0% found this document useful (0 votes)

33 views20 pagesRF MAINT R 01-Maintance Check List

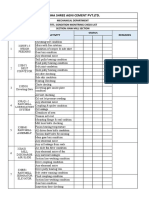

The document outlines a comprehensive preventive maintenance checklist for various machinery and equipment at Shri Andavar Engineering Works, including core shooters, melting furnaces, sand plants, and general equipment. Each section specifies daily, weekly, and monthly maintenance tasks to ensure optimal operation and safety. The checklist is organized by machine name and includes specific checkpoints for monitoring and maintenance activities.

Uploaded by

qualityCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

33 views20 pagesRF MAINT R 01-Maintance Check List

The document outlines a comprehensive preventive maintenance checklist for various machinery and equipment at Shri Andavar Engineering Works, including core shooters, melting furnaces, sand plants, and general equipment. Each section specifies daily, weekly, and monthly maintenance tasks to ensure optimal operation and safety. The checklist is organized by machine name and includes specific checkpoints for monitoring and maintenance activities.

Uploaded by

qualityCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

/ 20