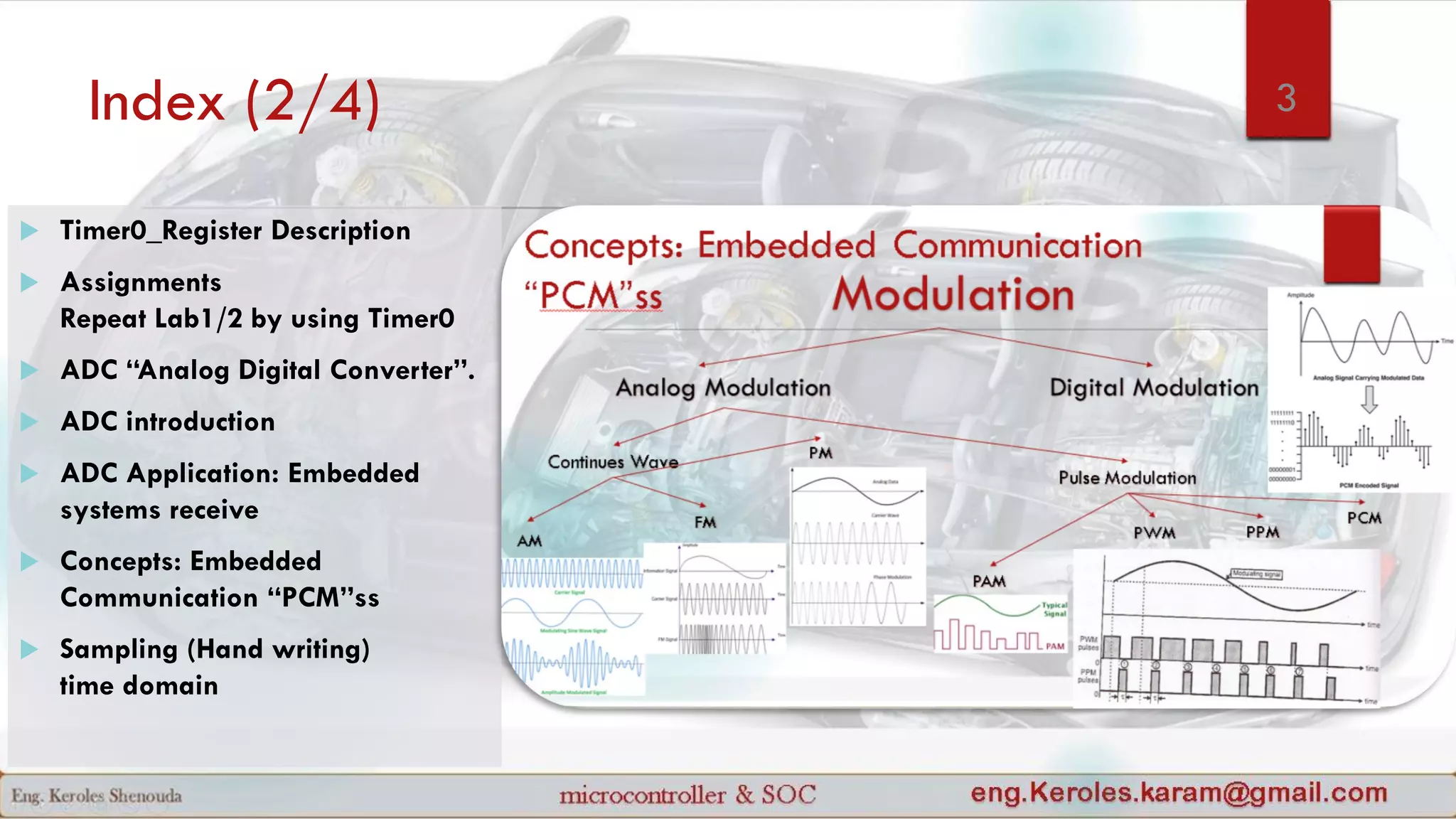

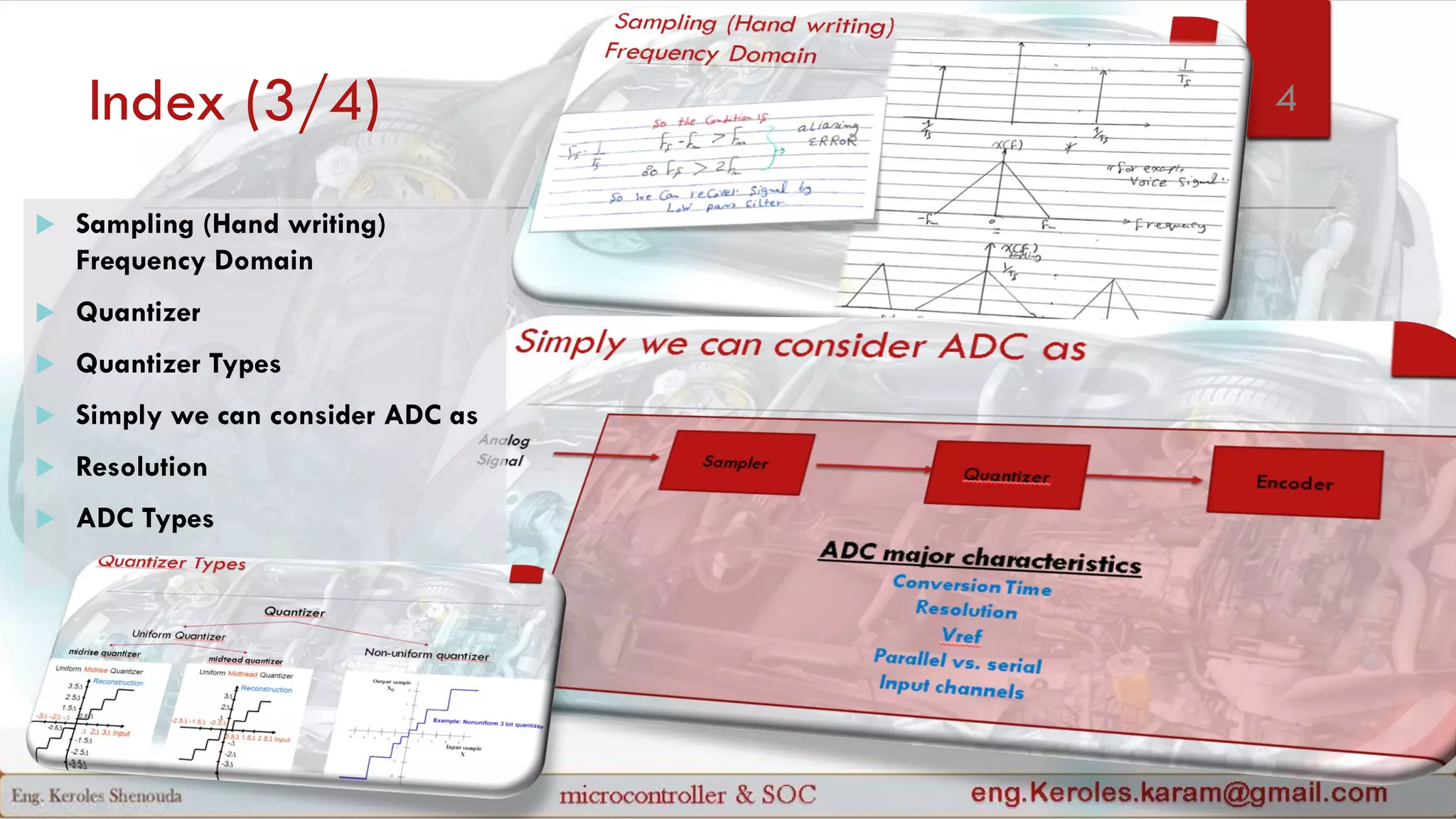

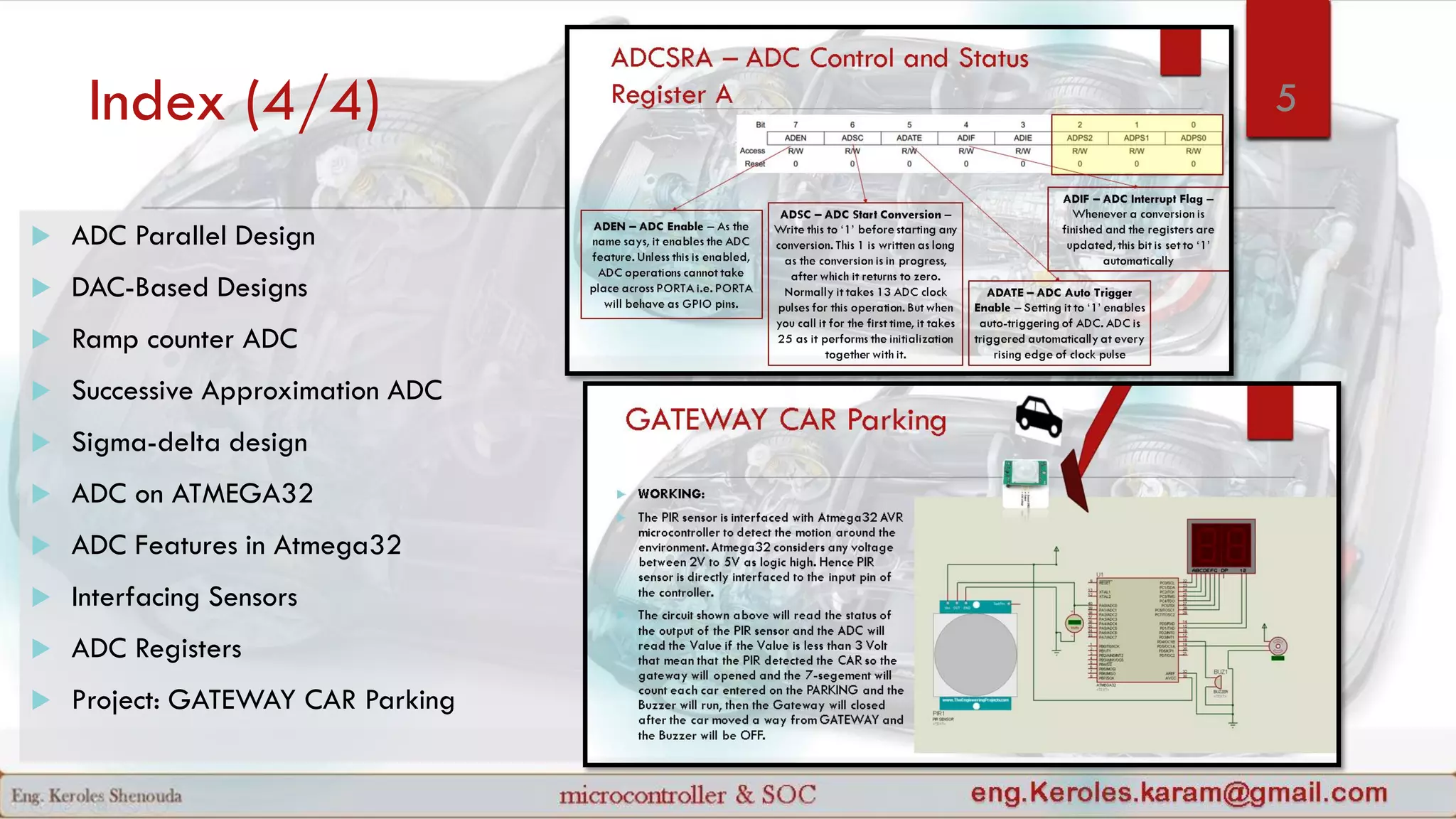

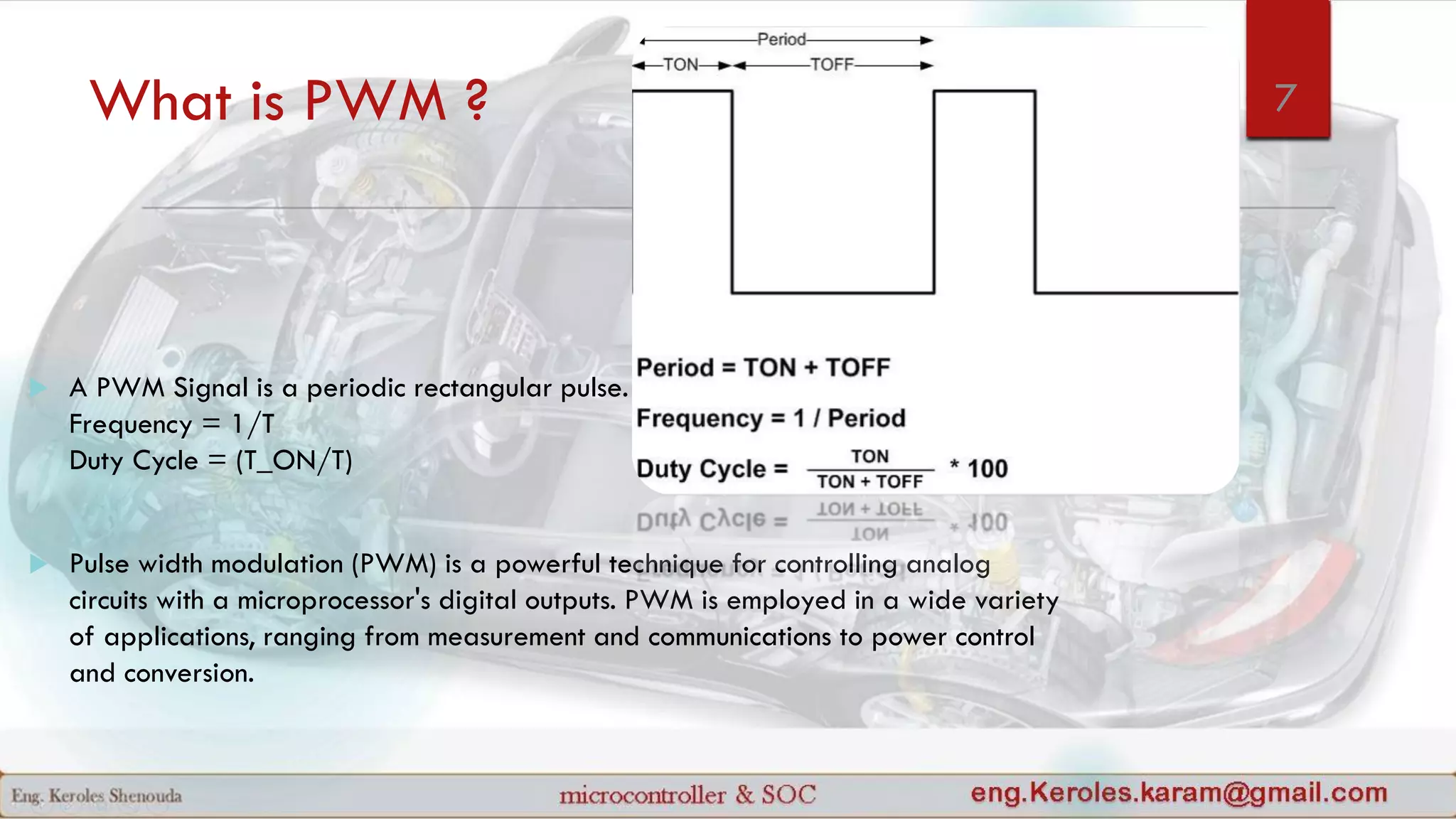

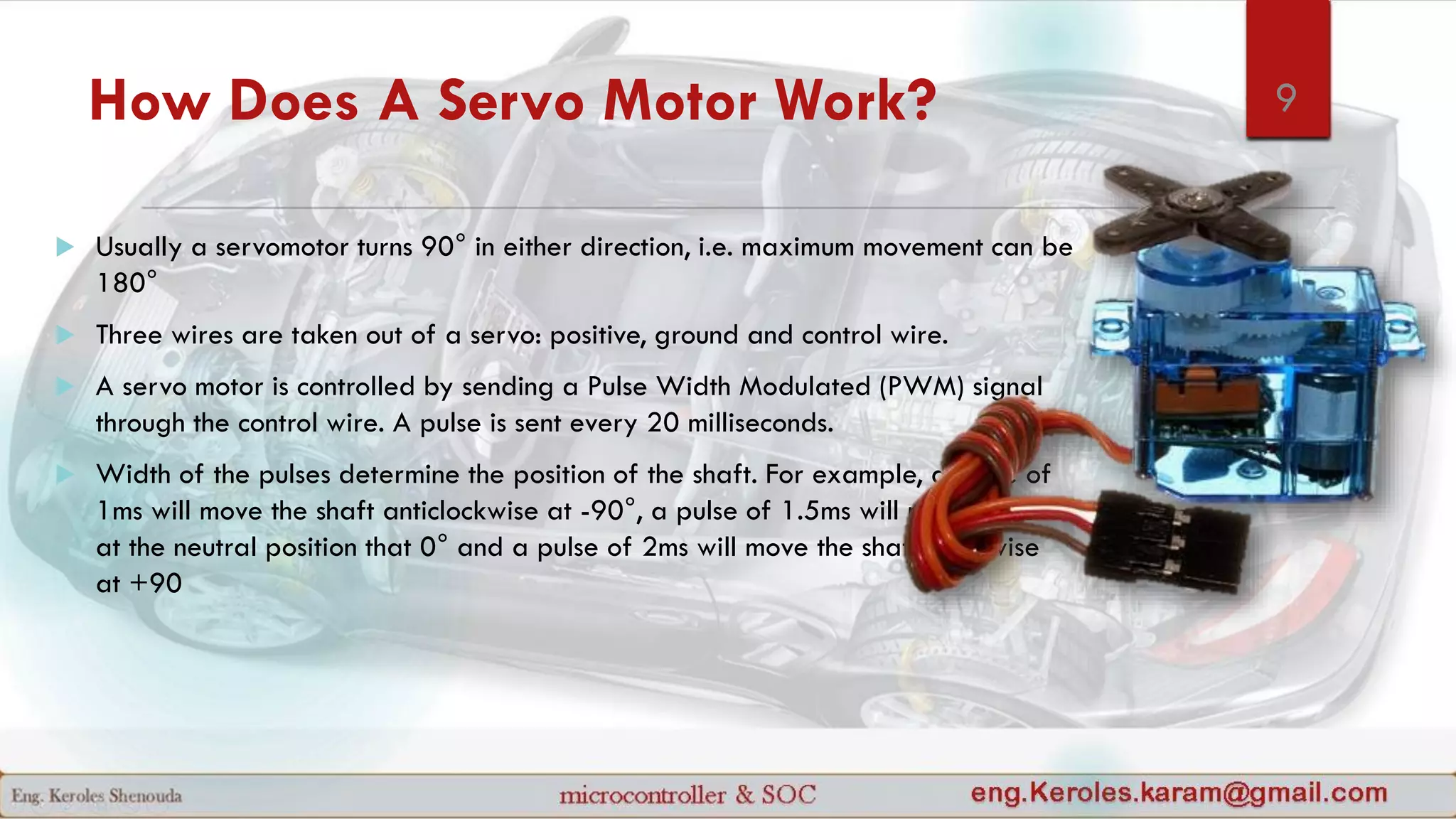

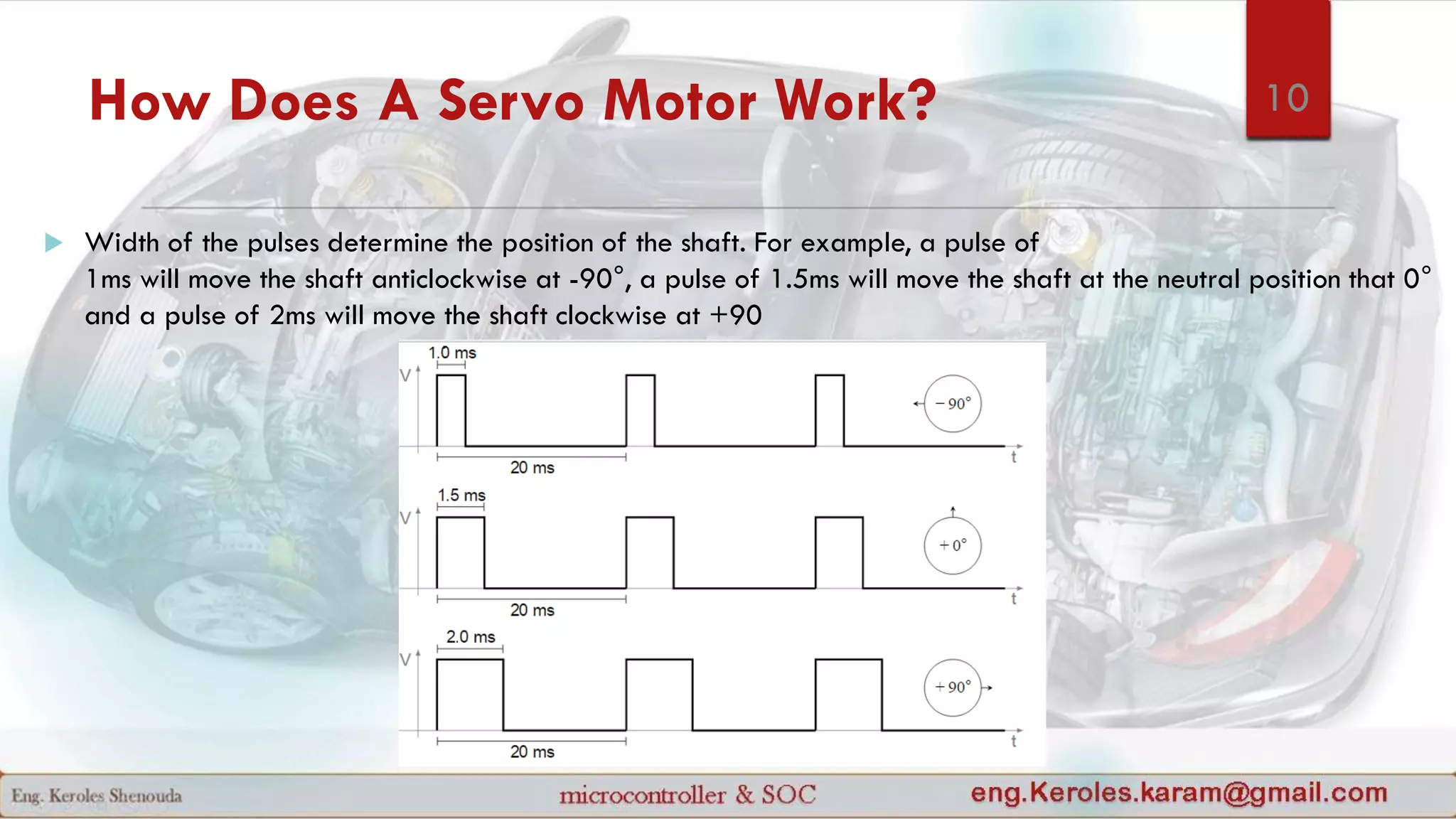

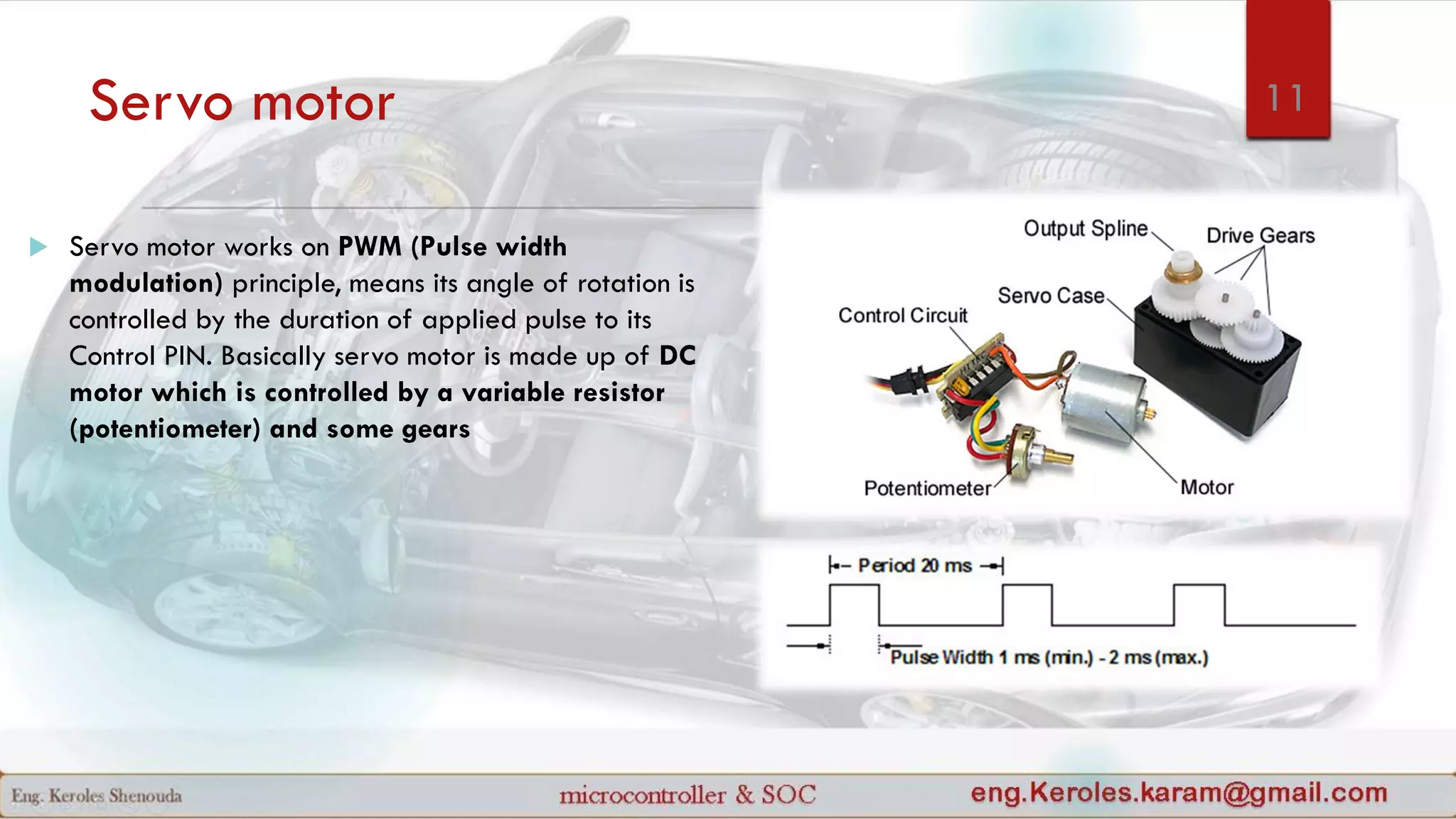

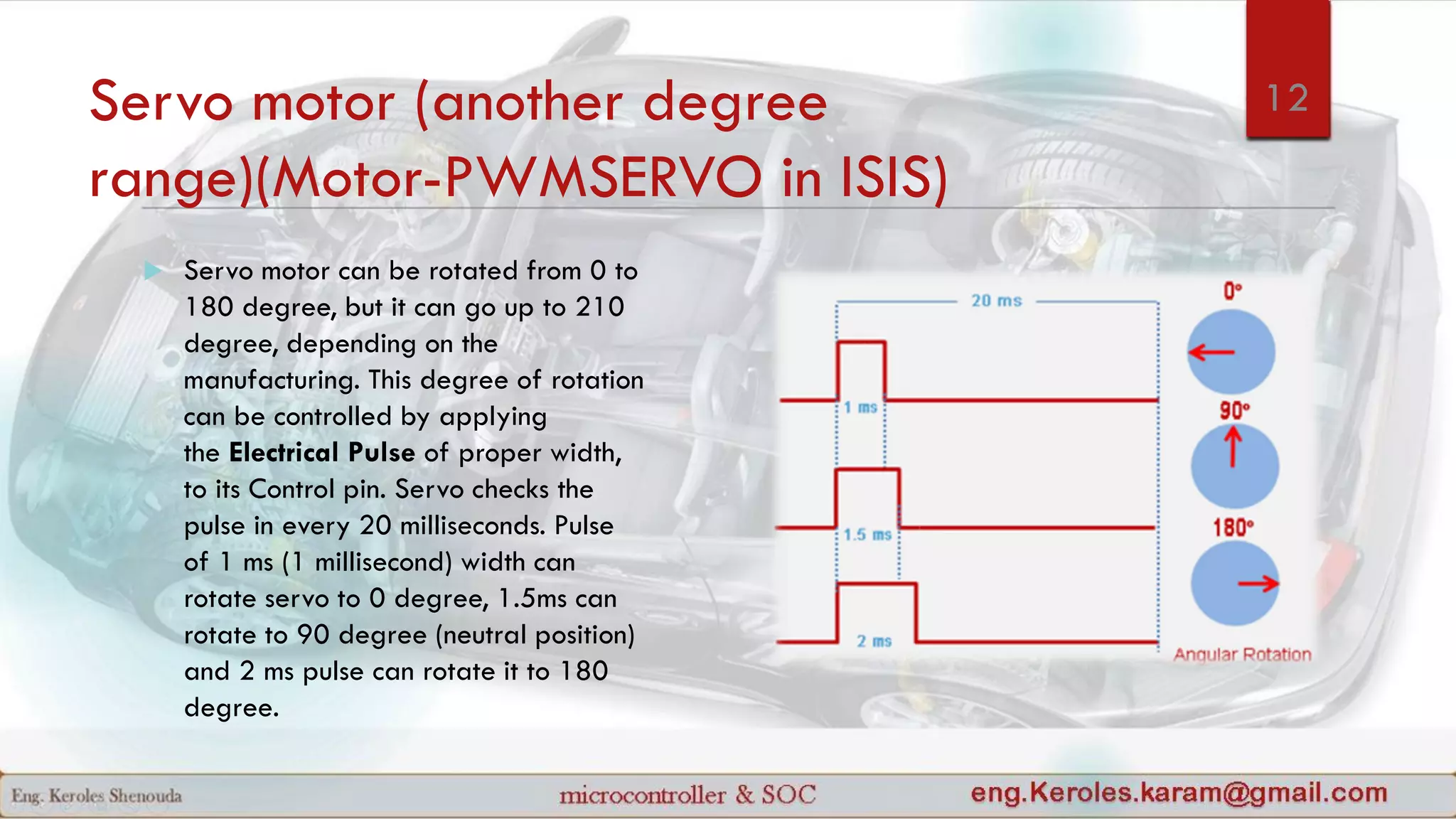

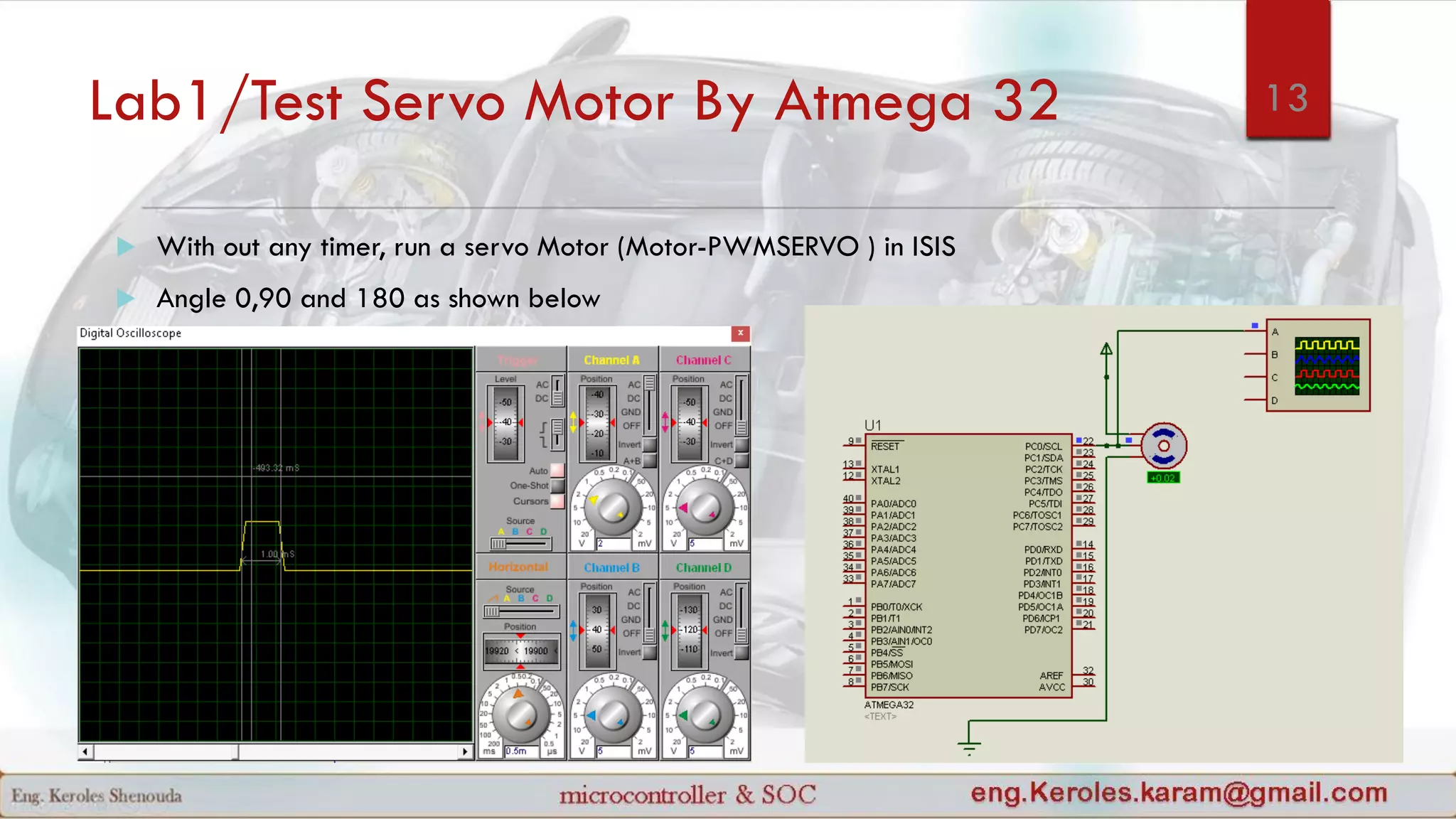

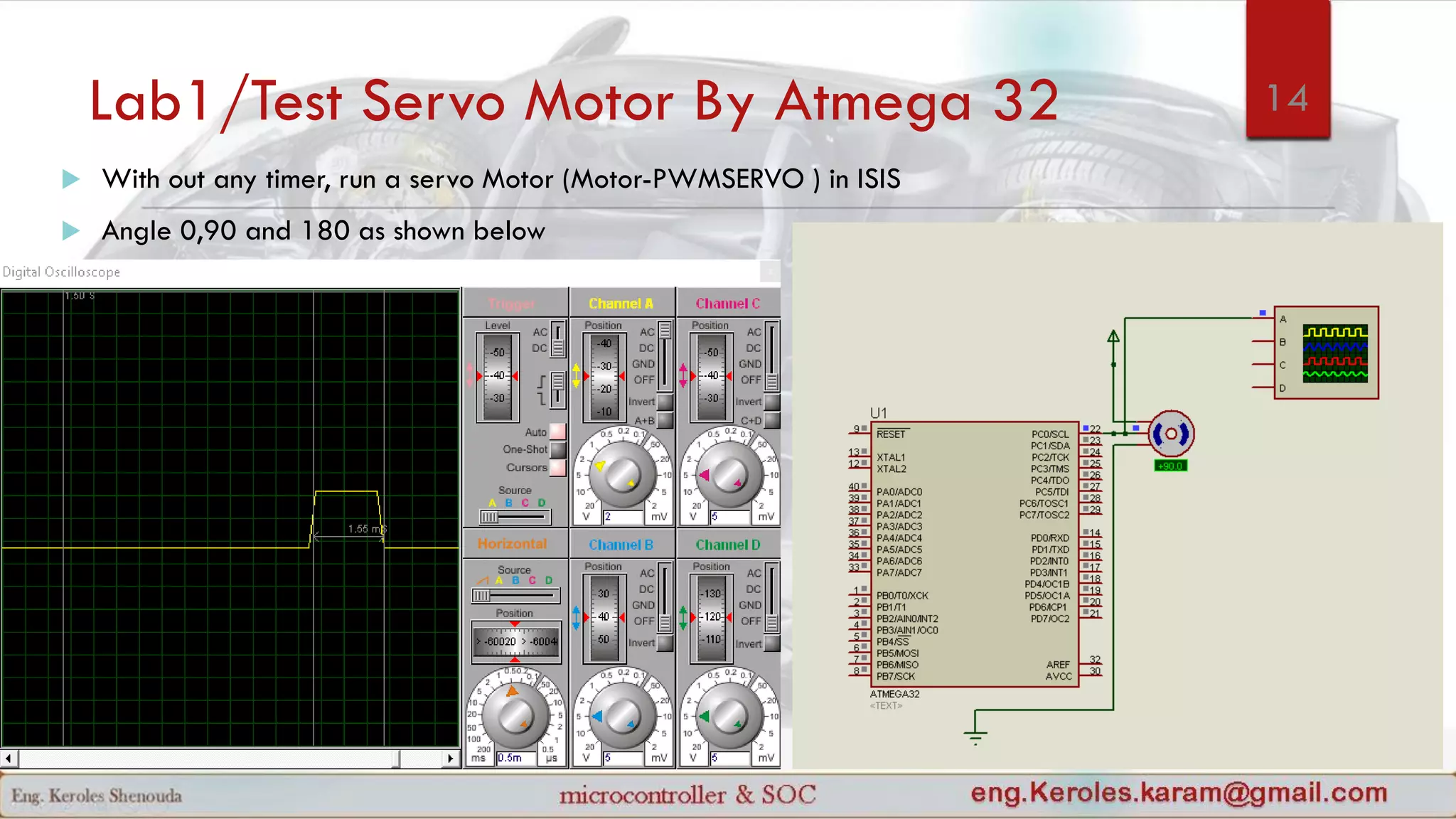

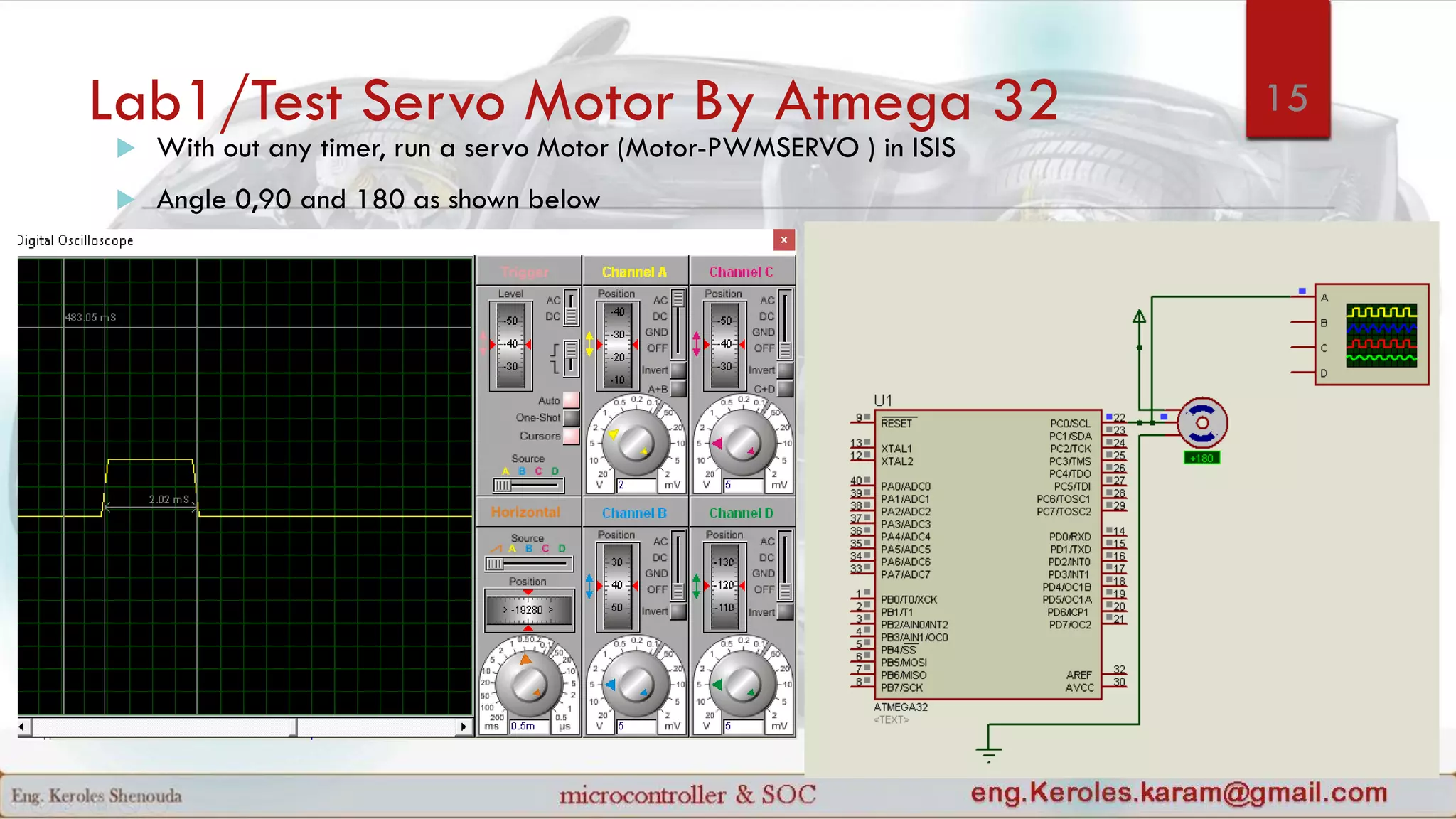

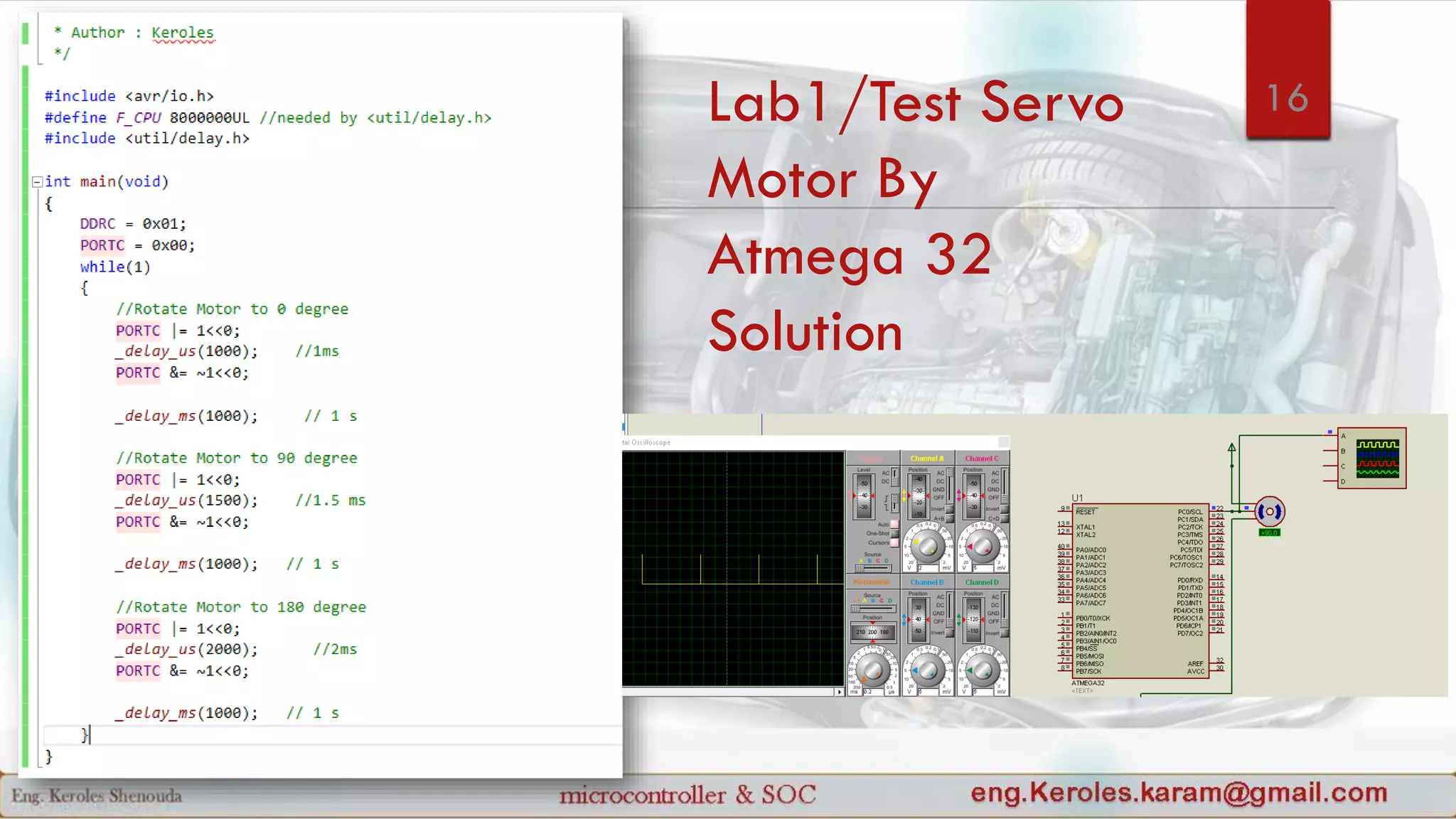

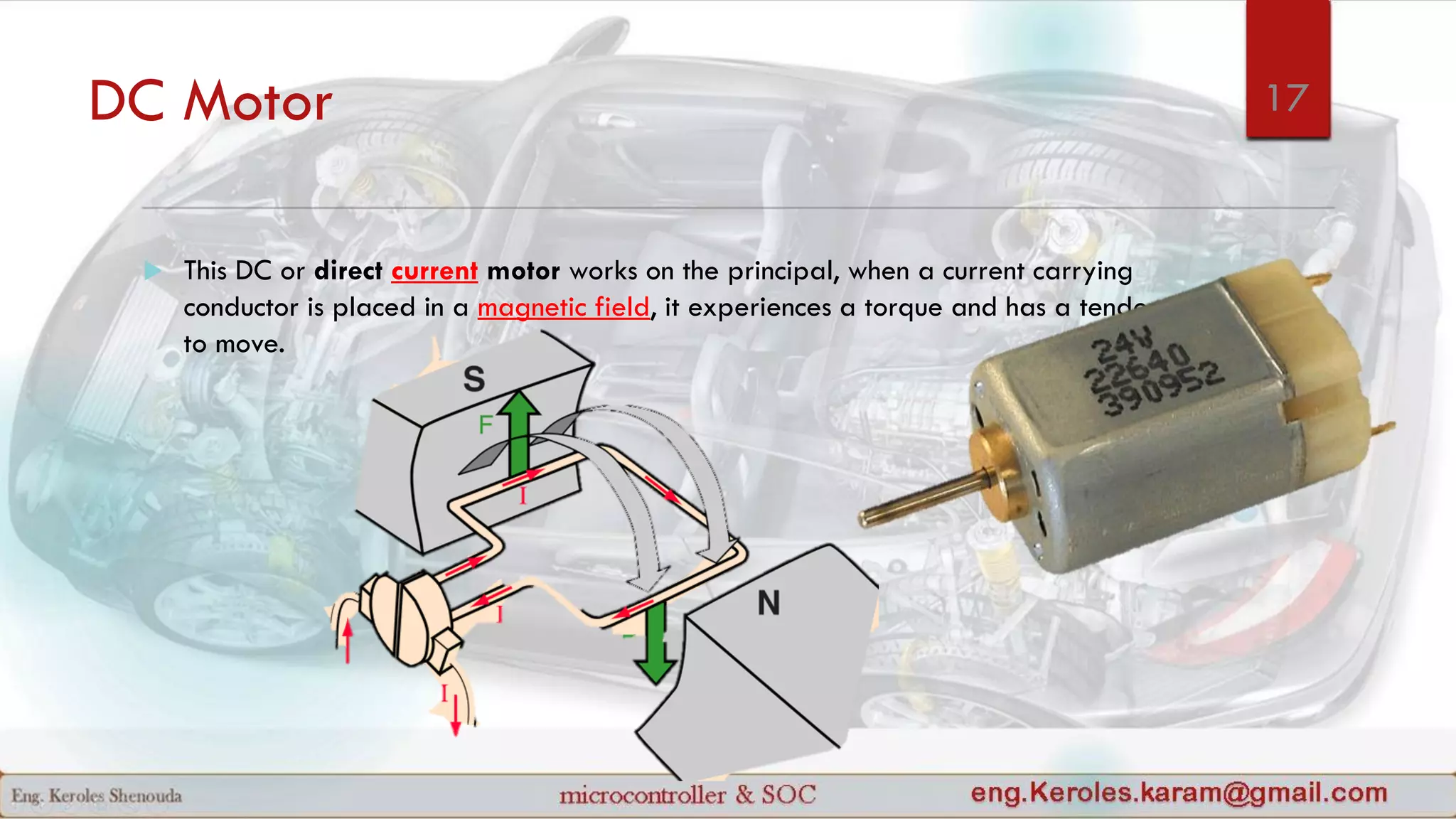

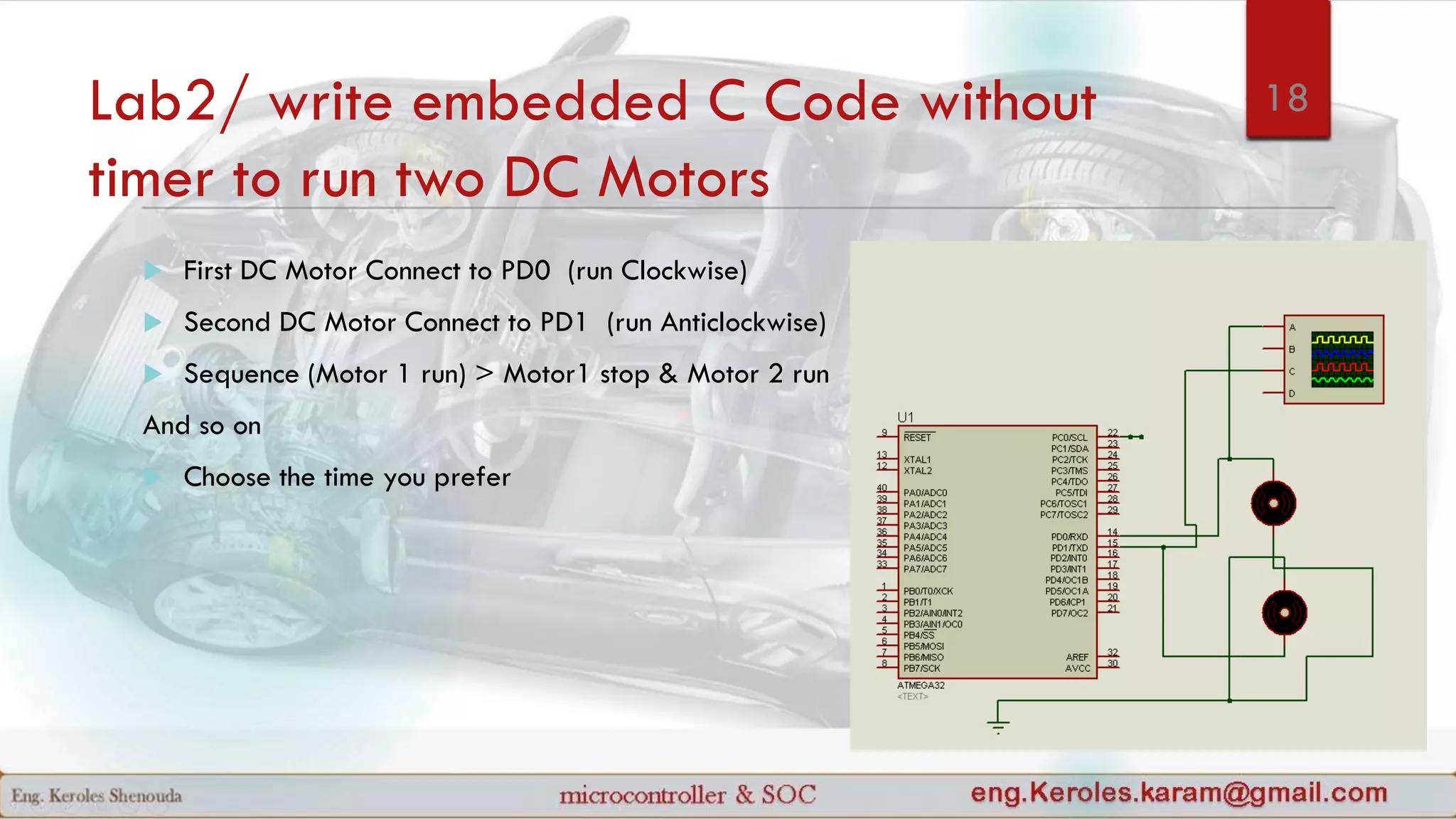

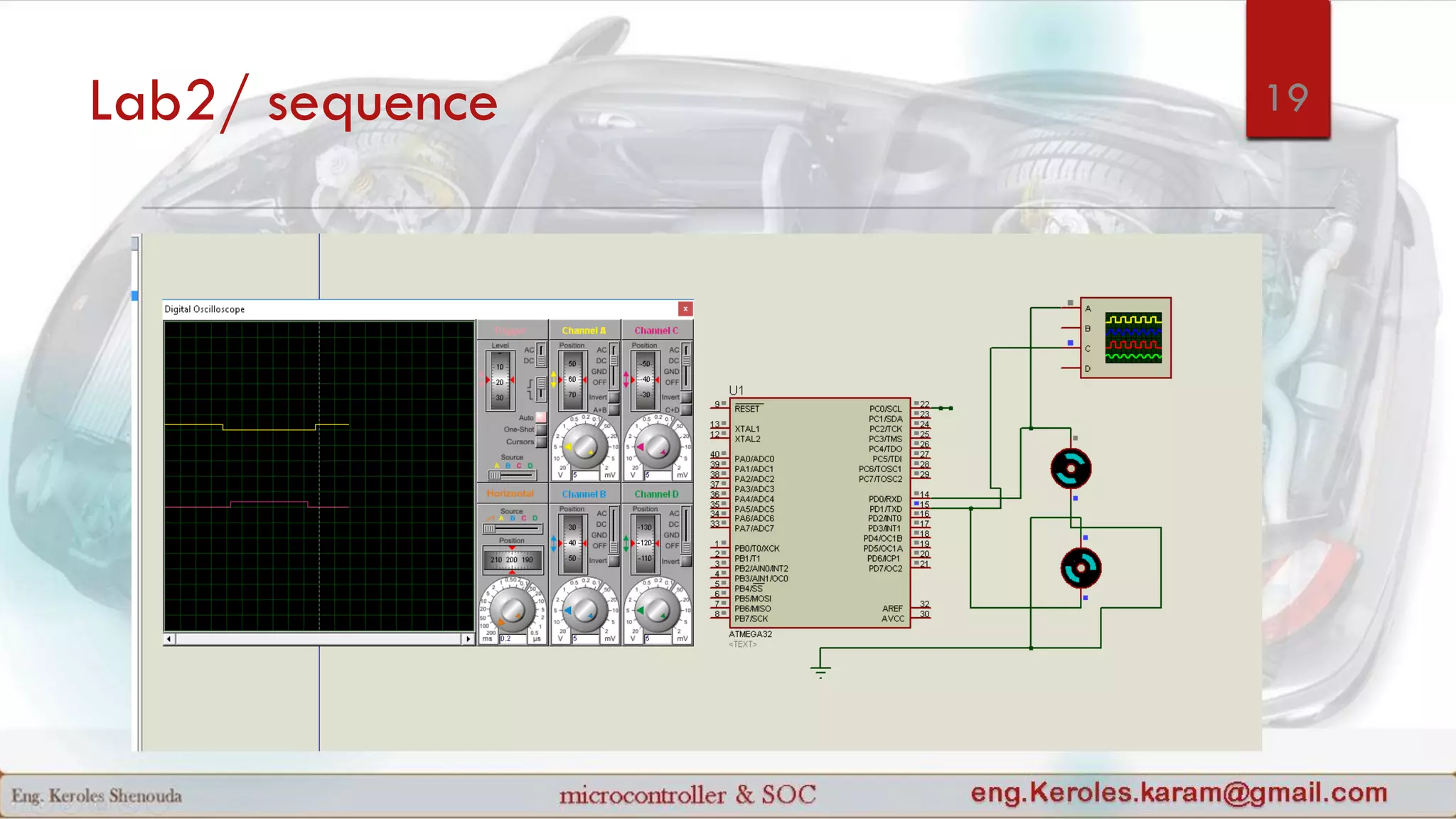

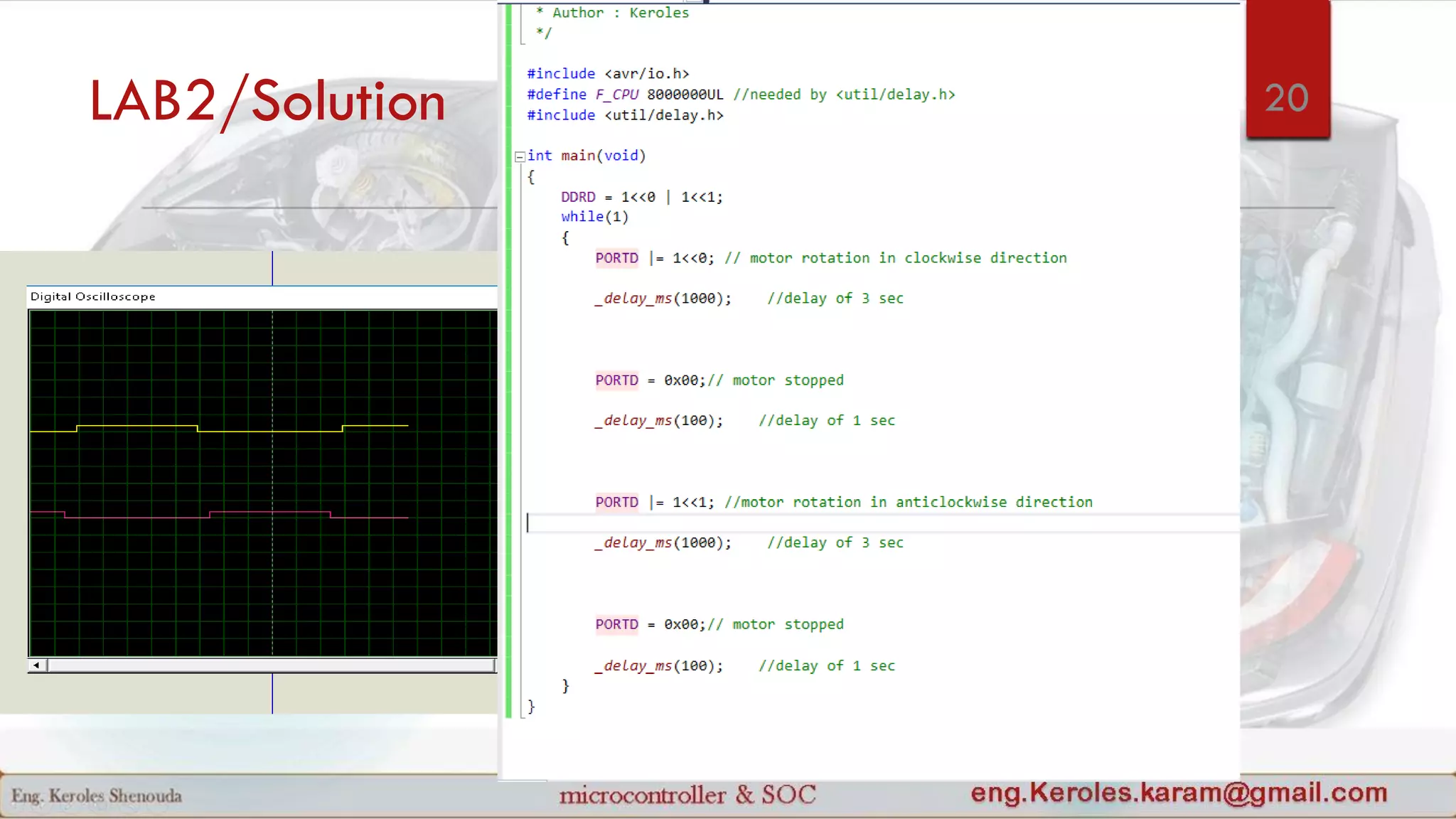

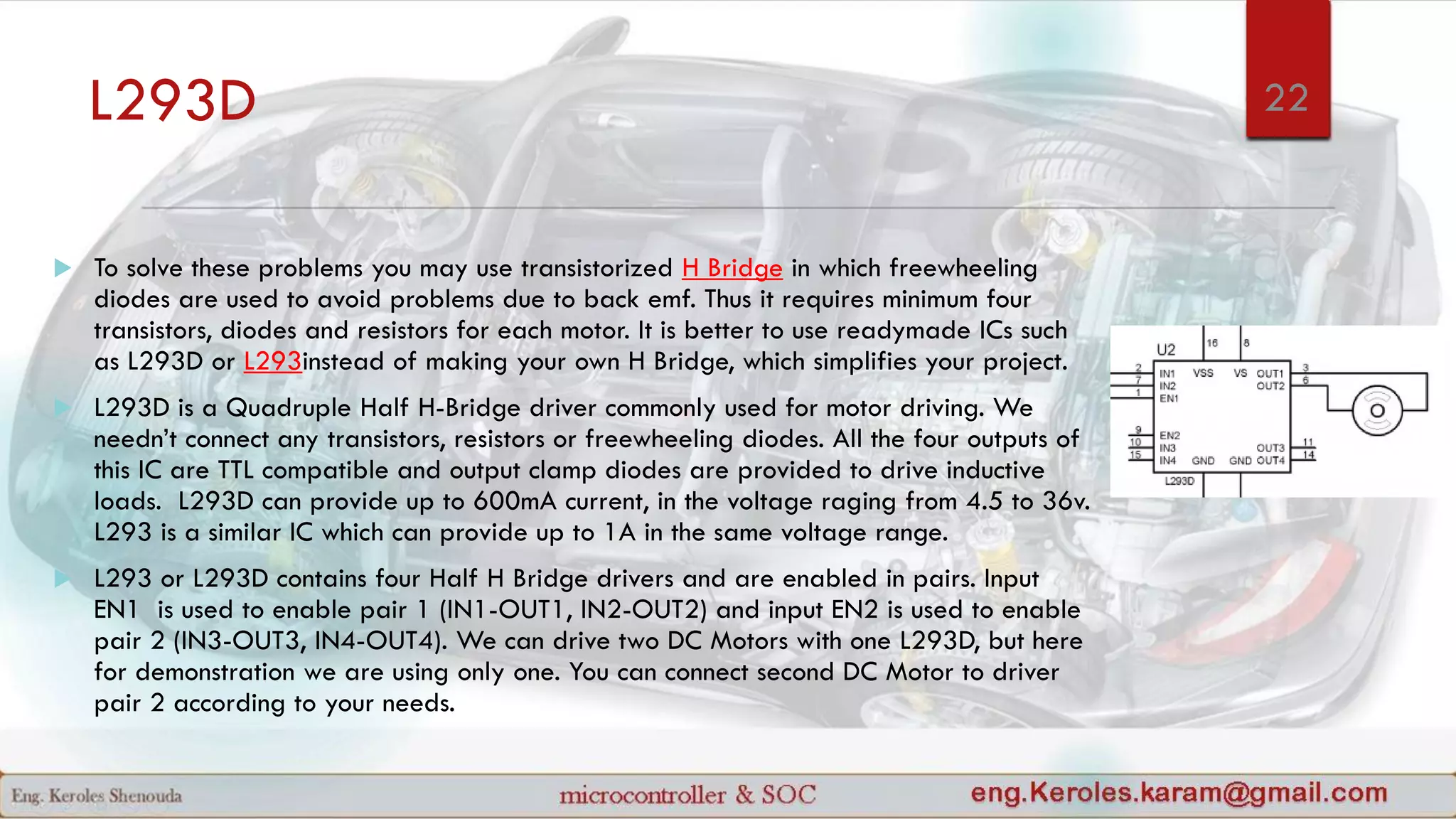

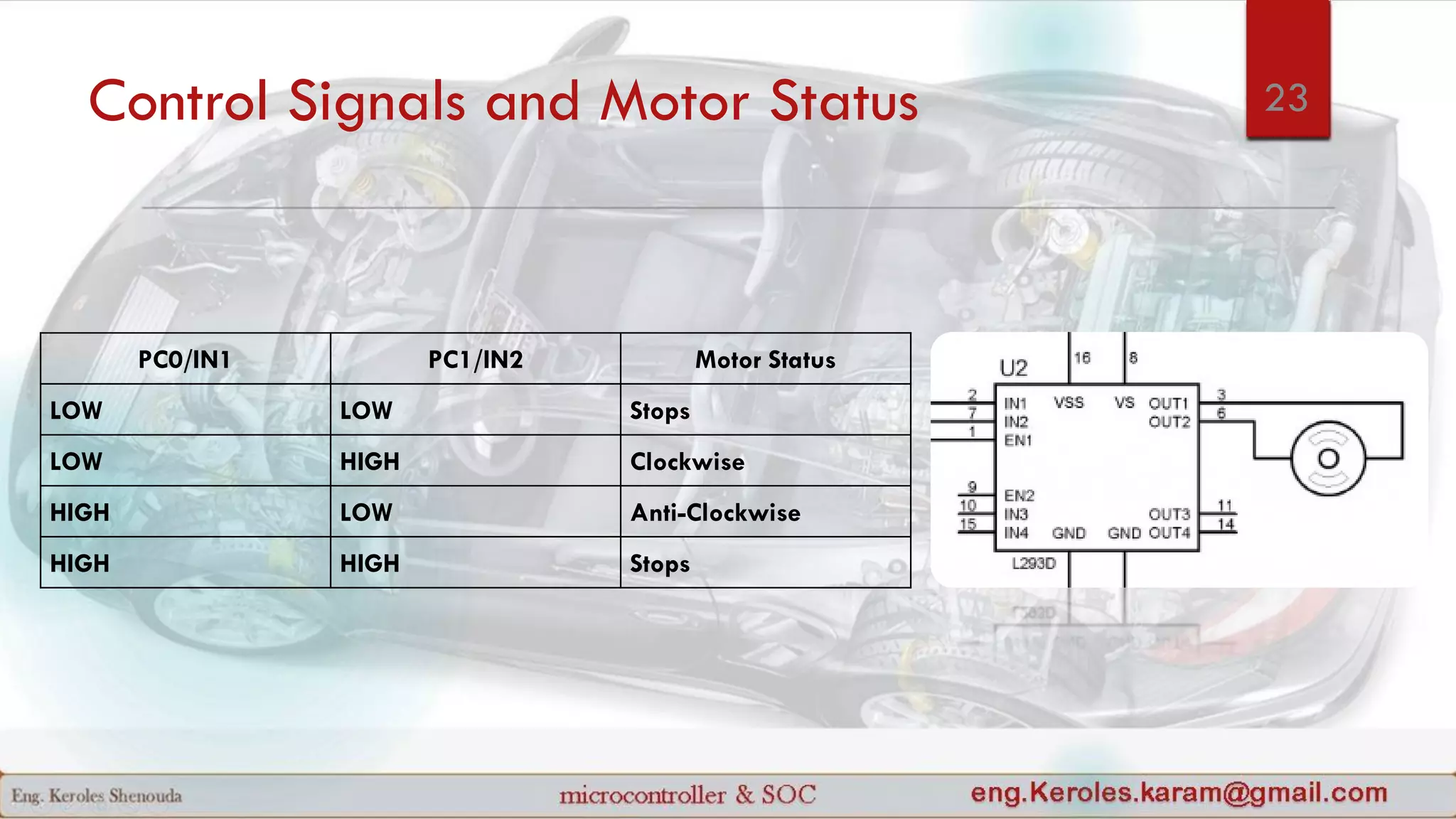

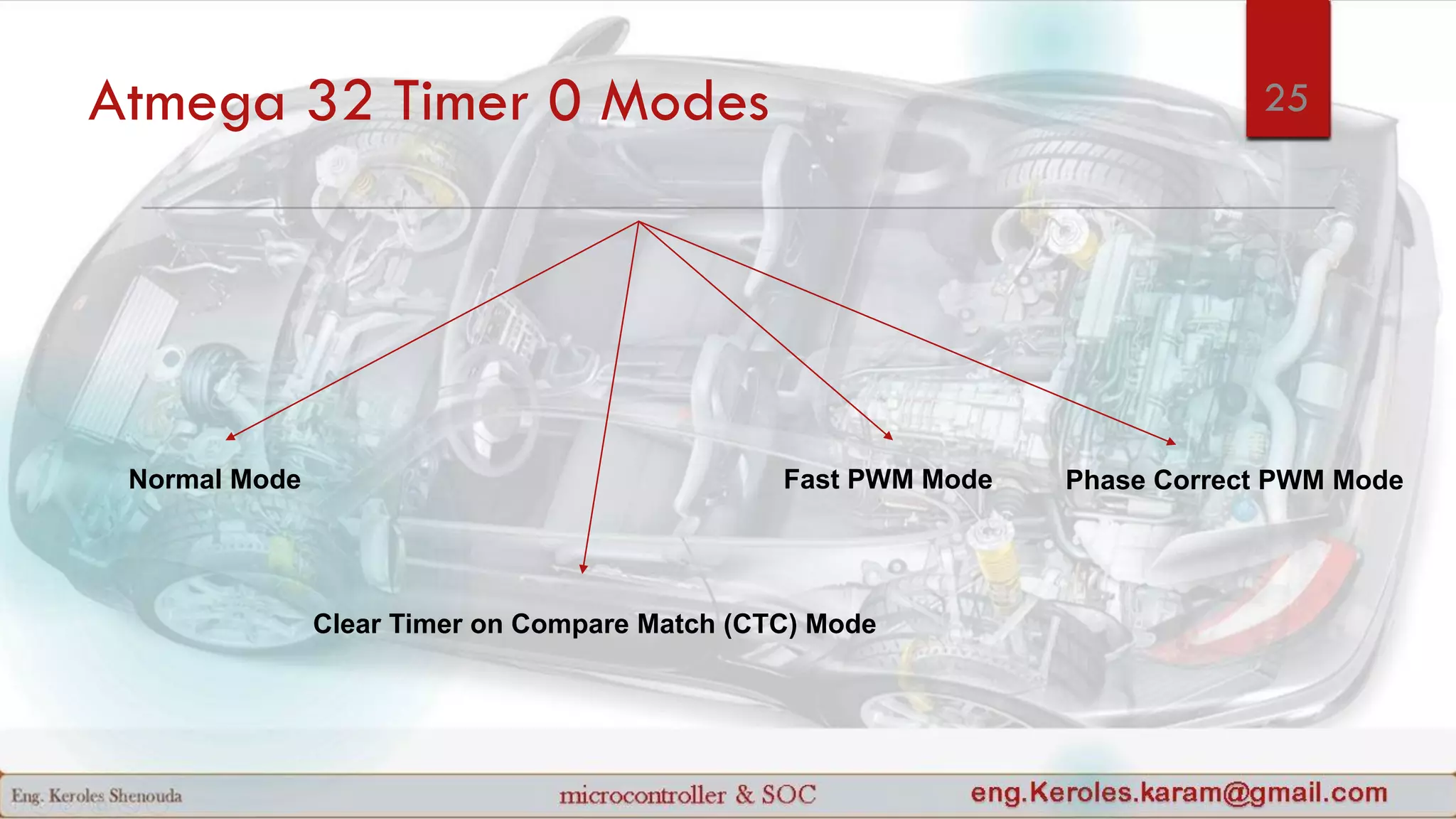

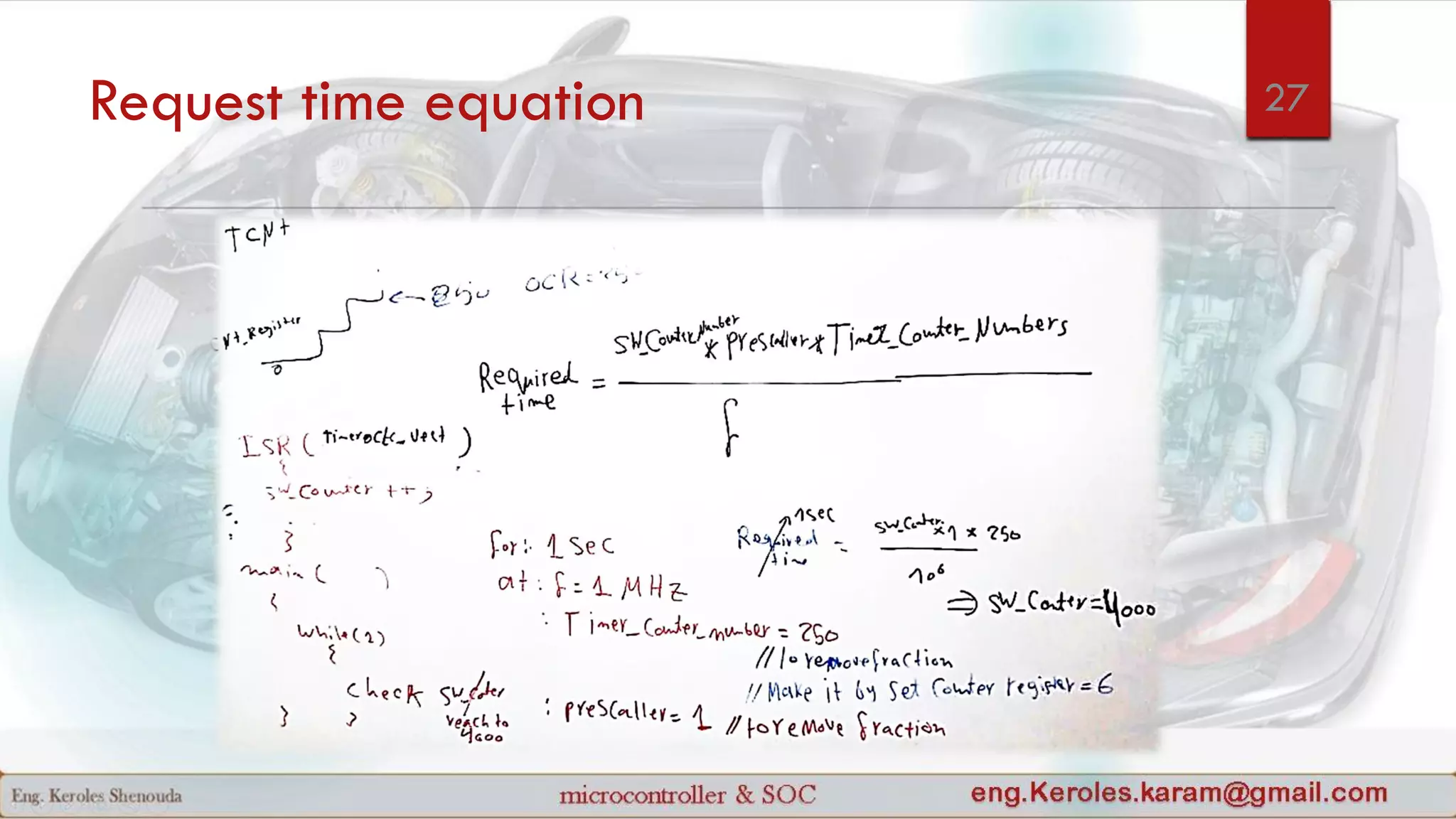

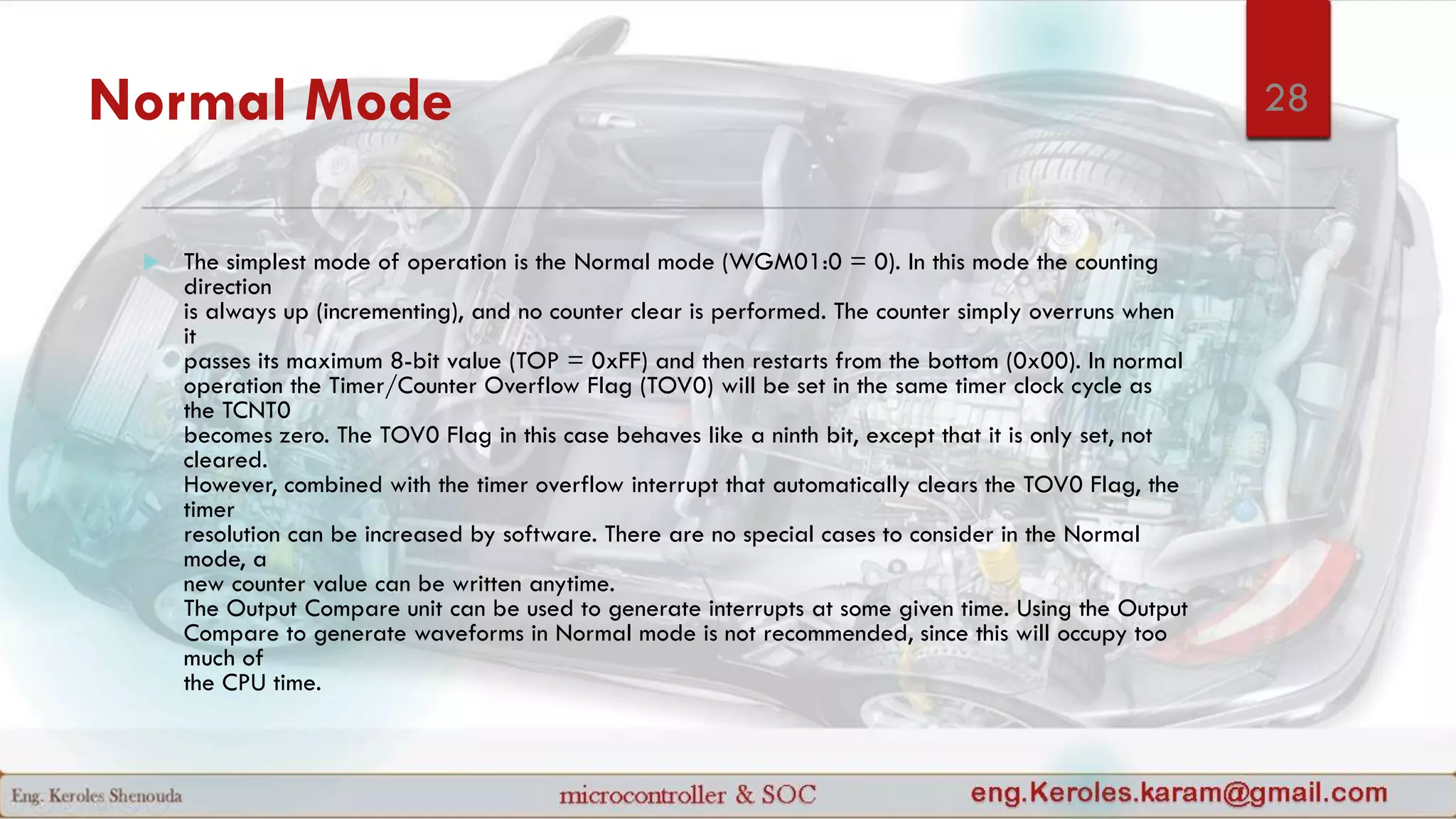

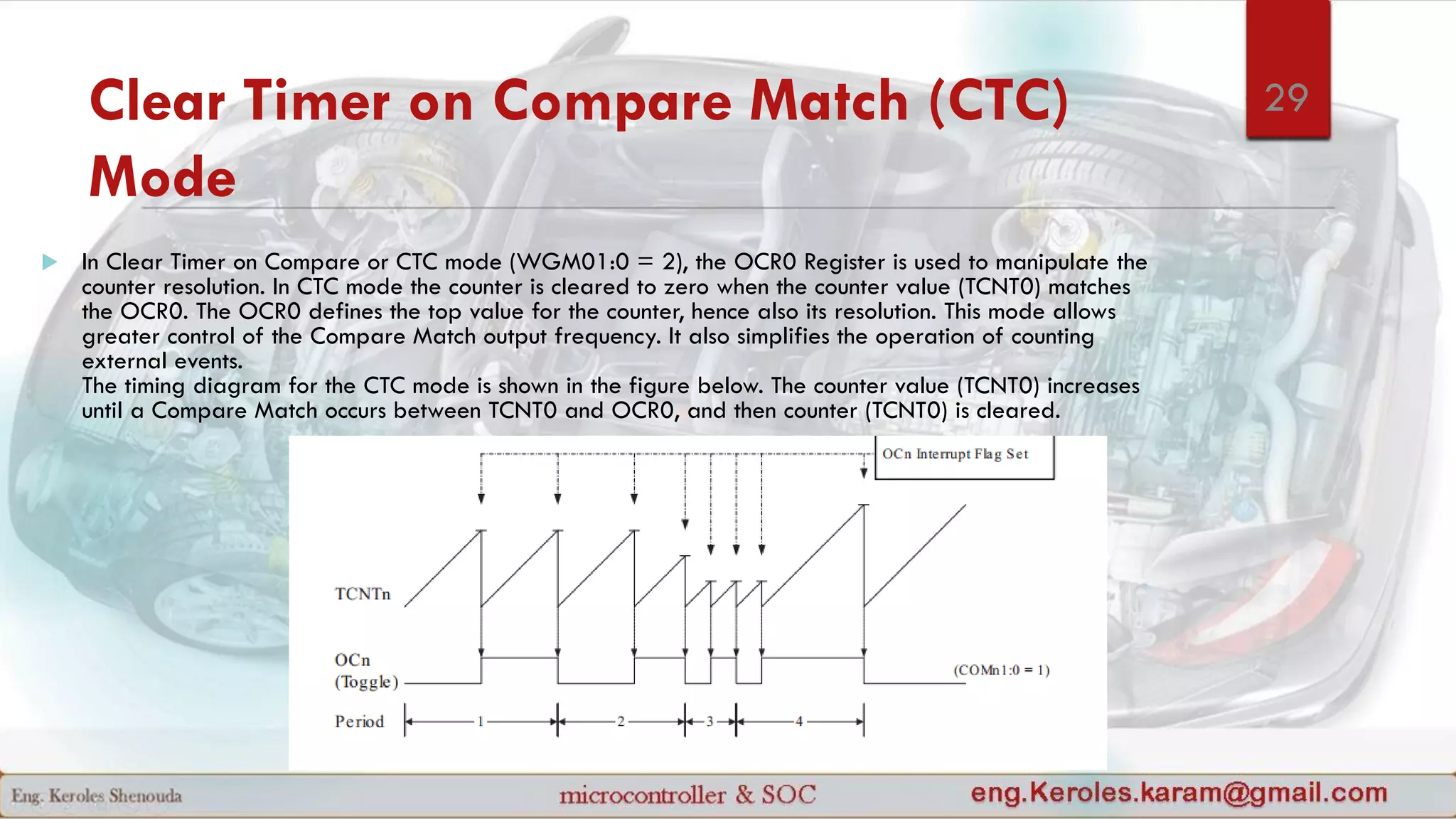

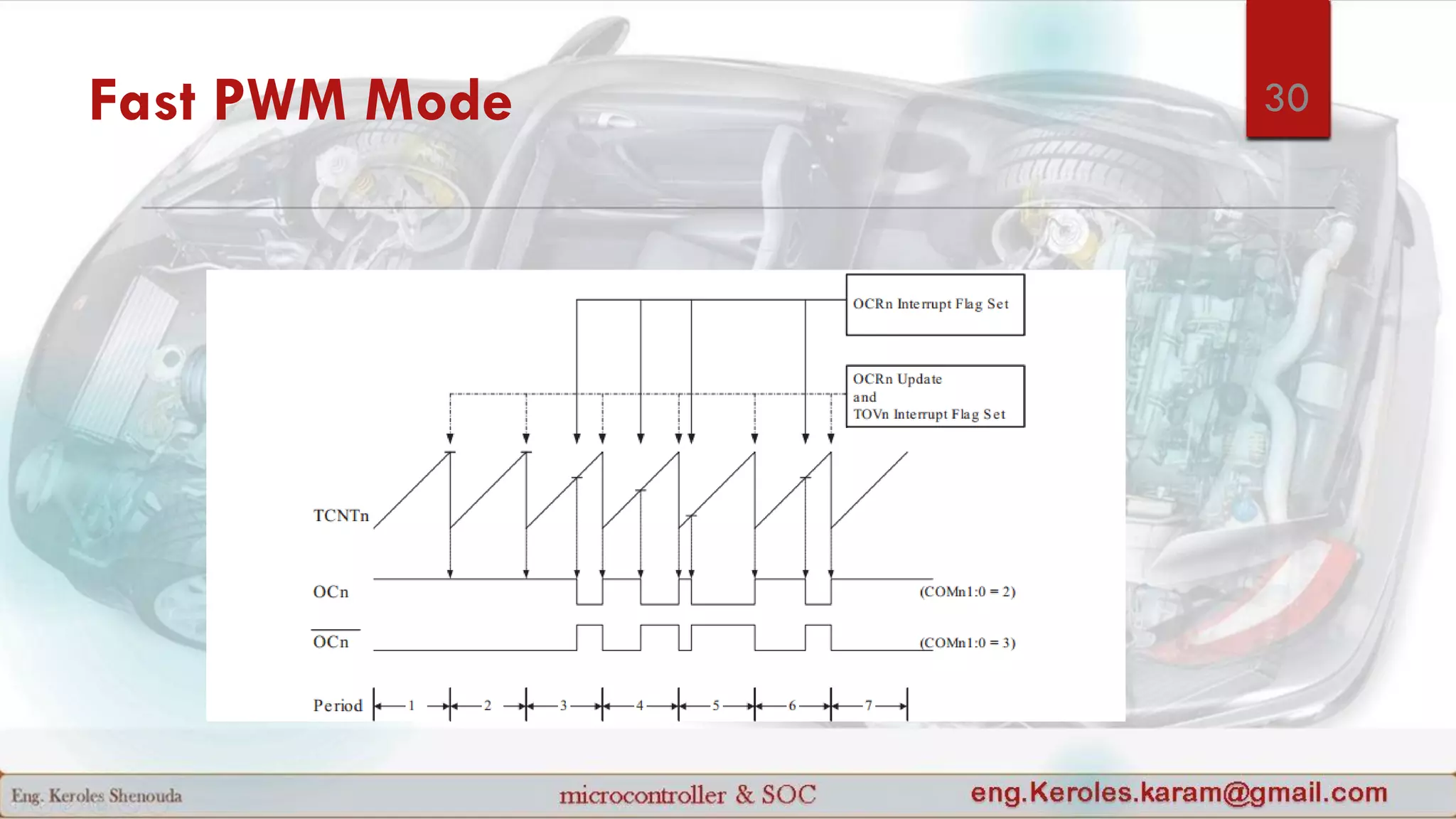

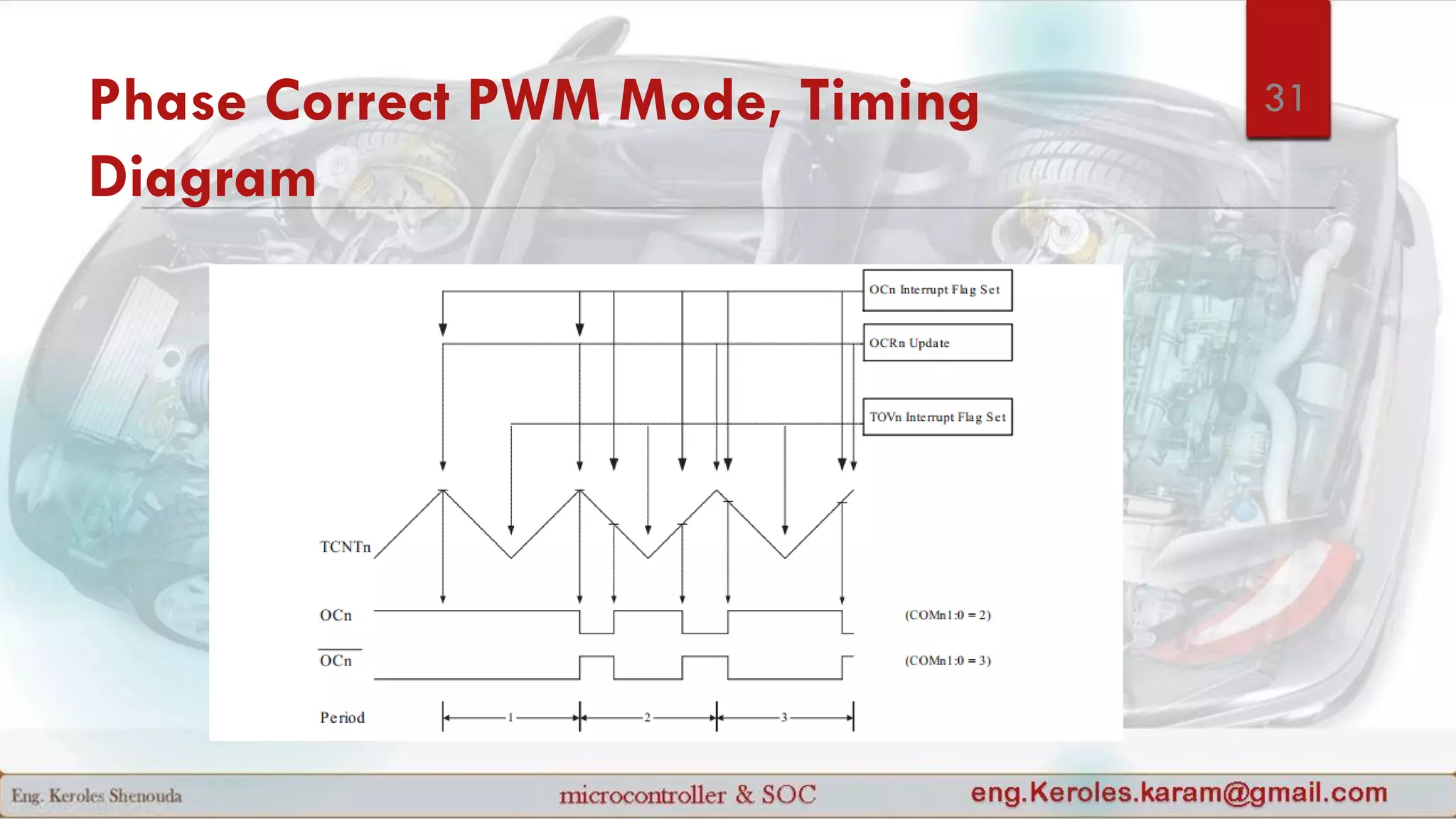

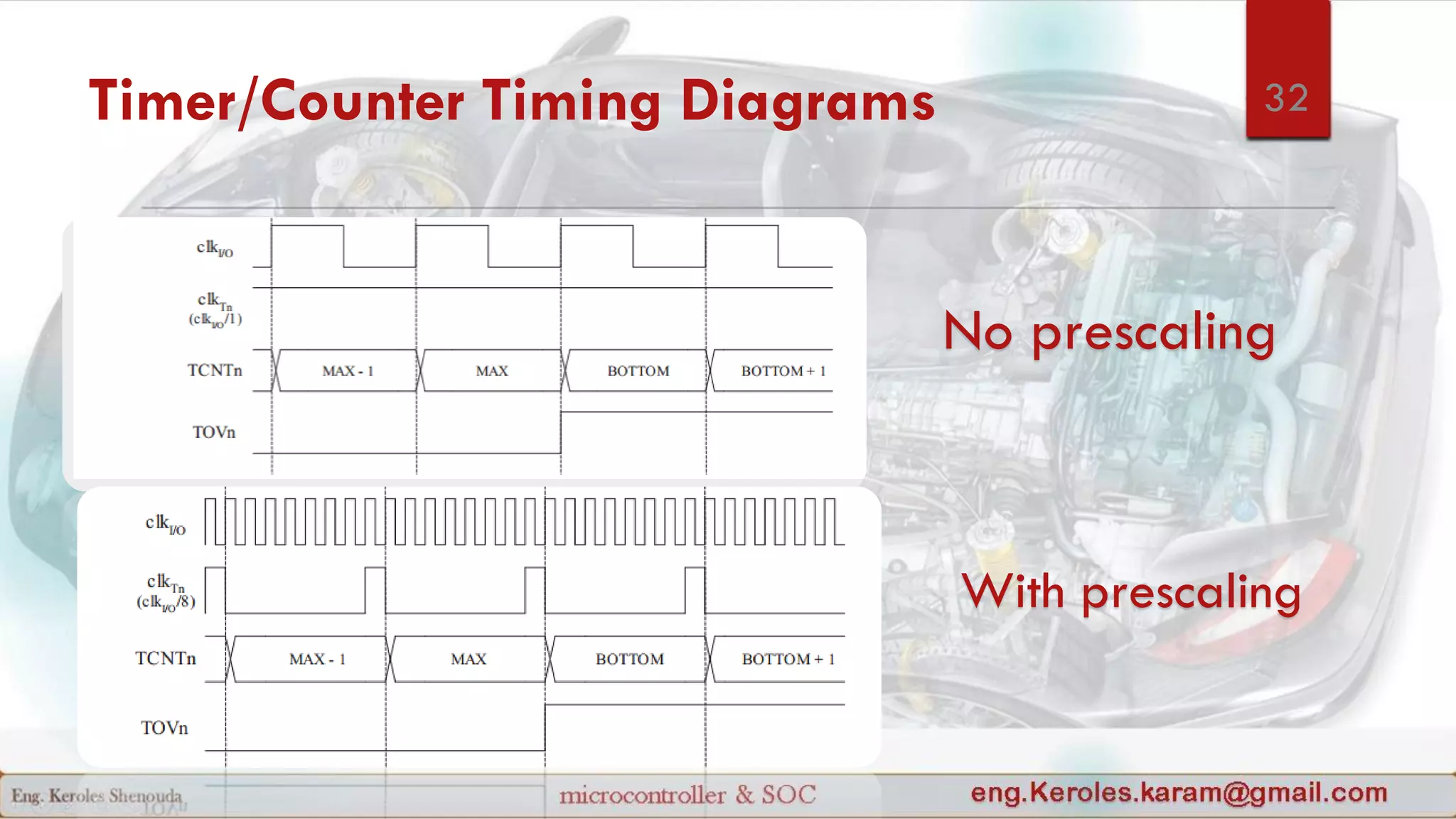

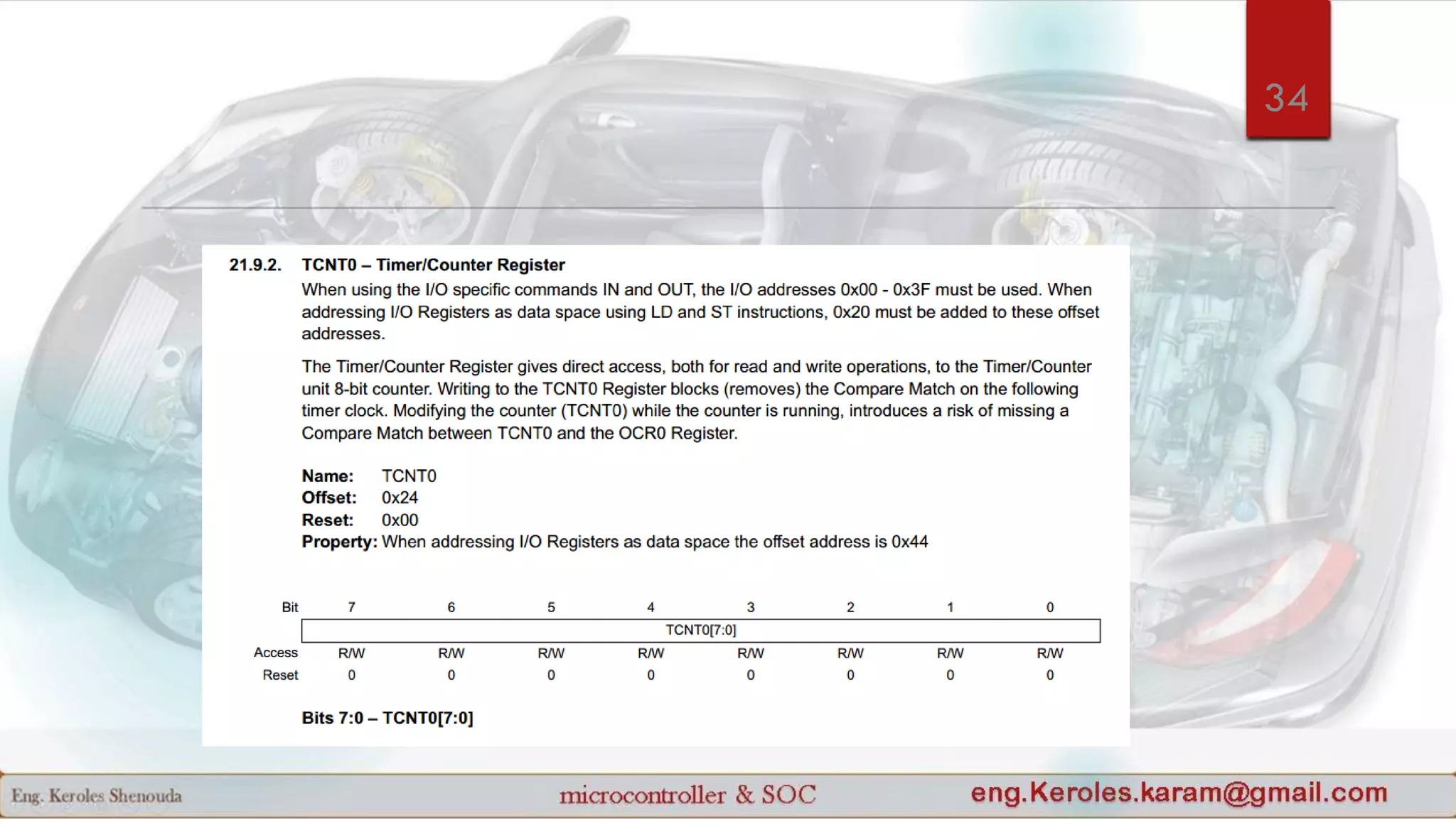

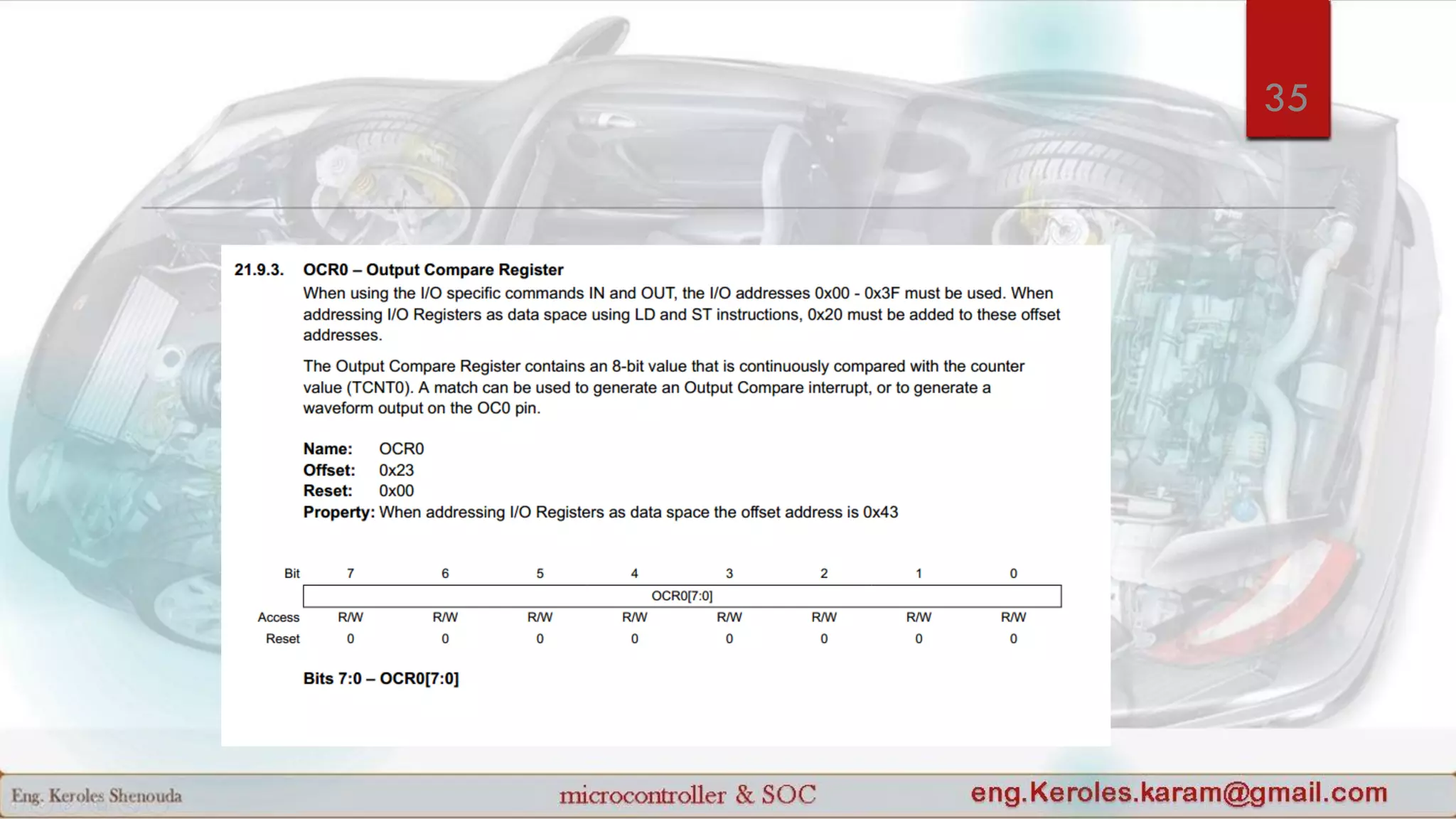

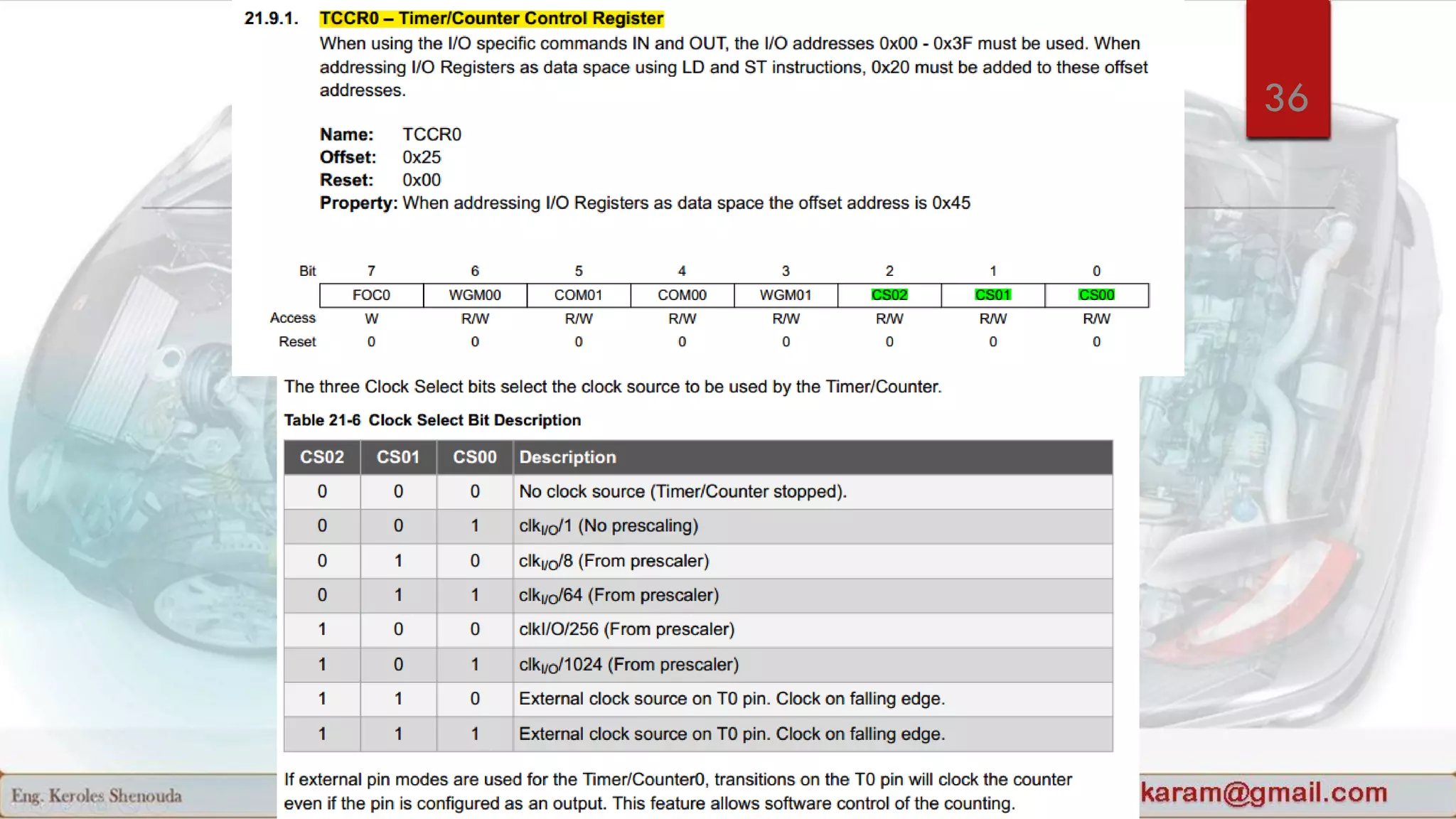

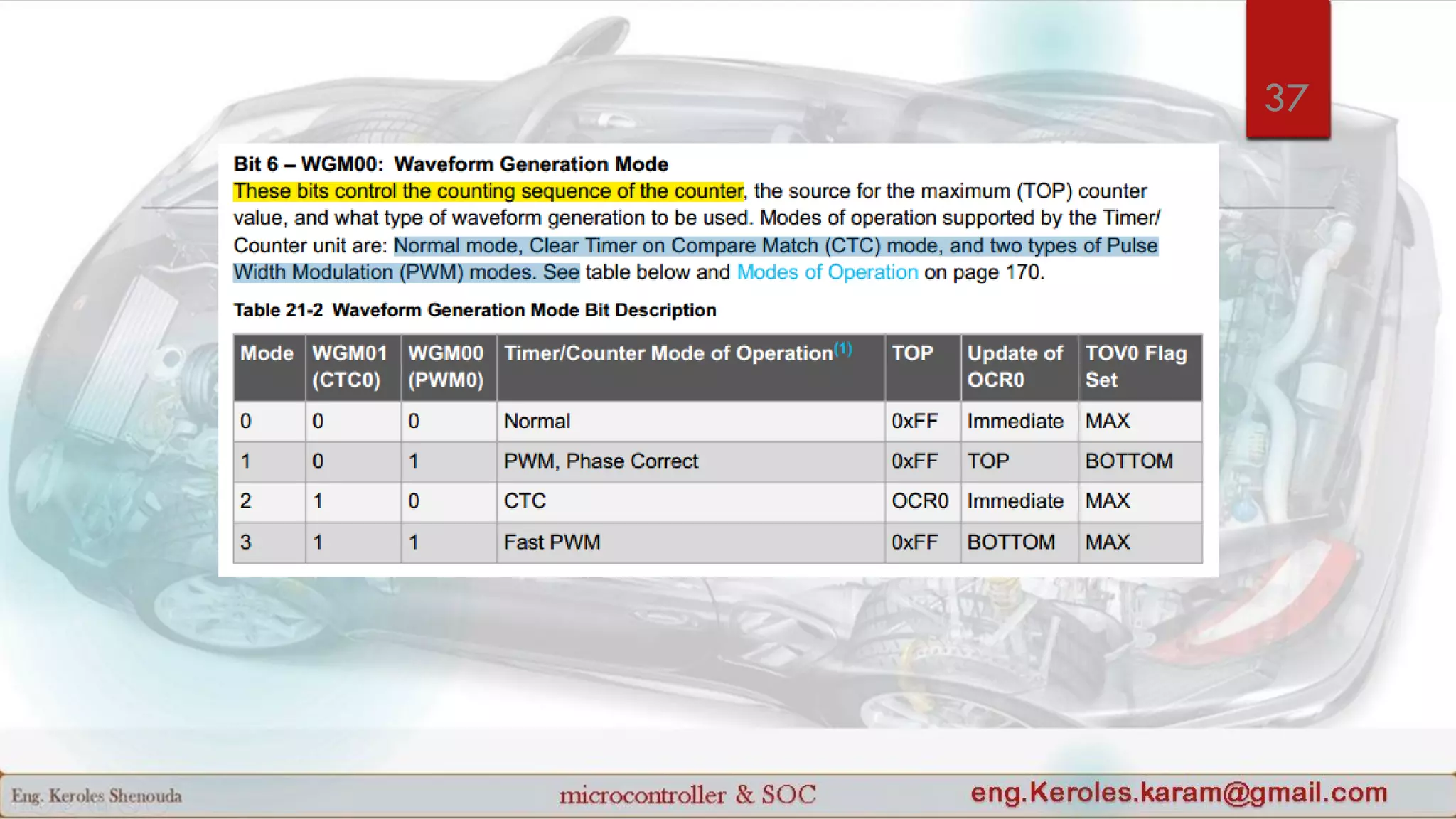

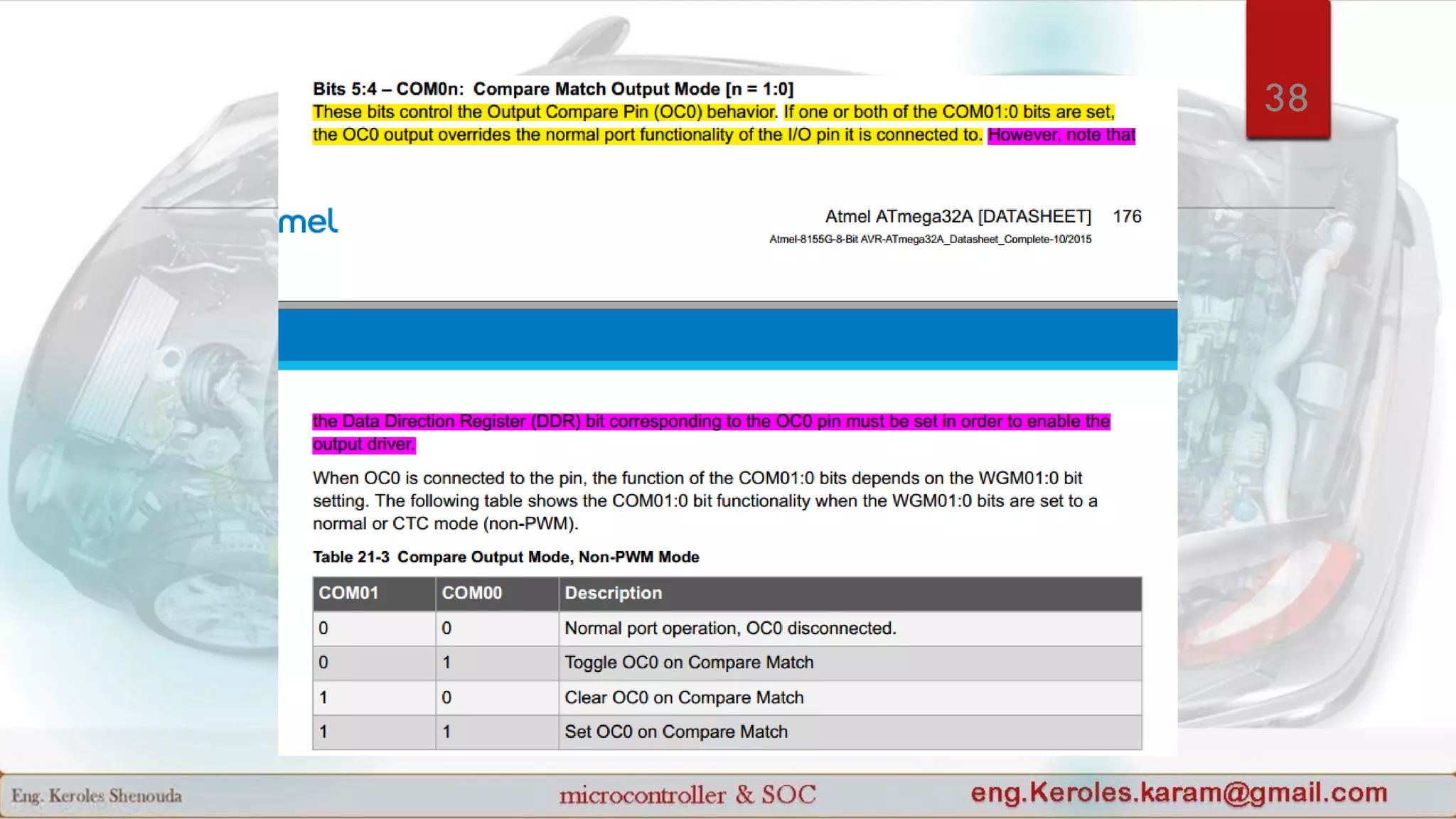

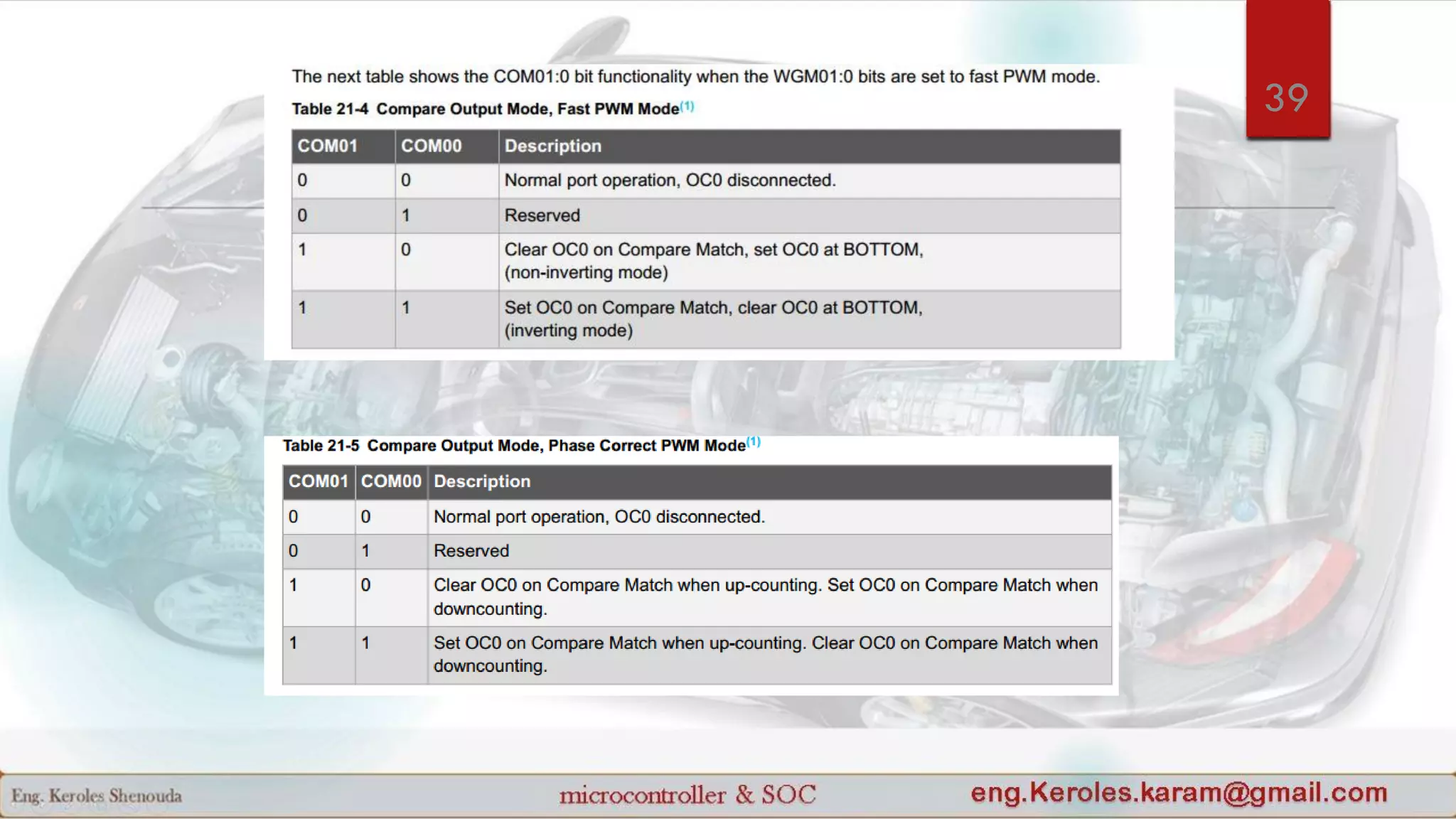

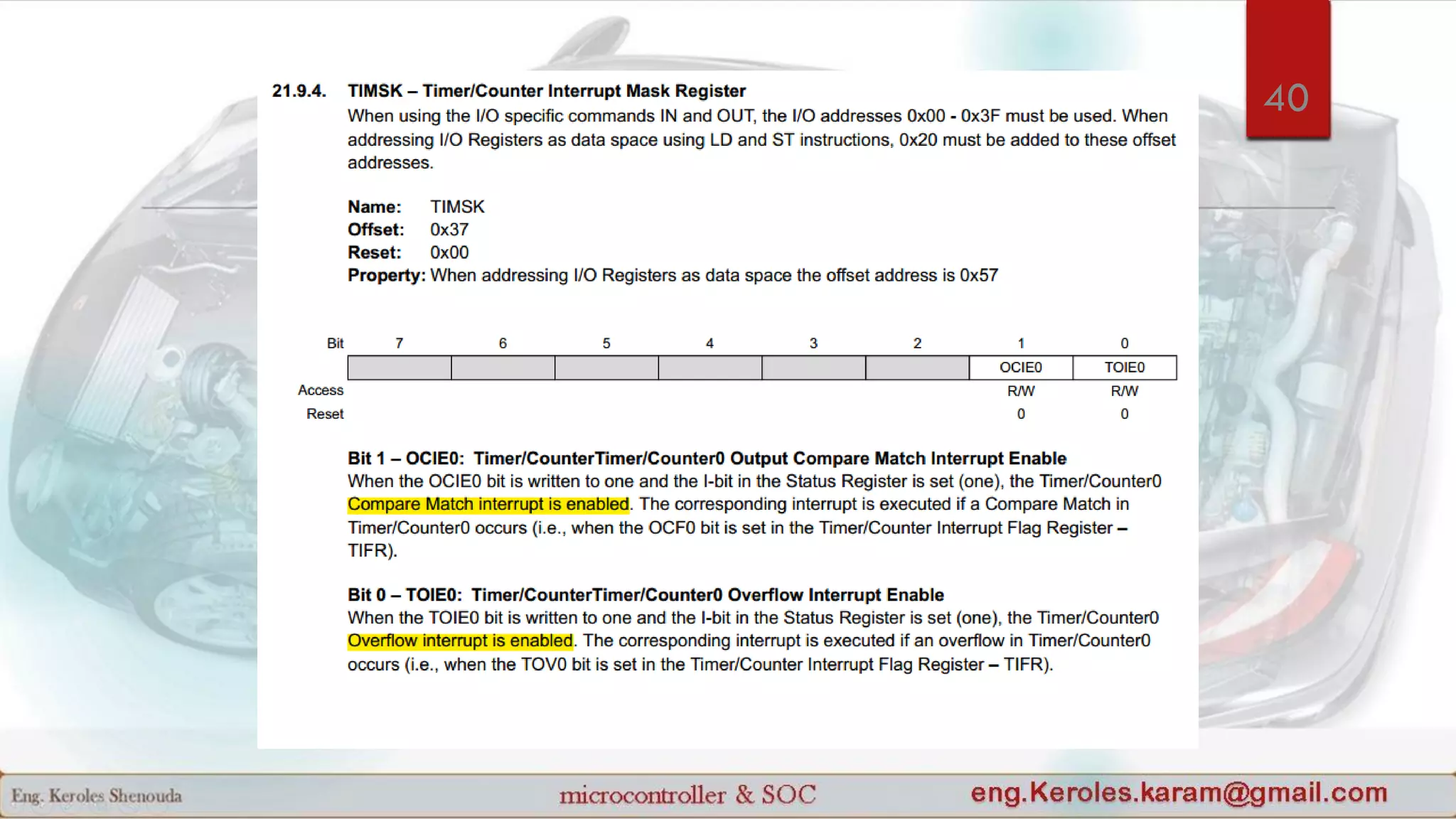

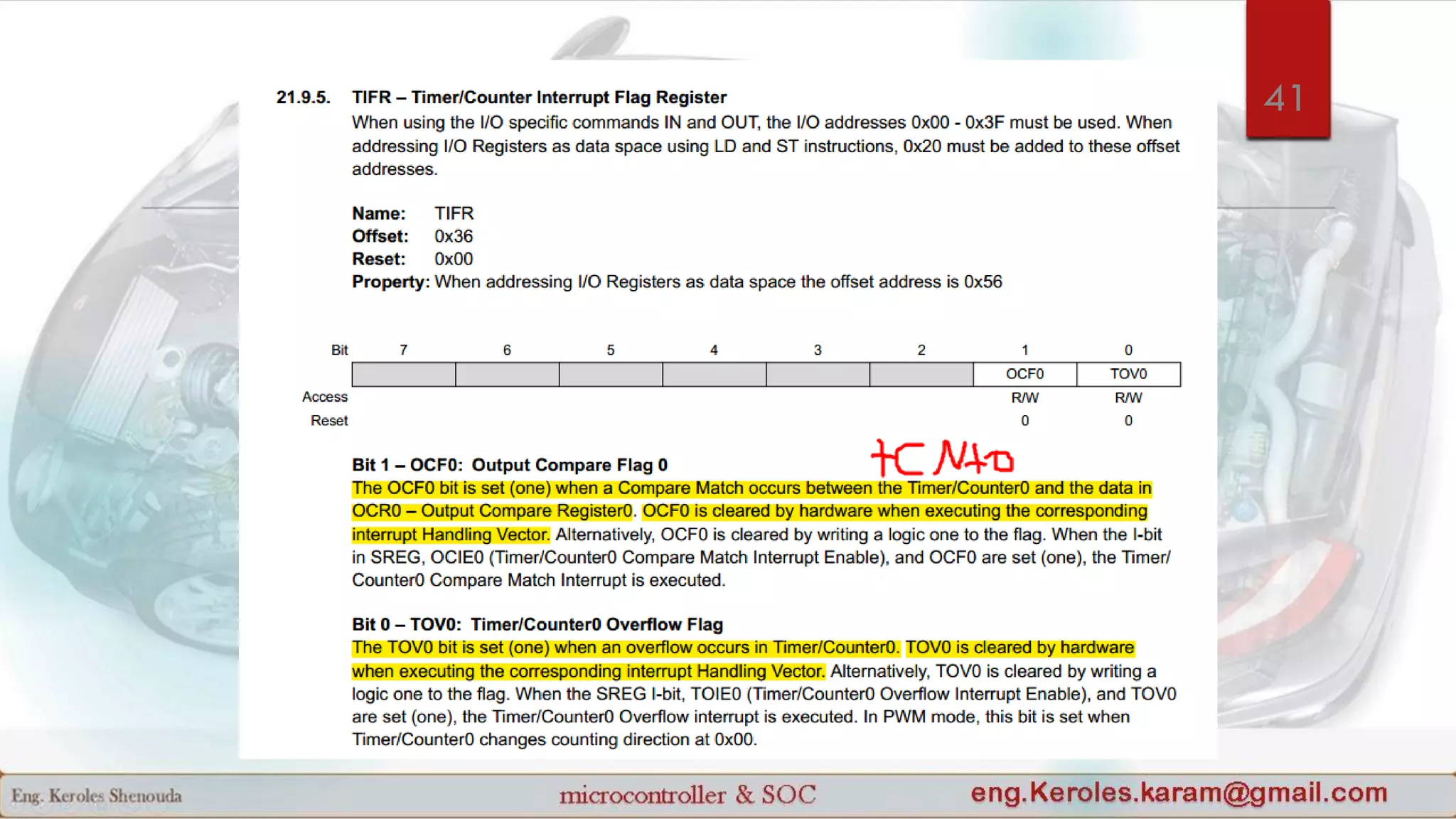

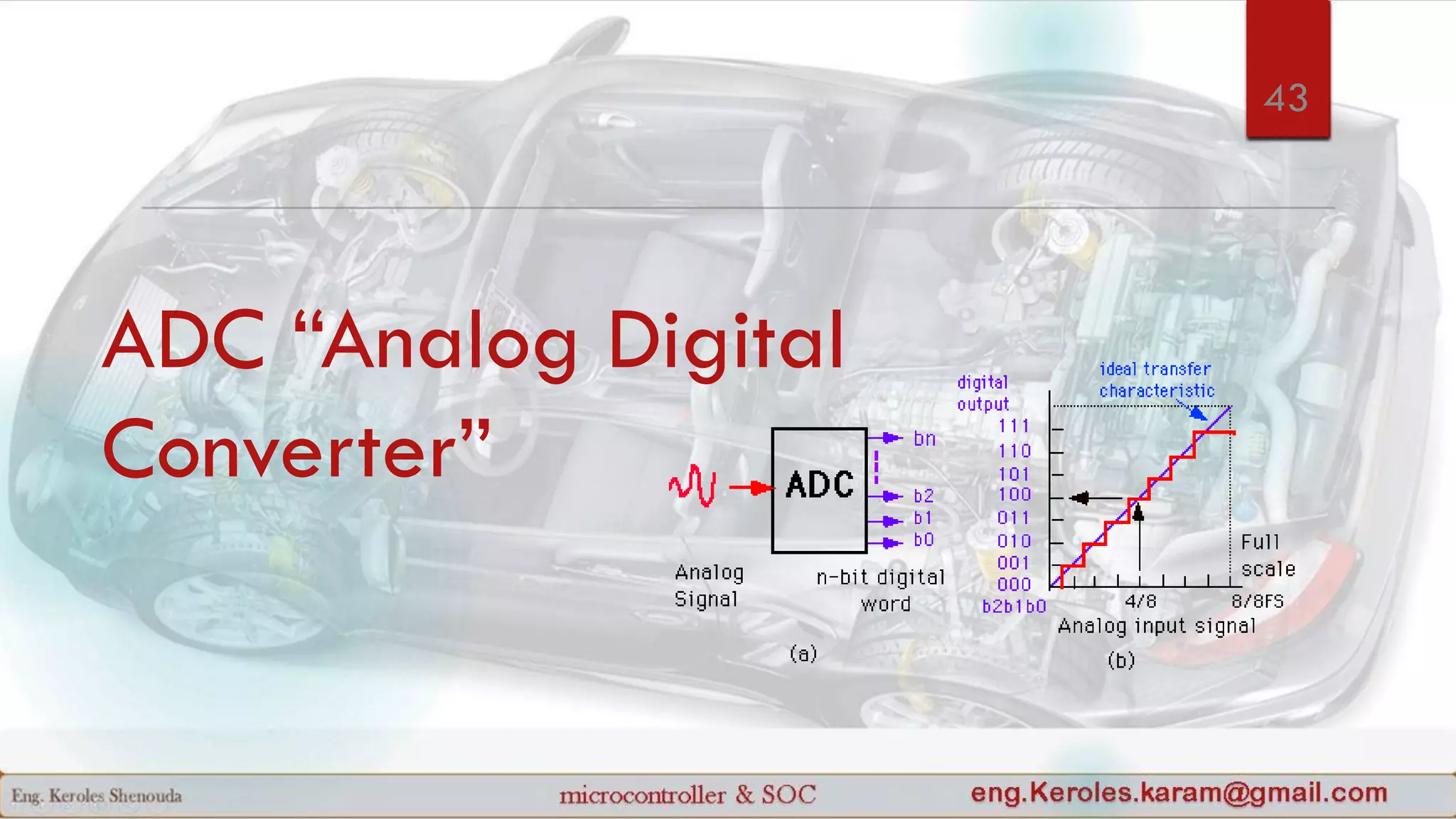

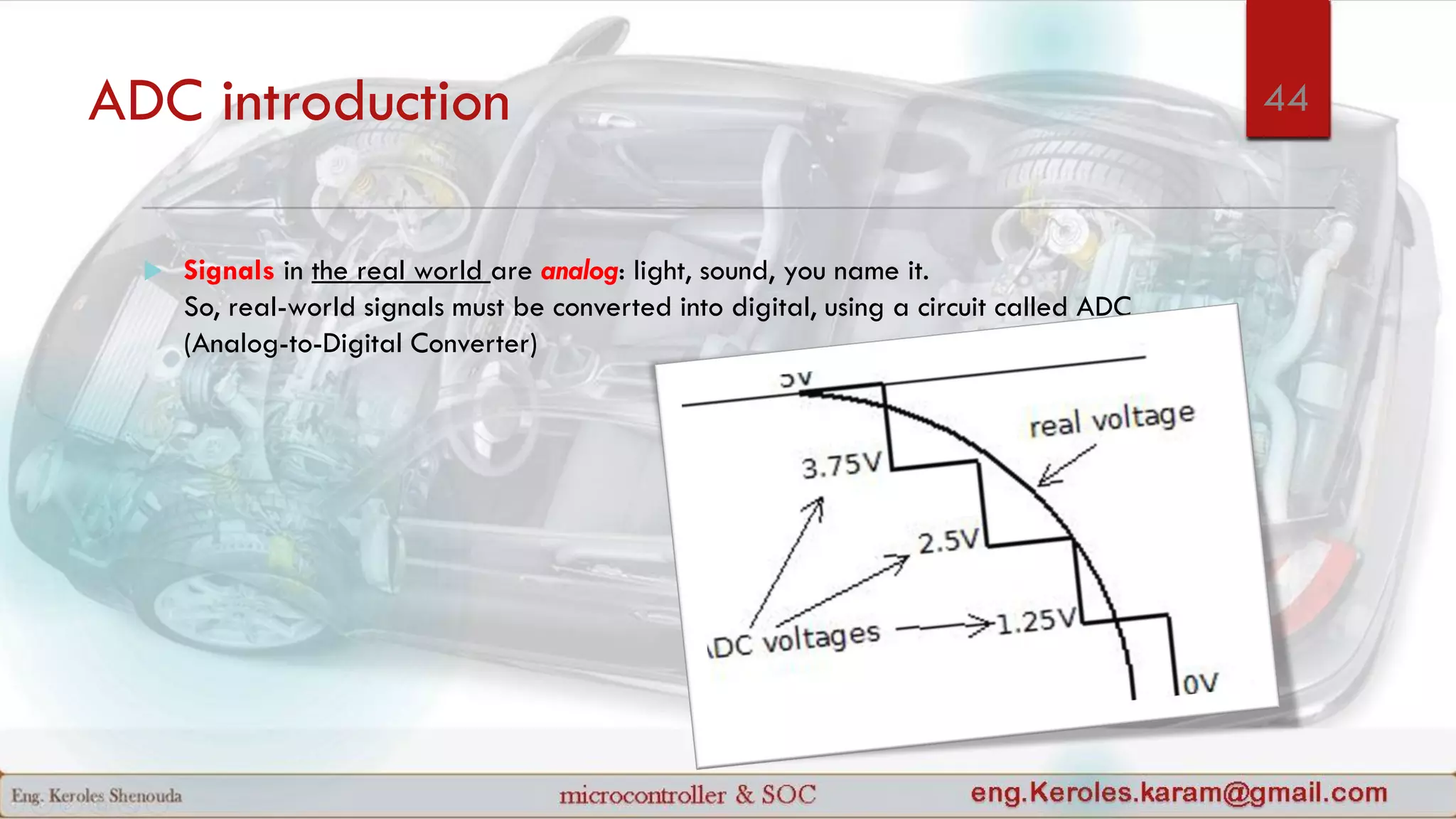

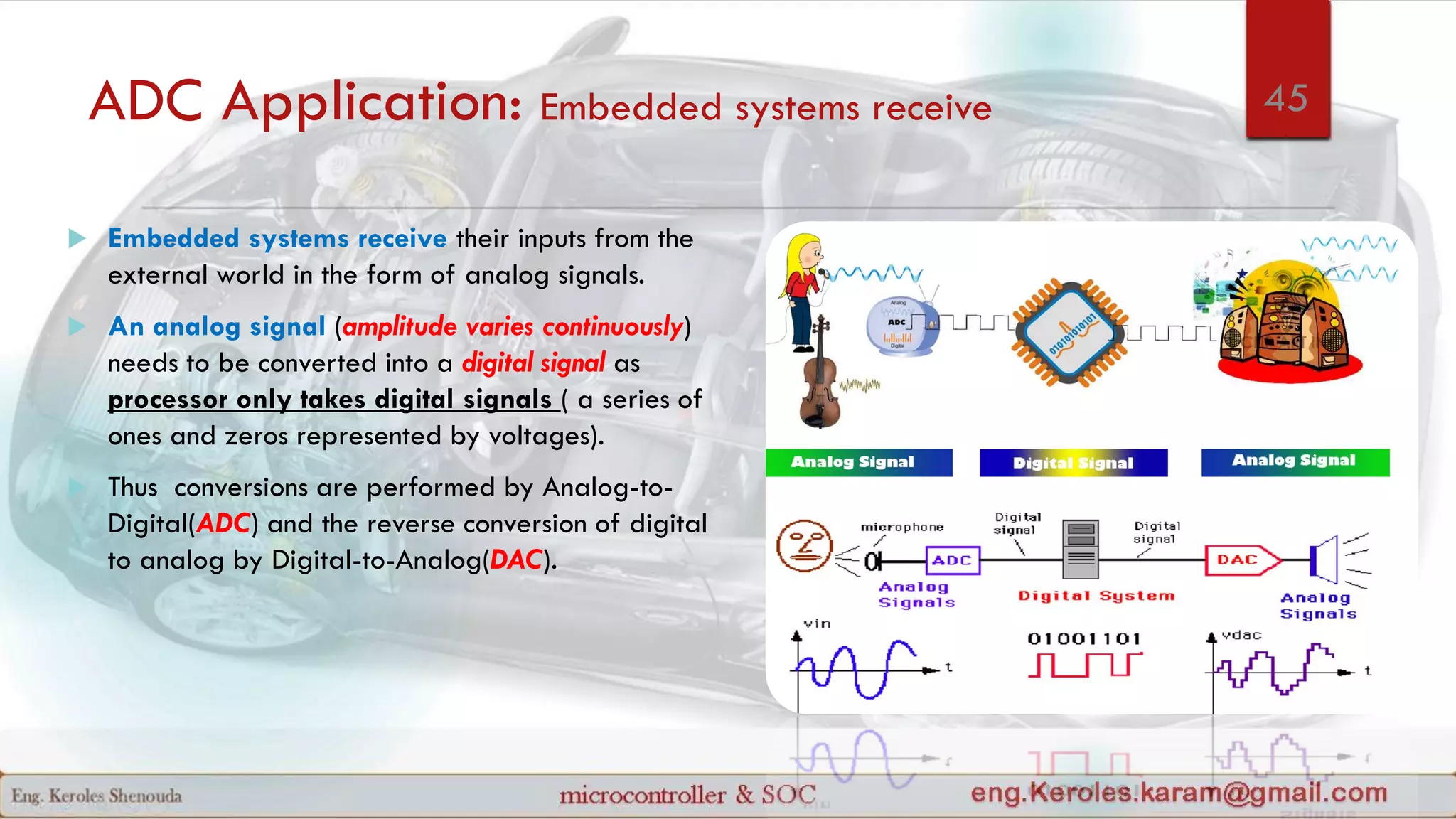

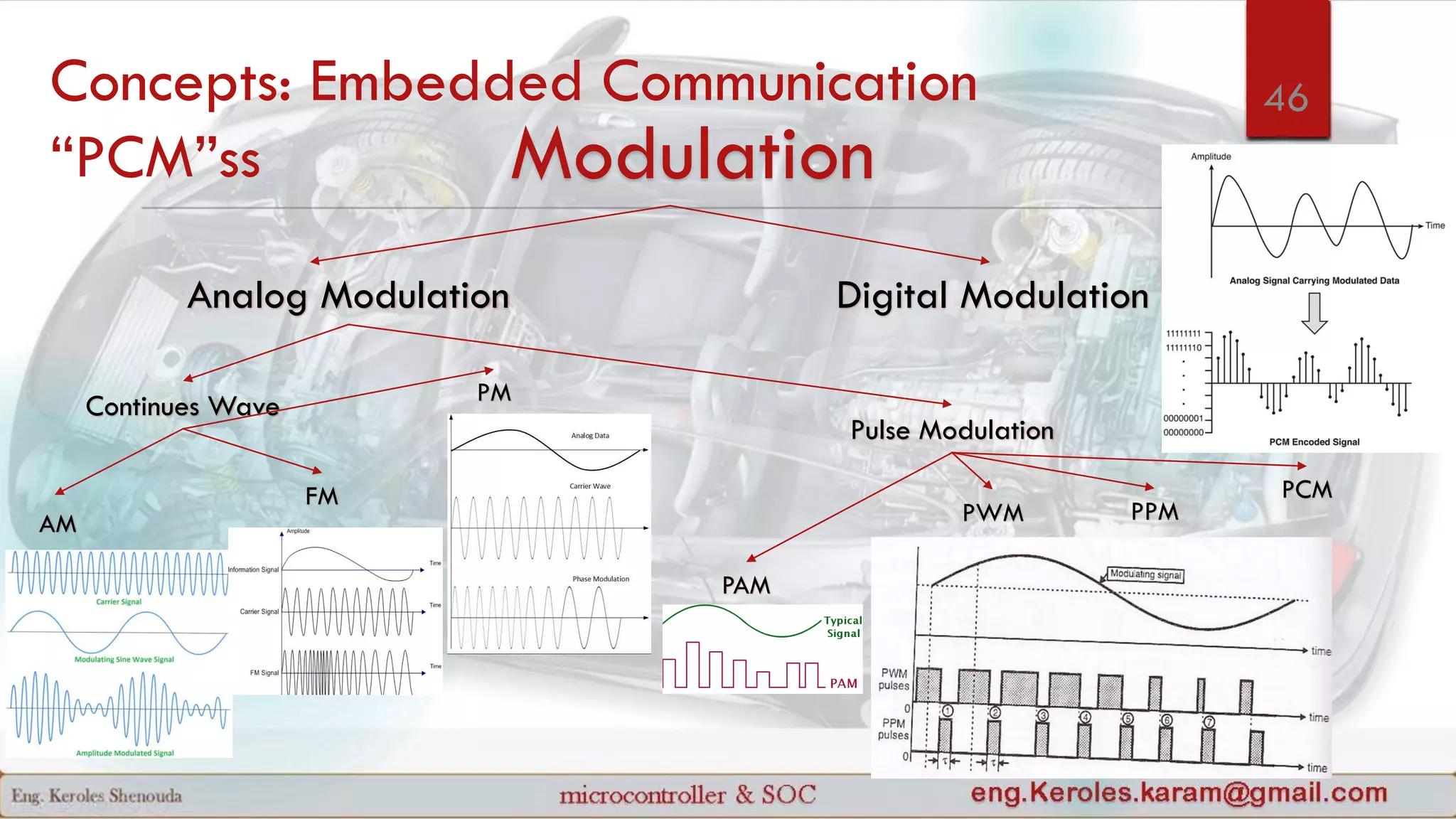

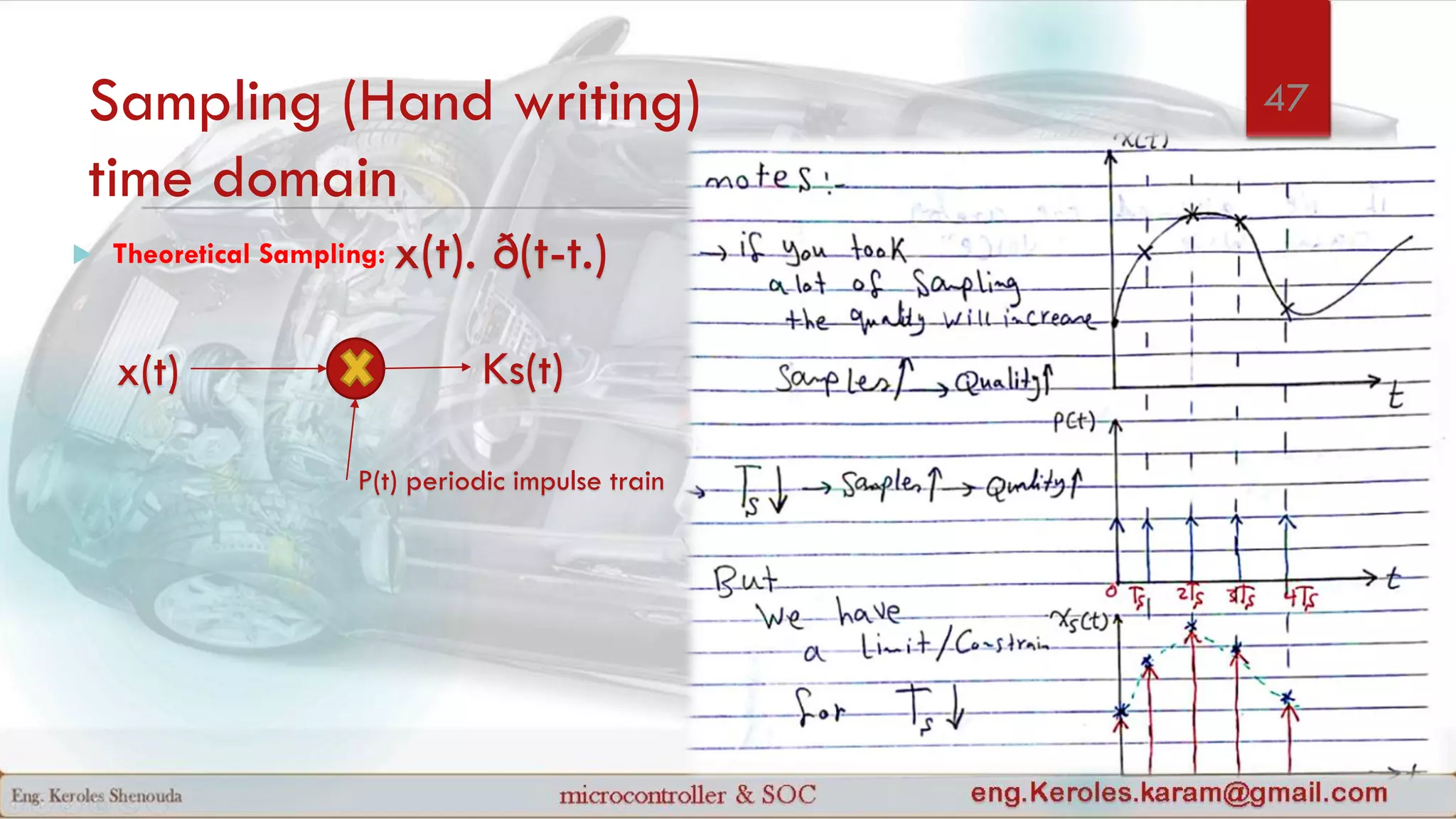

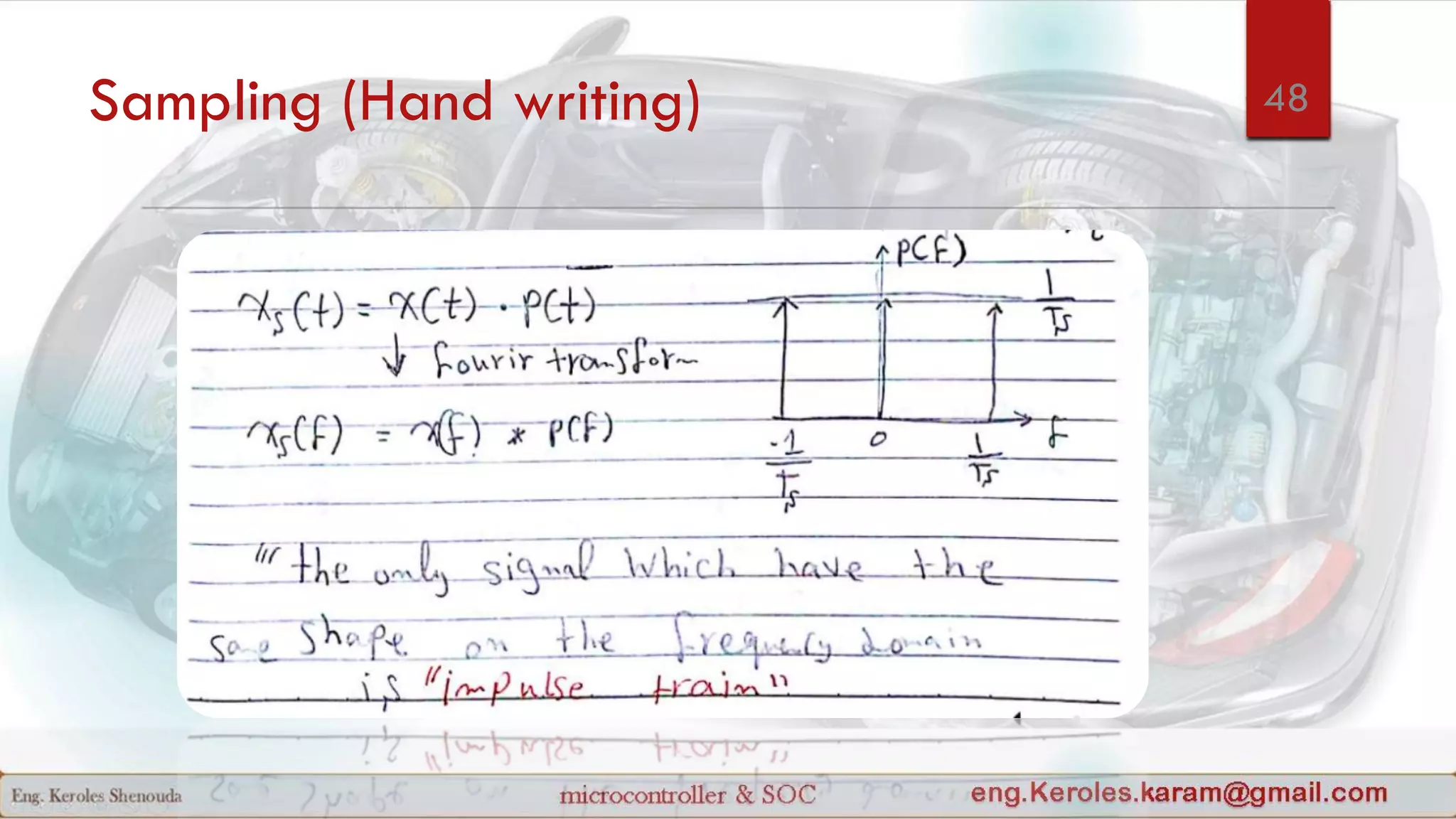

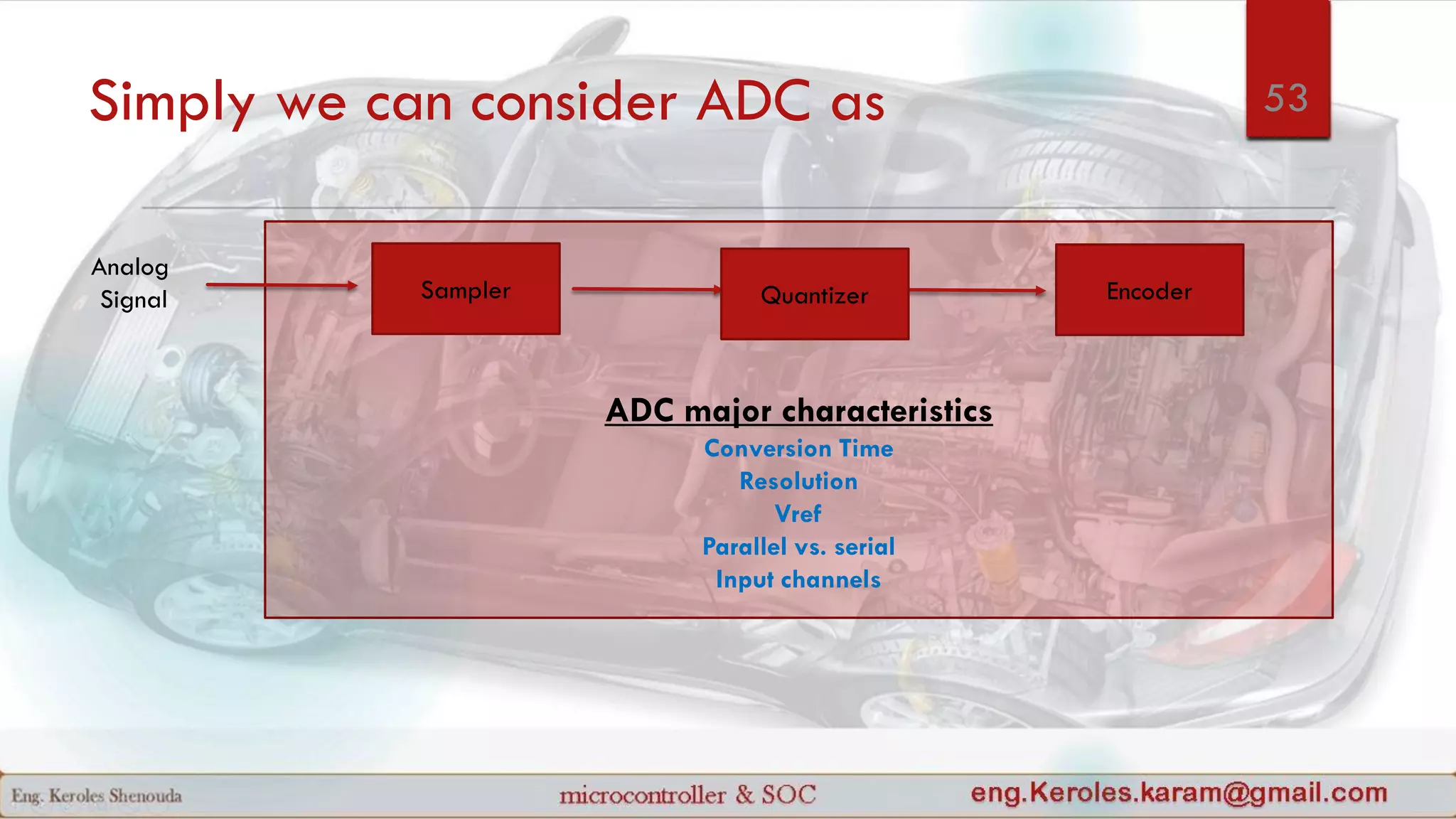

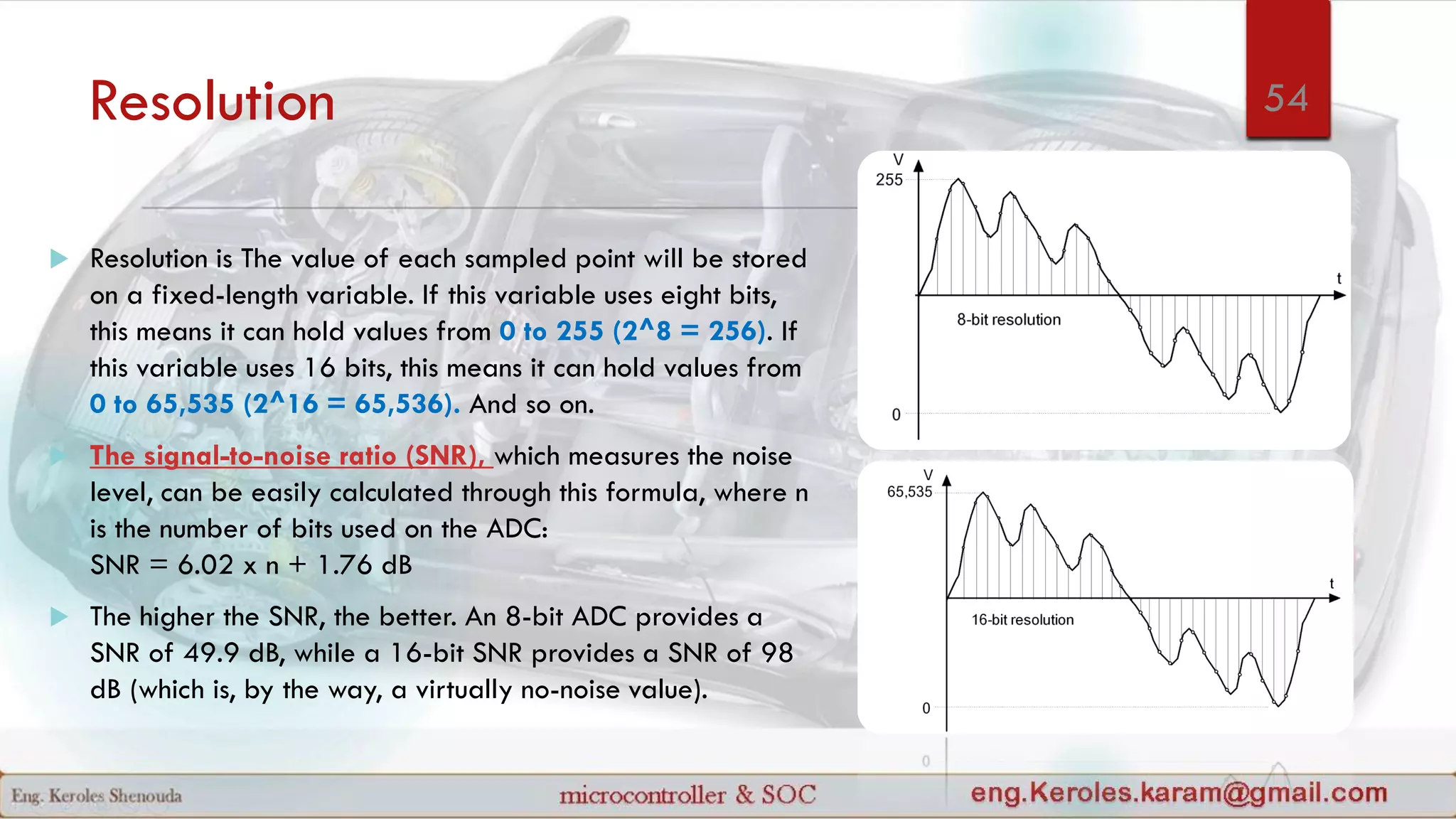

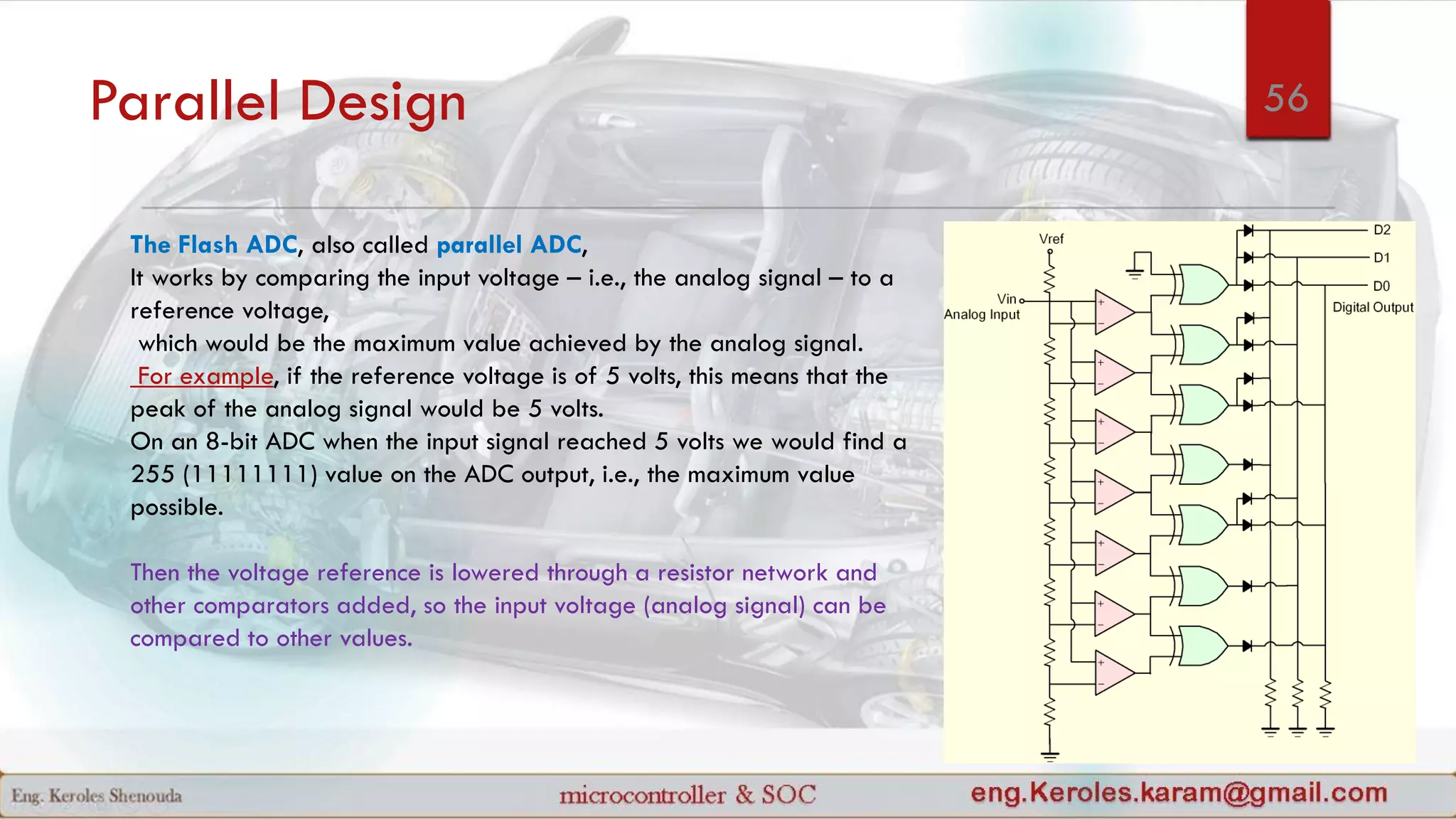

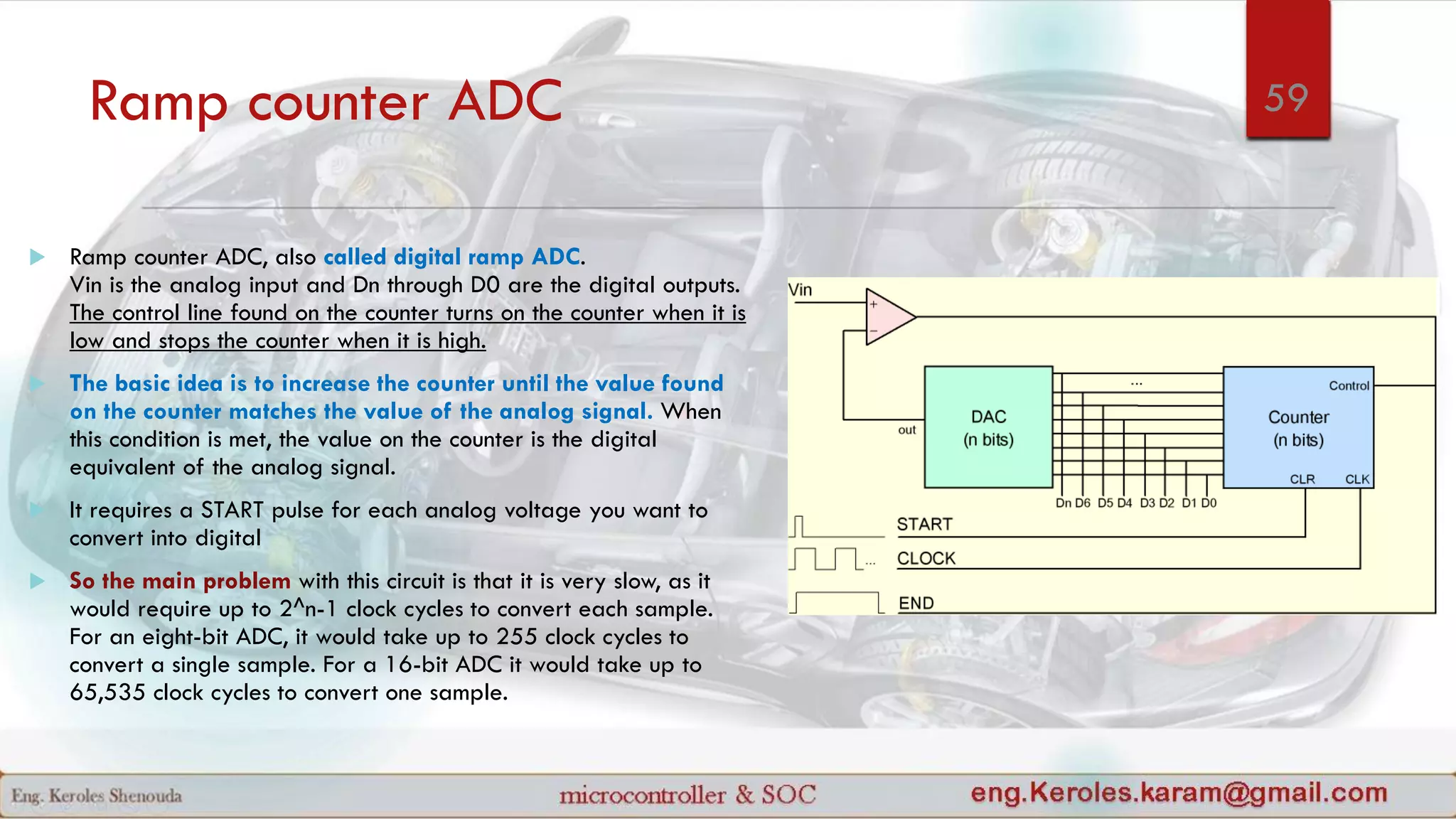

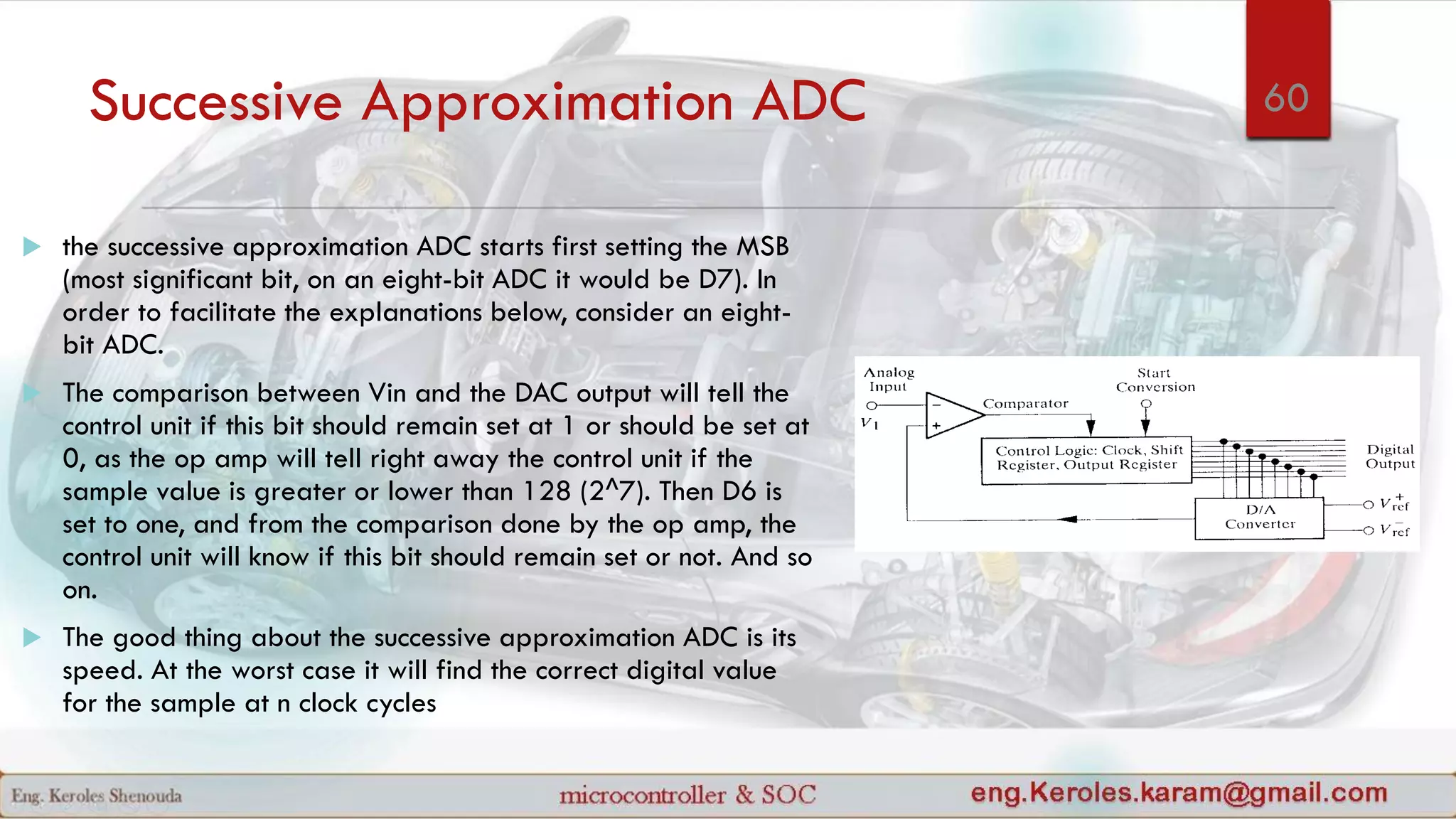

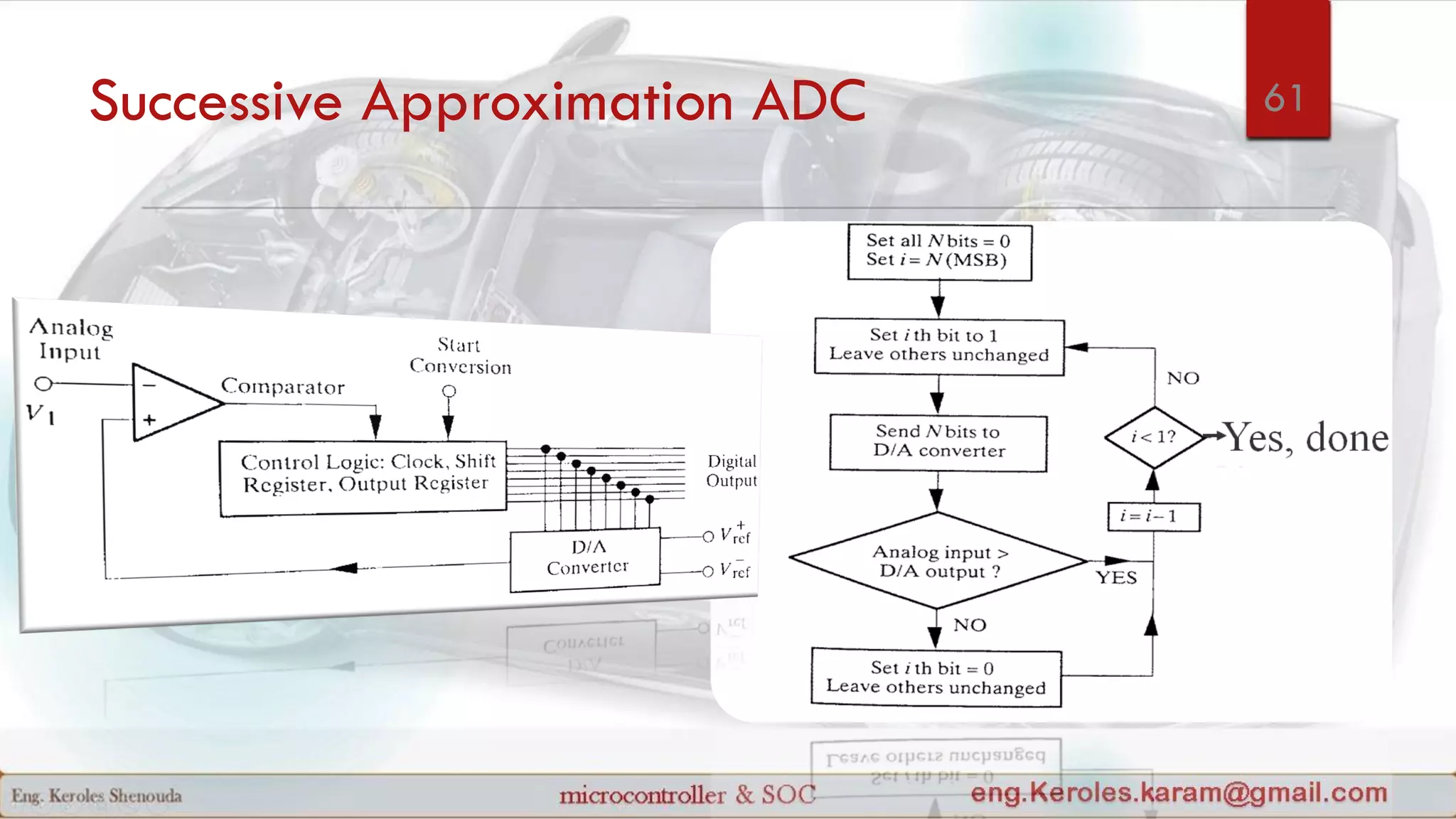

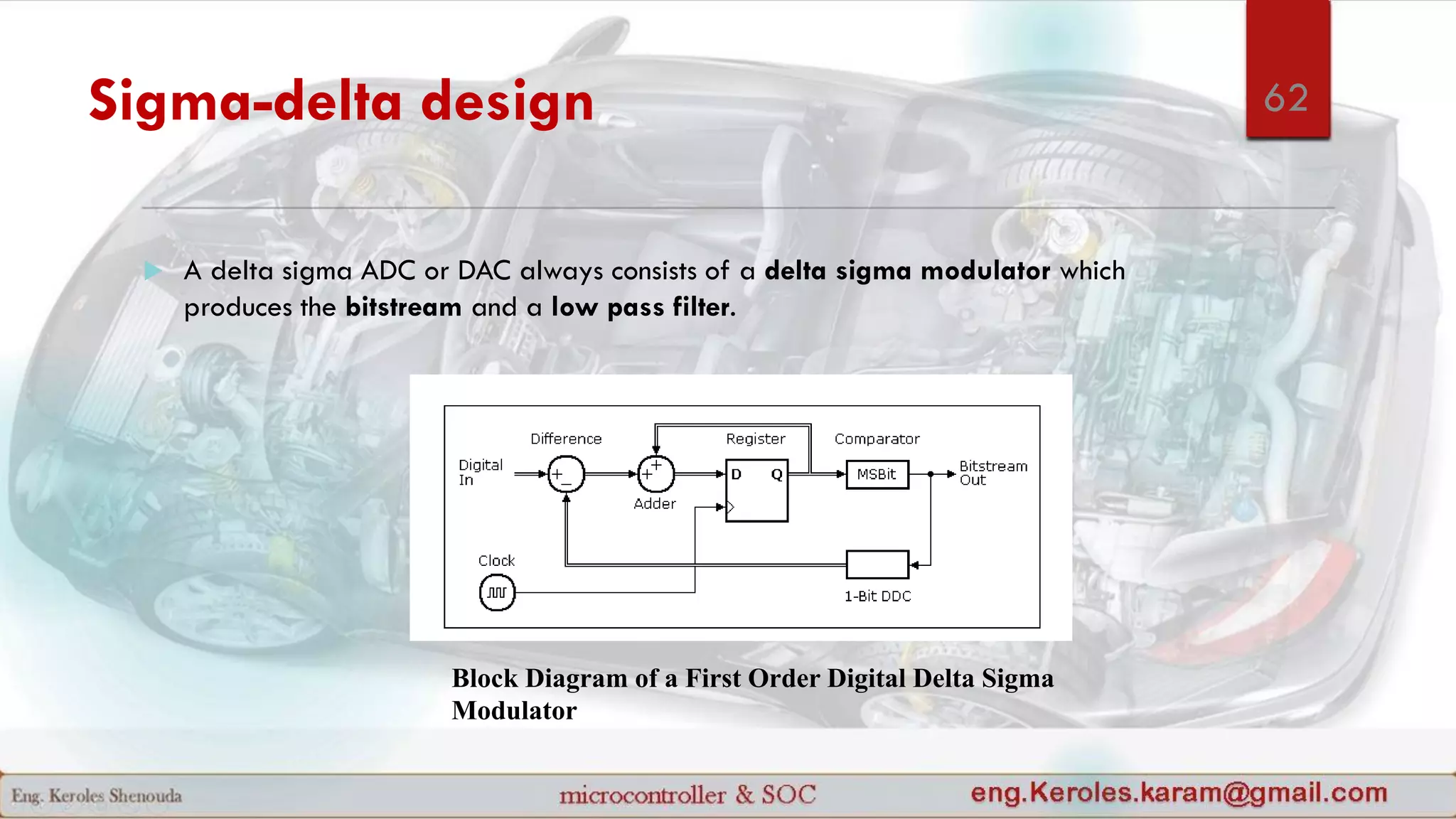

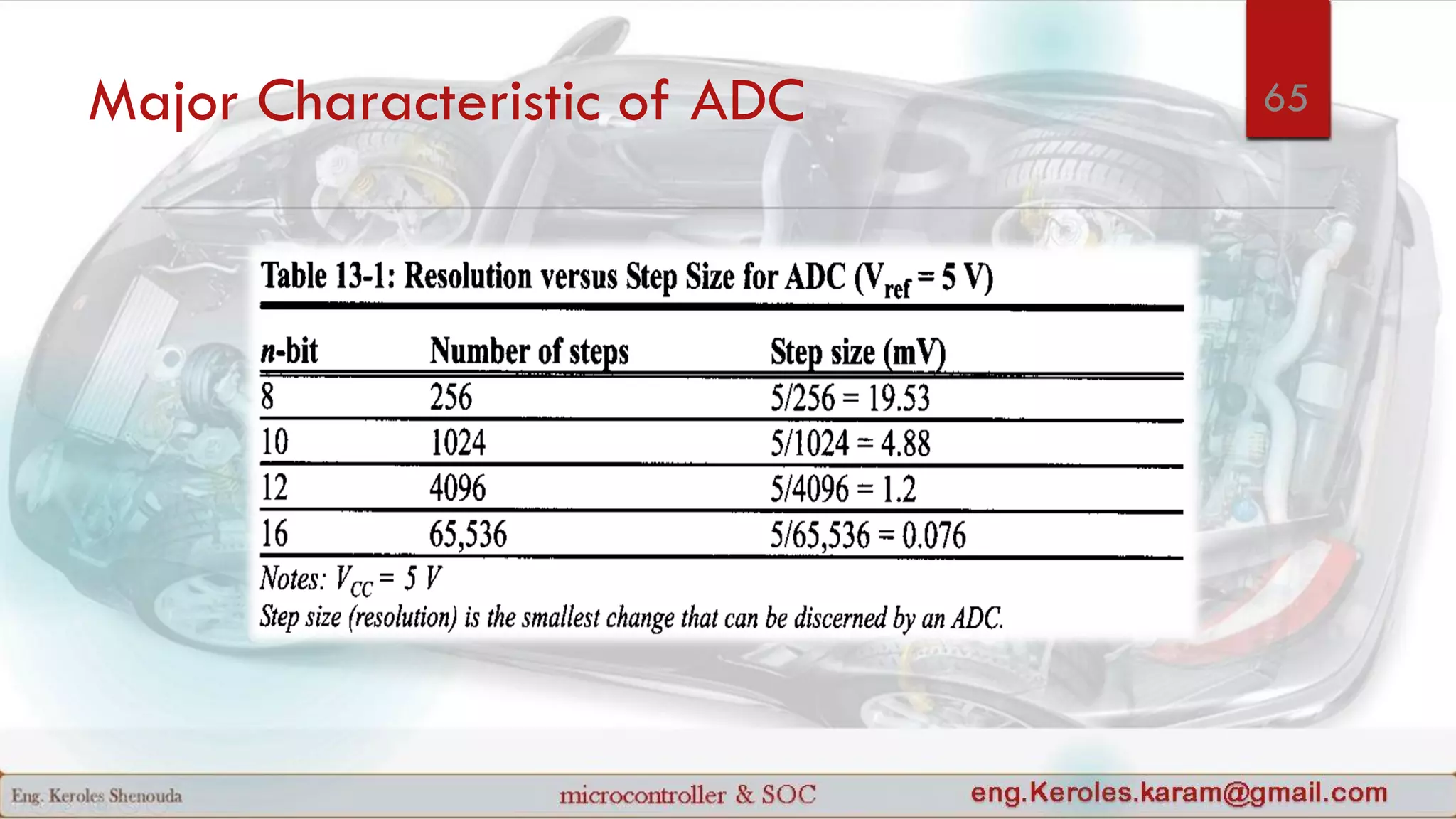

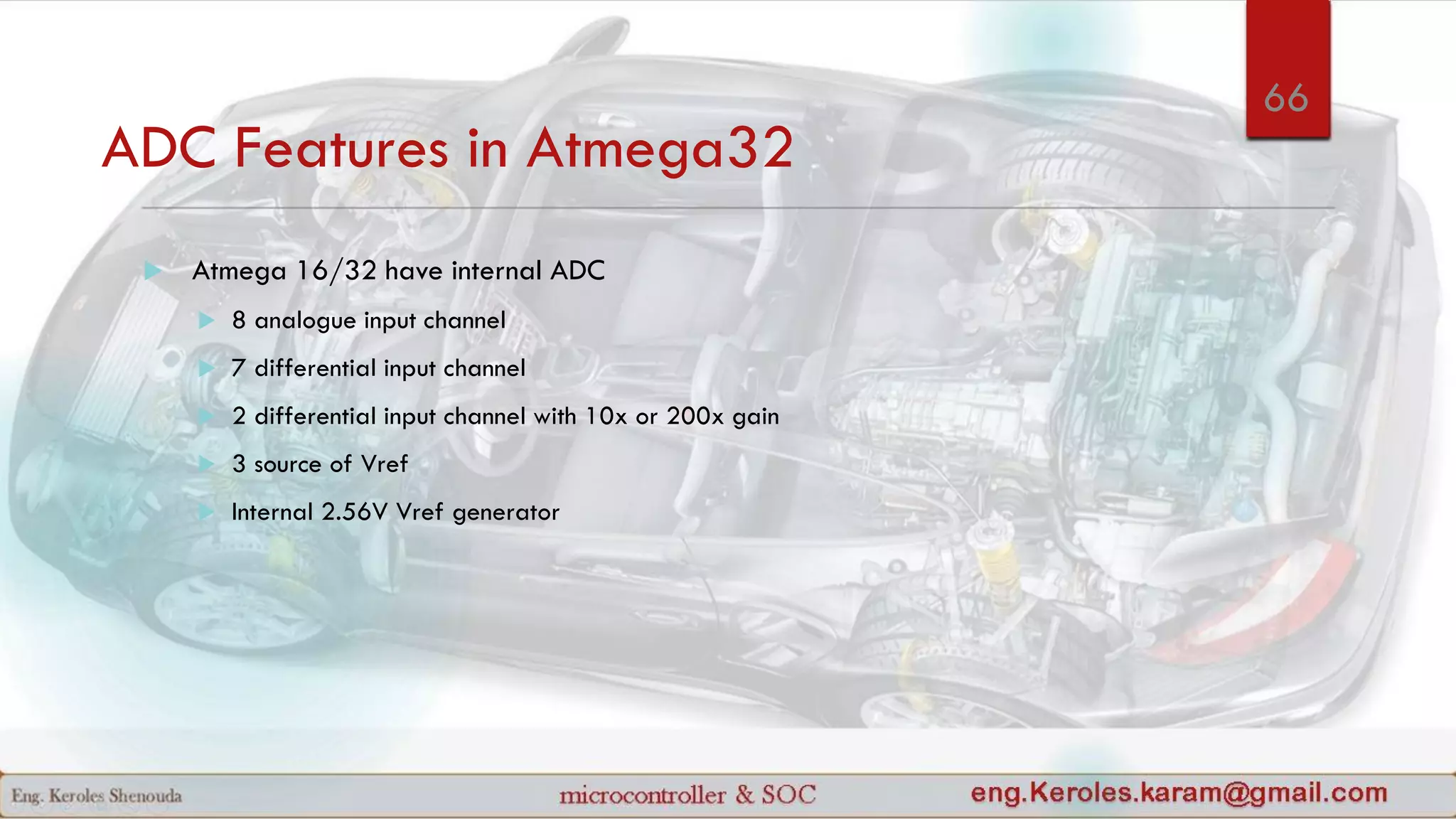

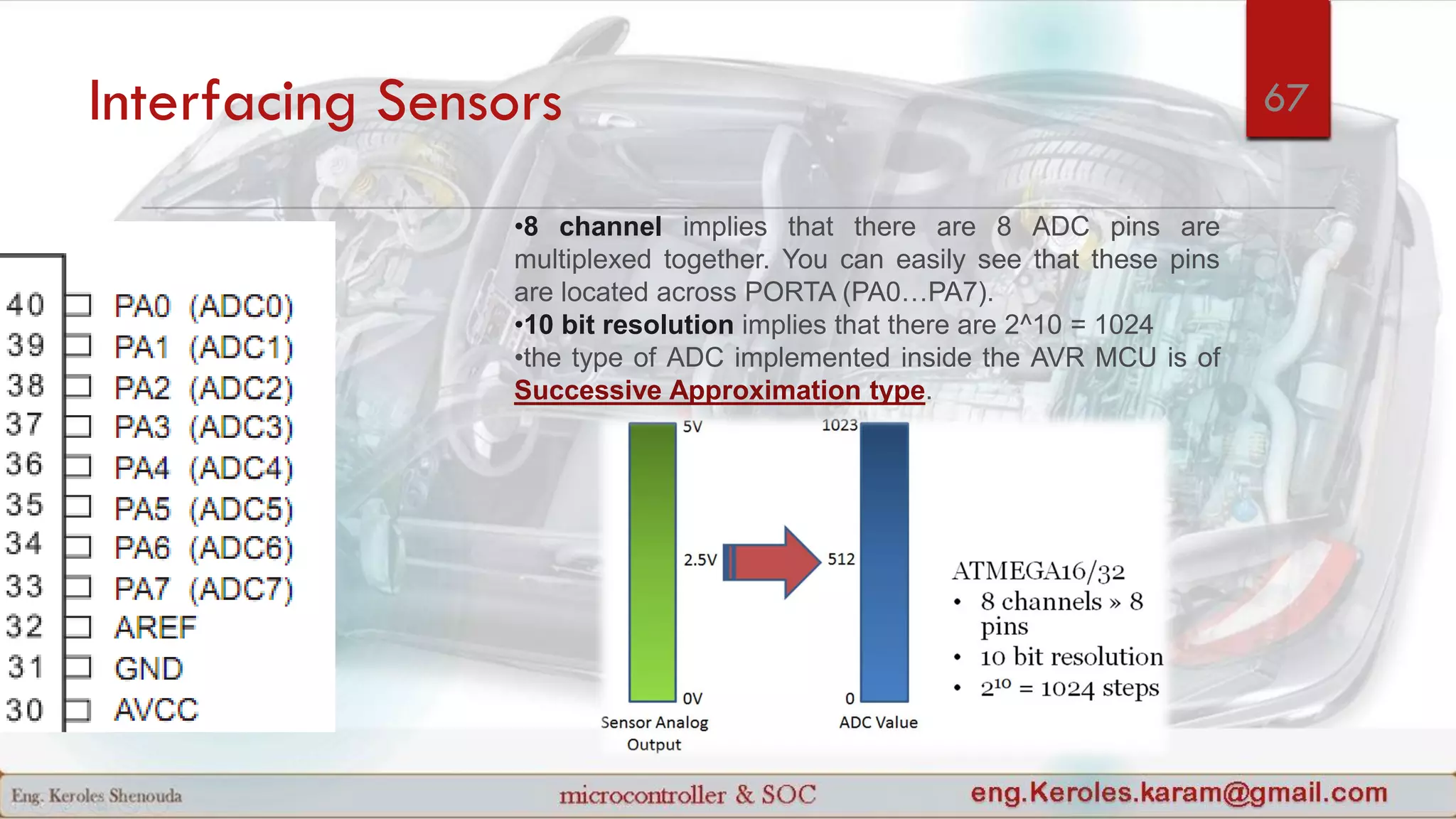

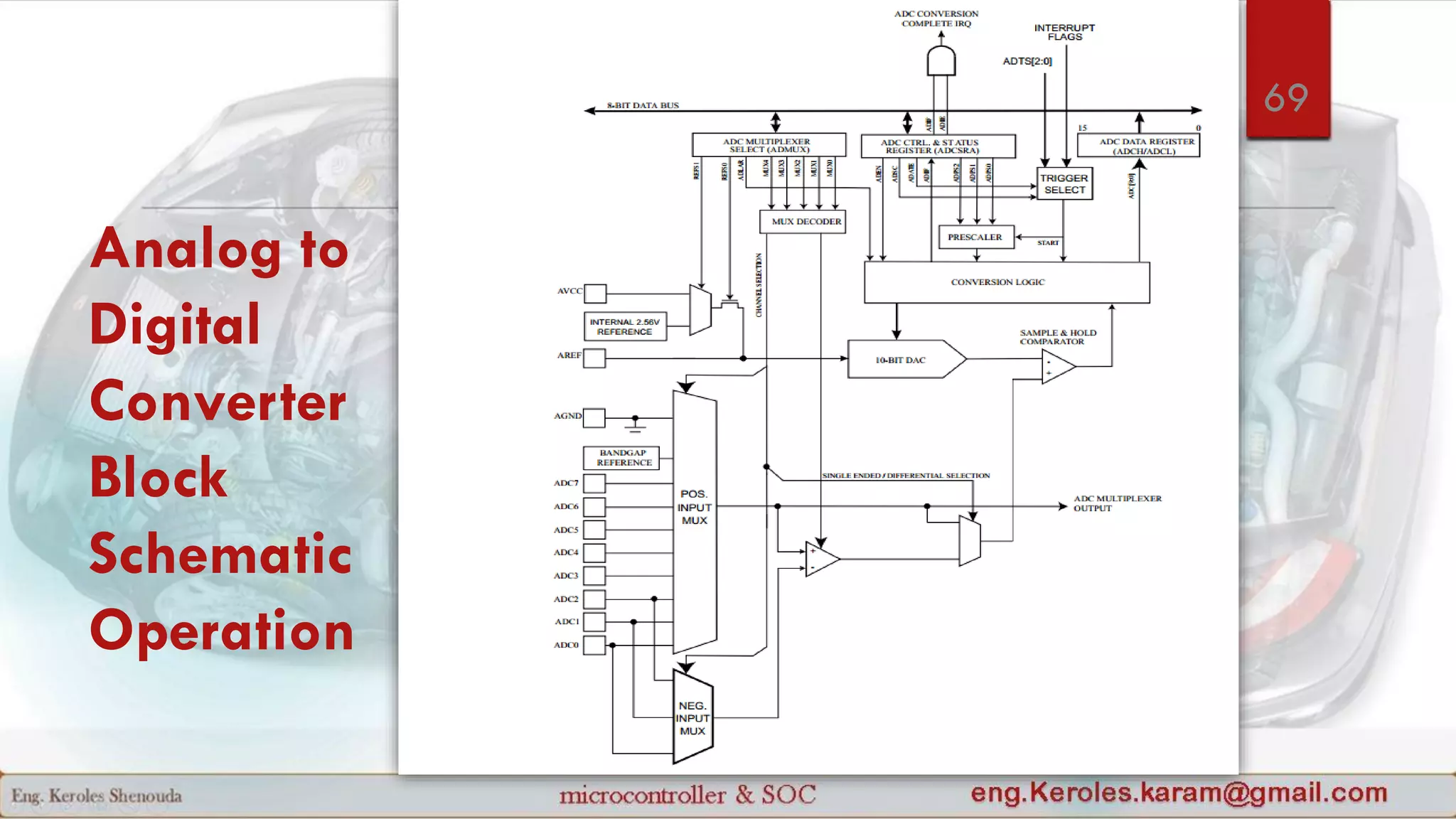

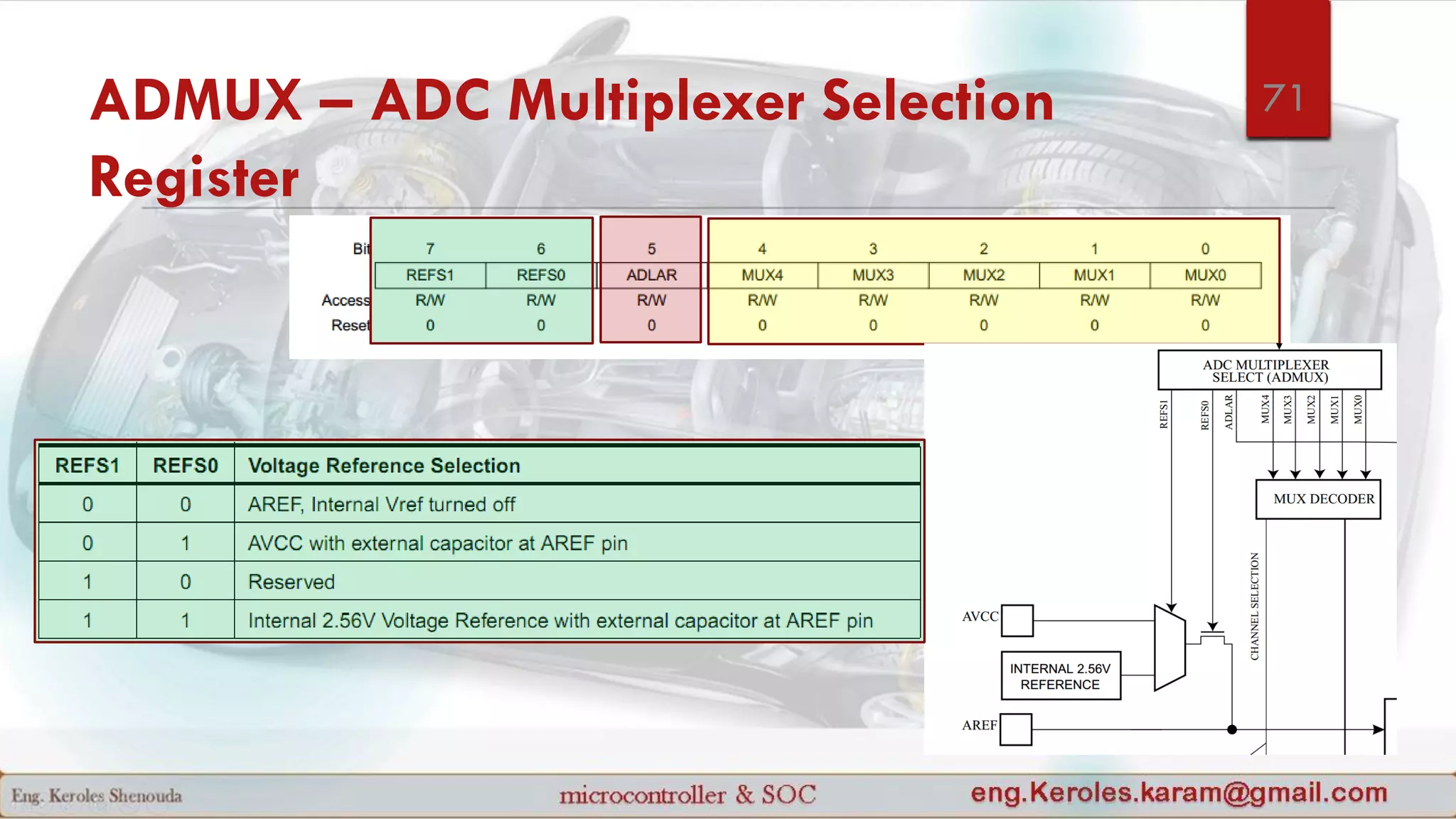

This document provides an overview of embedded systems concepts including pulse width modulation (PWM), servo motors, DC motors, timers, analog to digital converters (ADCs), and different types of ADCs. It discusses how PWM is used to control servo and DC motors. It also explains the different timer modes for microcontrollers and how timers can generate PWM signals. Finally, it summarizes various ADC types including parallel, ramp counter, and successive approximation designs.